Patents

Literature

72results about How to "Reduce loosening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

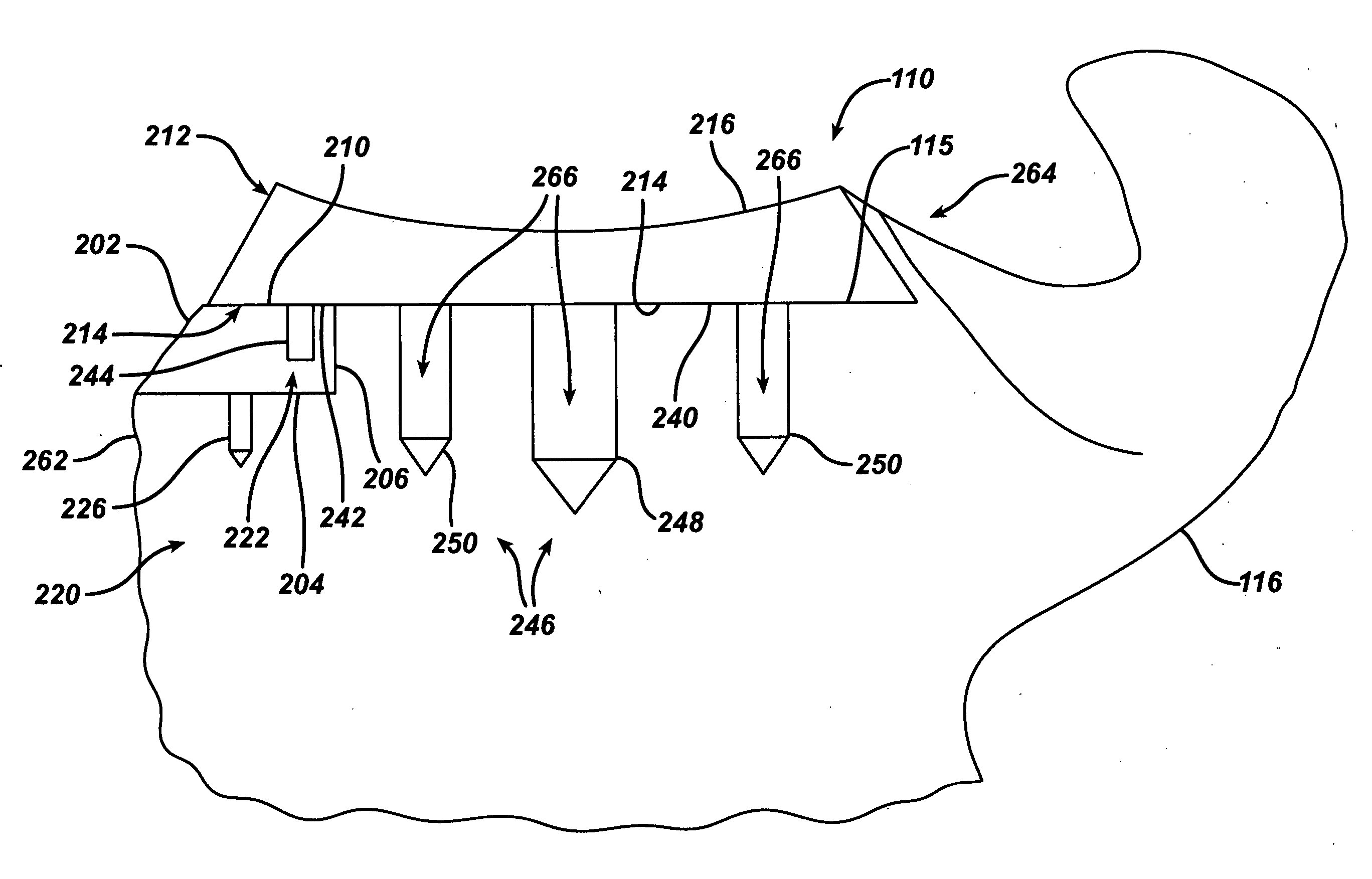

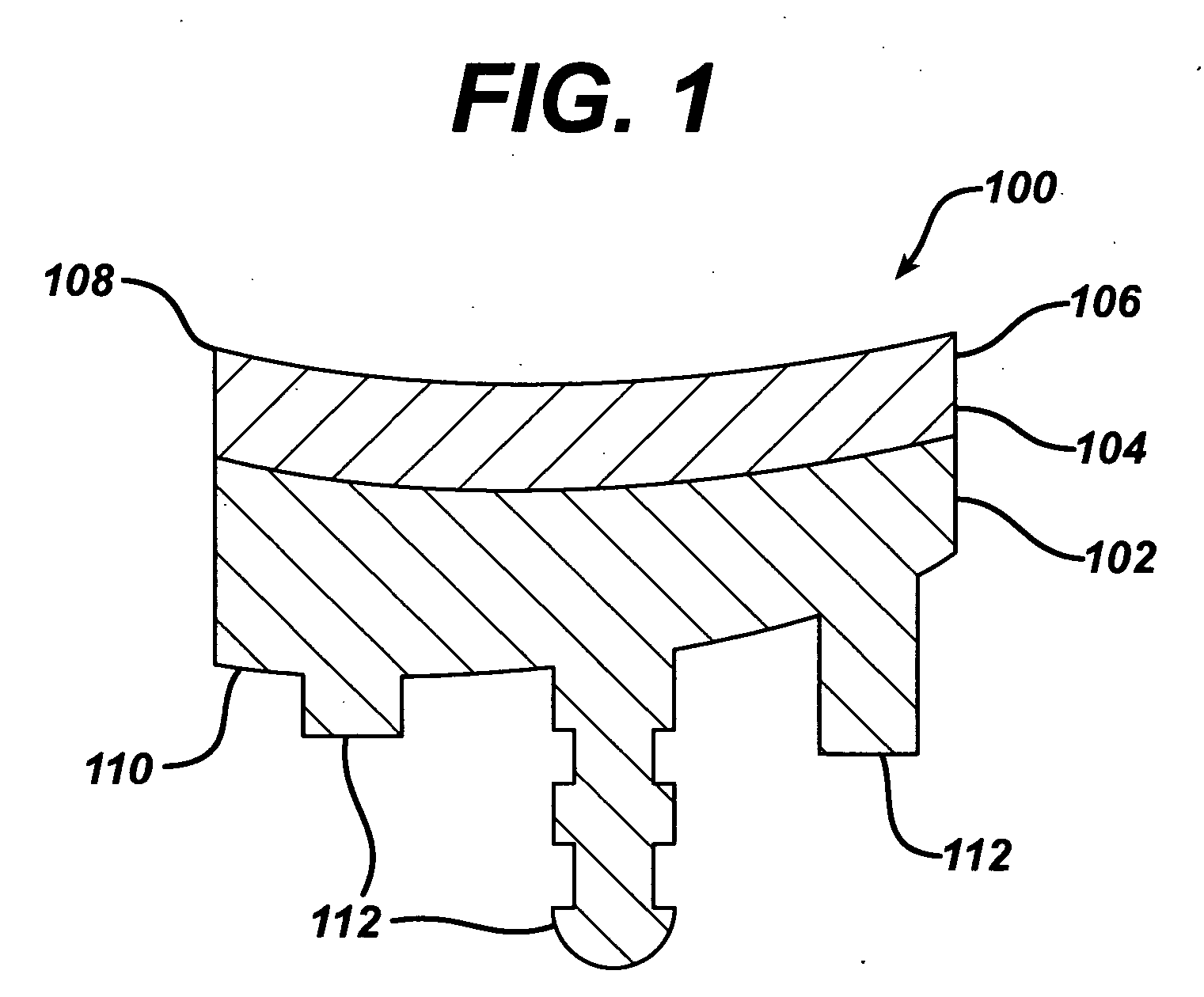

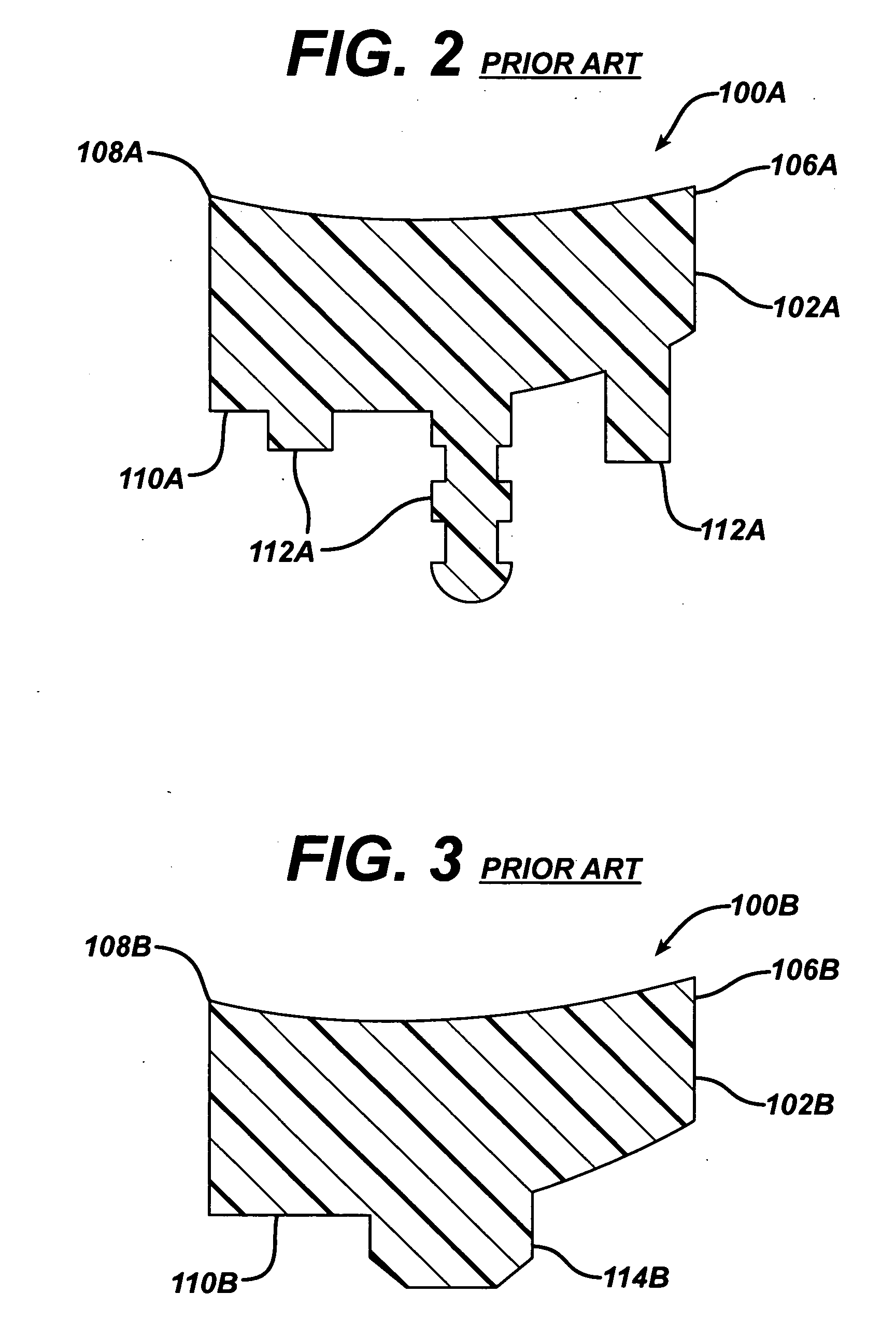

Glenoid augment and associated method

ActiveUS20060069444A1Reduce looseningEliminate shear forceJoint implantsShoulder jointsSacroiliac jointBiomedical engineering

A augmented glenoid implant assembly for use in performing shoulder arthroplasty is provided. The augmented glenoid implant assembly is used for cooperation with the glenoid fossa of a scapula. The implant assembly includes a first component for attachment to the scapula. The first component defines a support surface for cooperation with the glenoid fossa, a second surface positioned adjacent a buttress formed in the glenoid fossa and an assembly surface. The implant assembly also includes a second component removably secured to the first component. The second component includes an assembly face of the second component. The assembly surface of the second component is in close approximation to the assembly surface of the first component. The second component further includes an articulating surface opposed to the assembly surface.

Owner:DEPUY PROD INC

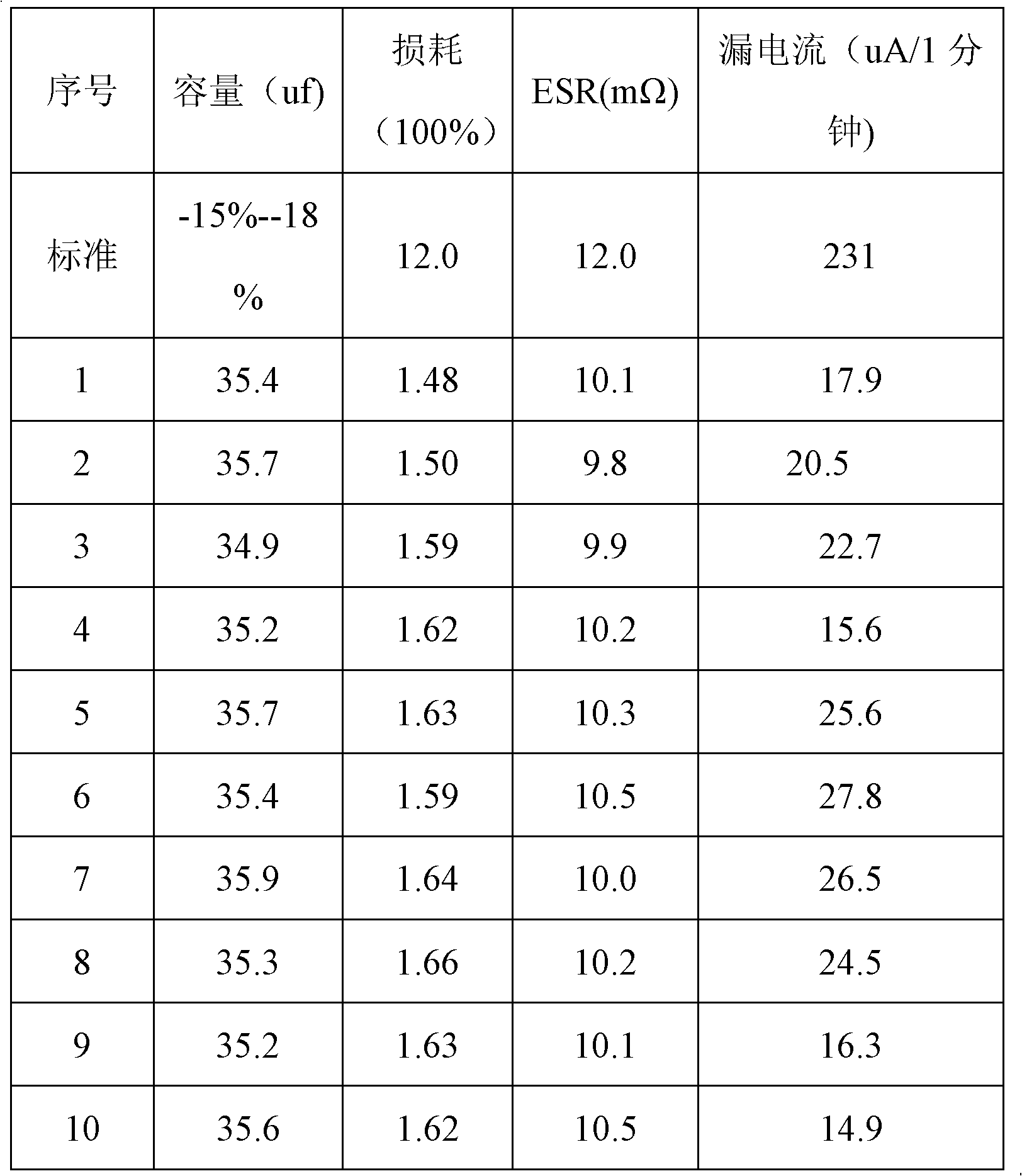

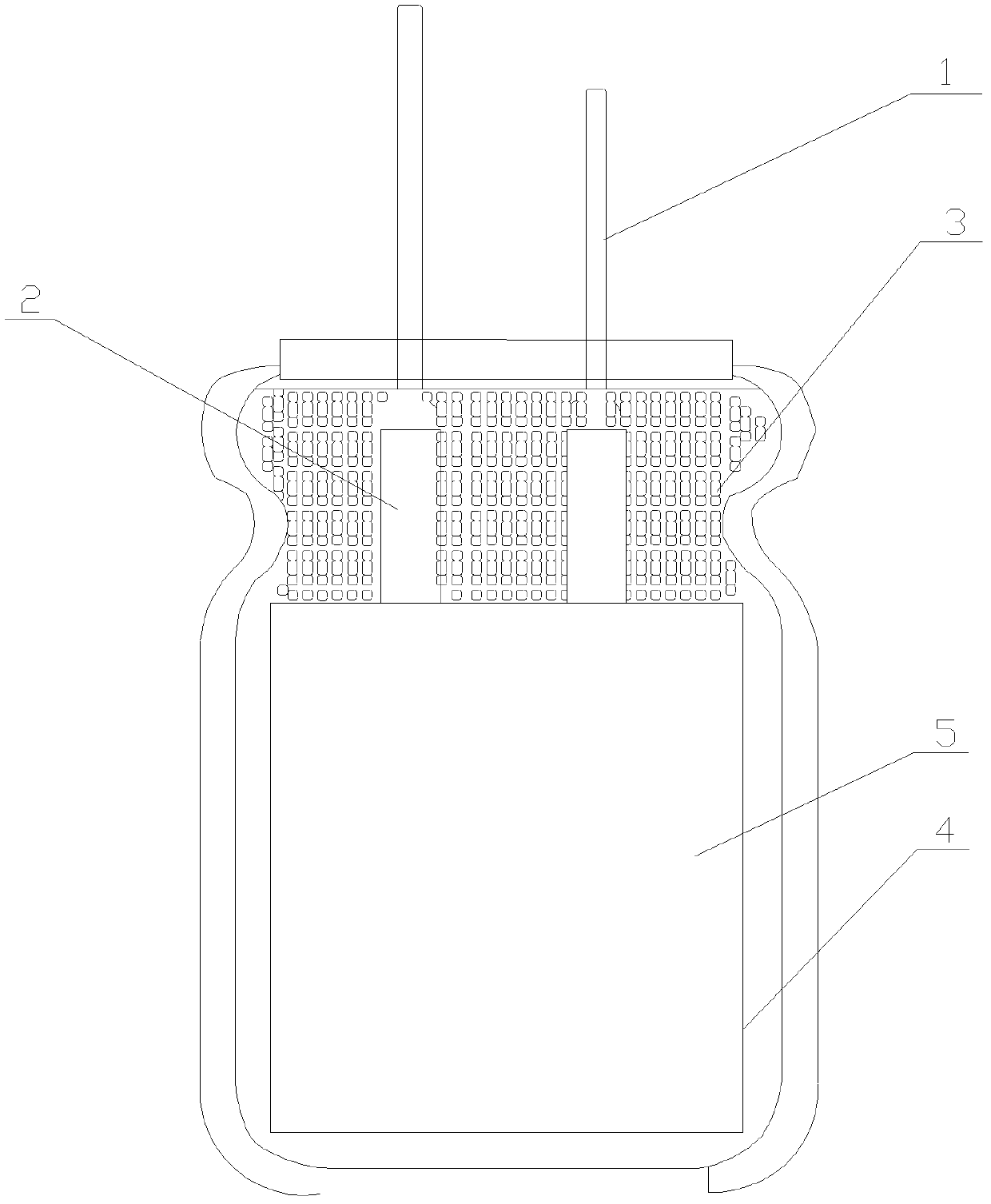

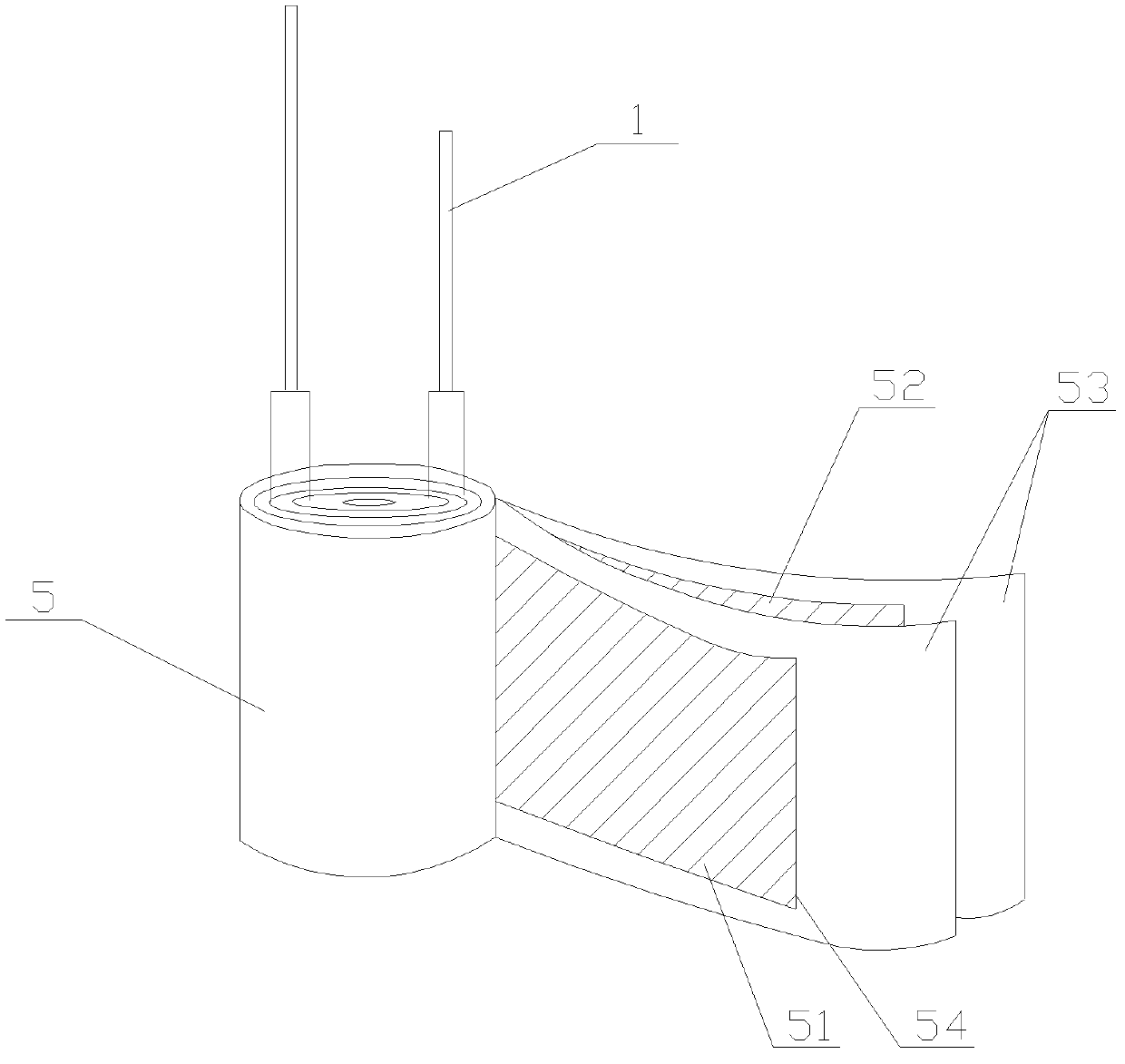

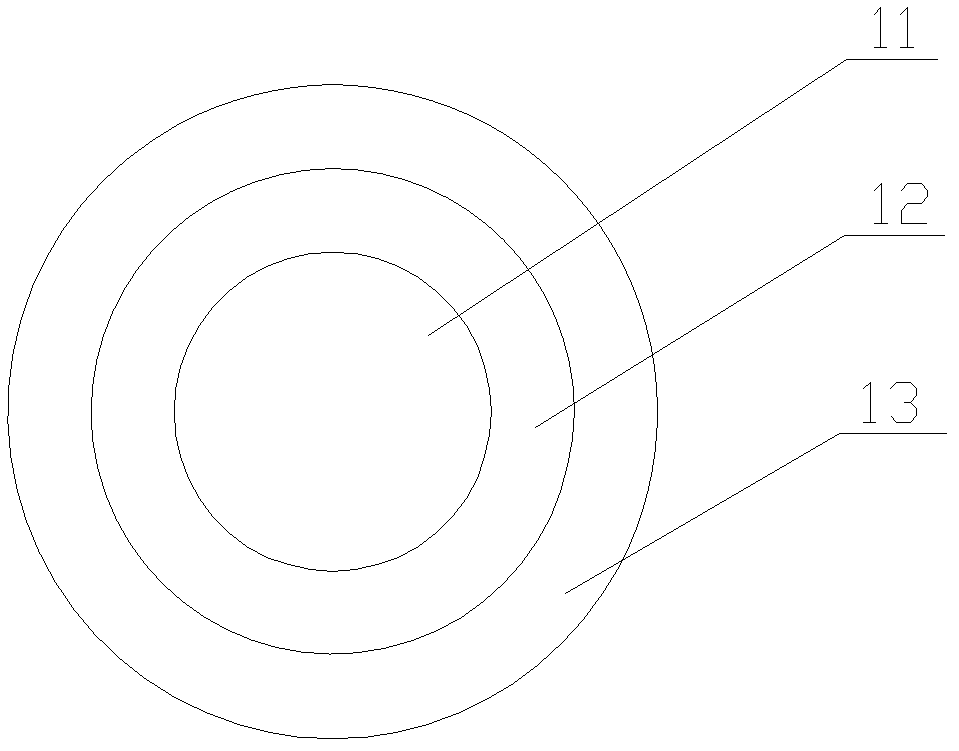

Improved method for manufacturing solid electrolyte/aluminum electrolytic capacitor

ActiveCN102592848AReduce dosageGood temperature resistanceSolid electrolytic capacitorsAluminium foilAluminium

The invention relates to an improved method for manufacturing a solid electrolyte / aluminum electrolytic capacitor. The method comprises the following steps: 1, electrolytic papers between an anode formation aluminium foil and a cathode foil are reeled to form core bags, wherein the cathode foil faces outwards and wraps the electrolytic papers, a high-temperature rubber belt is used for clinging and fixing both in a ring manner, and sealing rubber covers are mounted on the core bags; 2, the core bags are immersed into formation liquid to be subjected to repair processing, and the repaired core bags are subjected to carbonization processing, wherein the step 2 is repeated about 2-10 times; 3; the core bags are immersed into the formation liquid again to be subjected to formation and repair processing; 4, the carbonized core bags are immersed into an oxide-film protection liquid and then are dried at the temperature of 50-150 DEG C; and 5, firstly, the core bags are respectively placed into monomers and oxidant for immersion and heating convergence, then the processed core bags are mounted in an aluminum shell and a sealing procedure is performed, and lastly, the produced products are subjected to ageing processing.

