Superhard strong toughness and high-entropy alloy nitride nano-composite coating carbide blade and preparation method thereof

A technology of cemented carbide blades and high-entropy alloys, which is applied in the direction of metal material coating technology, coating, vacuum evaporation coating, etc., can solve the problems that affect the processing performance of coated tools and the decrease of coating hardness, and achieve the goal of overcoming layers. Effects of inner grain coarsening, reduced coating stress, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

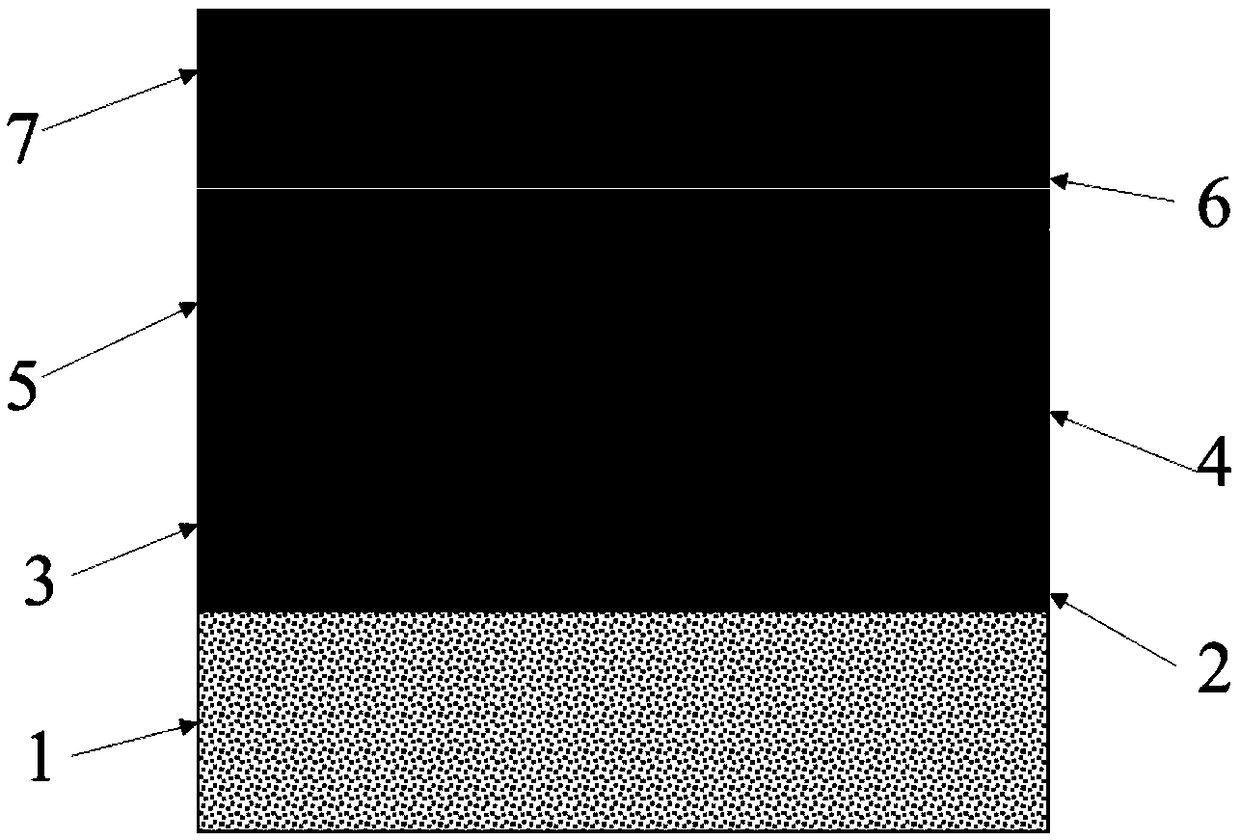

[0041] A super-hard, tough, high-entropy alloy nitride-coated cemented carbide blade, the schematic diagram of which is shown in figure 2 , the specific preparation steps are as follows:

