Semi-aromatic polyamide resin and preparation method thereof

A polyamide resin and semi-aromatic technology, which is applied in the field of semi-aromatic polyamide resin and its preparation, can solve the problems of inability to prepare by polyamide polymerization process, difficult to form thin walls, easy to warp products, etc., and achieve excellent fluidity , Low water absorption, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

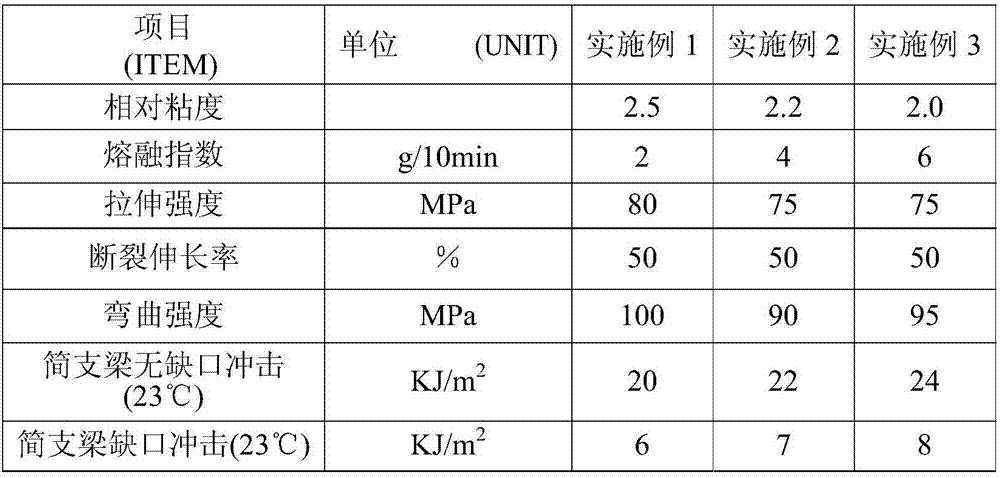

Examples

Embodiment 1

[0033] Drop into 2.02kg sebacic acid, 20g stearic acid, 5g phosphoric acid in the jacketed reaction kettle that is provided with agitator, partial condenser, cooler, thermometer, dropping tank and nitrogen inlet pipe. Feed inert gas into the reactor, remove the air in the reactor, and maintain the pressure of the reactor at 0.2Mpa. Heat the reaction kettle to raise the temperature of the reaction kettle to 240° C., start stirring, and the stirring speed is 60 rpm. Then slowly add molten p-xylylenediamine to the reactor while slowly raising the temperature of the reactor to 290°C. The dropwise addition took 120 minutes. During the dropwise addition process, the pressure of the reactor was maintained at 0.2MPa, and the generated water was discharged out of the reaction system through a dephlegmator and a cooler. The temperature of the partial condenser is controlled in the range of 140-150°C. After adding 1.36 kg of p-xylylenediamine, the addition was stopped. Slowly reduce ...

Embodiment 2

[0035] Put 2.30kg of dodecanedioic acid, 20g of stearic acid, and 5g of phosphorous acid into a jacketed reaction kettle equipped with agitator, partial condenser, cooler, thermometer, dropping tank and nitrogen inlet pipe. Feed inert gas into the reactor, remove the air in the reactor, and maintain the pressure of the reactor at 0.3MPa. The reaction kettle was heated to raise the temperature of the reaction kettle to 230° C., and the stirring was started at a stirring speed of 60 rpm. Then slowly add molten p-xylylenediamine to the reactor while slowly raising the temperature of the reactor to 290°C. The dropwise addition took 120 minutes. During the dropwise addition process, the pressure of the reactor was maintained at 0.3 MPa, and the generated water was discharged out of the reaction system through a dephlegmator and a cooler. The temperature of the partial condenser is controlled in the range of 140-150°C. After adding 1.36 kg of p-xylylenediamine, the addition was s...

Embodiment 3

[0037] 2.58kg tetradecanedioic acid, 20g stearic acid, and 5g sodium hypophosphite were dropped into a jacketed reaction kettle equipped with agitator, partial condenser, cooler, thermometer, dropping tank and nitrogen inlet pipe. Feed inert gas into the reactor, remove the air in the reactor, and maintain the pressure of the reactor at 0.4MPa. The reaction kettle was heated to raise the temperature of the reaction kettle to 220° C., and the stirring was started at a stirring speed of 60 rpm. Then slowly add molten p-xylylenediamine to the reactor while slowly raising the temperature of the reactor to 290°C. The dropwise addition took 120 minutes. During the dropwise addition process, the pressure of the reactor was maintained at 0.4 MPa, and the generated water was discharged out of the reaction system through a dephlegmator and a cooler. The temperature of the partial condenser is controlled in the range of 140-150°C. After adding 1.36 kg of p-xylylenediamine, the additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com