Owner:ZHAOQING BERYL ELECTRONICS TECH

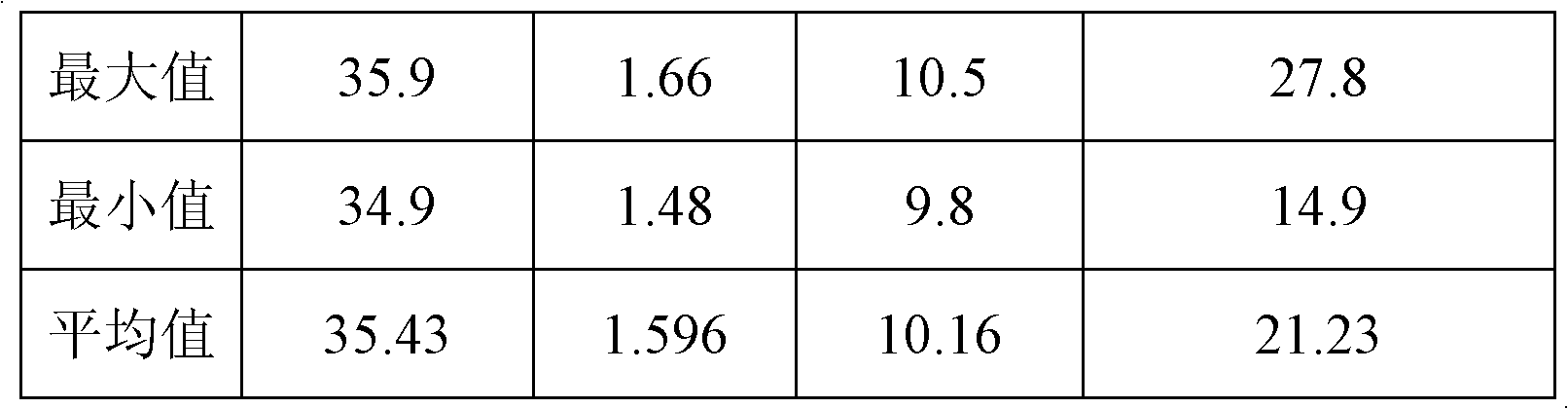

Solid electrolyte aluminium electrolytic capacitor and method for manufacturing same

InactiveCN102610401AAvoid meltingImprove the carbonization effectSolid electrolytic capacitorsSilver coatingOxidizing agent

The invention discloses a solid electrolyte aluminium electrolytic capacitor, wherein a core wrap is connected with a positive terminal and a negative terminal, the external surfaces of the positive and the negative terminals are plated with silver coatings, and the method for manufacturing the capacitor comprises the following steps: 1) the external surfaces of the positive and the negative terminals are plated with silver coatings; 2) an electrolytic paper is interposed between an anode formed aluminium foil and a cathode foil and is wound to be core wrap, and the cathode foil faces the outer side, wraps the electrolytic paper and is fixed by a high-temperature tape; 2) the core wrap is soaked into formed liquid to undergo formation repair; 3) the core wrap is placed in an oven to undergo the carbonating; 4) the core wrap is subjected to the formation repair treatment; 5) the core wrap is dried; 6) the core wrap is respectively placed into a monomer and an oxidizing agent to be impregnated, heated and aggregated; and 7) a rubber cover is assembled on the core wrap, the core wrap is assembled in an aluminium shell, sealed and aged into a product. Because the terminals adopt silver coating instead of tinning, tin melting is avoided during the high-temperature carbonating, a higher-temperature carbonating mode can be adopted, so a better carbonating effect can be obtained within shorter time, energy resources are saved, and the cost is reduced.

Owner:ZHAOQING BERYL ELECTRONICS TECH

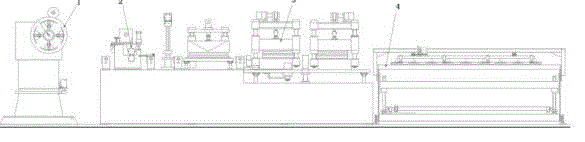

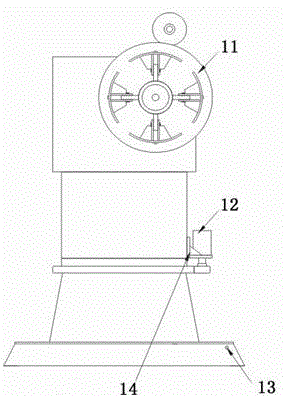

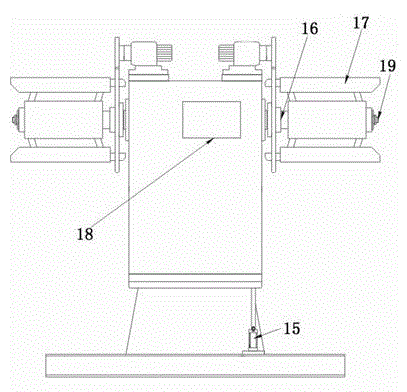

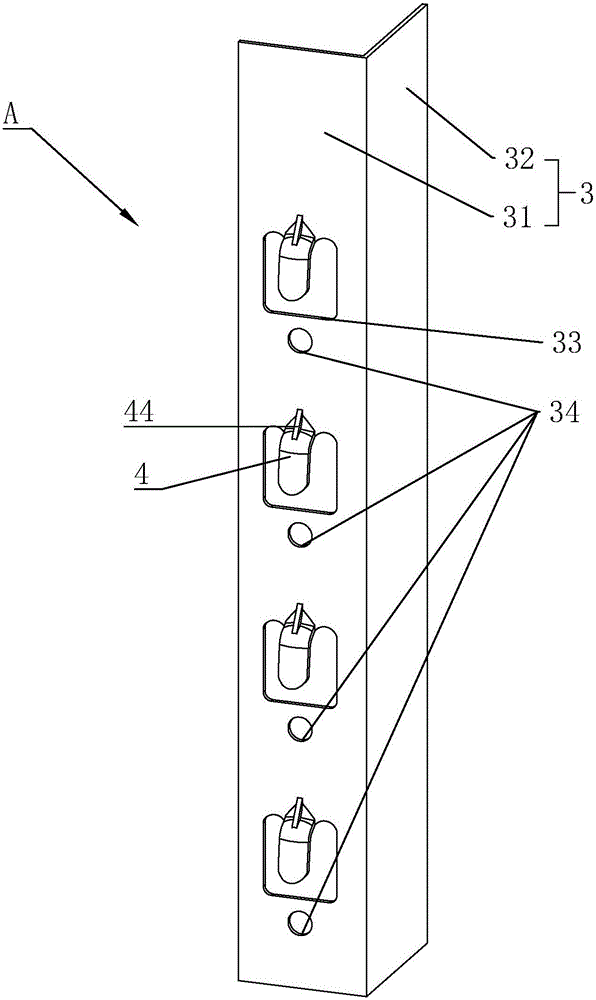

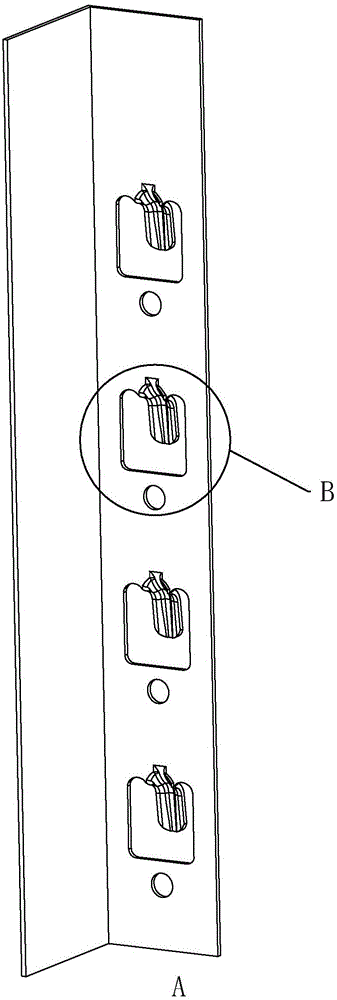

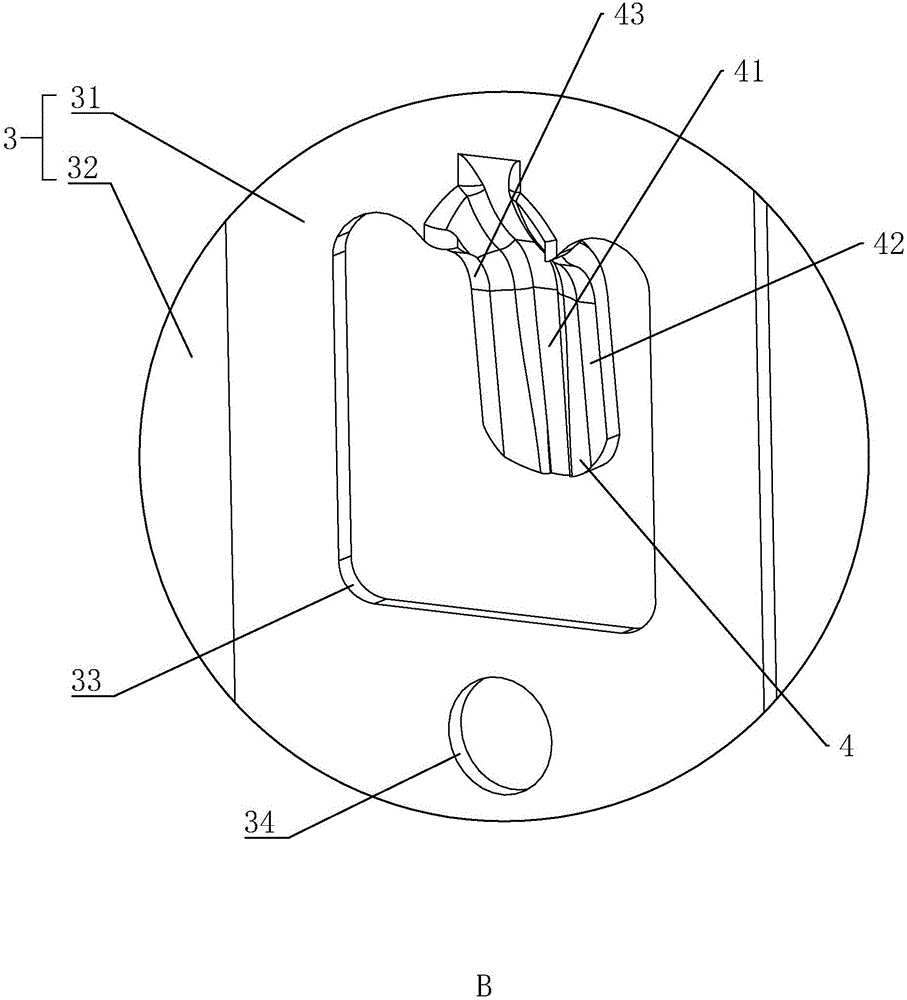

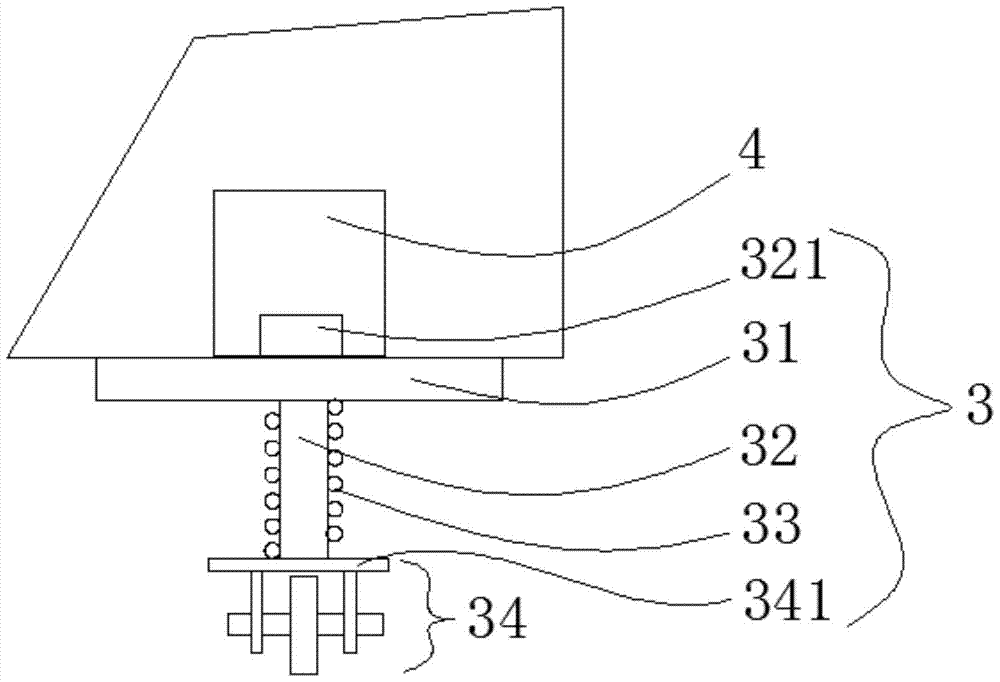

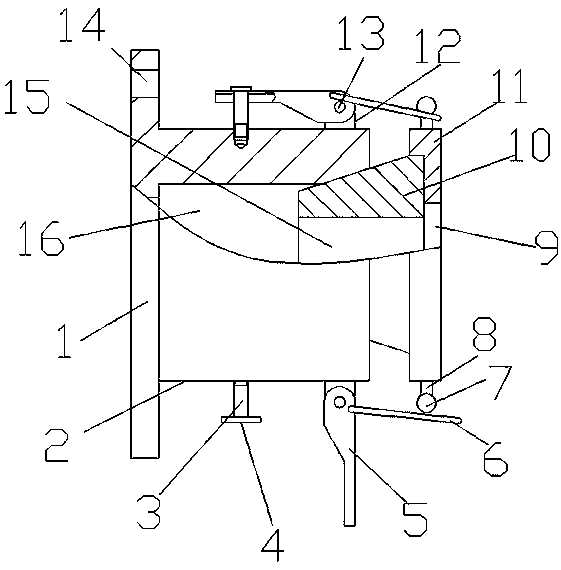

Efficient silicon steel sheet cross line shearing device

InactiveCN104801626AImprove work efficiencyReduce the possibility of looseningMetal-working feeding devicesPositioning devicesMagnetElectric machine

The invention relates to steel sheet machining equipment, and specifically relates to a silicon steel sheet cross line shearing device. The silicon steel sheet cross line shearing device comprises a winding device (1), a feed device (2), a shearing device (3) and a discharge device (4), wherein the winding device comprises at least two winding shafts (11), a hydraulic motor (12), a photoelectric inductive switch (13), a photoelectric proximity switch (14) and an air cylinder (15). Each winding shaft (11) comprises a winding shaft body (16), a press plate (17), a hydraulic cylinder (18) and a hydraulic cylinder pull rod (19). The discharge device (4) comprises a magnet suction disk (41), an air cylinder (42), a servo motor (43) and a photoelectric inductive switch (44). The efficient silicon steel sheet cross line shearing device has the advantages of finishing the integrated full-automatic design of the whole machining line shearing and discharging, accordingly saving a plenty of labor cost, and increasing the efficiency and the stability of machining the lines.

