Improved method for manufacturing solid electrolyte/aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and solid electrolytes, applied in the direction of solid electrolytic capacitors, etc., can solve problems such as difficulties and low pass rates, and achieve the effects of reducing dosage, ensuring consistency, and small expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

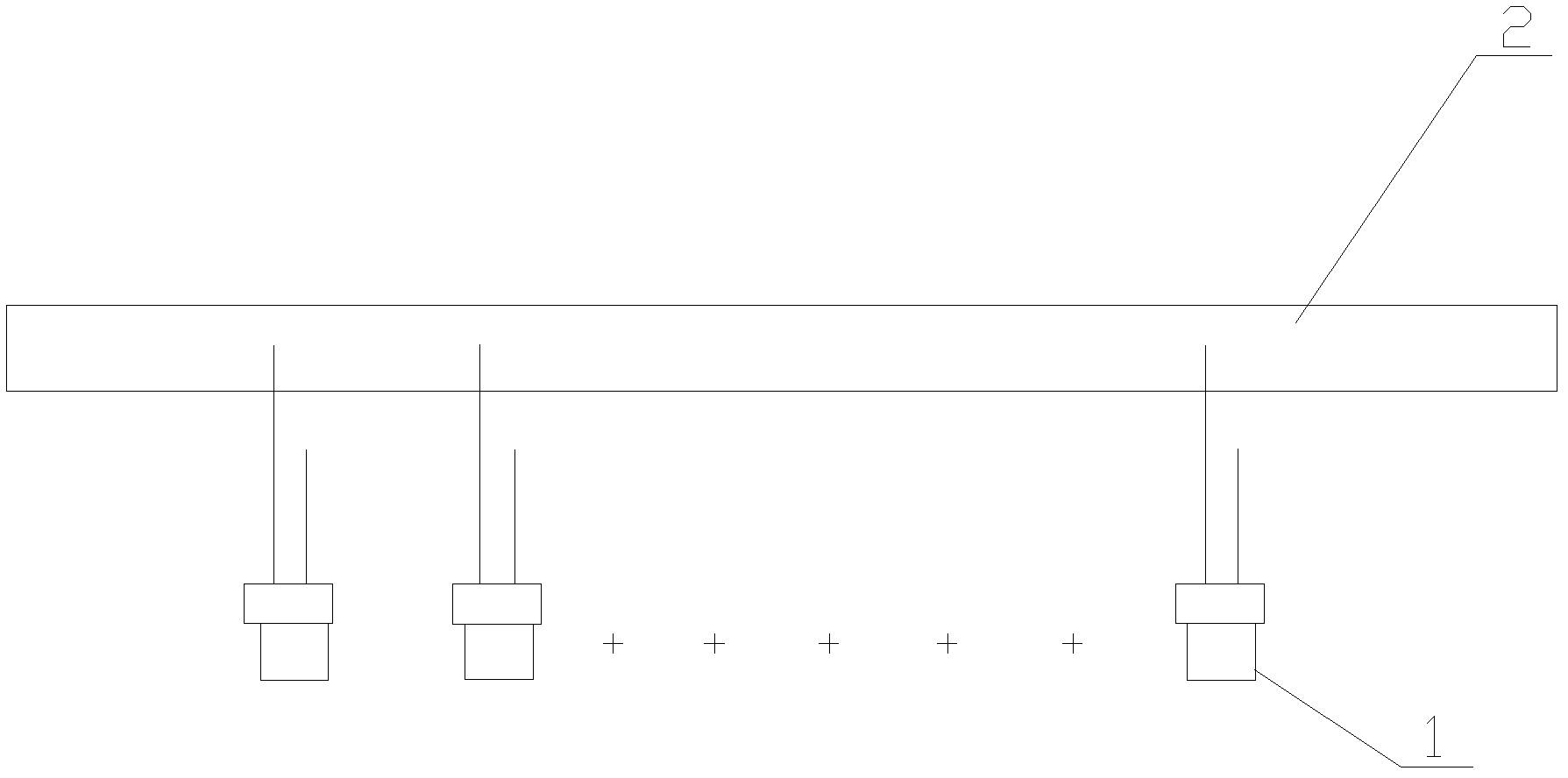

[0030] refer to figure 1 , the improved polymer solid electrolyte aluminum electrolytic capacitor of the present invention has a specification of 25V47μF and a production quantity of 4500. The steps of making it are as follows:

[0031] 1. Anodized aluminum foil with a VF value of 62V, cathode foil, and electrolytic paper are wound into a core pack 1 through a core wrap winding machine. The electrolytic paper is placed between the anodized aluminum foil and the cathode foil, and the cathode foil wraps the core after winding Pack 1, and then use high-temperature tape to surround and fix it tightly. The high-temperature tape is polyphenylene sulfide or polyimide tape;

[0032] 2. Install the rubber cover on the core package 1, and spot weld the anode guide pin of the core package 1 on the iron bar 2. To ensure the consistency of the welding height, connect the positive pole of the power supply to a stand, and the stand and the iron bar 2 are connected, the negative pole of the ...

Embodiment 2

[0048] A polymer solid electrolyte aluminum electrolytic capacitor, the specification is 35V33μF, and the production quantity is 5000 pieces. The production steps are as follows:

[0049] 1. Anodized aluminum foil with a VF value of 82V, cathode foil, and electrolytic paper are wound into a core pack 1 through a core wrap winding machine. The electrolytic paper is placed between the anodized aluminum foil and the cathode aluminum foil, and the cathode foil wraps the core after winding package 1;

[0050] 2. Install the rubber cover on the core package 1, and spot weld the anode guide pin of the core package 1 on the iron bar 2. To ensure the consistency of the welding height, connect the positive pole of the power supply to a stand, and the stand and the iron bar 2 are connected, the negative pole of the power supply is connected with the negative pole of core pack 1, and the material of the stand is conductive material, which can be stainless steel, iron, or copper, etc.;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com