Fracturing fluid which resists temperature of 200 DEG C

A fracturing fluid and temperature-resistant technology, applied in the field of fracturing fluids, can solve the problems of jelly-carrying performance drop, guar gum viscosity drop, etc. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Preparation and Performance Evaluation of Thickener Modified Guar Gum

[0034] 1. Preparation of thickener modified guar gum

[0035] Install a stirrer, condenser, titration device and thermometer in a 500mL four-hole reaction bottle; add 220mL industrial ethanol at room temperature; add 100g of guacamole collagen powder after stirring; then slowly add NaOH solution (the solution Stirring 30g of sodium hydroxide and 55mL of water), that is alkalization; after the alkalization reaction is completed, start to rise to the set temperature of 55°C, slowly add 35mL of chloroacetic acid and 20mL of ethylene oxide dropwise, and at the same time put the flask on In a water bath, the temperature was raised to a predetermined temperature of 75°C and maintained, and the reaction was continued for 4 hours; after the reaction was completed, the flask was cooled to room temperature, and neutralized by adding hydrochloric acid while stirring. When the pH value was 7.0, the ...

Embodiment 2

[0044] Embodiment 2: Preparation of organo-titanium-zirconium composite crosslinking agent

[0045] 1) Put 200 mL of zirconium oxychloride and water mixture into a four-necked reaction flask equipped with a reflux condensing device according to the compounding ratio of 1:10, stir until completely dissolved, add 10 mL of isopropanol, and pass through N 2 , heated up to the reaction temperature of 80 ° C, stirred for 1 hour; stop passing N 2 , add glycerol 15g and polyalkyl carboxylate sodium R 2 COONa 15g, continue to stir the reaction, neutralize the reaction product to a pH value of 3 to 4, and obtain the organic zirconium crosslinking agent;

[0046] 2) Take organic zirconium crosslinking agent and organic titanium crosslinking agent respectively (purchased from Daqing Qixing Petroleum Technology Co., Ltd., specification WD-51B), mix according to the molar ratio of titanium to zirconium of 40~50:1, stir 30 min, the organic titanium zirconium composite crosslinking agent wa...

Embodiment 3

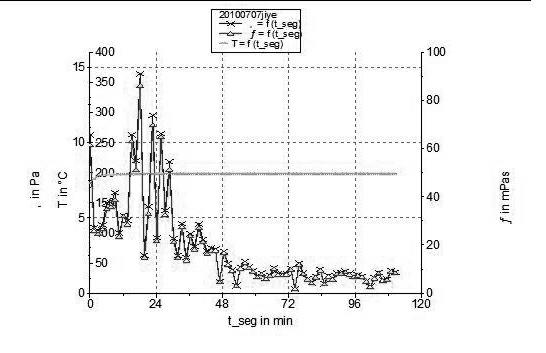

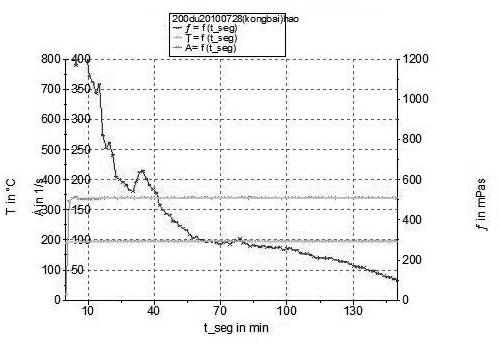

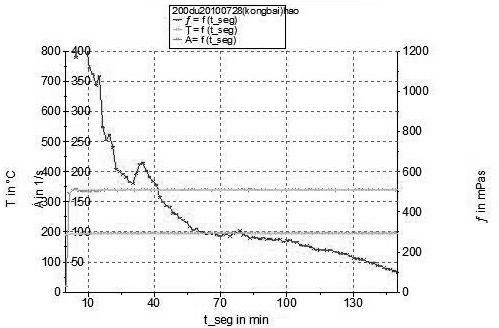

[0048] Embodiment 3: Determination of rheological properties of high temperature fracturing fluid

[0049] First, measure 100mL of tap water, weigh 1.0g of thickener, dissolve the thickener into a beaker, stir until completely dissolved, and let it stand for 5-10min. After the thickener is completely swollen, measure 100mL of base liquid, and add 0.5 Stir fully after g high-temperature stabilizer, then add 0.45g cross-linking accelerator to it, add clay stabilizer 1.0g, drainage aid 0.1g, demulsifier 0.08g to it respectively after fully stirring, fully stir, after dissolving completely Add 0.8g of high-temperature cross-linking agent to it, stir for about 3 minutes, and put it on the machine after the solution can be hung. Fill the fracturing fluid into the HAKE RS6000 instrument, heat it up to 200°C in a sealed chamber, and then keep the temperature constant. -1 Under continuous shearing for 150min, the change of apparent viscosity with time is measured as figure 2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com