Owner:上海祯驰电气设备有限公司

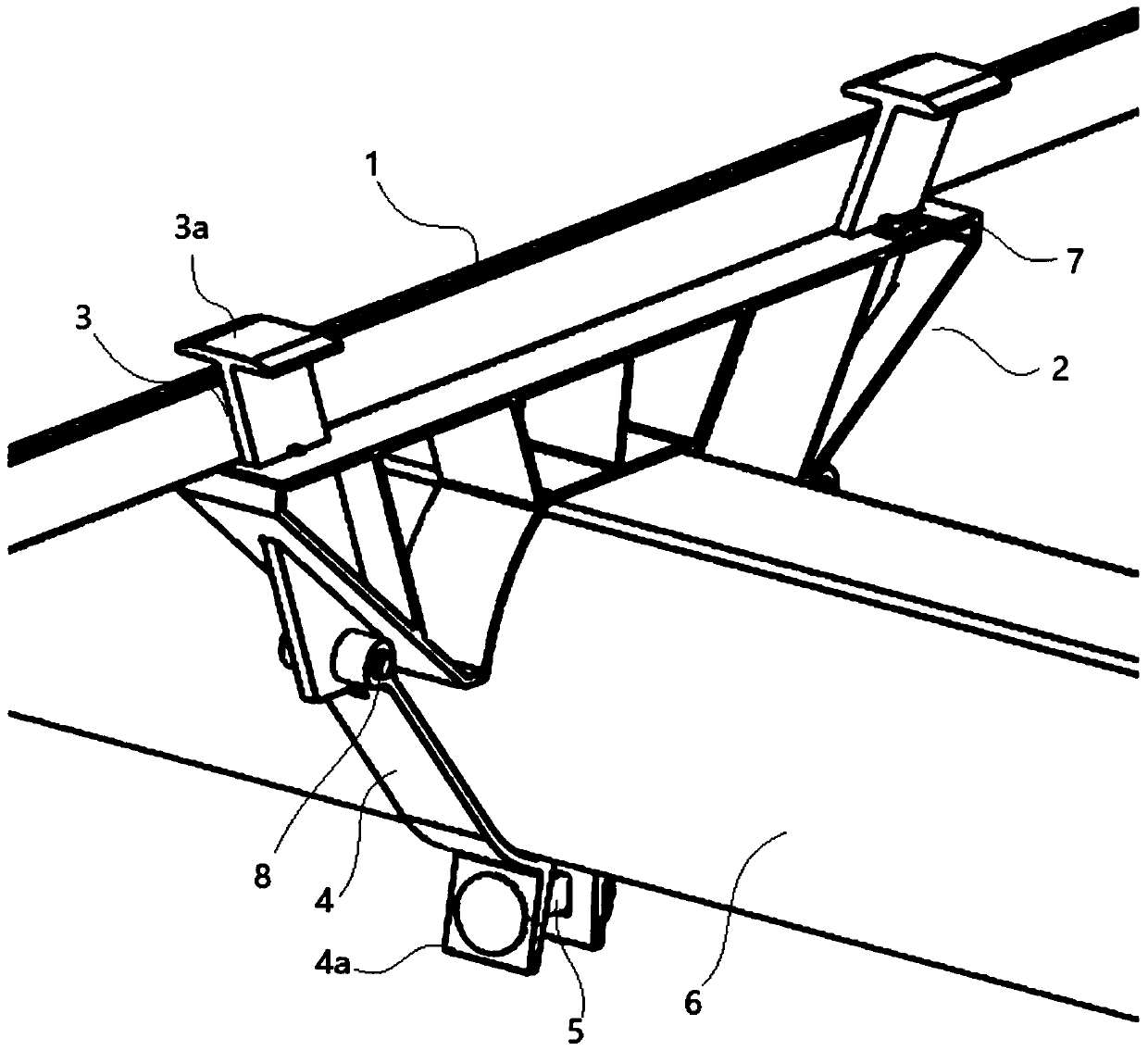

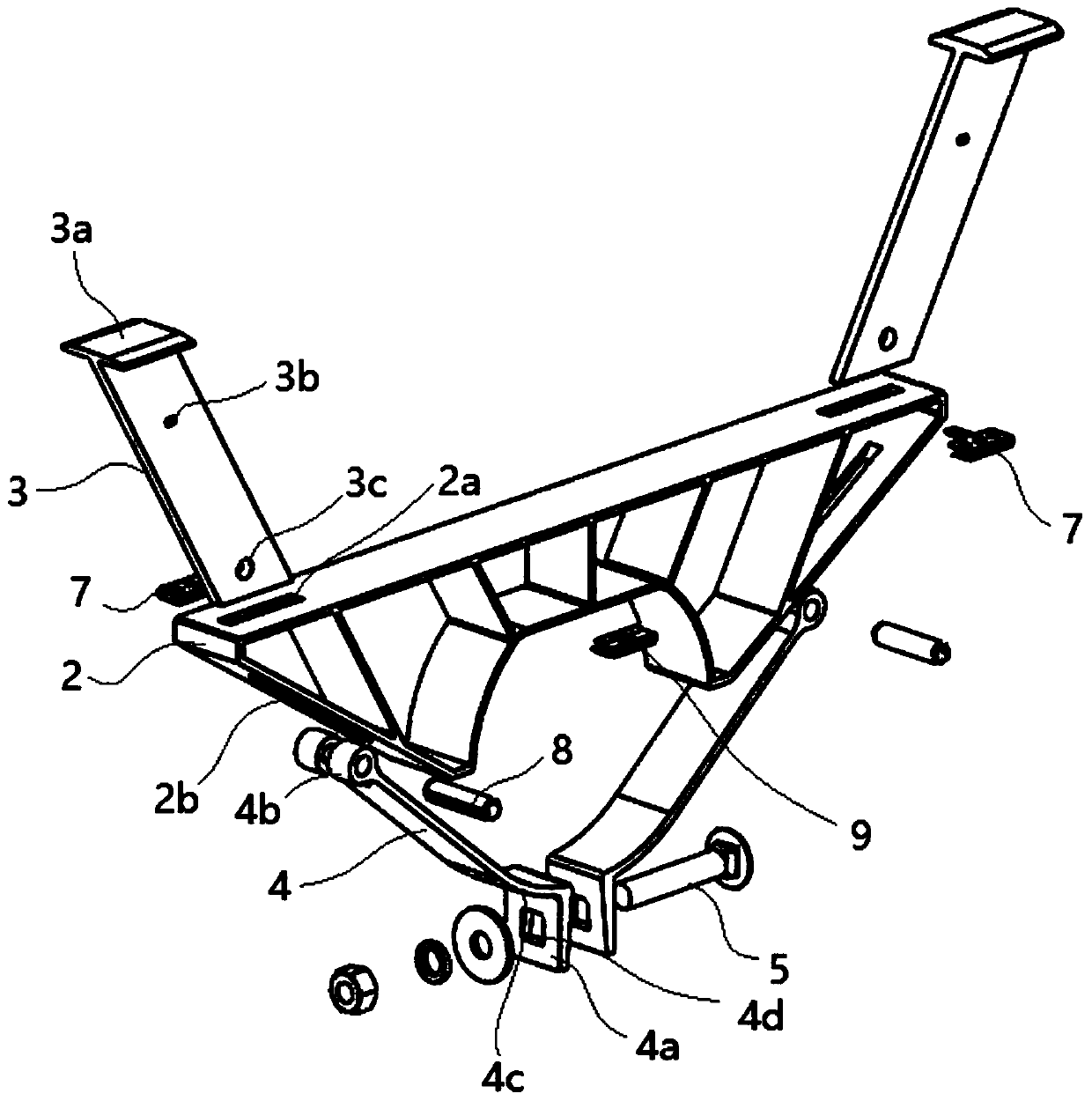

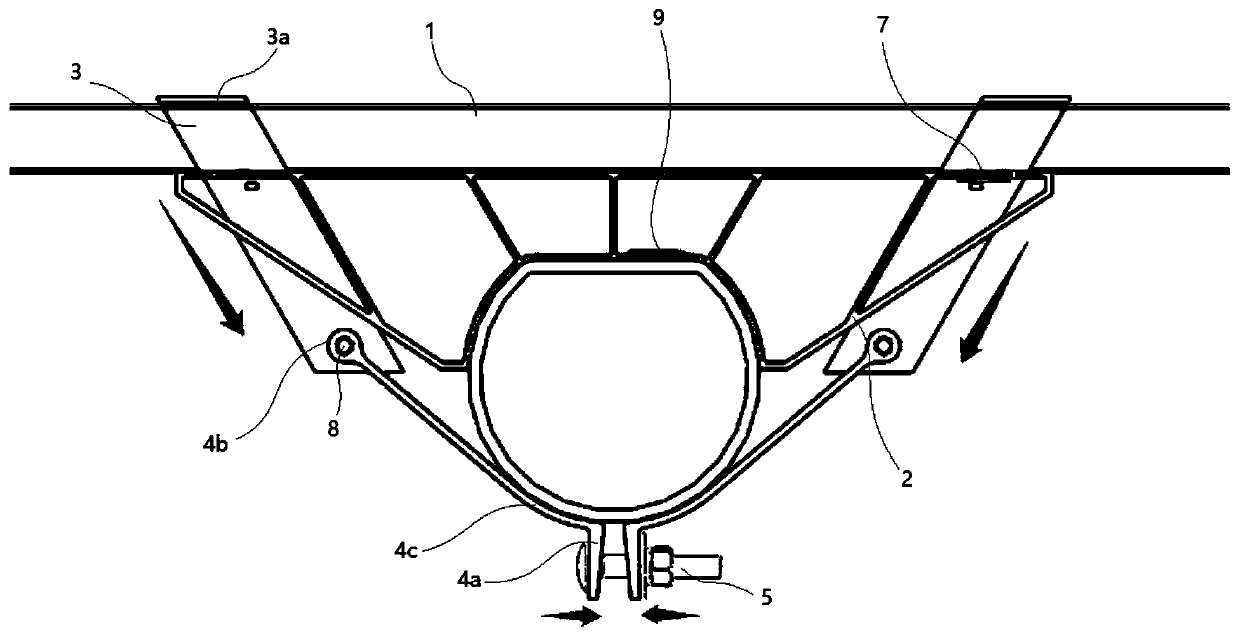

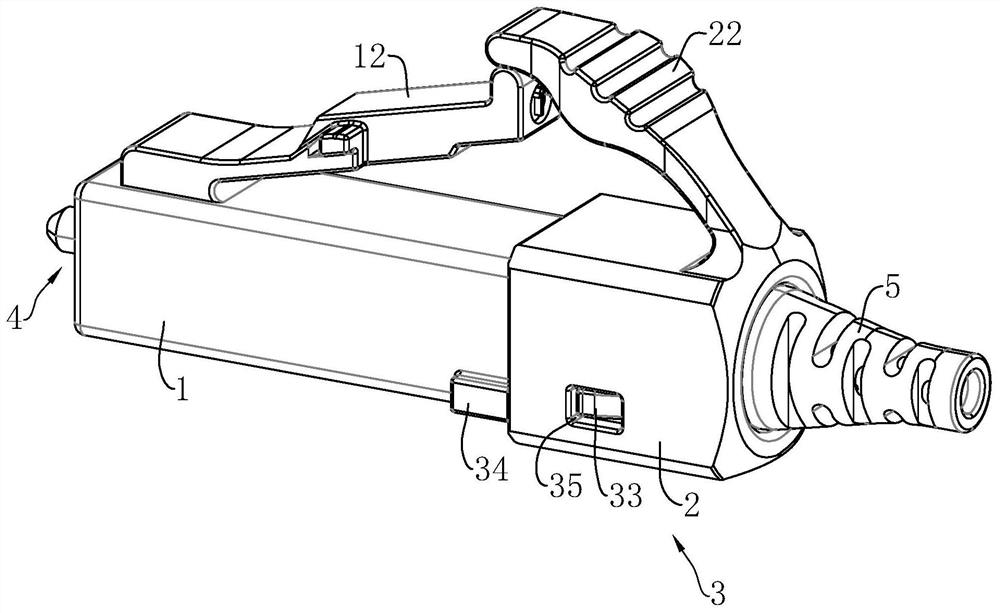

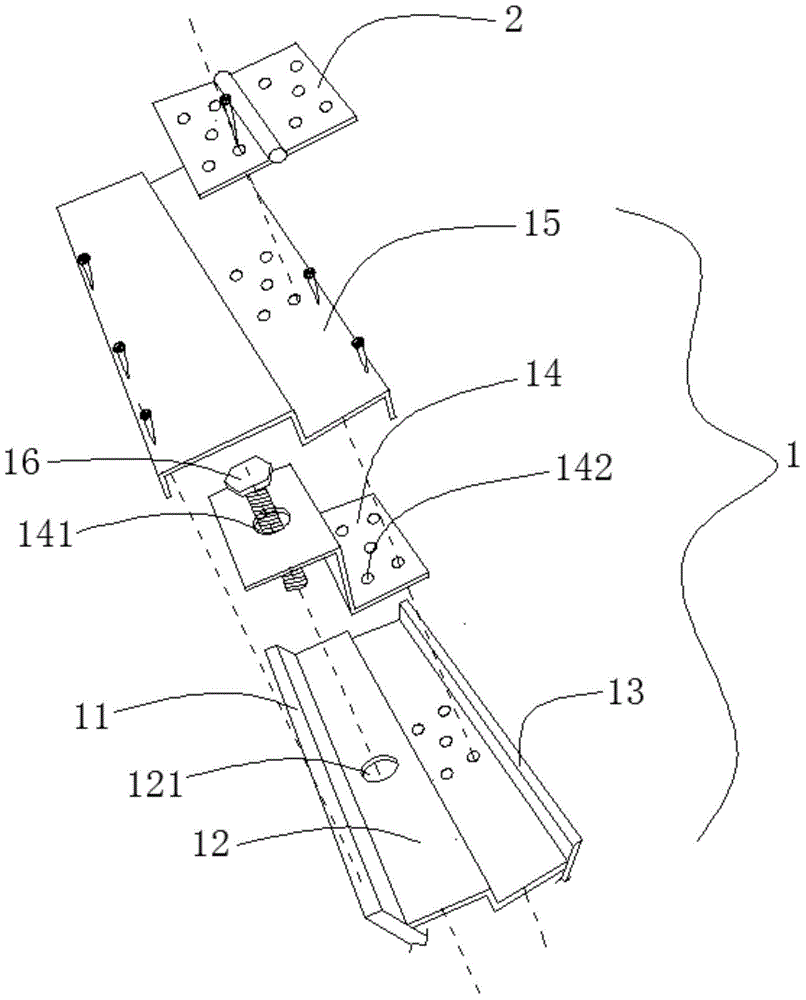

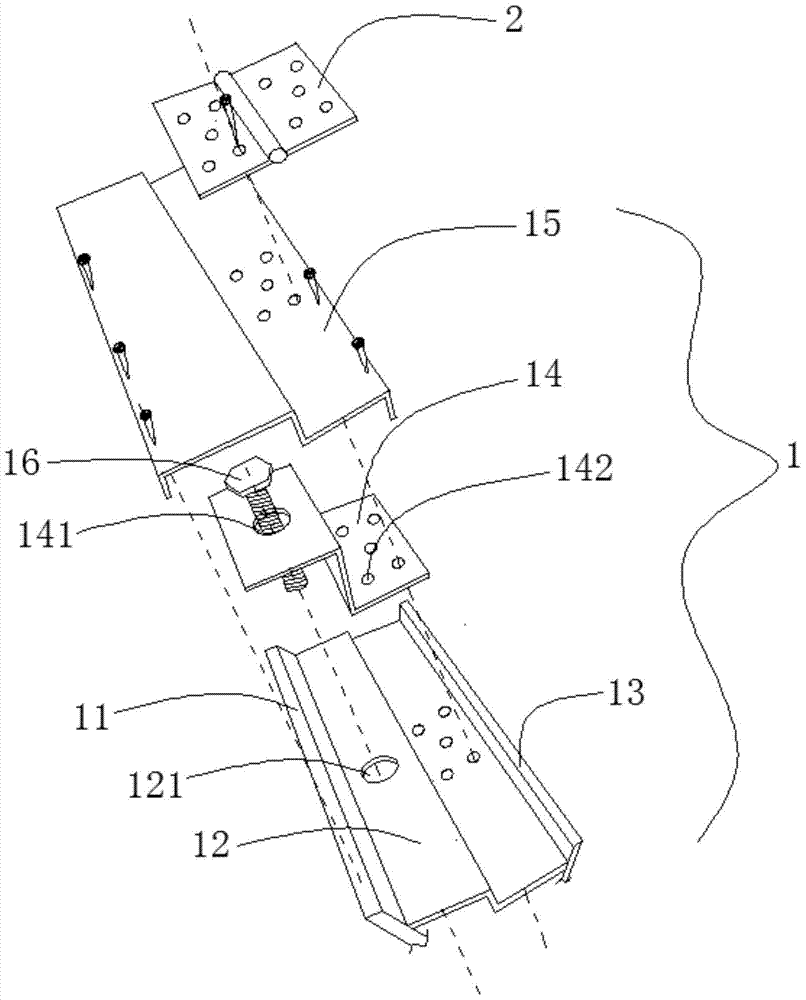

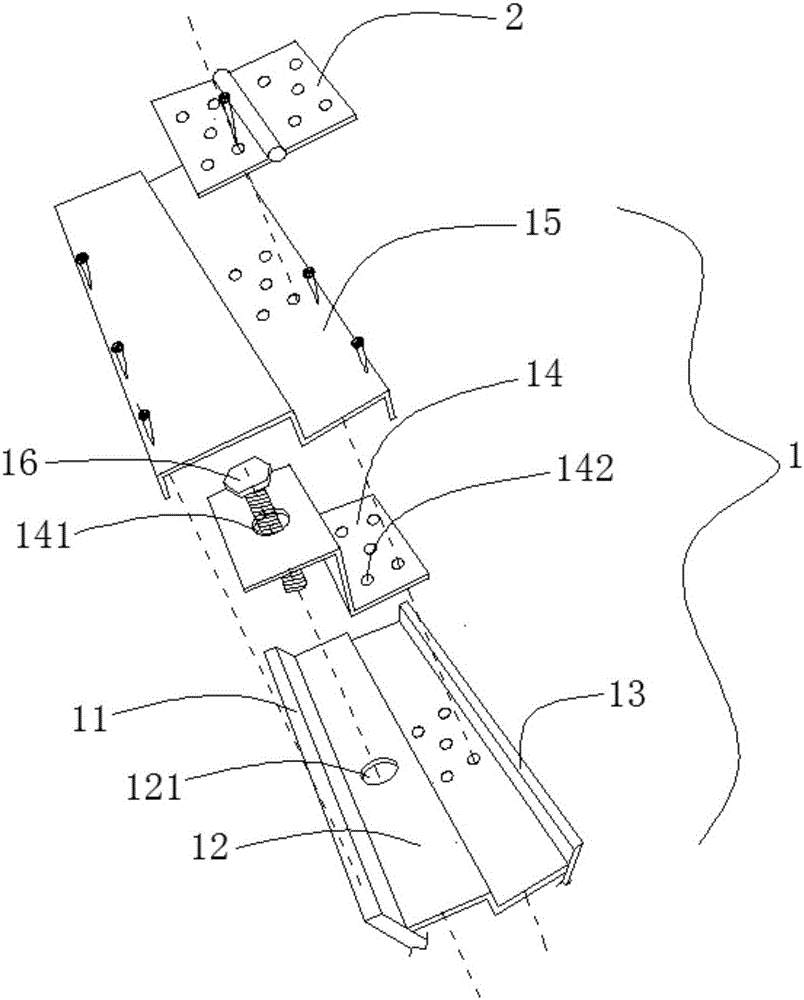

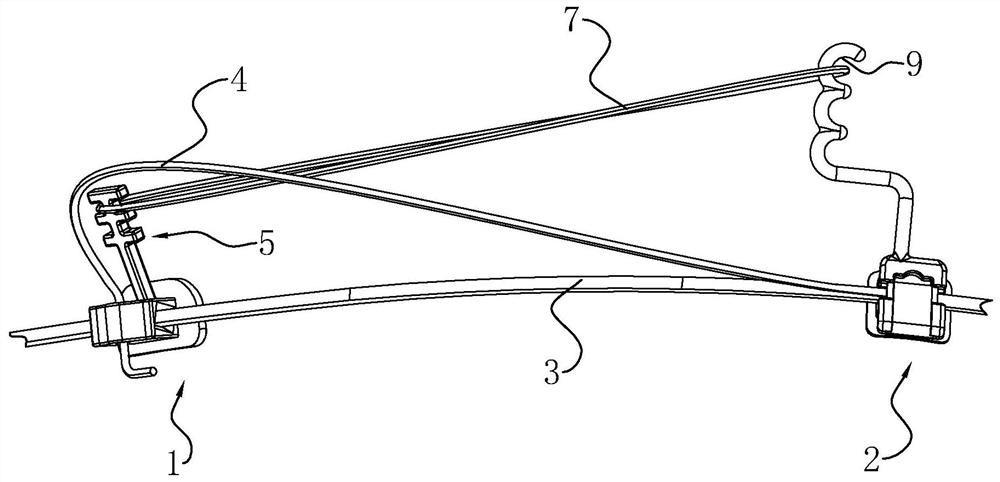

Fast installation fixture for photovoltaic module

PendingCN109768761AQuick installationReduce looseningPhotovoltaic supportsSolar heating energyPurlinEngineering

The invention discloses a fast installation fixture for a photovoltaic module. The fast installation fixture comprises a purlin, two pressing blocks and two connecting plates, wherein the purlin is placed at the upper end of a main beam, wherein first chute holes are symmetrically formed in the two ends of the upper end face of the purlin along the extension direction perpendicular to the main beam; second chute holes are symmetrically formed in the two ends of the lower end face of the purlin; the first chute holes and the second chute holes in the same side of the purlin constitute chute channels; the first ends of the pressing blocks are provided with clamping parts for pressing the photovoltaic module; the pressing blocks are inserted into the chute channels, and the second ends of thepressing blocks incline towards the main beam; the pressing blocks correspond to the chute channels one by one; the first ends of the connecting plates are rotationally connected with the second endsof the pressing blocks extending out the chute channels on the side; and the second ends of the two connecting plates are connected by a distance adjustment structure. The fast installation fixture can install photovoltaic modules with different thickness on the main beam, and has wider applicability.

Owner:ARCTECH SOLAR HLDG CO LTD

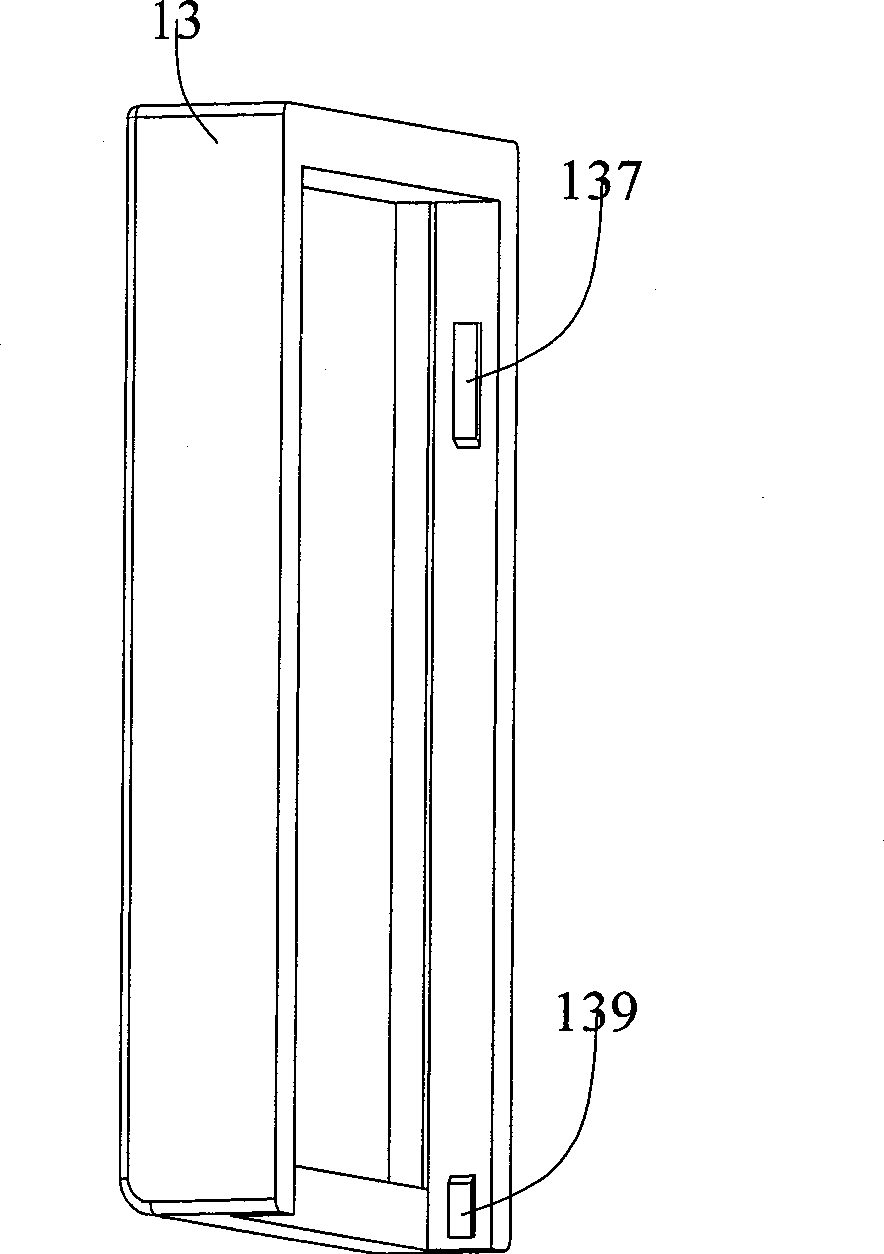

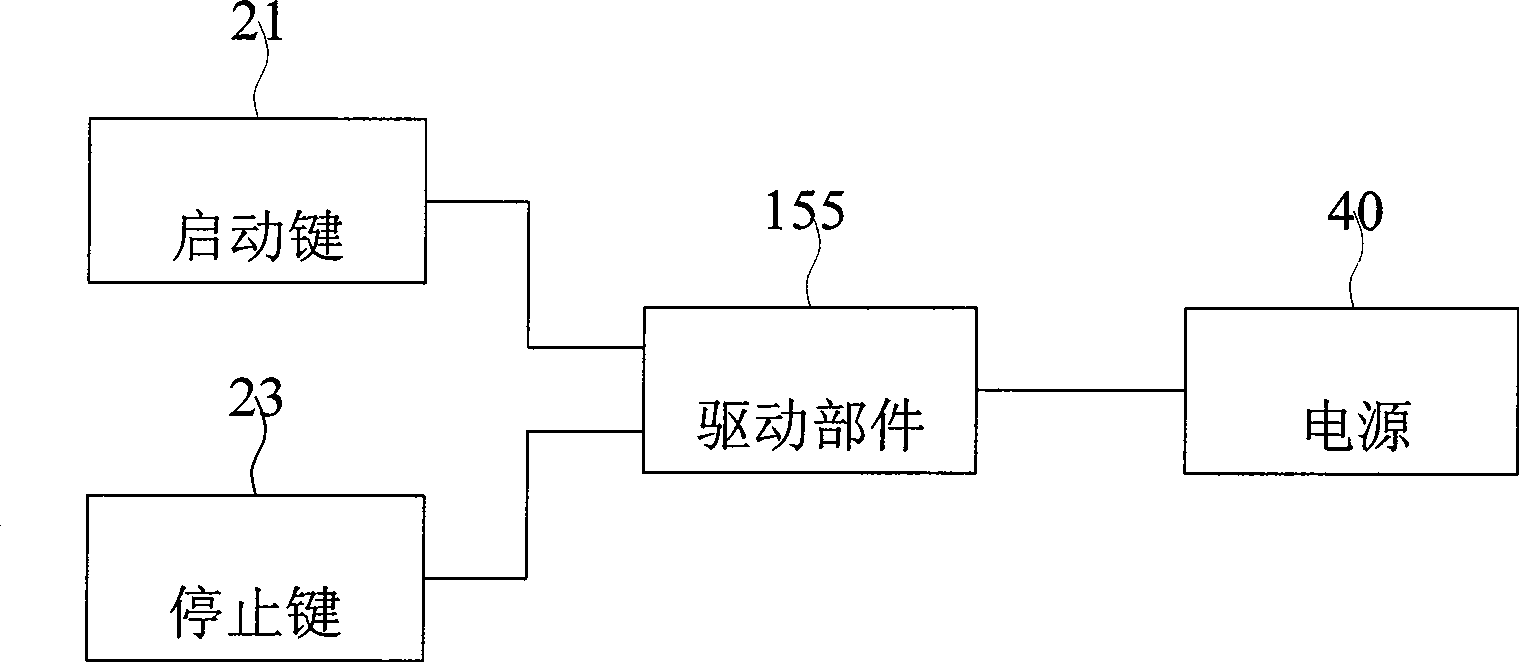

Sliding cover mechanism, sliding cover method and electronic device applying the mechanism

InactiveCN101426040AImprove smoothnessImprove stabilityTelephone set constructionsElectric driveEngineering

A slip cover mechanism, a slip cover method and an electronic device using the slip cover mechanism. The user can press the key of the electronic device to break a first block piece away from a first raised line, and simultaneously start-up a transmission component to drive the slip cover to move from a first position to a second position, to achieve automatic slip cover effect. The present invention can achieve automatic slip cover effect by pressing keys. The electric drive may hold the fixed speed shift between the slip cover and the host mobile, whereby it greatly enhances the smoothness of the moving of the slip cover, simultaneously avoids the problem that the slip cover moves to a second position to knock with the host mobile; can increase the stability of hand-held electronic device of users, improve comfort feeling of the electronic device; and can reduce the loosing and breakage risk of the electronic device components and can improve the overall service life of electronic devices.

Owner:QISDA SUZHOU

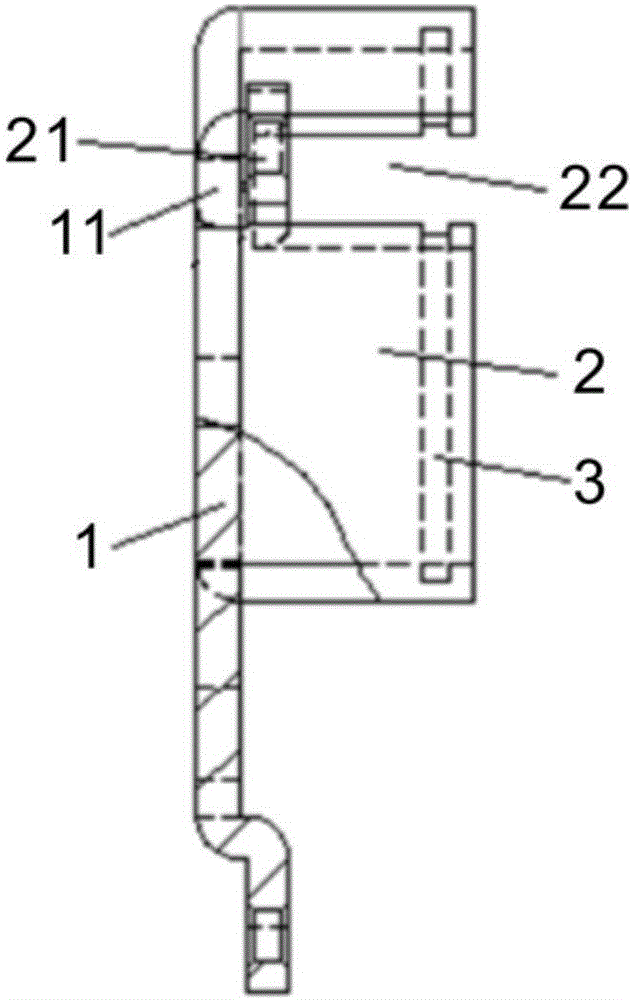

Fixing device for tracheal intubation

InactiveCN105477760ASmall footprintSolve the disadvantages of lack of dropTracheal tubesMedical devicesIntratracheal intubationEngineering

The invention relates to a medical care instrument, in particular to a fixing device for tracheal intubation. The fixing device comprises a pair of U-shaped fixators and a hood. The pair of U-shaped fixators are fixedly connected through a bolt and a spigot to form an oval fixator. Side face ring buckles are arranged at the two ends of the long axis part of the oval fixator respectively, and a top face ring buckle is arranged at the upper end of the short axis part of the oval fixator. The hood is connected with a pair of side fixing straps and a pair of face fixing straps. One end of each side fixing strap is connected with the corresponding side face ring buckle, and the face fixing straps are connected with the top face ring buckle. A tracheal intubation catheter fixing bayonet is formed in the center of the oval fixator. A phlegm suction opening is formed between the outer wall of the tracheal intubation catheter fixing bayonet and the U-shaped fixators. The fixing device for tracheal intubation is suitable for fixing an intubation tube in emergent rescue tracheal intubation of a critical patient, operation is extremely easy and convenient, and a space can be conveniently made for oral care.

Owner:AFFILIATED HOSPITAL OF JIANGSU UNIV

Light steel house connecting structure

Owner:ZHEJIANG FEIWU ARCHITECTURAL TECH CO LTD

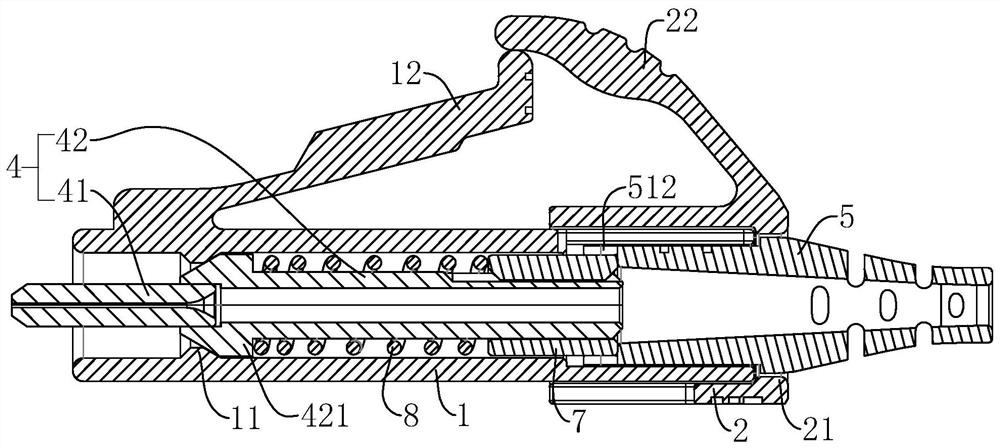

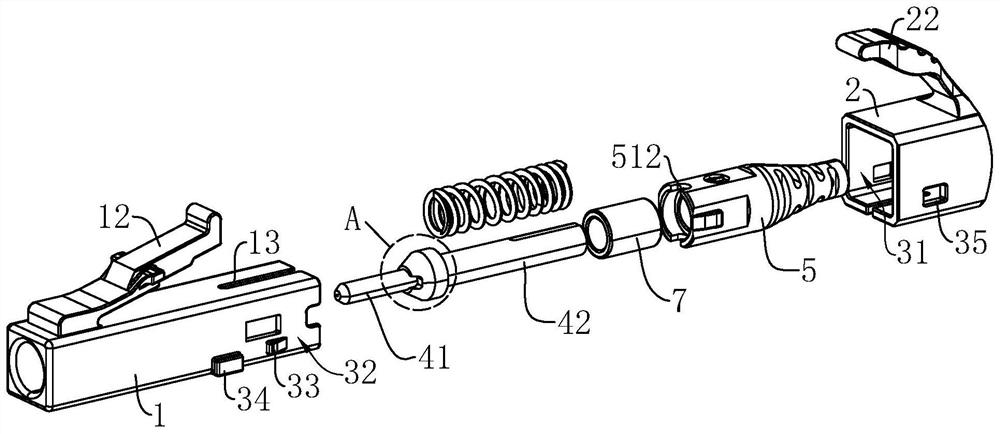

LC type polarization-maintaining connector

ActiveCN113820795AReduce looseningImprove stabilityCoupling light guidesStructural engineeringFibre Channel

The invention discloses an LC type polarization-maintaining connector, and relates to the field of optical fiber connectors, the LC type polarization-maintaining connector comprises an outer frame sleeve and an insertion core assembly in sliding fit with the outer frame sleeve, an integrated tail sleeve is arranged at the tail end of the outer frame sleeve, an angle fixing ring is arranged at one end, close to the insertion core assembly, of the integrated tail sleeve, one end of the insertion core assembly is in sliding fit with the angle fixing ring, the insertion core assembly, the angle fixing ring and the integrated tail sleeve are communicated to form an optical fiber channel for an optical fiber to pass through, and a spring used for applying acting force away from the angle fixing ring to the insertion core assembly is arranged in the outer frame sleeve; the integrated tail sleeve comprises a positioning part located at one end close to the angle fixing ring and a flexible part located at the other end, the flexible part and the positioning part are integrally formed, and the positioning part is clamped to the inner side of the tail end of the outer frame sleeve through an inner buckle structure. The integrated tail sleeve has the advantages that the situation that the integrated tail sleeve is loosened due to pressure is reduced, and the stability of the integrated tail sleeve is improved.

