Partially hydrolyzed acrylamide water-soluble polymer with utlralong hydrophobic long chain, preparation method therefor and application thereof

A technology for hydrolyzing acrylamide and water-soluble polymers, which is applied in the field of water-soluble polymer synthesis, can solve the problems of poor underground environment in oilfields and limited application of HPAM, and achieves the effects of safe use, wide potential use value and strong stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

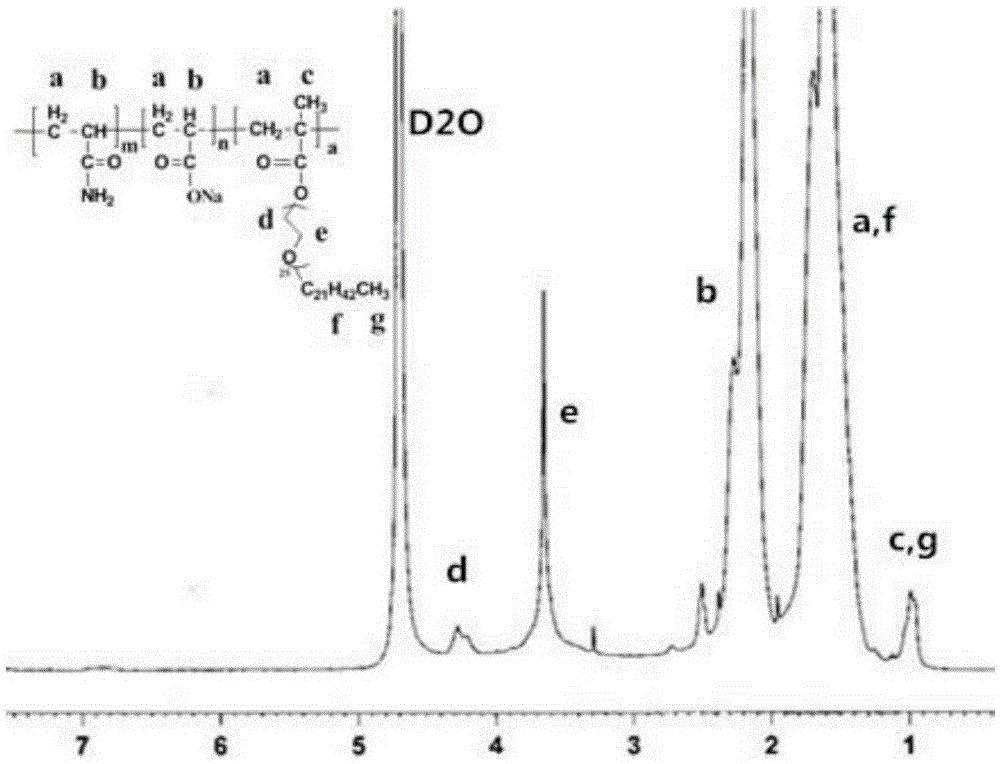

[0048] Example 1, preparation of partially hydrolyzed acrylamide water-soluble polymer containing ultra-long hydrophobic long chains

[0049] (1) Weigh 3.192 g (0.045 mol) of acrylamide and 0.150 g (0.05 mmol) of hydrophobic monomer behenyl polyoxyethylene ether methacrylate and dissolve them in water.

[0050] (2) Weigh 0.36g (0.005mol) of acrylic acid and dissolve it in water, and adjust the pH value of the solution to 6-7 with NaOH. Mix the solution obtained in step (1) with the neutralized acrylic acid solution, add it into a 100mL three-neck flask equipped with a nitrogen tube, a condenser tube and a stirring magnet, and stir with nitrogen gas at room temperature until it is completely dissolved;

[0051] (3) Add initiator potassium persulfate (KPS) to the system obtained in step (2), place it in a constant temperature water bath at 25°C after stirring evenly, and pass nitrogen to remove oxygen for 0.5h; relative to the volume of the polymerization system, potassium persu...