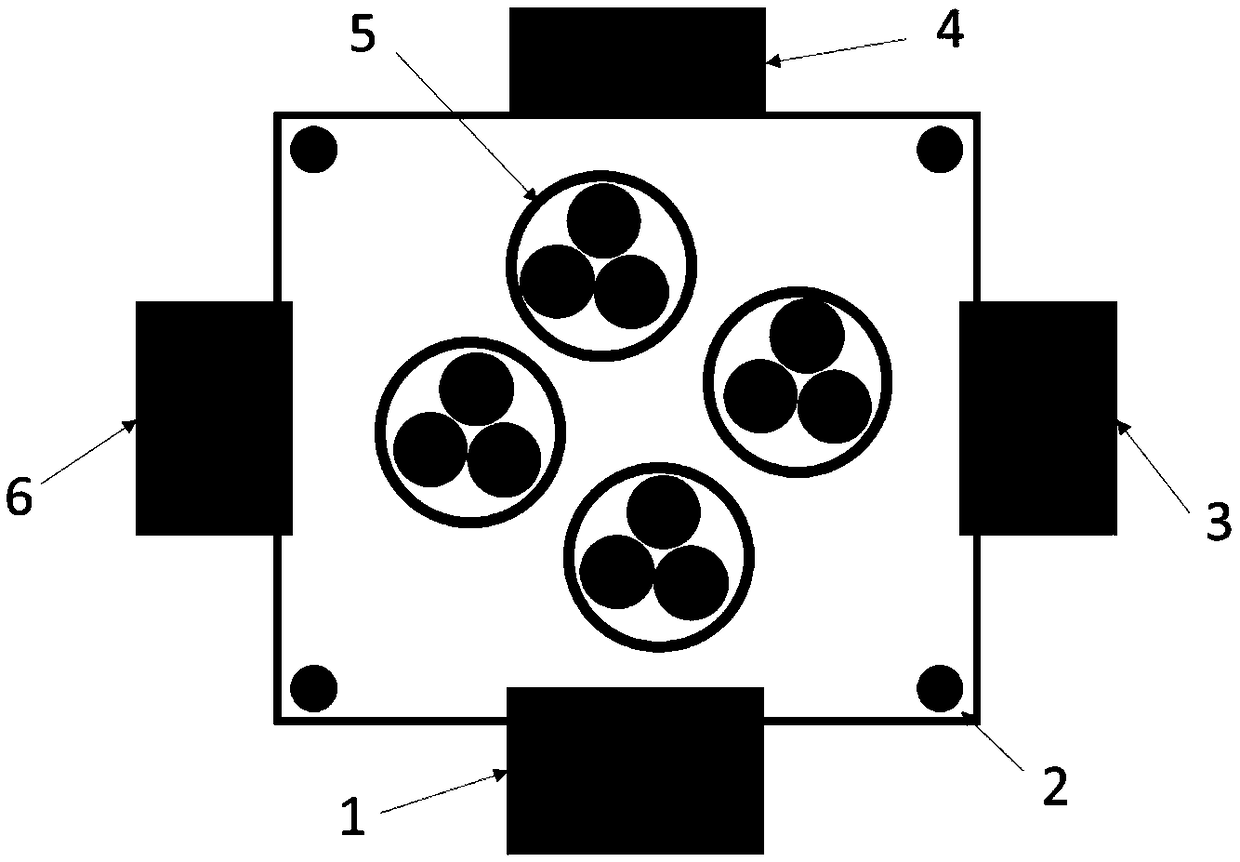

[0042] 1) use figure 1 Described coating device, in 400 ℃, in argon and hydrogen environment (Ar and H 2 The volume ratio is 2:1), and the cemented carbide blade is plasma etched 0.1 micron (20min);

[0043] 2) Then turn on the Cr target, under the condition of 0.01Pa, -1000V, use the arc ion plating technology to deposit a transition metal Cr bonding layer with a thickness of 5 nanometers; layer; then open the TiVZrNbHf target, at 0.5Pa (nitrogen atmosphere), deposit 500 nanometers of alternately grown CrN / TiVZrNbHfN support layers under 150V conditions (the thickness of single-layer CrN is 5 nanometers, the thickness of single-layer TiVZrNbHfN is 5 nanometers, and the modulation period is 10 Nano), during the deposition process, the workpiece is rotated in the equipment, TiVZrNbHfN is ...

Embodiment 2

[0047] A super-hard, tough, high-entropy alloy nitride-coated cemented carbide blade, the schematic diagram of which is shown in figure 2 , the specific preparation steps are as follows:

[0048] 1) use figure 1 Described coating device, in 600 ℃, in argon and hydrogen environment (Ar and H 2 The volume ratio is 2:1), and the cemented carbide blade is plasma etched 0.2 microns (40min);

[0049] 2) Then turn on the Cr target, and use arc ion plating technology to deposit a transition metal Cr bonding layer with a thickness of 30 nanometers under the condition of 0.1Pa and 1200V; Then turn on the TiVZrNbHf target, deposit 1500 nanometers alternately grown CrN / TiVZrNbHfN support layer under 2.3Pa (nitrogen atmosphere) and 250V conditions (the thickness of single-layer CrN is 10 nanometers, the thickness of single-layer TiVZrNbHfN is 10 nanometers, and the modulation period is 20 nanometers) ;

[0050] 3) Turn off the Cr target, deposit 2000 nanometers of TiVZrNbHfN high-entr...

Embodiment 3

[0053] A super-hard, tough, high-entropy alloy nitride-coated cemented carbide blade, the schematic diagram of which is shown in figure 2 , the specific preparation steps are as follows:

[0054] 1) use figure 1 Described coating device, in 500 ℃, in argon and hydrogen environment (Ar and H 2 The volume ratio is 2:1), and the cemented carbide blade is plasma etched 0.1 micron (20min);

[0055] 2) Then turn on the Cr target, and use arc ion plating technology to deposit a transition metal Cr bonding layer with a thickness of 20 nanometers under the condition of 0.1Pa and 1200V; Then turn on the TiVZrNbHf target, and deposit 1000 nanometers of alternately grown CrN / TiVZrNbHfN support layers under the condition of 2.3Pa and 200V (the thickness of single-layer CrN is 10 nanometers, the thickness of single-layer TiVZrNbHfN is 20 nanometers, and the modulation period is 30 nanometers);

[0056] 3) Turn off the Cr target, deposit 1000 nanometers of TiVZrNbHfN high-entropy alloy h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com