Owner:EAST POINT COMM TECH CO LTD

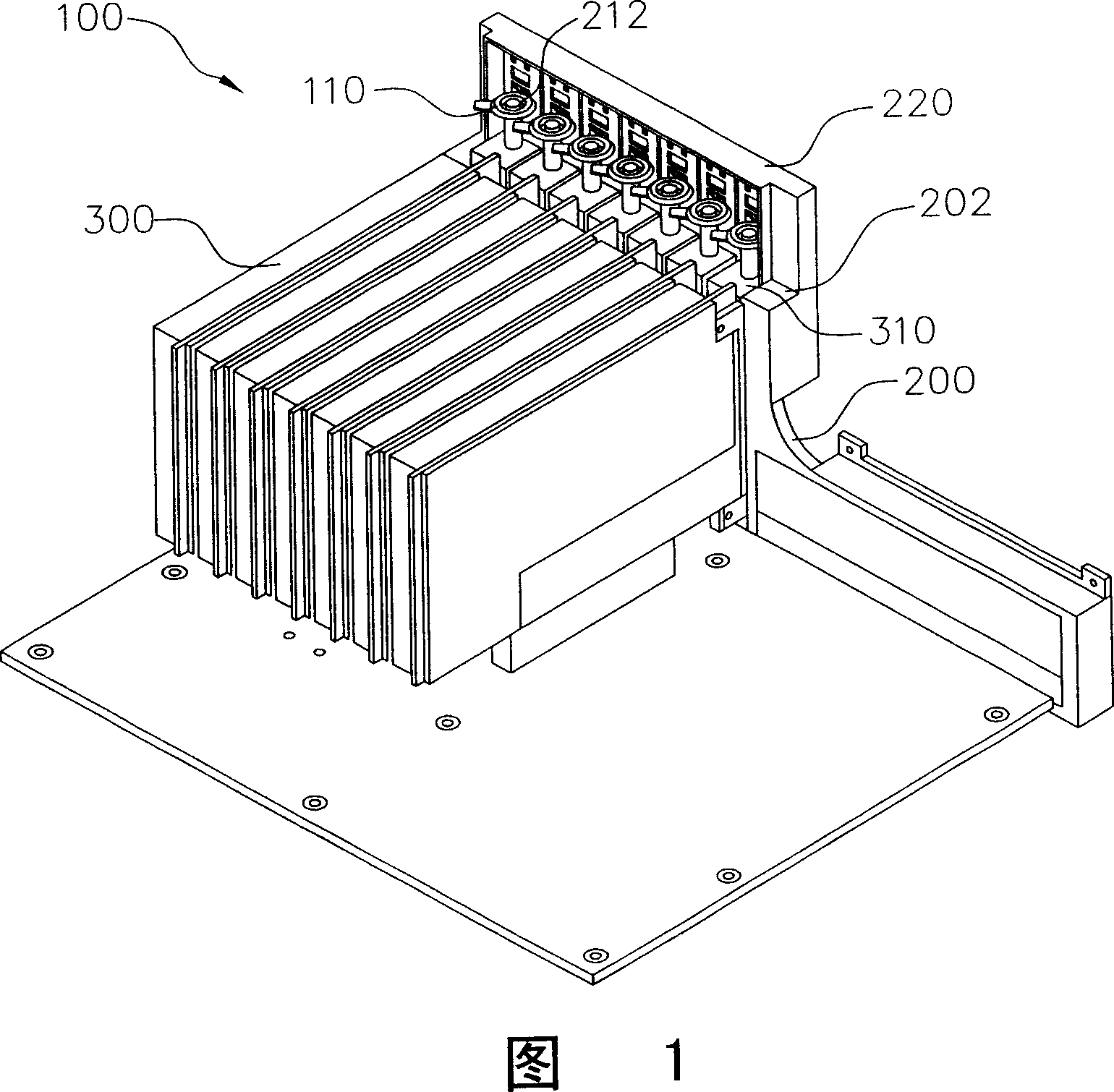

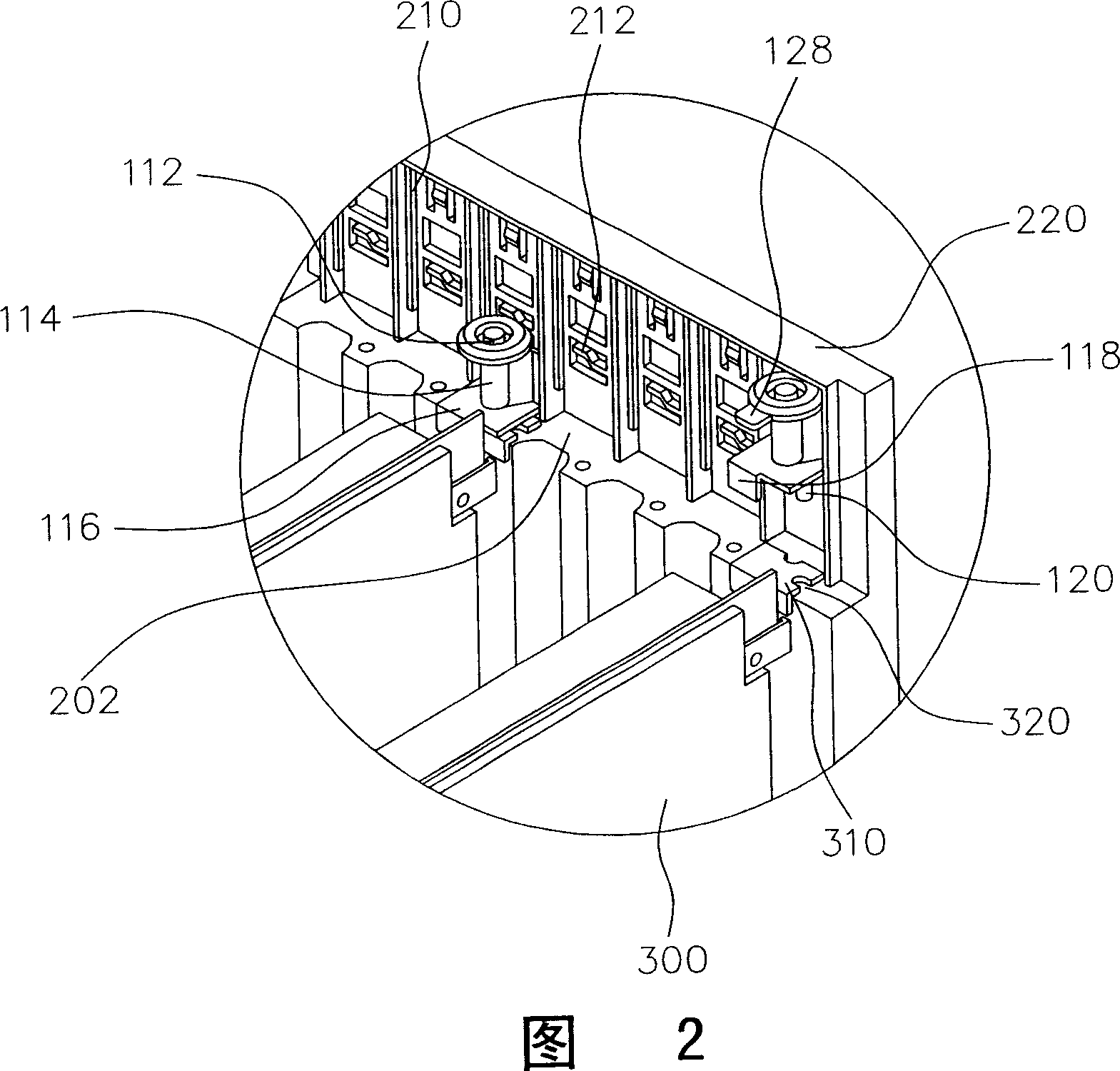

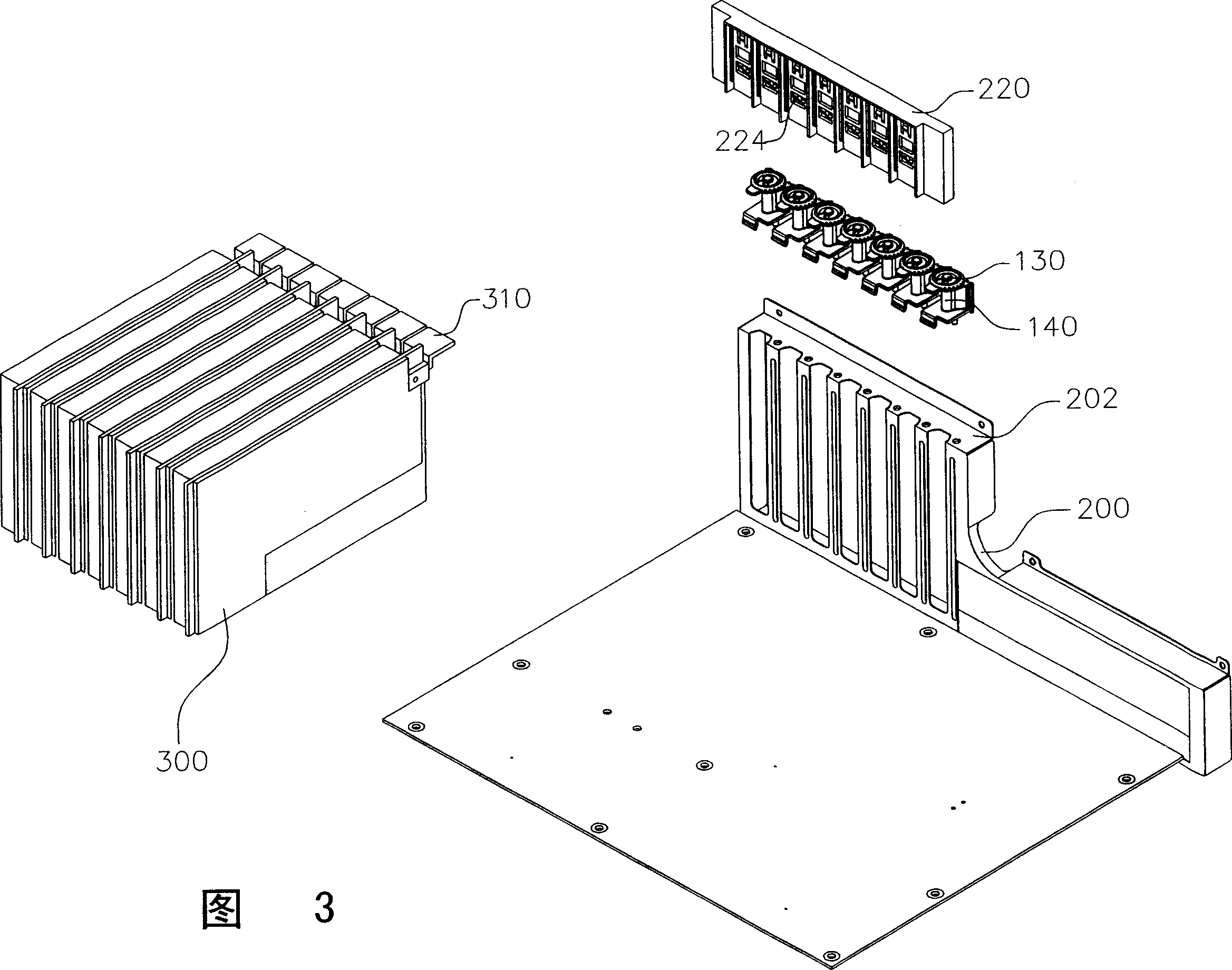

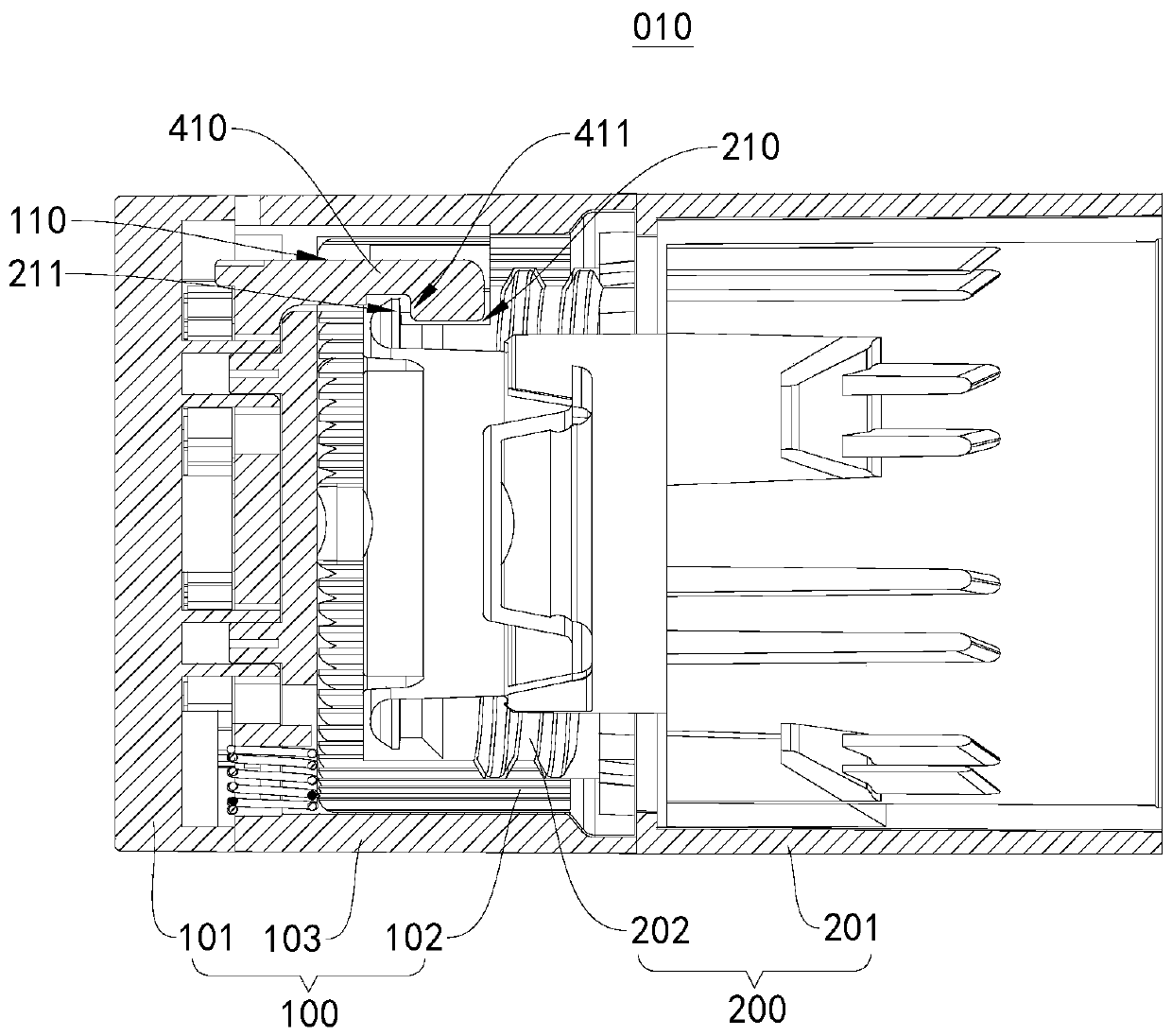

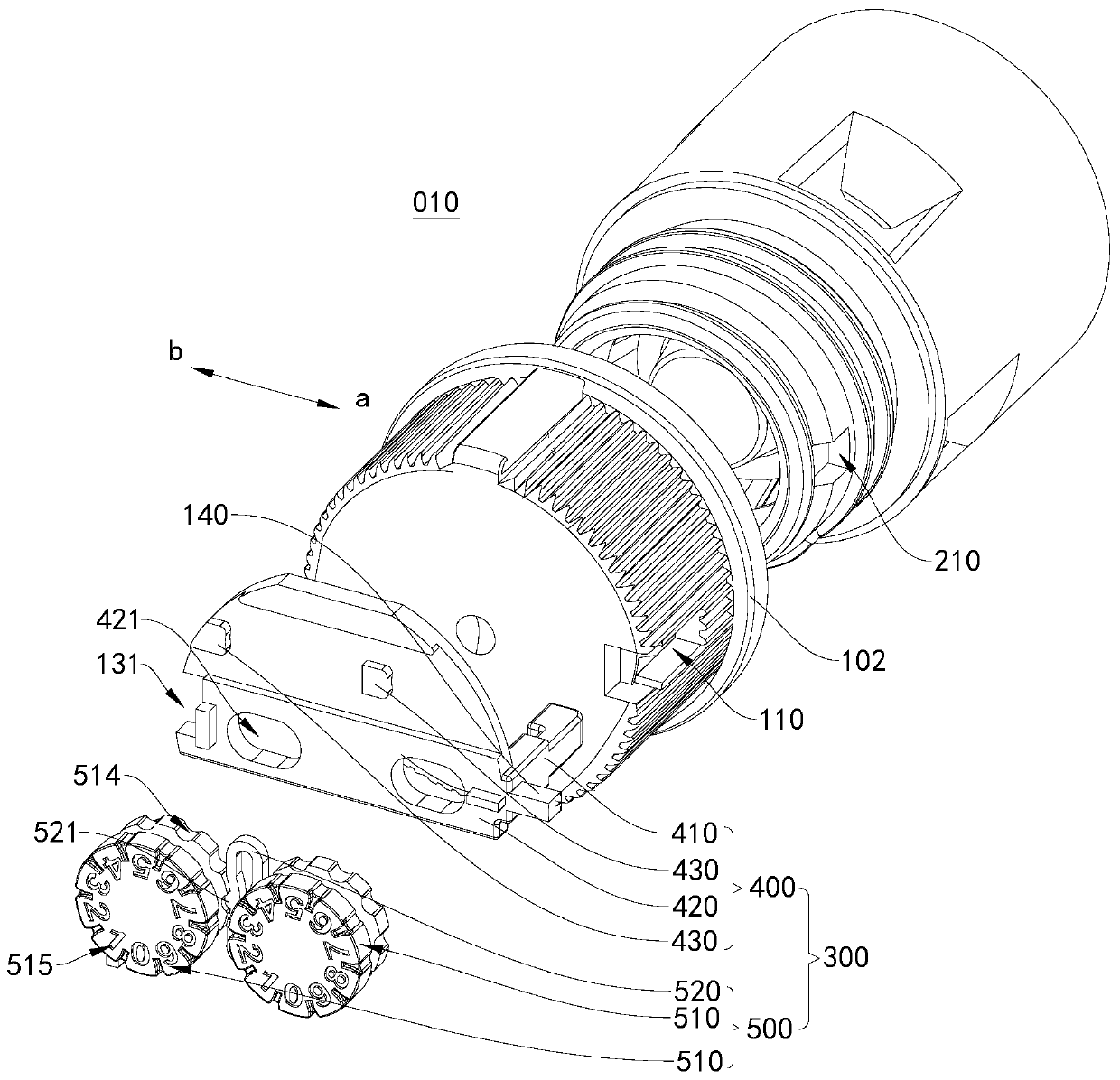

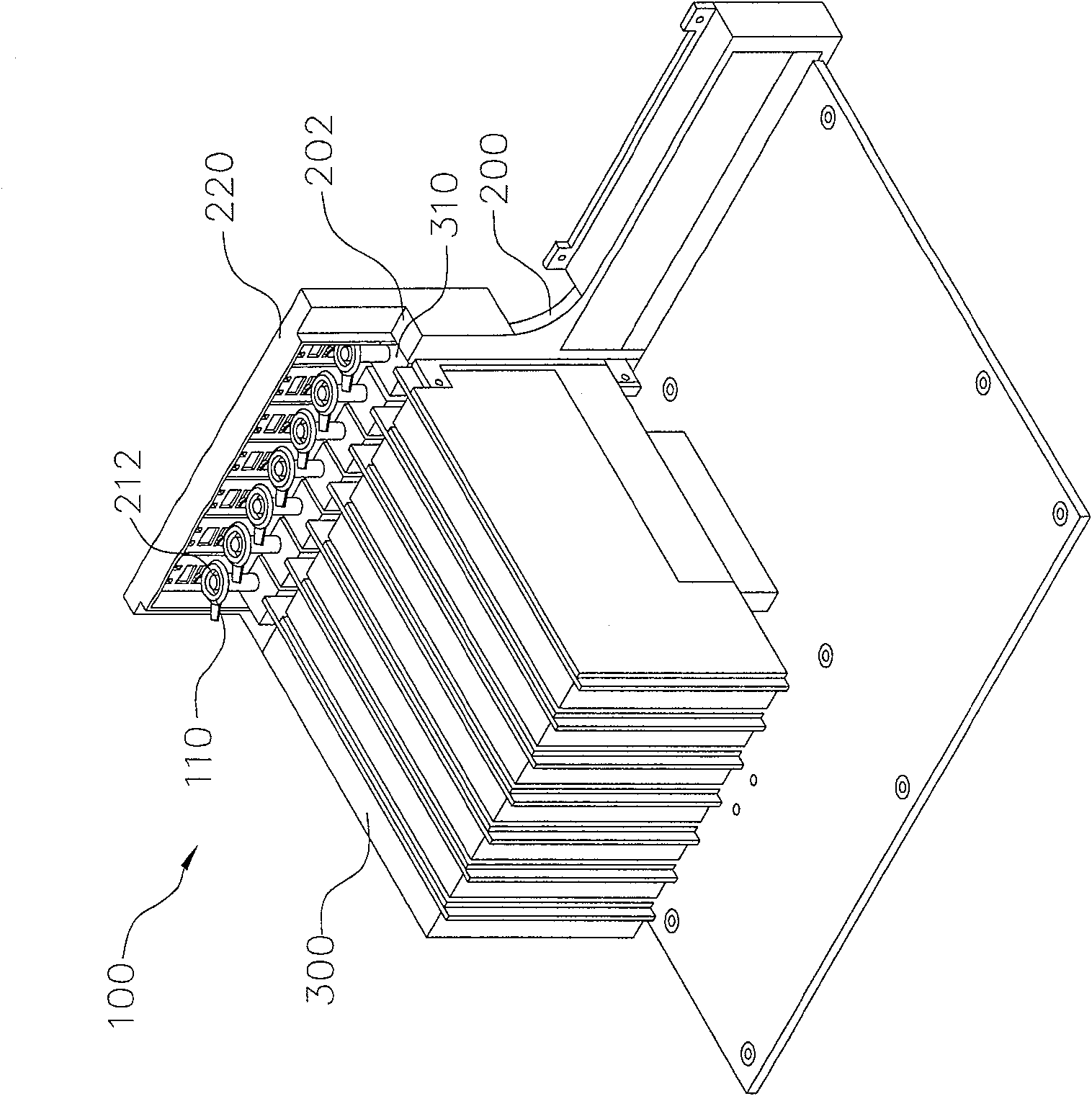

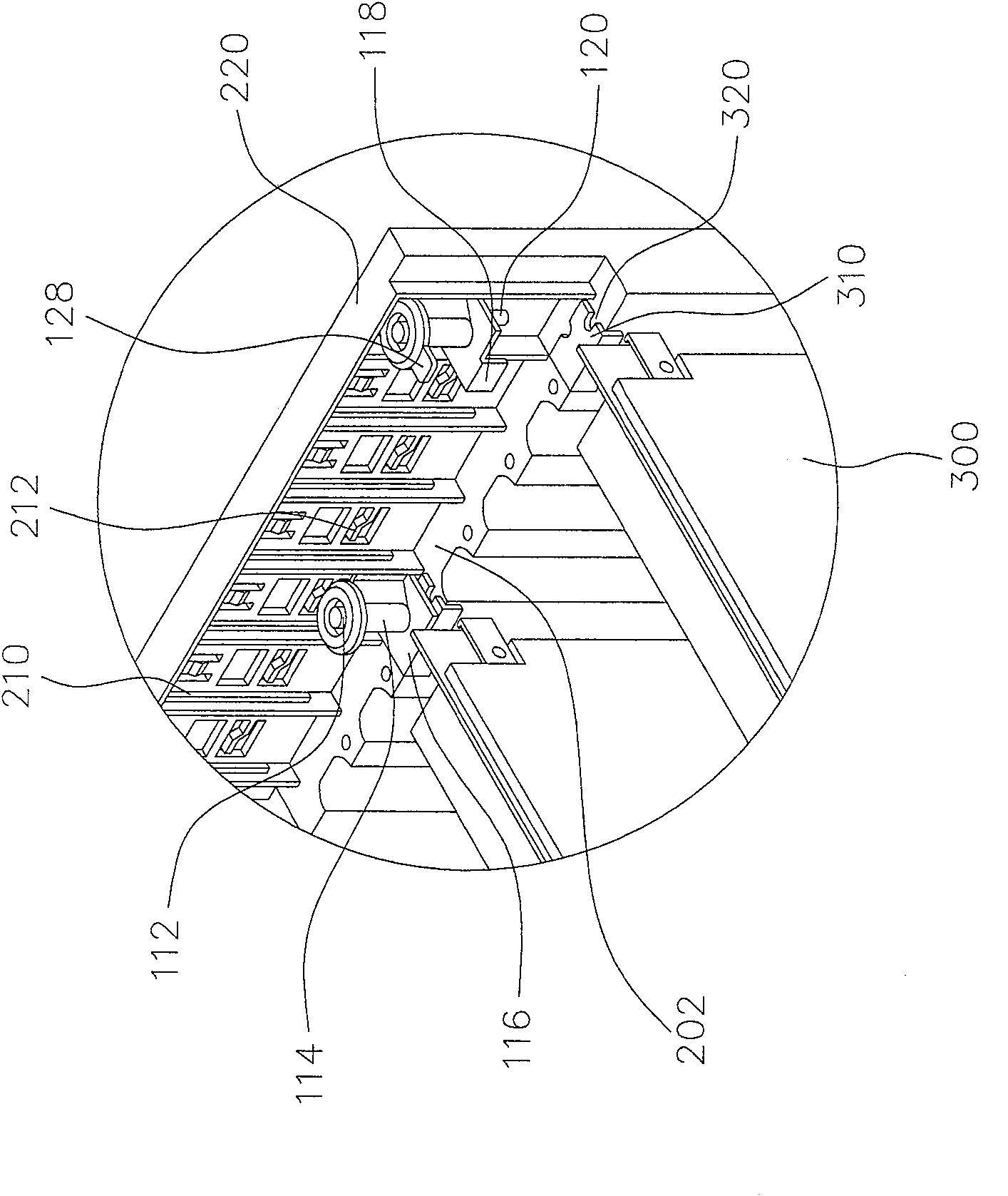

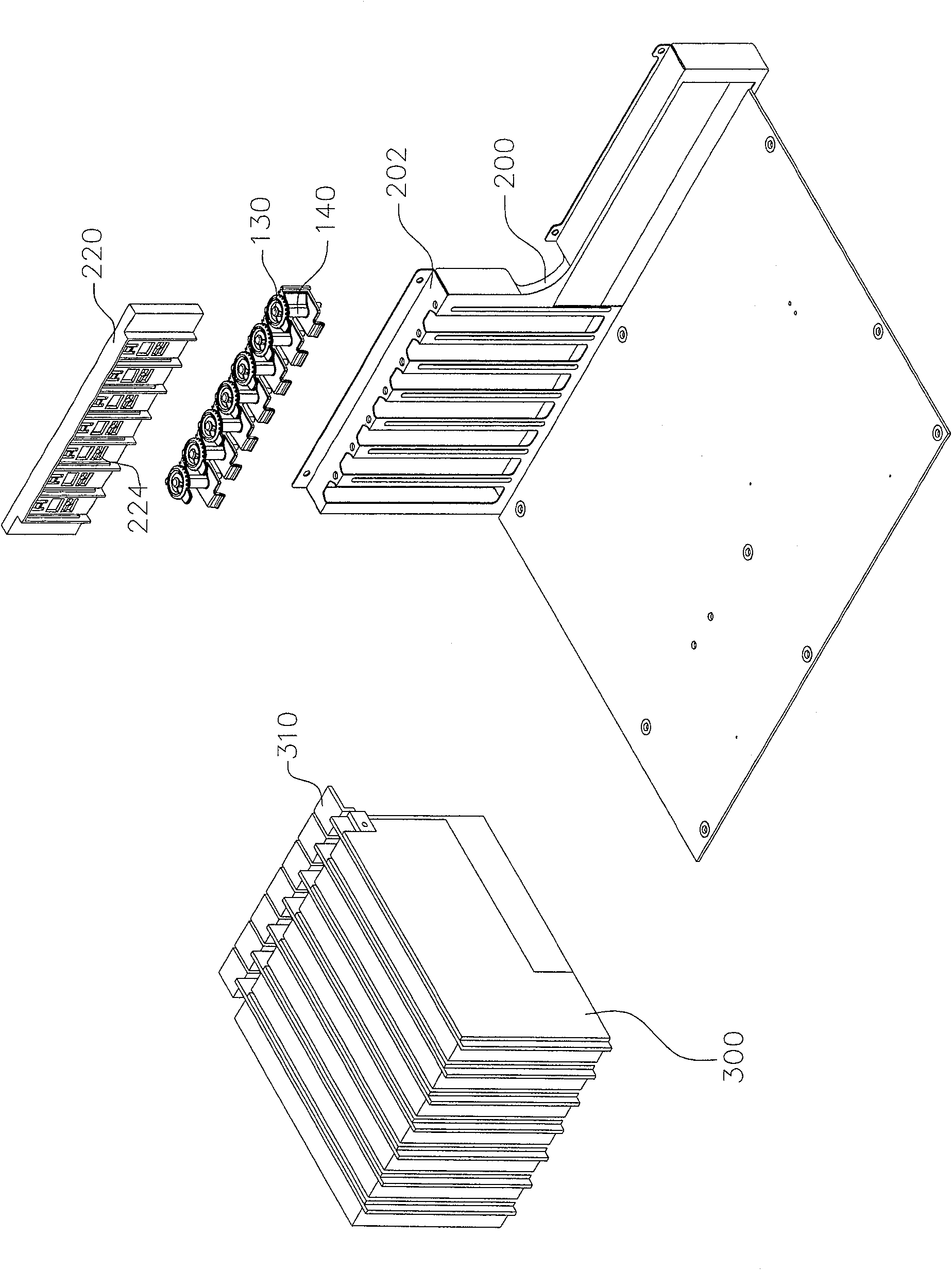

Interface card fixture

ActiveCN101135922AReduce looseningShorten the timeResilient/clamping meansDigital processing power distributionEngineering