Embodiment 2

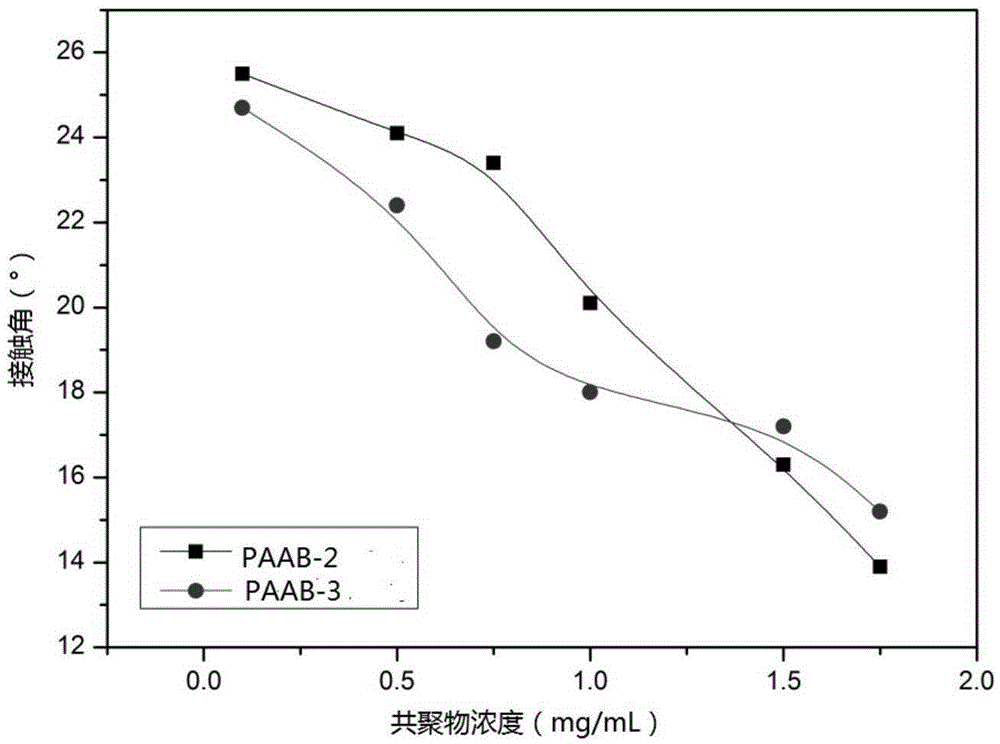

[0057] Example 2, Preparation of Partially Hydrolyzed Acrylamide Water-Soluble Polymer Containing Superlong Hydrophobic Long Chains

[0058] The preparation method is the same as in Example 1, the difference is: the charging amount of acrylamide in the step (1) is 3.184g (0.0449mol), and the charging amount of the hydrophobic monomer behenyl polyoxyethylene ether methacrylate The amount is 0.45g (0.15mmol); the feeding amount of acrylic acid in step (2) is 3.36g (0.005mol).

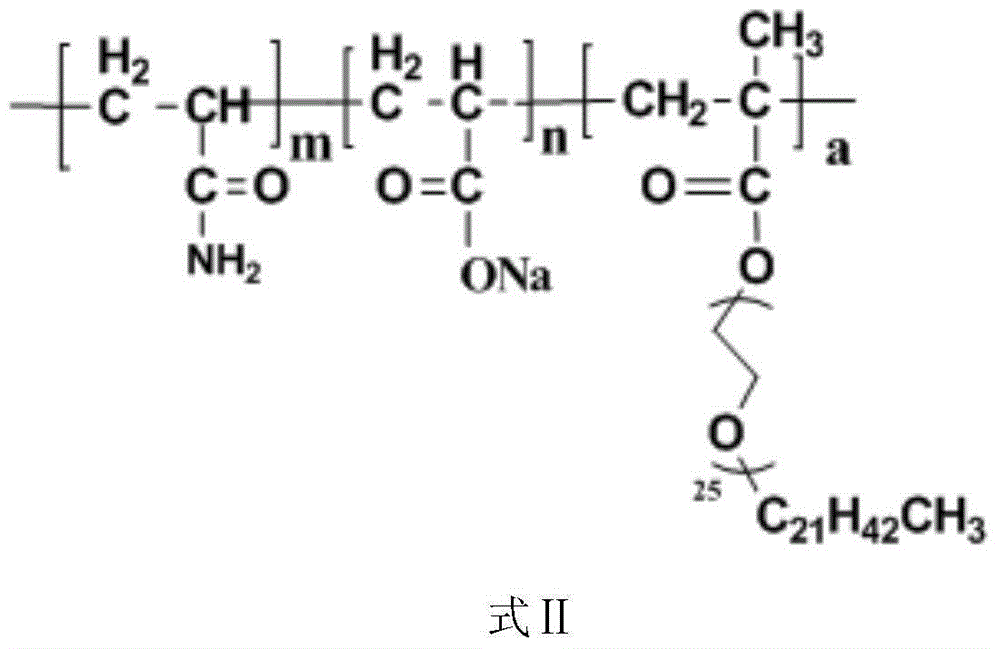

[0059] 3.724 g of modified acrylamide water-soluble polymer powder containing ultra-long hydrophobic long chain represented by formula II was obtained, and the yield was ≥93%.

[0060] In formula II, m / (m+n+a)=89.92%, n / (m+n+a)=9.80%, a / (m+n+a)=0.28%, weight average molecular weight M w =2.746×10 6 g·mol -1 .

Embodiment 3

[0061] Example 3, Preparation of Partially Hydrolyzed Acrylamide Water-Soluble Polymer Containing Superlong Hydrophobic Long Chains

[0062] The preparation method is the same as in Example 1, the difference is: the charging amount of acrylamide in the step (1) is 3.177g (0.04735mol), and the charging amount of the hydrophobic monomer behenyl polyoxyethylene ether methacrylate The amount is 0.75g (0.25mmol), and the feeding amount of acrylic acid in step (2) is 0.36g (0.005mol).

[0063] 3.946 g of modified acrylamide water-soluble polymer powder containing ultra-long hydrophobic long chain represented by formula II was obtained, and the yield was ≥92%.

[0064] In formula II, m / (m+n+a)=89.79%, n / (m+n+a)=9.75%, a / (m+n+a)=0.46%, weight average molecular weight M w =3.188×10 6 g·mol -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal degradation temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com