Owner:ASUSTEK COMPUTER INC

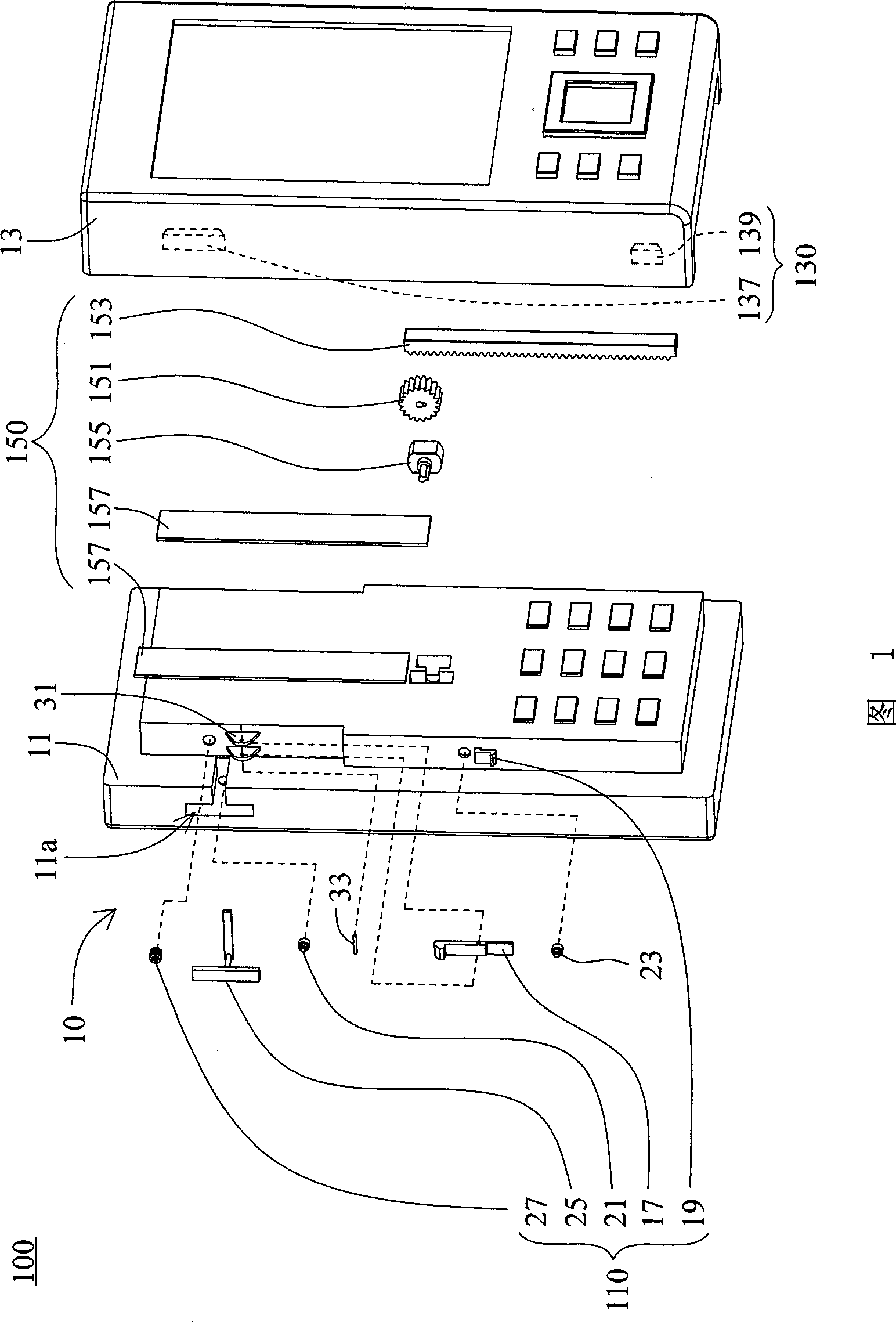

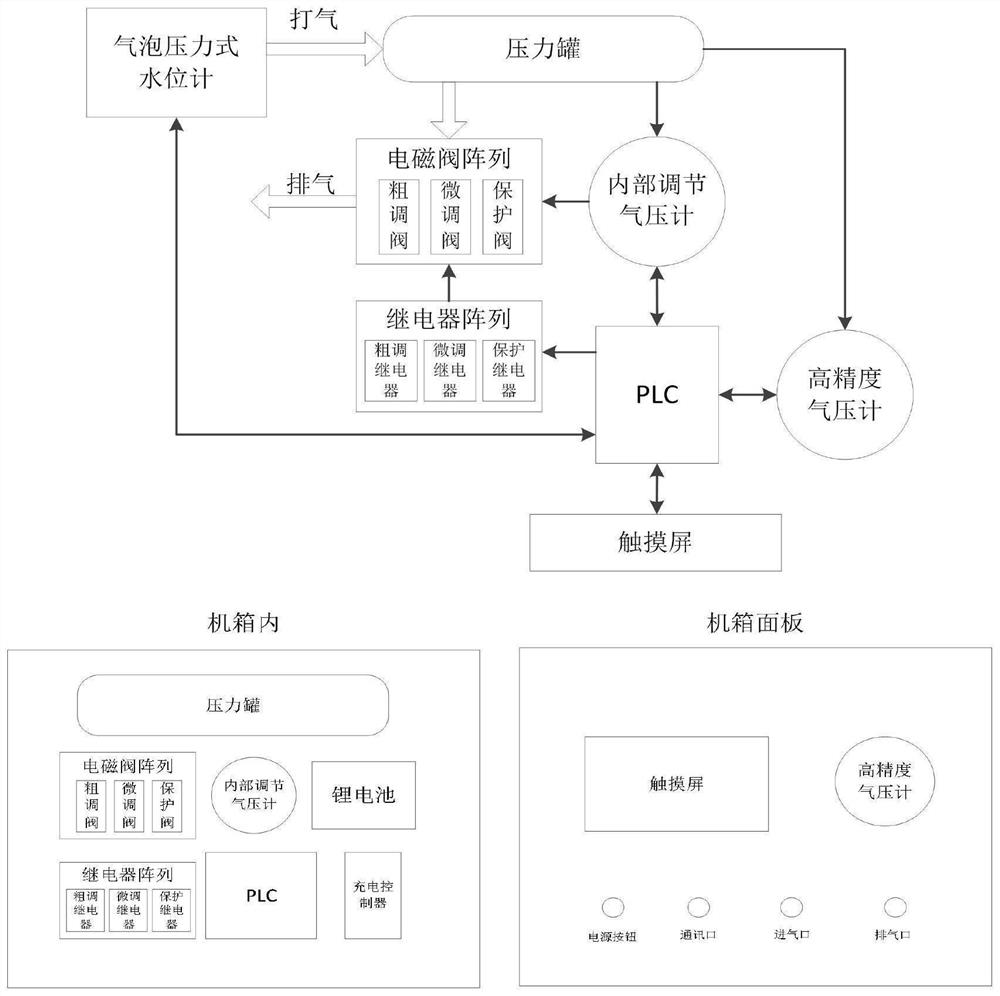

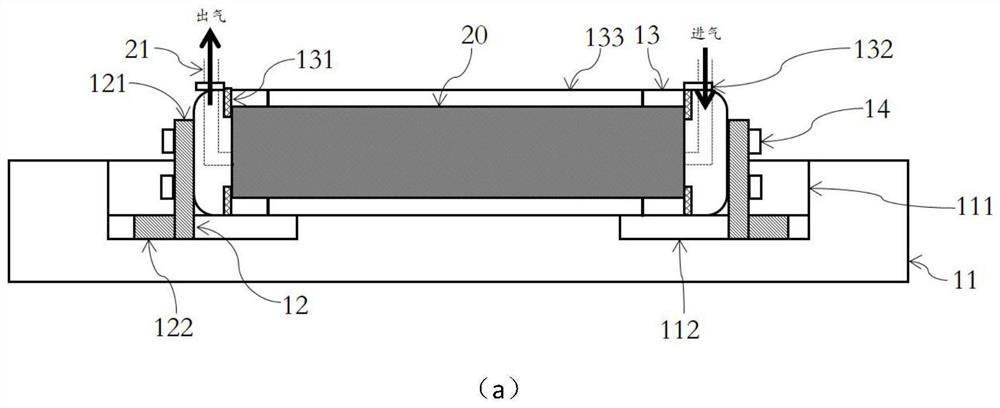

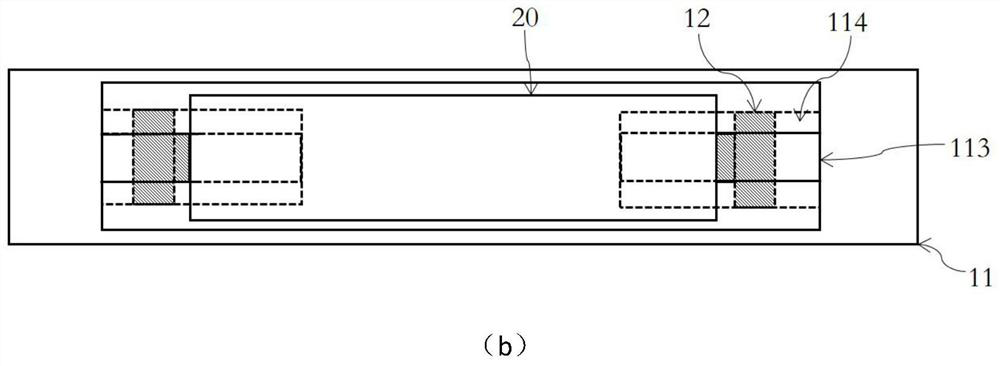

Portable high-precision bubble pressure type water level gauge detection device and detection method

The invention provides a portable high-precision bubble pressure type water level gauge detection device and method. The portable high-precision bubble pressure type water level gauge detection devicecomprises a box body, a touch display screen, a processor, a digital barometer, an internal adjusting barometer, an electromagnetic valve array, a switch array, a connecting pipeline and a pressure tank. According to the invention, the problems of installation difficulty, inconvenience of carrying, low detection precision and the like in the existing bubble pressure type water level gauge field inspection test can be solved, and the field rapid and accurate detection and calibration can be realized.

Owner:JIANGSU NANSHUI WATER AFFAIRS TECH CO LTD +1

Anti-sinking door

ActiveCN105201350AReduce the chance of looseningReduce noiseBuilding braking devicesWing accessoriesEngineeringElectrical and Electronics engineering

The invention provides an anti-sinking door which comprises a door frame and a door leaf. The door frame comprises a connection column connected with the door leaf through hinges. The connection column is sequentially provided with a first panel, a rib and a second panel in the thickness direction. The first panel and the second panel are connected together through the rib. A fixing element is further arranged in the connection column. The two ends of the fixing element are connected with the first panel and the second panel respectively. One blade of each hinge is fixed to the side, close to a third panel, of the fixing element. Compared with the prior art and a common door, the fixing element is arranged in the door frame, besides, the fixing element is fixed to a wall through an expansion bolt, the gravity of the door leaf is transmitted to the fixing element through the hinges, the fixing element transmits the gravity to the wall through the expansion bolt, the probability that the hinges disengage from the door frame is reduced, and the door leaf is controlled to not sink. When the door leaf is opened and closed, noise is lowered, and the door is environmentally friendly and reliable.

Owner:安徽智扬门业股份有限公司

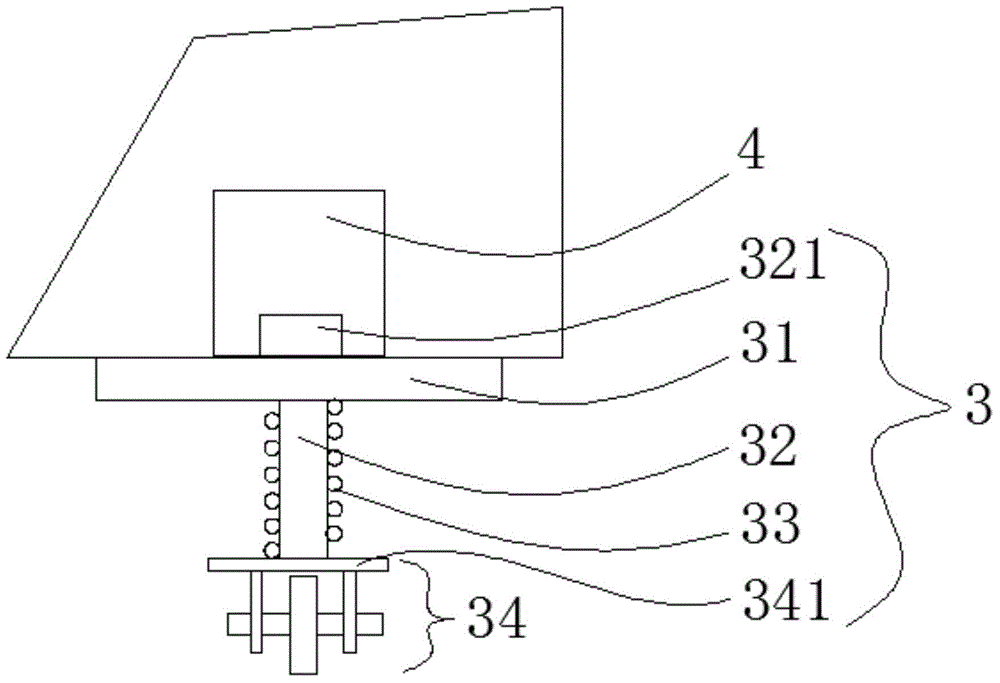

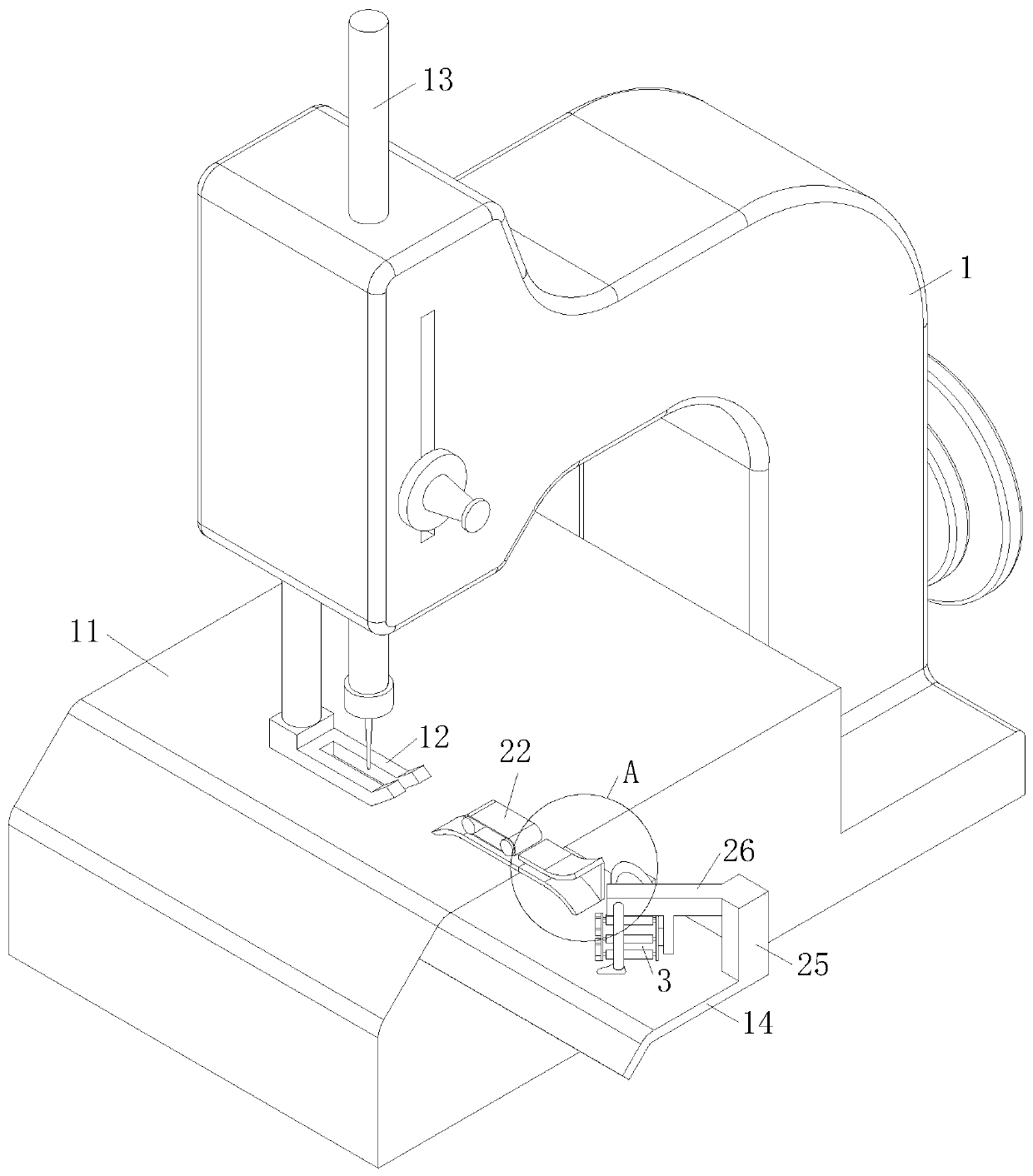

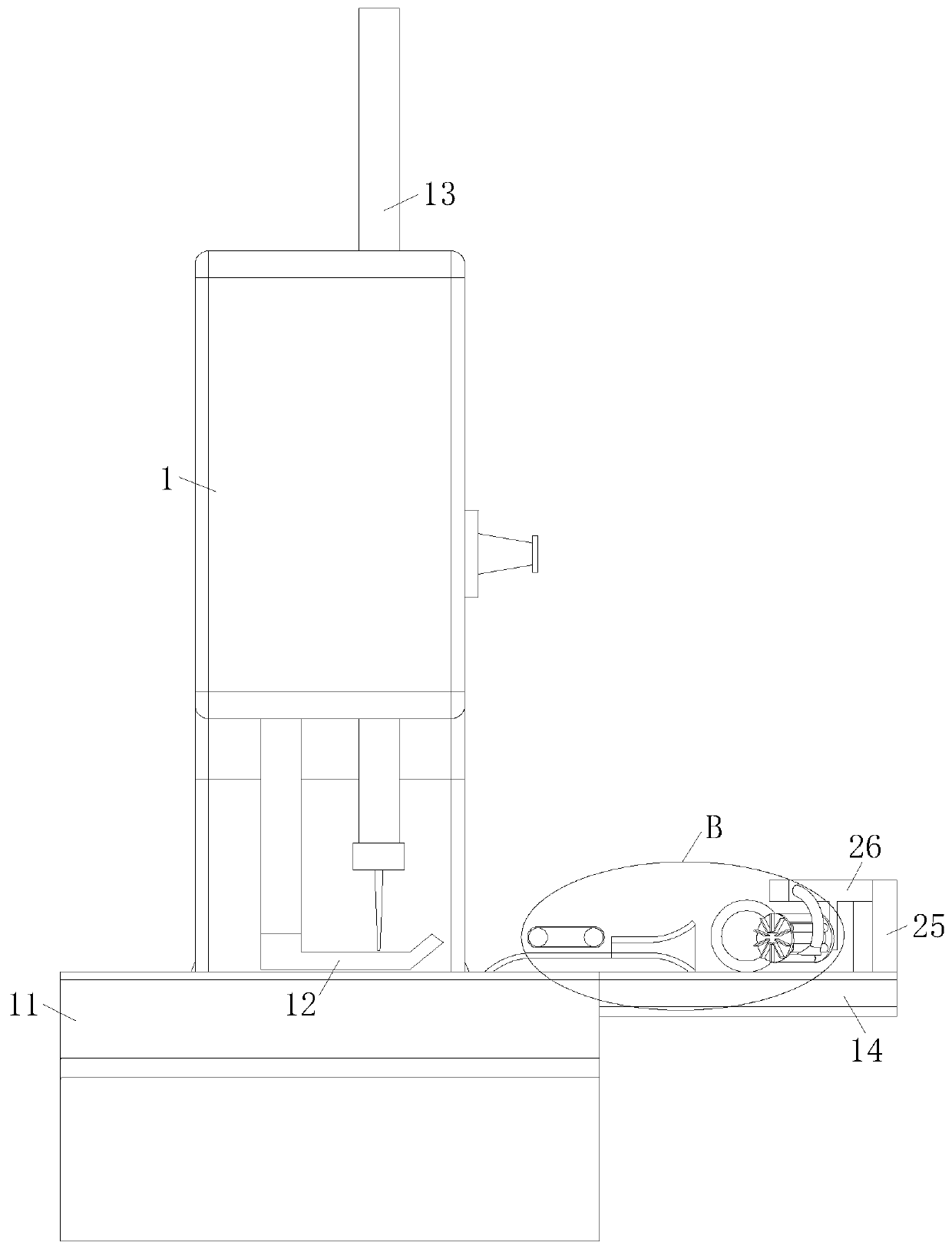

Woven bag covering machine

InactiveCN111534940AReduces tangling and snaggingImprove sewing efficiencyWorkpiece carriersTextile selvedgesSewing needleStructural engineering

The invention belongs to the technical field of woven bag edge covering, and particularly relates to a woven bag covering machine. The woven bag covering machine comprises an covering machine body, aworkbench is arranged at the bottom of the covering machine body, the top of the covering machine body is connected with a presser foot plate through a round rod, a needle rod is connected to the covering machine body at one side of the round rod in a sliding mode, the needle rod is driven by a transmission device to do up-down reciprocating motion, and a sewing needle is fixedly connected to thebottom of the needle rod; and an extension plate is connected to a position, corresponding to the presser foot plate, of one side of the workbench, a hot melting plate is fixedly connected to the extension plate through a support, a pair of horn-shaped guide plates are arranged in front of the hot melting plate, one end, far away from the presser foot plate, of each guide plate is provided with afeeding port, the other end of each guide plate is provided with a discharging port, and the hot melting plate is connected with a power supply through a controller. According to the woven bag covering machine, the edge of a woven bag is subjected to hot melting through the hot melting plate, so that the thread generation of the edge of the woven bag is reduced, and the edge covering quality is improved.

Owner:滁州三界外工业设计有限公司

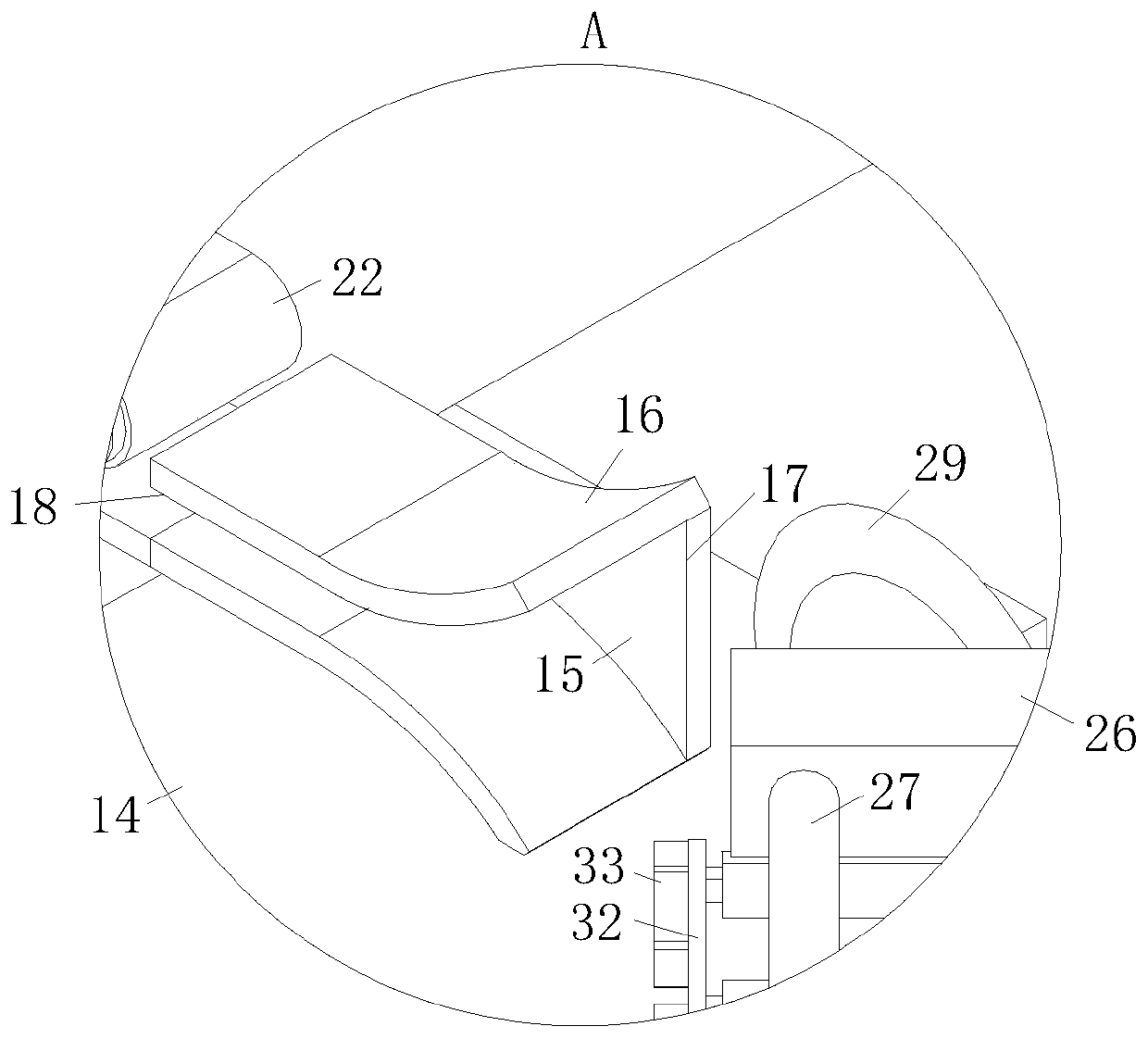

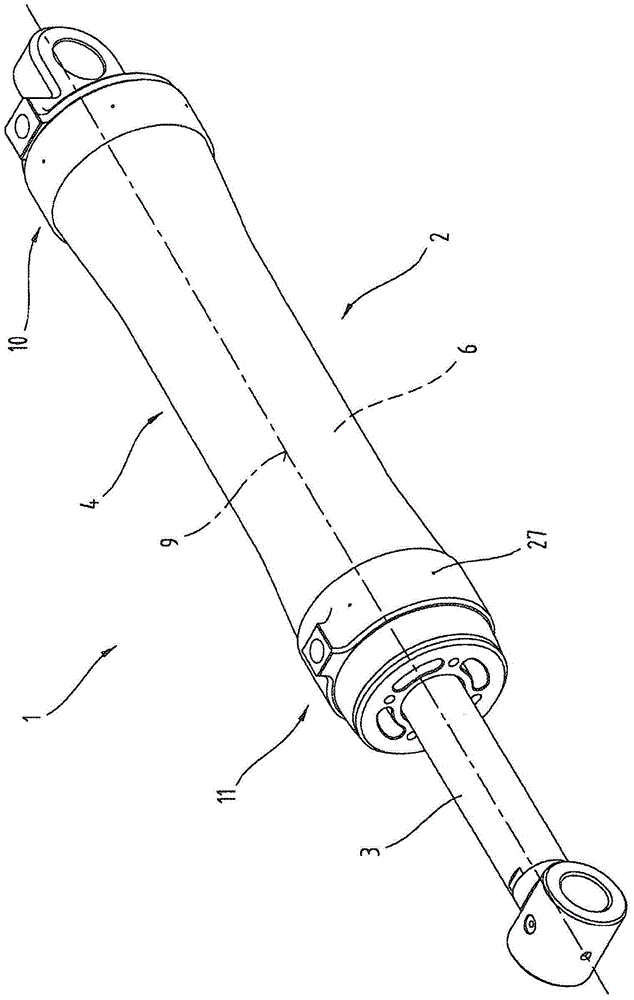

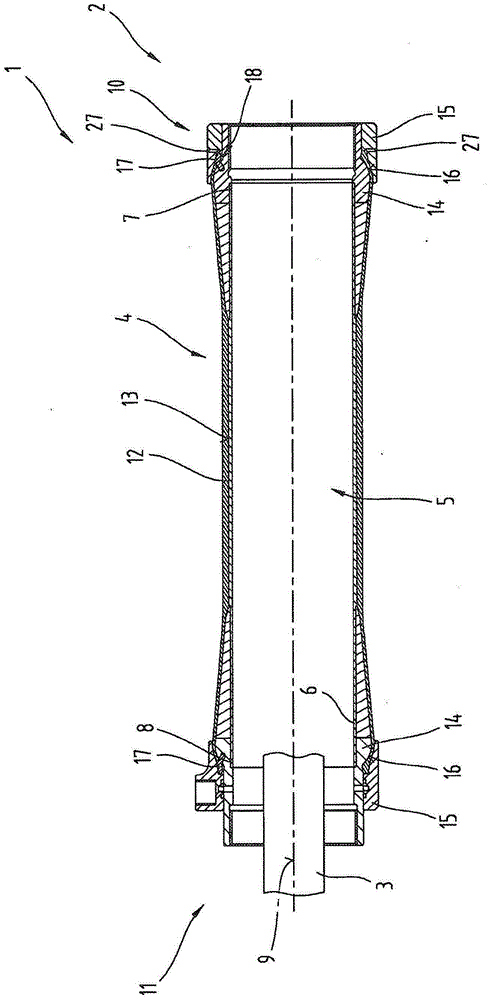

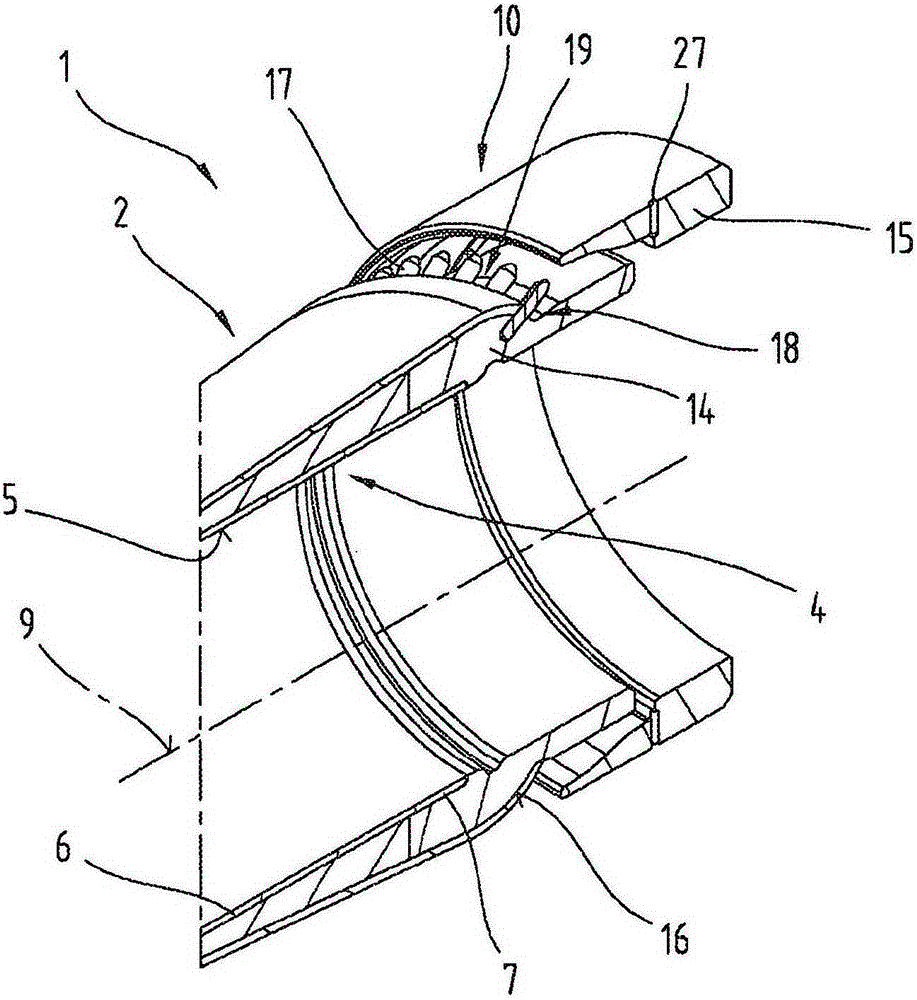

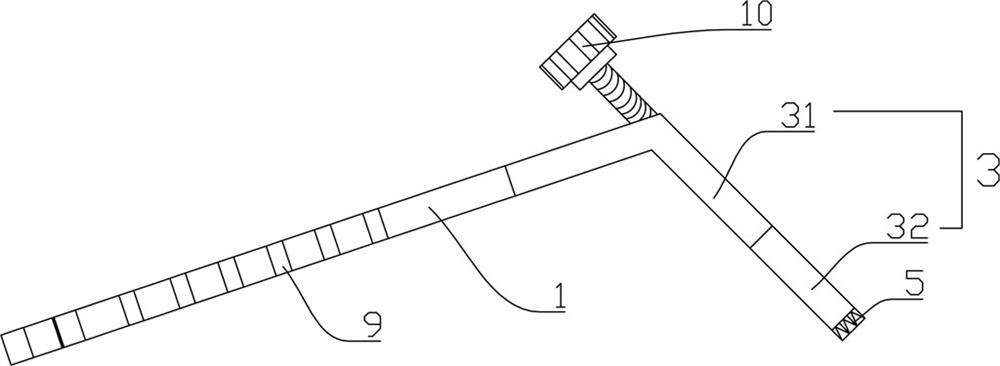

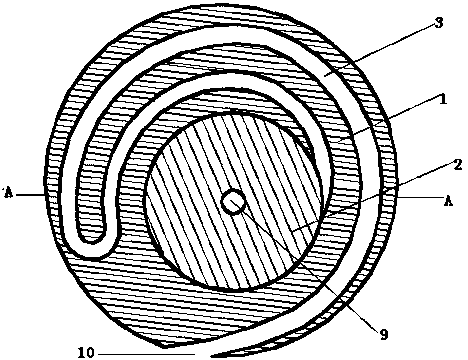

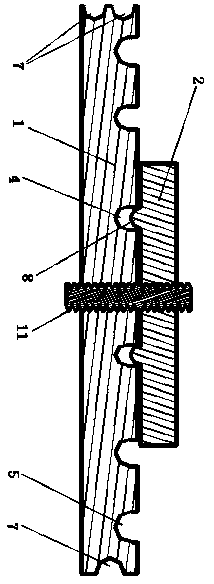

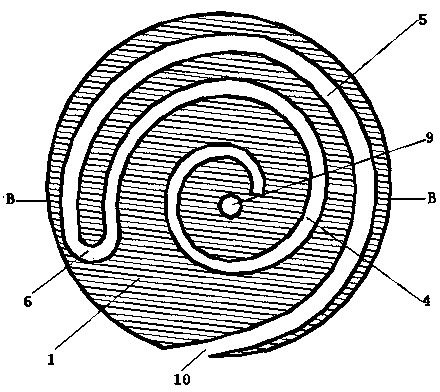

Cylinder housing of lightweight/hybrid construction and method for the production thereof

InactiveCN105228815AAchieve holdAchieve steeringCylindersFluid-pressure actuatorsFiberPlastic materials

The invention relates to a cylinder housing (2) for a pressure cylinder (1) of lightweight / hybrid construction, having a support structure (4) comprising an inner tube (6) with ends (7, 8) that are spaced apart in the axial direction, and a first and a second end piece (10, 11) in the region of one of the ends (7, 8) of the inner tube (6). A composite structure (12) made of a fibre-reinforced plastics material is arranged on an outer surface (13) of the inner tube (6). Arranged on an outer surface (16) of the first and the second end piece (10, 11) in each case in a manner distributed over the circumference thereof are a plurality of rod-like winding aids (17) that protrude from the outer surface (16). The winding aids (17) have sufficient strength to allow a winding operation during the application of the threads of the composite structure (12), individual threads of the composite structure (12) being guided during said winding operation around at least one of the winding aids (17) in a deflection region (18) on sides that face away from one another in each case in the axial direction. Following the formation of the composite structure (12), the winding aids (17) are reshaped and at least regionally embedded in the composite structure (12). The invention also relates to a pressure cylinder (1) having such a cylinder housing (2) and to a method for the production thereof.

Owner:MARK HYDRAULIK

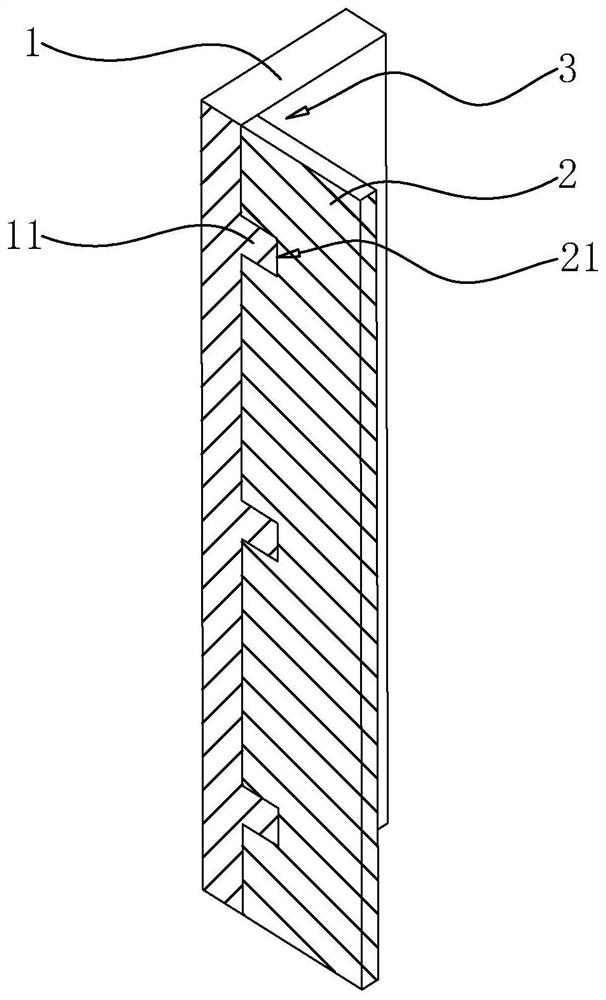

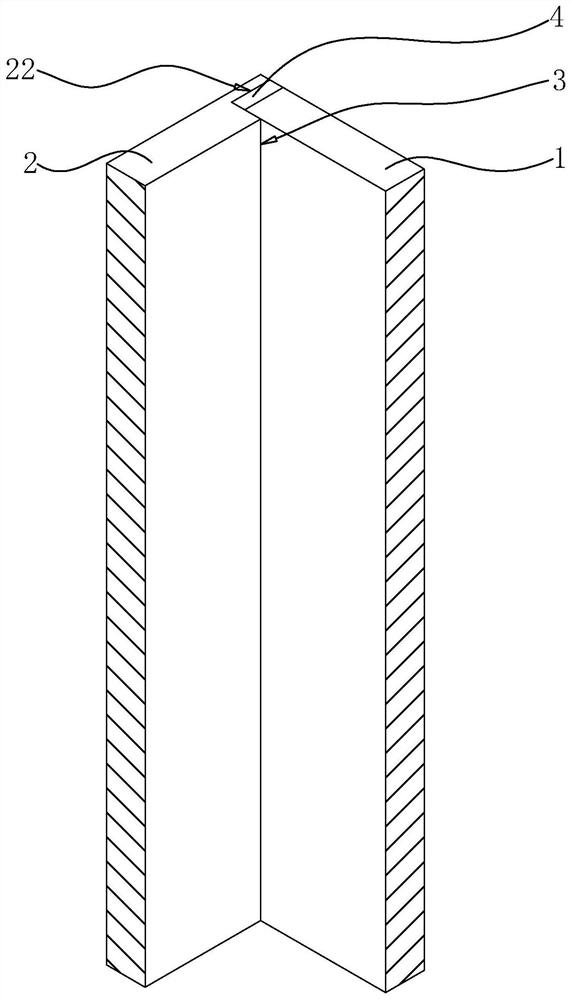

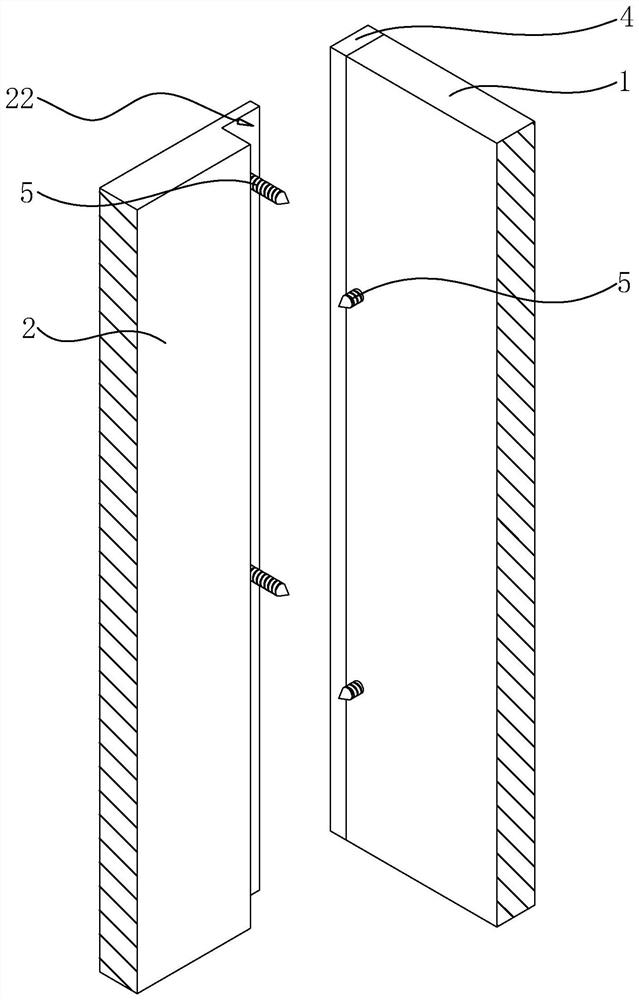

Wood veneer internal corner connecting structure, forming process of wood veneer internal corner connecting structure and wood cabinet with wood veneer internal corner connecting structure

ActiveCN113017315AImprove stabilityReduce breakageFurniture joining partsWood working apparatusWood veneerStructural engineering

The invention relates to the technical field of furniture production, in particular to a wood veneer internal corner connecting structure, a forming process of the wood veneer internal corner connecting structure and a wood cabinet with the wood veneer internal corner connecting structure. According to the technical scheme, the connecting structure is characterized by comprising a first wood veneer, a second wood veneer and a connecting piece, wherein the second wood veneer abuts against the first wood veneer and forms an internal corner, the connecting piece is fixedly connected to the first wood veneer and the second wood veneer, and the connecting piece is used for fixedly connecting the first wood veneer and the second wood veneer. The product has the technical effect of improving the stability of fixed connection between the two wood veneers.

Owner:东莞市大境华家具发展有限公司

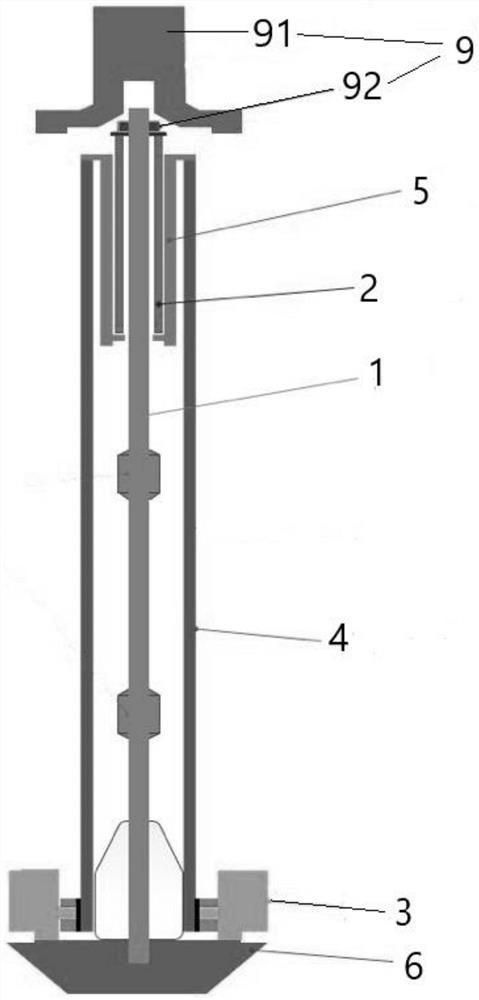

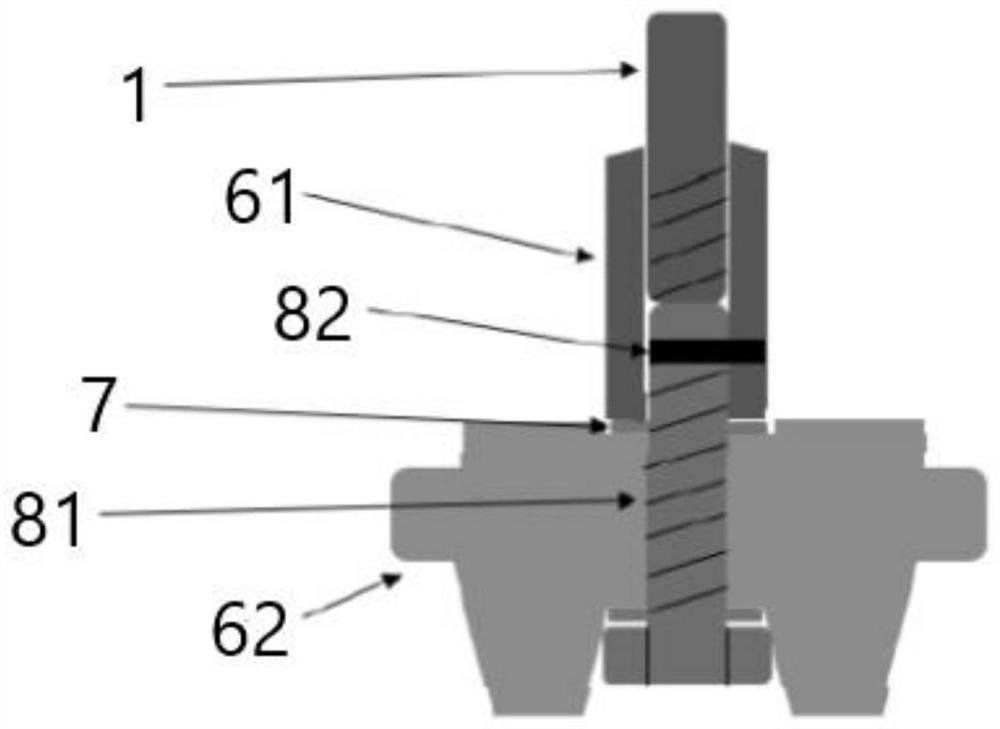

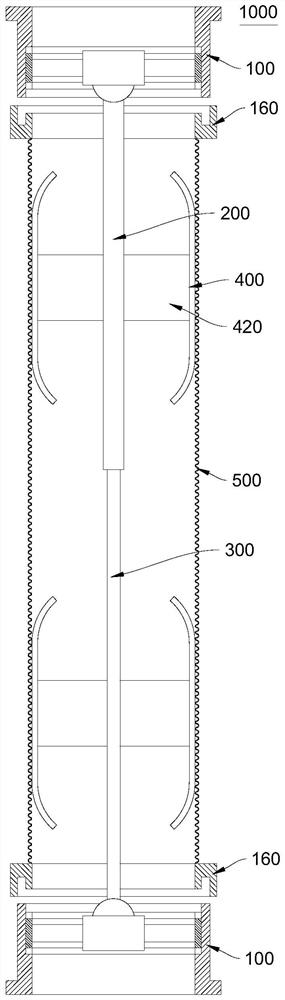

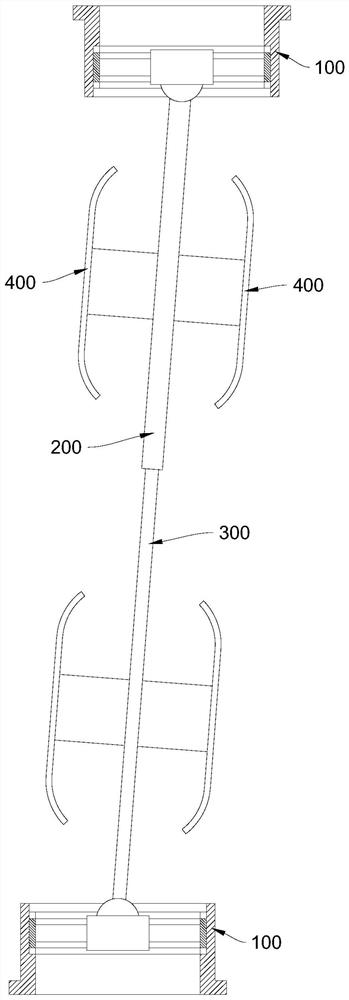

A bushing tie rod system on the side of the transformer grid

ActiveCN111667997BReduce cloggingAvoid damageTransformers/inductances coils/windings/connectionsTransformerClassical mechanics

The invention relates to a bushing pull rod system on the converter grid side, comprising a pull rod, the bottom of the pull rod is connected with a wiring device, the top of the pull rod is connected with a fixing device, and the bottom of the fixing device is connected with a vertical compensation aluminum tube; the wiring device A current-carrying bottom plate is arranged on the top of the current-carrying bottom plate, and a positioning compensation tube is connected to the current-carrying bottom plate. The aluminum pipe is in contact with the compensation steel pipe. By adopting the above technical scheme, the current-carrying base plate and the wiring device are combined more closely, and the loosening of the tie rod and the wiring device caused by the thermal expansion and contraction of the tie rod itself is reduced, so that the tie rod system is more stable and the internal occurrence of the transformer is reduced. possibility of failure.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

Lead length metering device

ActiveCN110455234AReduce inertiaReduce looseningMeasurement devicesCleaning using toolsEngineeringControl switch

The invention discloses a lead length metering device. According to the device, a stand column is vertically arranged on a base and is movably connected with the base through a support bearing; the support shaft is vertically connected with the side part of the stand column; a wire wheel is sleeved on the support shaft and is movably connected with the support shaft; a gasket is sleeved on the support shaft and is arranged between the wire wheel and the stand column; iron blocks are symmetrically arranged at the end parts around the support shaft and face the stand column; electromagnets are symmetrically arranged at the side part of the stand column around the support shaft and face the iron blocks; the lower end of an oscillation rod is vertically connected with a horizontal shaft and ismovably connected with a connection seat through the horizontal shaft; a guiding wheel is arranged at the upper end of the oscillation rod; a tension spring is located above the connection seat and two ends of the tension spring are respectively connected with the oscillation rod and the stand column; a knob switch is fixedly connected with the side part of the connection seat; the knob of the knob switch is in transmission connection with the horizontal shaft of the oscillation rod; and the knob switch is a control switch of the electromagnet.

Owner:郴州市伟强科技有限公司

anti sinking door

ActiveCN105201350BReduce looseningControl deformationBuilding braking devicesWing accessoriesElectrical and Electronics engineeringSurface plate

The invention provides an anti-sinking door which comprises a door frame and a door leaf. The door frame comprises a connection column connected with the door leaf through hinges. The connection column is sequentially provided with a first panel, a rib and a second panel in the thickness direction. The first panel and the second panel are connected together through the rib. A fixing element is further arranged in the connection column. The two ends of the fixing element are connected with the first panel and the second panel respectively. One blade of each hinge is fixed to the side, close to a third panel, of the fixing element. Compared with the prior art and a common door, the fixing element is arranged in the door frame, besides, the fixing element is fixed to a wall through an expansion bolt, the gravity of the door leaf is transmitted to the fixing element through the hinges, the fixing element transmits the gravity to the wall through the expansion bolt, the probability that the hinges disengage from the door frame is reduced, and the door leaf is controlled to not sink. When the door leaf is opened and closed, noise is lowered, and the door is environmentally friendly and reliable.

Owner:安徽智扬门业股份有限公司

Door frame

The invention provides a door frame. The door frame comprises a connection column connected with a door leaf through a hinge. The connection column sequentially comprises a first face plate, a rib and a second face plate in the thickness direction. The first face plate and the second face plate are connected into a whole through the rib. A fixing part is arranged in the connection column. The two ends of the fixing part are connected with the first face plate and the second face plate respectively. One leaf of the hinge is fixed to the side, close to a third face plate, of the fixing part. Compared with the prior art and compared with an ordinary door, a Z-shaped plate is arranged in the door frame and fixed to a wall through expansion bolts, the gravity of the door leaf is transmitted to the Z-shaped plate through the hinge and is transmitted to the wall body through the expansion bolts by means of the Z-shaped plate, and therefore the probability that the hinge is disengaged from the door frame is lowered, and sinking of the door leaf is controlled. In the door leaf opening and closing process, no extra noise can be generated, and the door frame is environmentally friendly and reliable.

Owner:安徽智扬门业股份有限公司

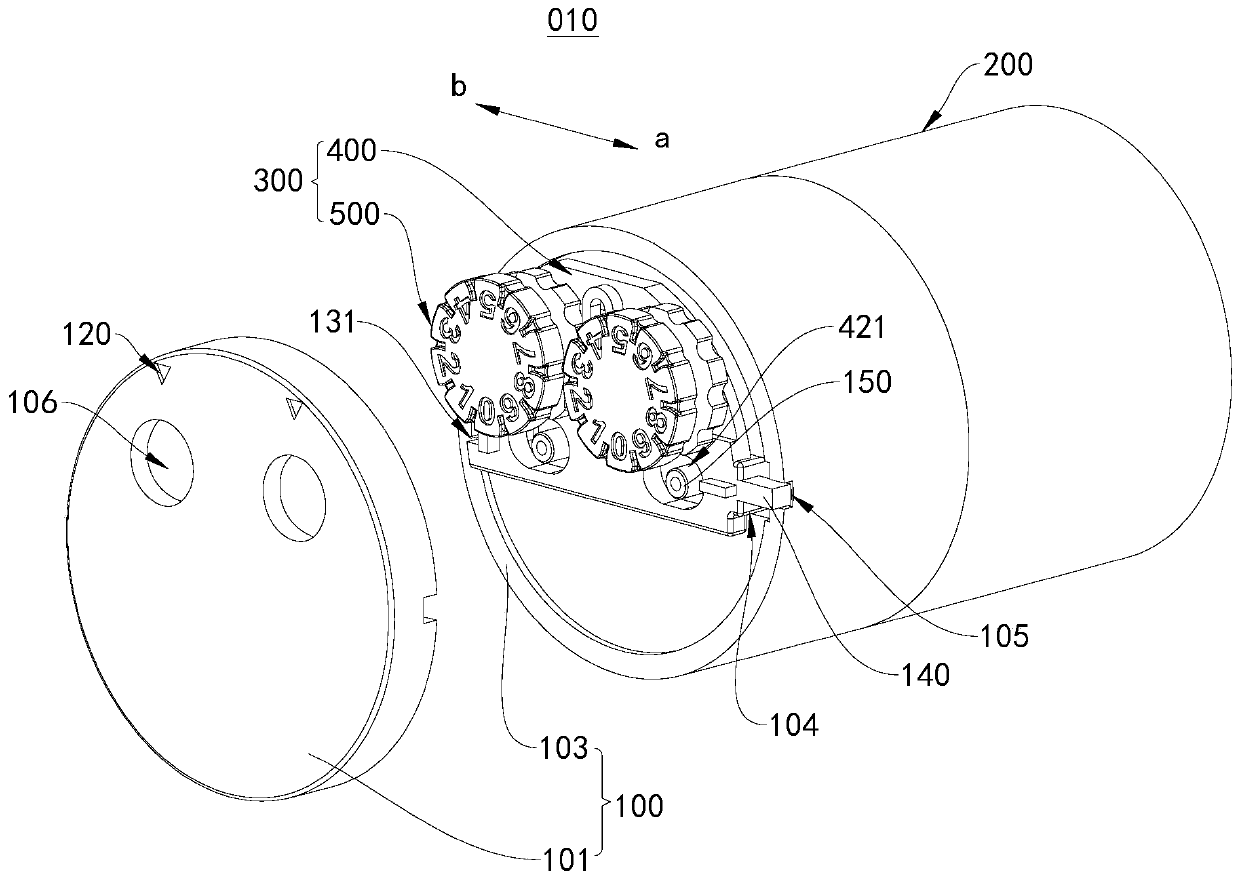

Bottle cap and container

PendingCN110422470AImprove sealingConducive to preservationPuzzle locksPermutation locksLocking mechanismEngineering

The invention relates to the technical field of storage containers, in particular to a bottle cap and a container. The bottle cap comprises an upper cap and a lower cap which are detachably connected; the upper cap is provided with a locking mechanism which comprises a lock cylinder and an unlocking assembly; the lock cylinder is movably arranged on the upper cap and provided with a locking position and an unlocking position, and when the lock cylinder is located at the locking position, the relative position of the upper cap and the lower cap can be locked; when the lock cylinder is at the unlocking position, the relative position of the upper cap and the lower cap can be unlocked; the unlocking assembly is used for locking the lock cylinder at the locking position or unlocking the lockcylinder from the locking position. The bottle cap can improve connection stability, reduce loosening during carrying and storage, and improve sealing and storage performance.

Owner:成都索真科技有限公司

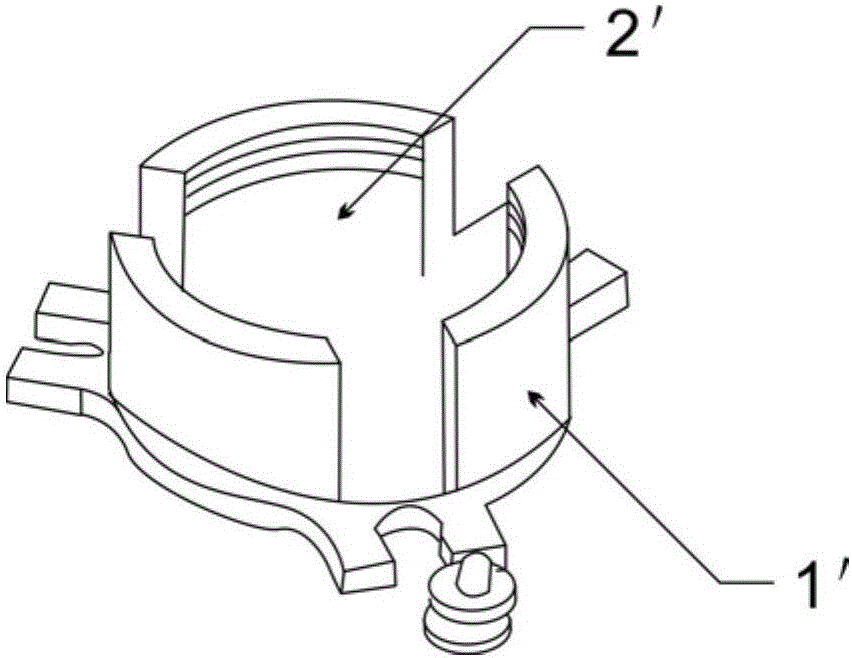

Microwave isolator cavity component

InactiveCN106229594AReduce looseningAvoid outward squeezing forceWaveguide type devicesEngineeringMicrowave

The invention provides a microwave isolator cavity component and belongs to the field of communication electronic elements. The microwave isolator cavity component comprises a base wall, side walls and elastic clamping elements, wherein the side walls are surrounding the base wall and extend toward the upper side of the base wall; the base wall and the side walls are encircled into a cavity for accommodating inner elements; limiting slots are formed on the inner walls of the side walls; the elastic clamping elements are clamped in the limiting slots under the elastic effect and are used for fixing the inner elements in the cavity. According to the microwave isolator cavity component provided by the invention, the elastic clamping elements are used for fixing the inner elements in the cavity, so that the outward extruding pressure of the threaded structure to the side walls is avoided and the loosening possibility of the inner elements is reduced; the structure is simple, the processing difficulty is low and the production cost is reduced; besides, the elastic clamping elements are adopted, so that the mounting efficiency is higher than that of threaded connection mode.

Owner:苏州市浩海精密机械有限公司

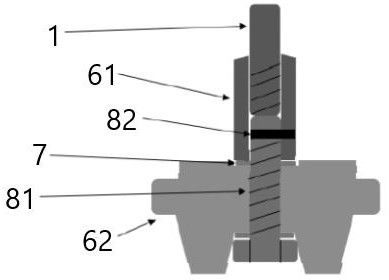

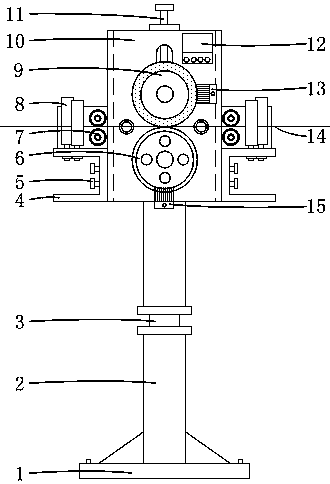

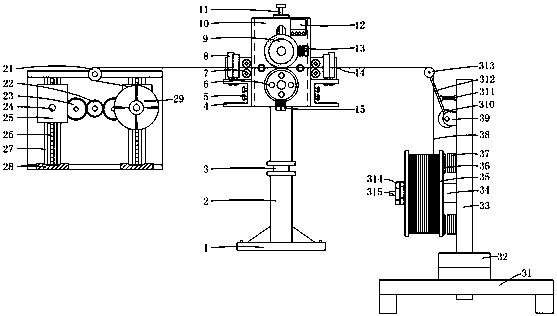

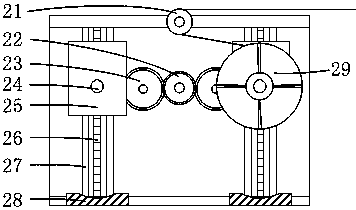

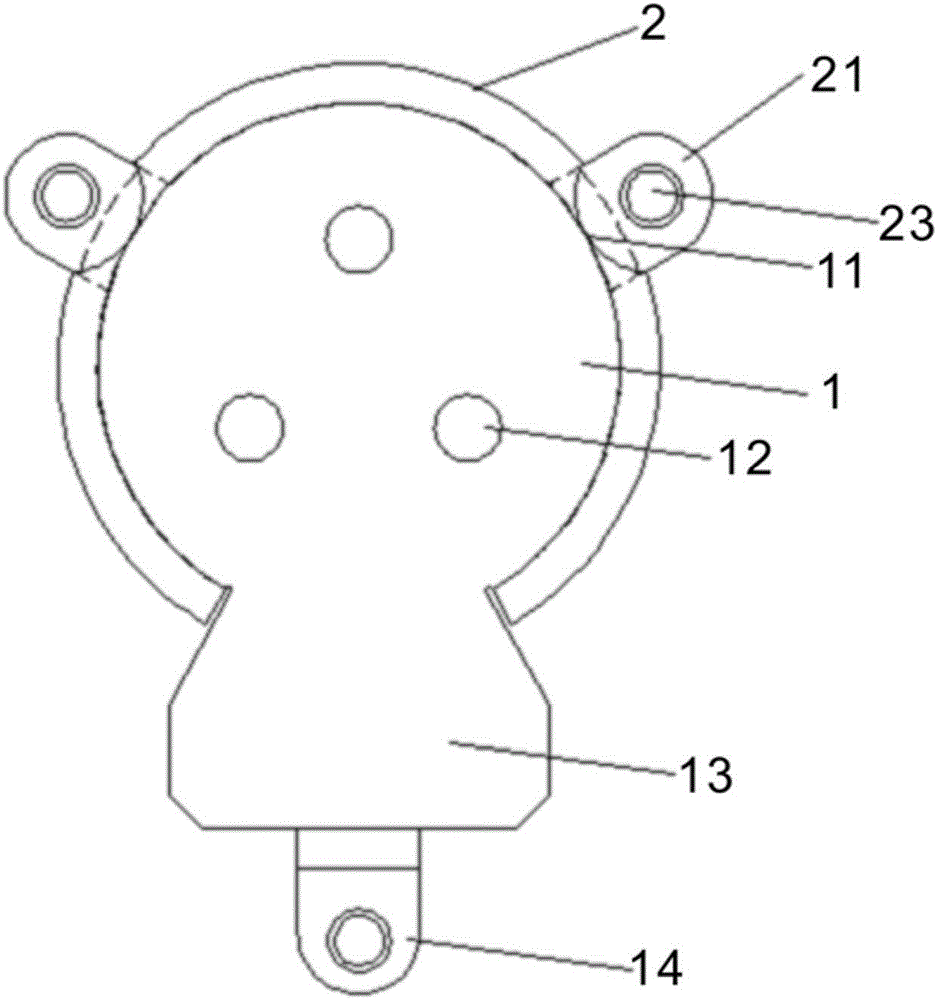

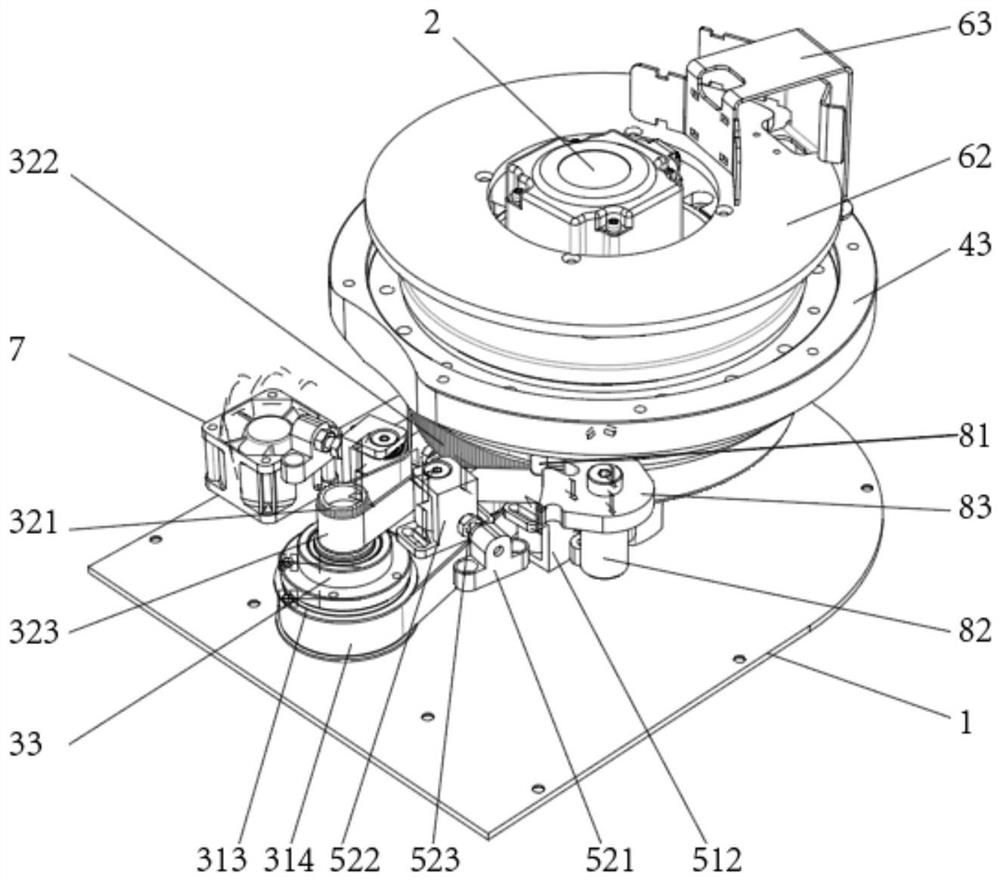

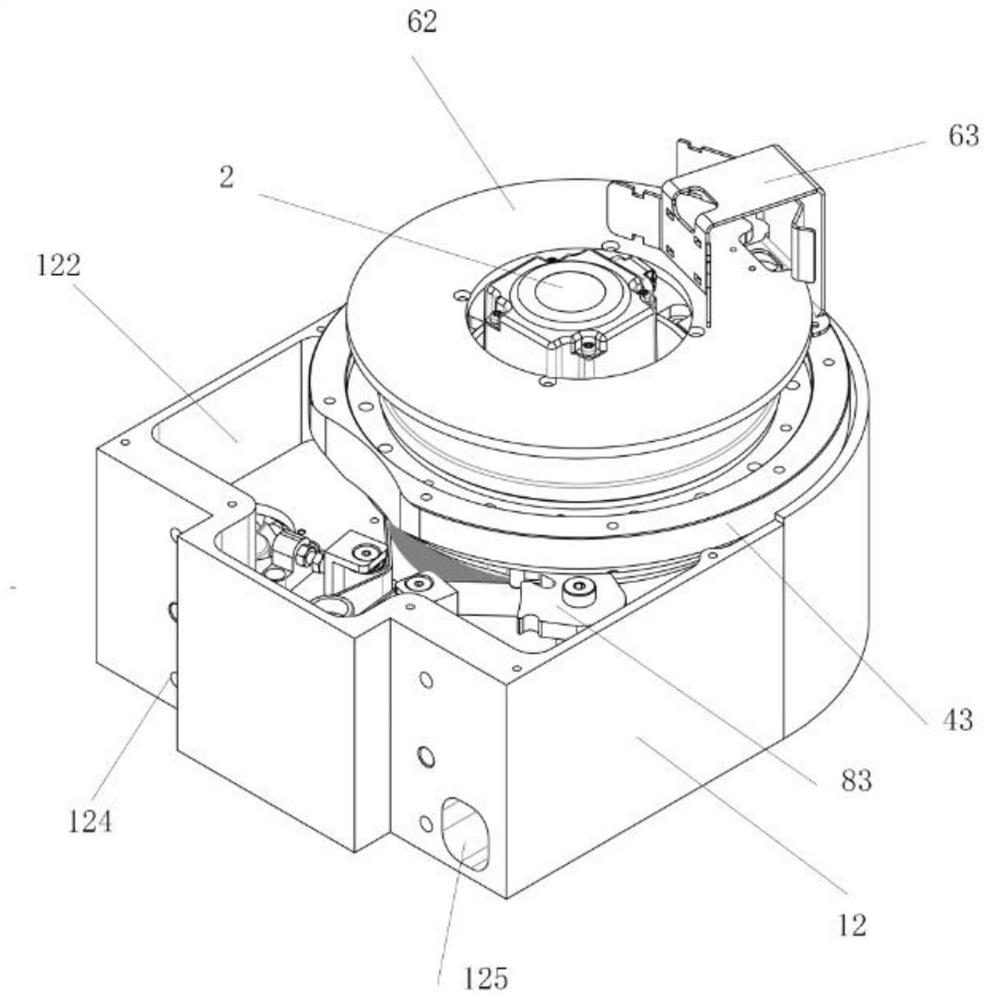

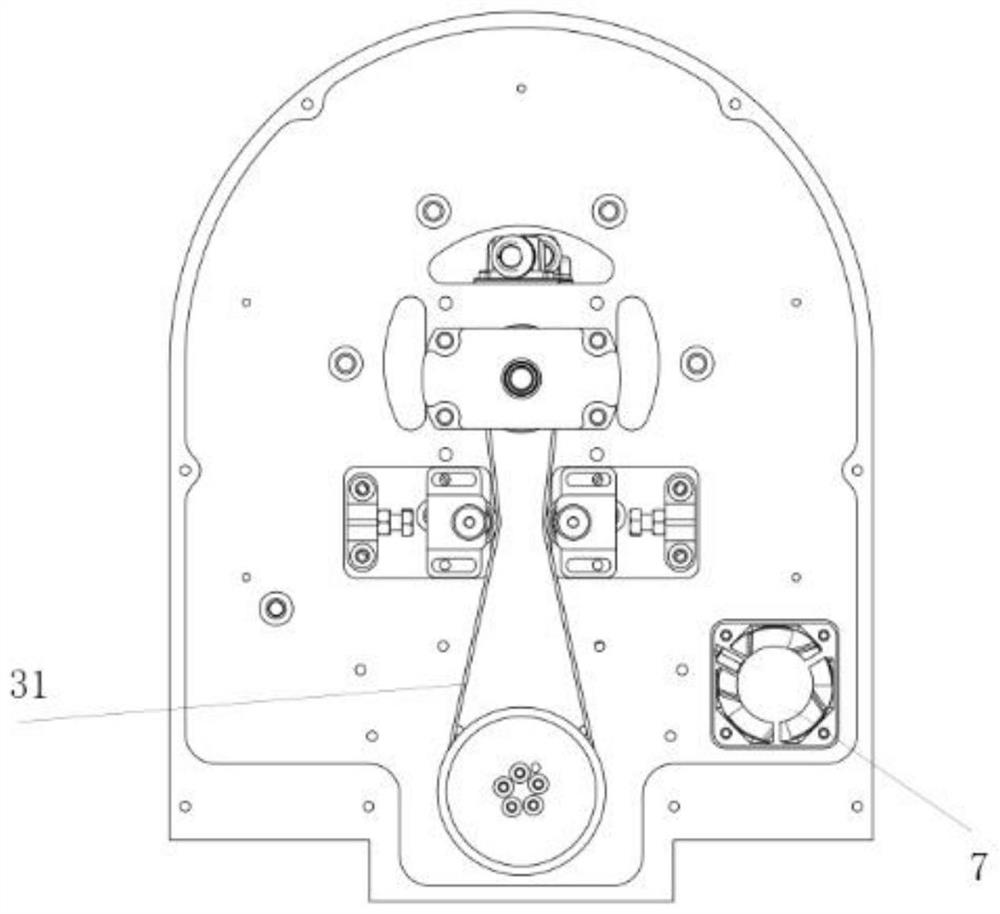

Rotation control structure for wafer transfer robot

PendingCN112828868AIncrease contact areaAdjustable tensionProgramme-controlled manipulatorStructural engineeringControl theory

The invention discloses a rotation control structure for a wafer transfer robot. The rotation control structure comprises a supporting structure, a driving structure, a transmission structure and a rotating structure; the supporting structure comprises a bottom plate, a base and a panel, the base is of a hollow cavity structure with a top opening and a bottom opening, a partition plate is arranged on the inner wall of the base and divides the base into a top-layer base body and a bottom-layer base body, and the panel and the bottom plate are installed on the base; the driving structure penetrates through the rotating structure and is mounted on the base; the transmission structure is mounted on the base and comprises a first transmission structure, a second transmission structure and a connecting shaft; the connecting shaft is rotationally connected to the base; the first transmission structure is located in the bottom-layer base body and fixedly connected with the bottom end of the connecting shaft and the driving structure; and the second transmission structure is located in the top-layer base body and fixedly connected with the top end of the connecting shaft and the rotating structure. The transmission mechanisms are arranged on the top layer and the bottom layer of the base and fixedly connected with the connecting shaft, so that the device is compact in structure, small in occupied space and good in control precision and movement stability.

Owner:昀智科技(北京)有限责任公司

High-stability cable positioning and sealing method

InactiveCN110707651AImprove stabilityImprove sealingCable inlet sealing meansElastomerClassical mechanics

The invention discloses a high-stability cable positioning and sealing method which comprises the following steps: a conical hole is formed in the front end of a first threading hole in a sleeve, an elastic body is a cylinder, and a circle of conical surface corresponding to the conical hole is arranged at the tail end of the elastic body, so that the elastic body is tightly matched with the sleeve, and the contact part of the sleeve and the elastic body is conveniently sealed; a second threading hole concentric with the first threading hole is formed in the elastic body, and the elastic bodyis extruded to deform, so that the second threading hole is shrunk, and the sealing of the cable is enhanced; and the lock catch assemblies are symmetrically arranged on the two sides of the sleeve and the pressing ring to pull and fix the pressing ring. According to the high-stability cable positioning and sealing method, the lock assembles is used for pulling and fixing the pressing ring, the elastic body is extruded to deform, so that the second threading hole shrinks, the sealing of the cable is enhanced, the stability of axial positioning of the cable is improved due to the increase of static friction, the loosening problem during pulling is reduced, and the wiring position is firmer.

Owner:苏师大半导体材料与设备研究院(邳州)有限公司

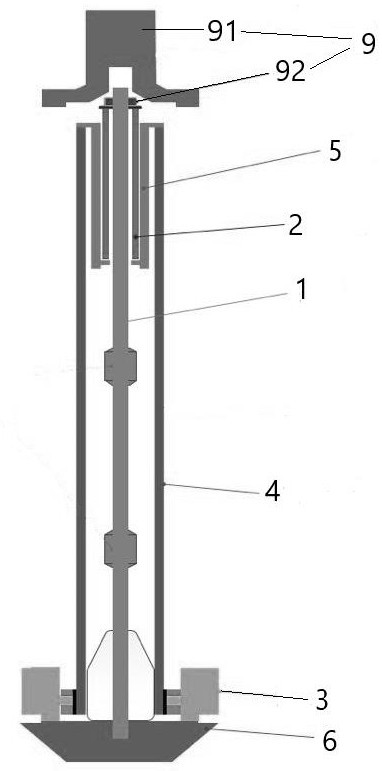

Converter transformer network side sleeve pull rod system

ActiveCN111667997AReduce cloggingAvoid damageTransformers/inductances coils/windings/connectionsTransformerSteel tube

The invention relates to a converter transformer network side sleeve pull rod system, which comprises a pull rod, wherein the bottom of the pull rod is connected with a wiring device, the top of the pull rod is connected with a fixing device, and the bottom of the fixing device is connected with a vertically-arranged compensation aluminum pipe; the top of the wiring device is provided with a current-carrying bottom plate, the current-carrying bottom plate is connected with a positioning compensation pipe, the periphery of the pull rod is sleeved with the positioning compensation pipe, a compensation steel pipe used for transmitting pressure applied by the compensation aluminum pipe to the positioning compensation pipe is hung on the positioning compensation pipe, and the compensation aluminum pipe abuts against the compensation steel pipe. By the adoption of the technical scheme, the current-carrying bottom plate and the wiring device are combined more tightly, the situation that the pull rod and the wiring device get loose due to expansion caused by heat and contraction caused by cold of the pull rod is reduced, a pull rod system is more stable, and the possibility of faults occurring in the transformer is reduced.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

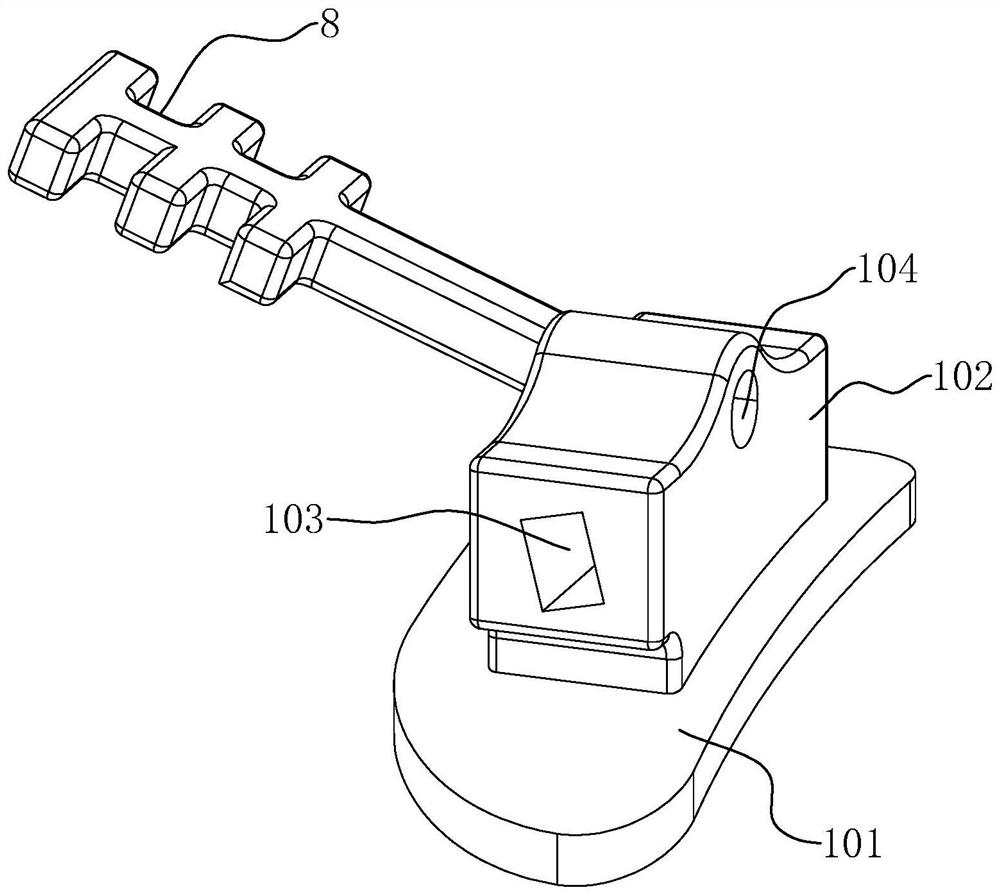

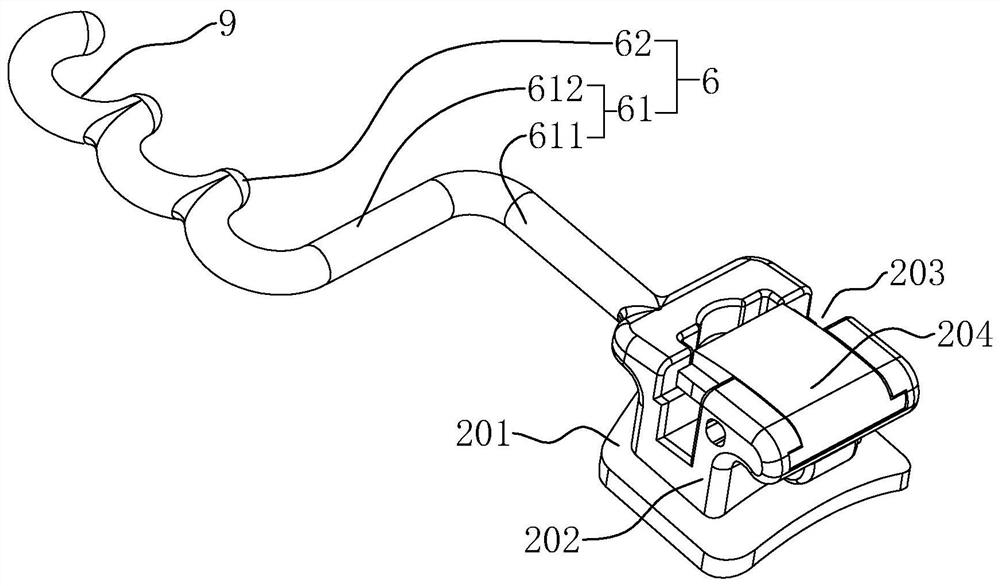

an orthodontic component

The invention relates to an orthodontic assembly, comprising a first appliance, a second appliance, and a first fastener and a second fastener connecting the first appliance and the second appliance, the first appliance includes a first The base, the first body arranged on the first base, the first through hole opened on the first body along the horizontal direction, and the second through hole opened on the vertical plane of the first body; the second appliance includes a second Two bases, the second body that is arranged on the second base, the draw-in groove that offers along the horizontal direction on the second body and the sliding cover that is arranged on the second body and is used for the sliding cover of the opening of switch draw-in groove; The first fastening One end of the piece passes through the first through hole and the other end passes through the slot and is fastened; one end of the second fastener passes through the second through hole and the other end passes through the slot and is fastened. For the phenomenon that part of the root of the tooth is exposed above the gum caused by the phenomenon of tooth loosening during the correction process, the invention can effectively correct the tooth and make the corrected tooth more beautiful.

Owner:HANGZHOU XINGCHEN 3B DENTAL INSTR & MATERIAL CO LTD

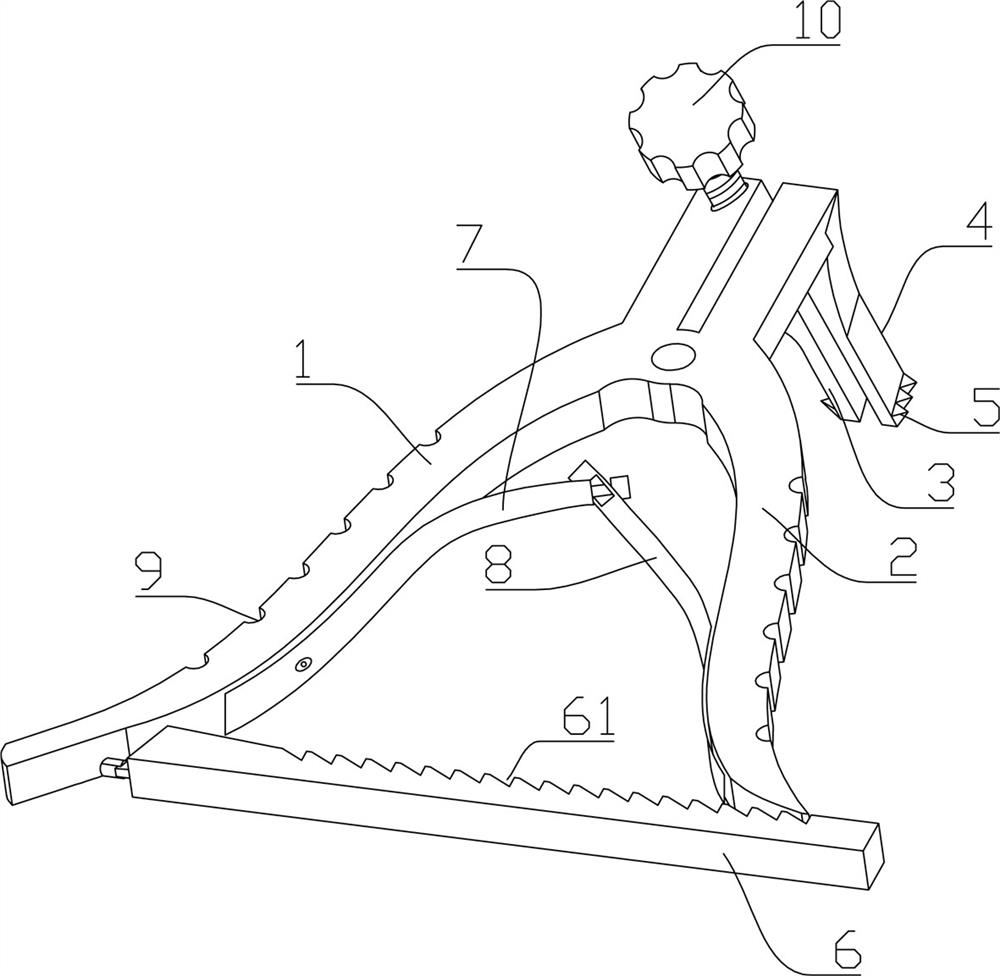

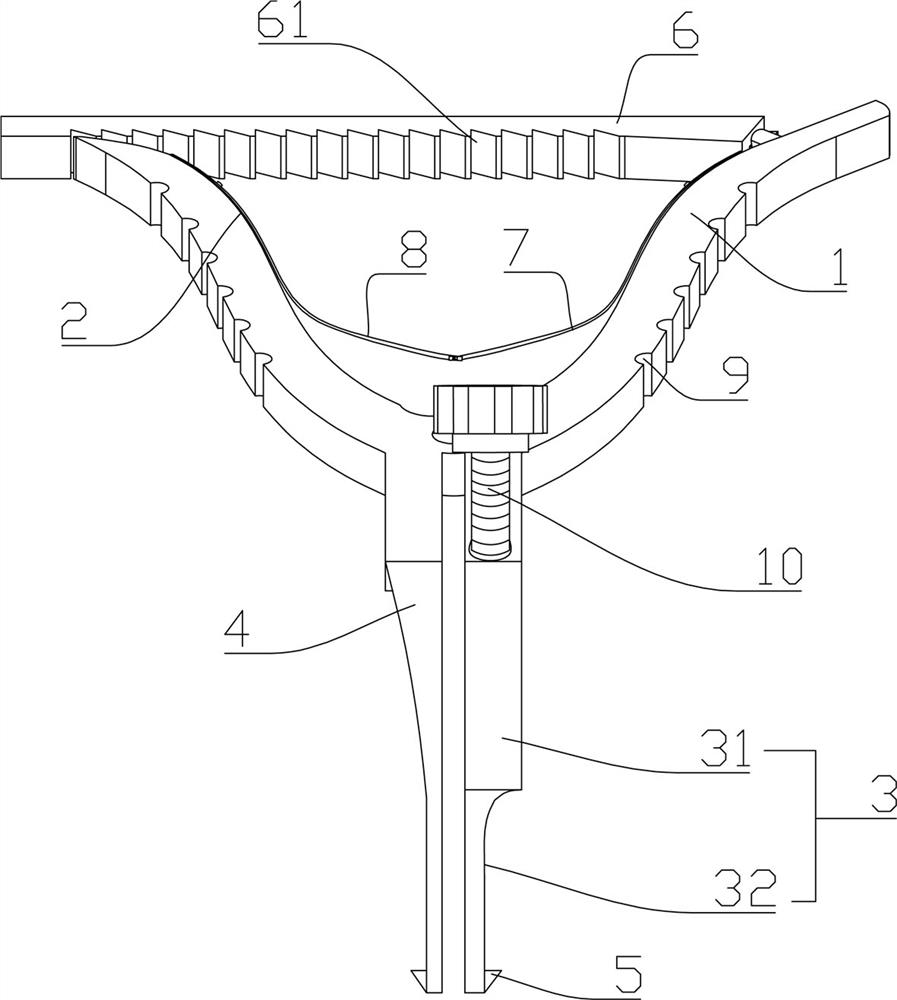

Lumbar spondylolisthesis reducer

ActiveCN109498077BLift achievedReduce stepsInternal osteosythesisLumbar spondylolisthesisEngineering

The invention belongs to the technical field of medical devices, and in particular relates to a spondylolisthesis resetter, which includes a handle and a support head, and an included angle is formed between the handle and the support head, and the included angle is 90°-145°. A handle and a second handle, the first handle is hinged to the second handle, the front ends of the first handle and the second handle are respectively provided with a first opening and a second opening, and the first opening includes a connecting rod and a lifting rod, so The rear part of the lifting rod is sheathed in the connecting rod, and the front end of the lifting rod and the front end of the second supporting head are both sheet-shaped, and the outer surfaces of both are provided with triangular teeth. The present invention can not only realize the distraction of the vertebral body, but also realize the lifting of the vertebral body. Unnecessary operations during the operation are greatly reduced, the operation time is saved, and the risk of the operation is greatly reduced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

End part anti-loosening self-locking rope sleeve for electric hoist steel wire rope

ActiveCN104210975APrevent looseningReduce looseningWinding mechanismsPull forceArchitectural engineering

Owner:SUZHOU ZHONGZHOU ANBO CRANE

Interface card fixture

ActiveCN100578424CReduce looseningShorten the timeResilient/clamping meansDigital processing power distributionEngineering

Owner:ASUSTEK COMPUTER INC

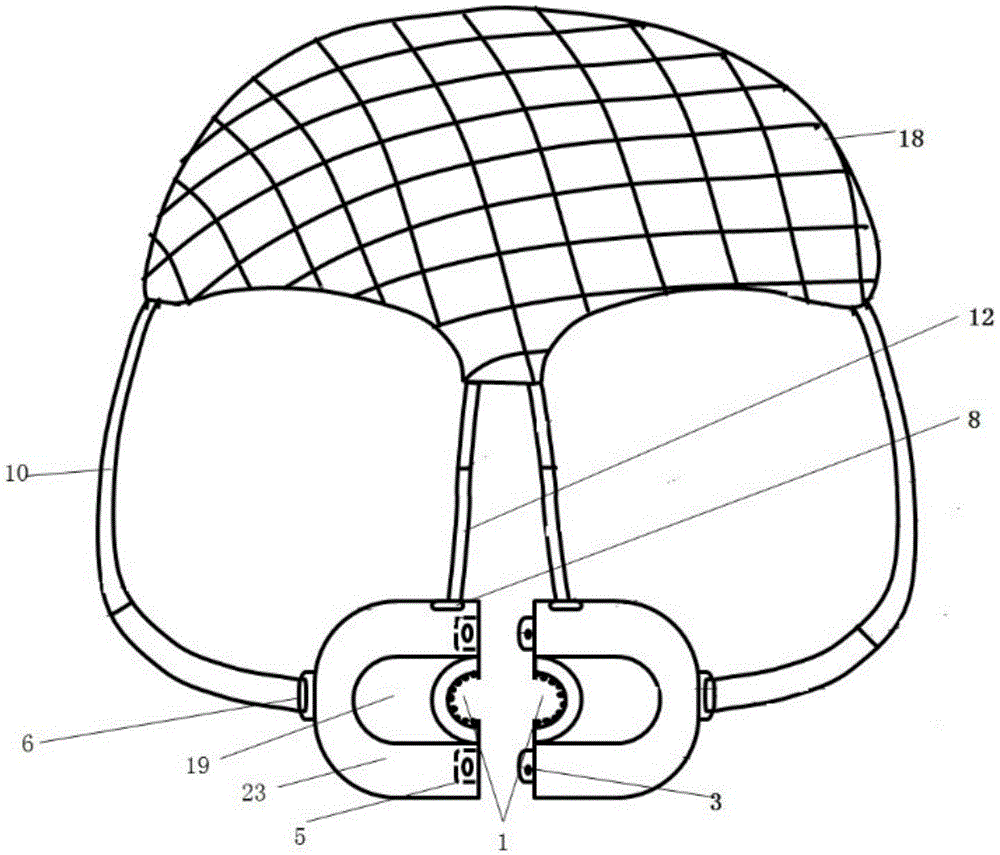

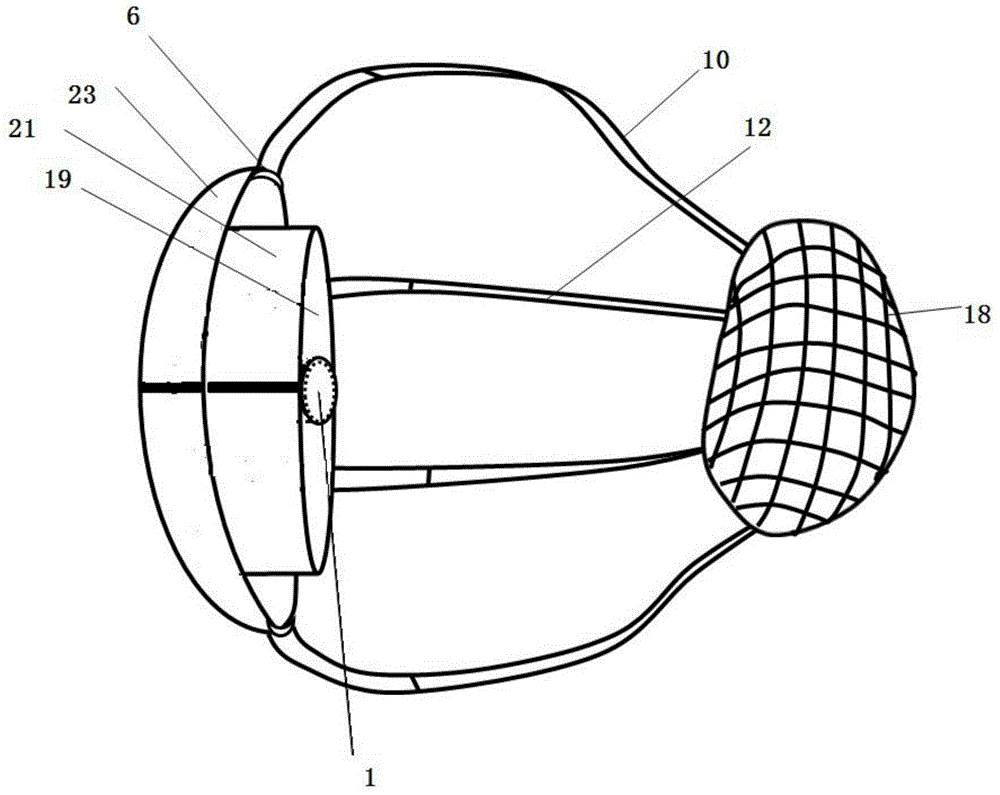

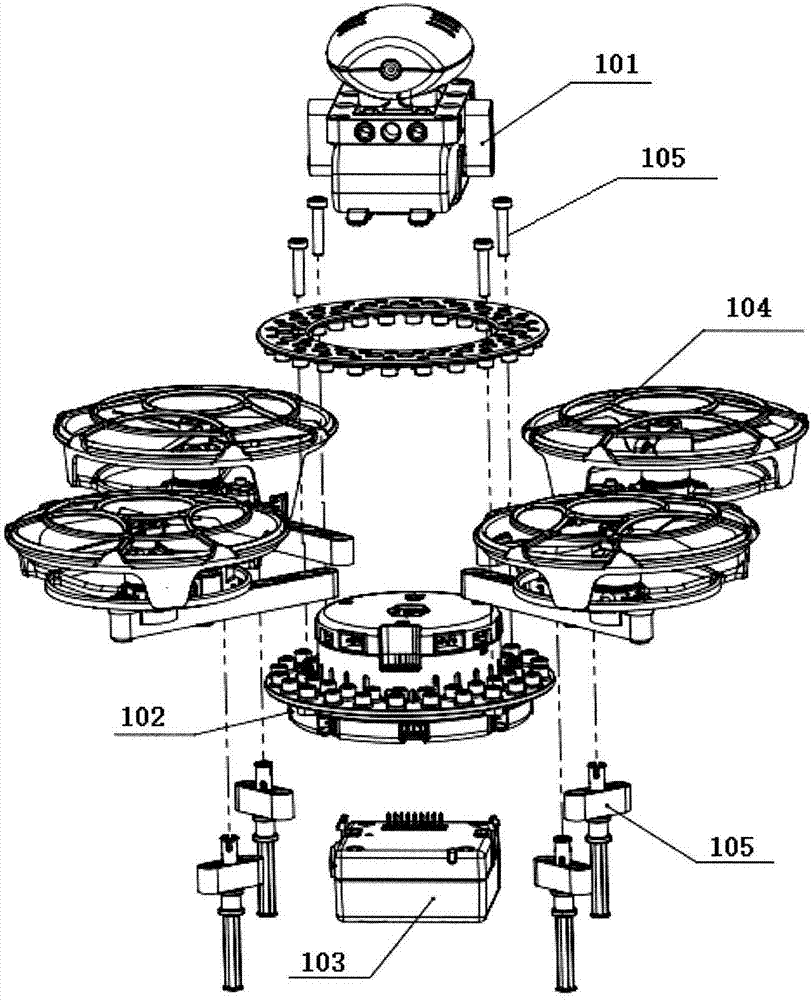

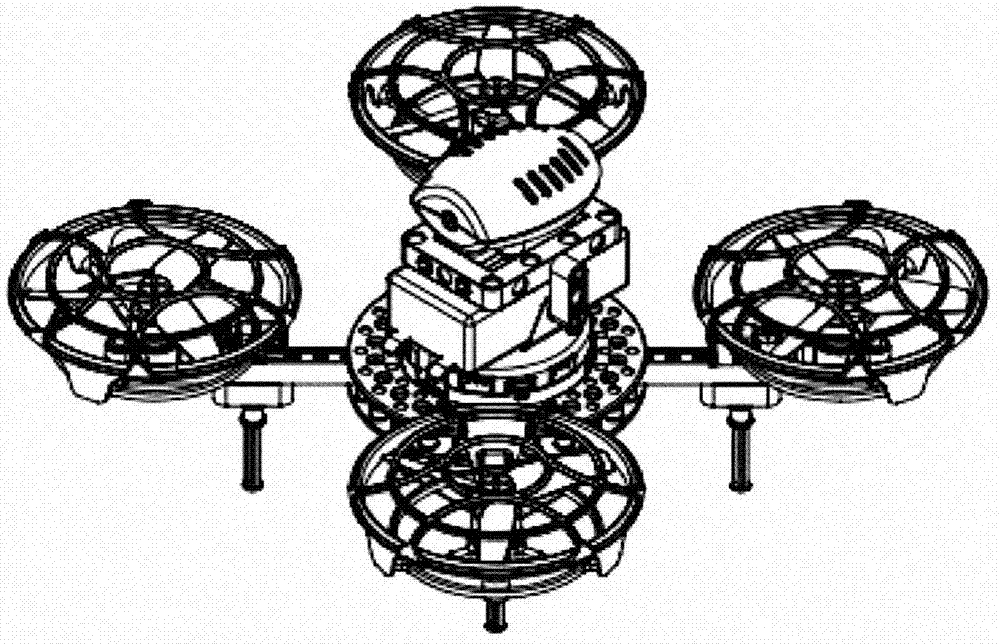

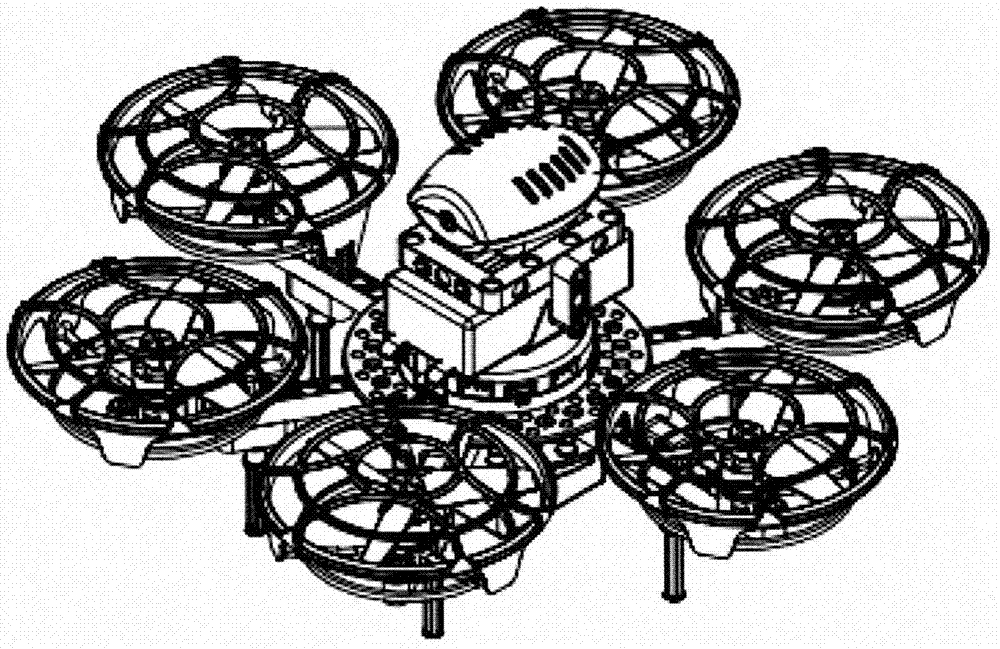

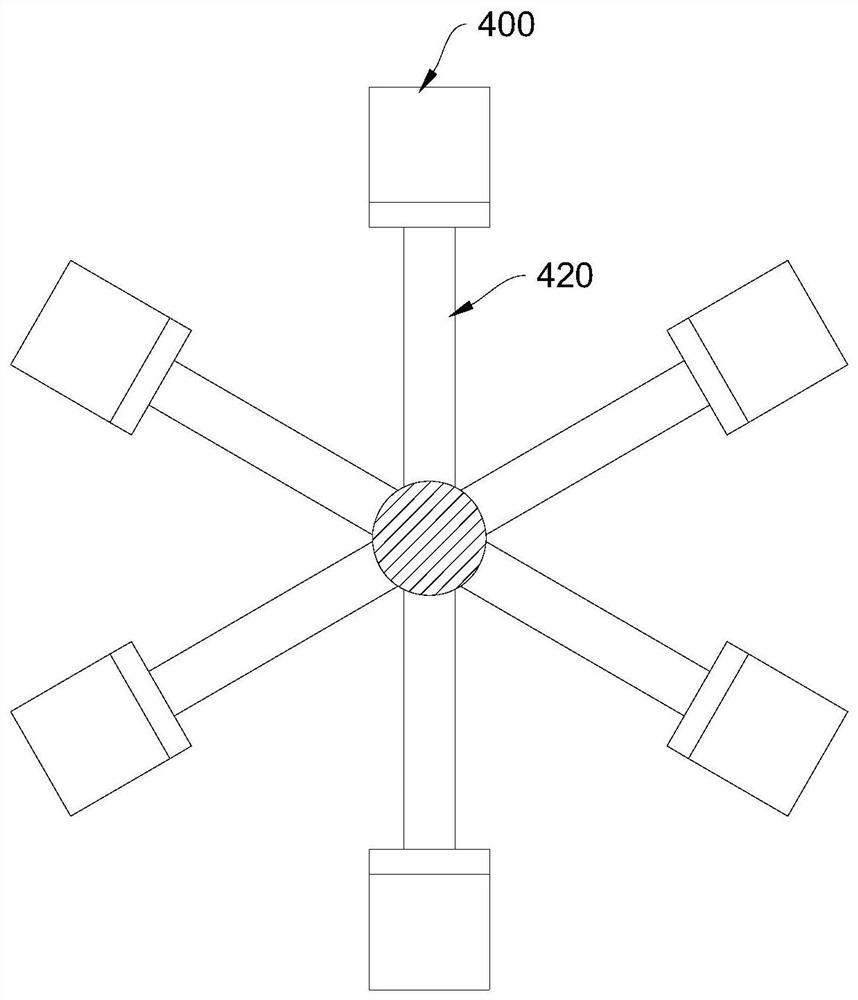

Multi-rotor aircraft

PendingCN107961550AImprove acceleration performanceIncrease flexibilityToy aircraftsElectricityElectrical battery

The invention discloses a multi-rotor aircraft, wherein the multi-rotor aircraft includes: a battery module, an electrical adjustment module, a flight control module and a plurality of power modules; wherein, the battery module and the electrical adjustment module are assembled with each other, and the electrical adjustment module and The flight control modules are assembled with each other; multiple power modules and the electric adjustment module are assembled with each other. The electric adjustment module is provided with a locking fastener, which is used to reinforce the multiple power modules and the electric adjustment module in the flight state. Adjust connections between modules. In the embodiment of the present invention, the multi-rotor aircraft is modularized, and the main modules are flexibly assembled by using assembly components, and expanded into various multi-axis multi-rotor aircraft, which greatly improves the scalability and flexibility of the modularization of the multi-rotor aircraft; In addition, locking fasteners are provided at key positions to strengthen the connection between modules in the flight state and improve the stability of the multi-rotor aircraft structure.

Owner:深圳市创客火科技有限公司

Novel drainage pipe flexible connection device at bridge expansion joint

PendingCN114811226ARealize soft connectionPlay a supporting roleAdjustable jointsBridge structural detailsWater leakDrainage tubes

The invention relates to the technical field of bridge drainage, in particular to a novel drainage pipe flexible connection device at a bridge expansion joint. Comprising a connector, a first reference rod, a second reference rod, a supporting piece and a corrugated pipe. The number of the connectors is two, and the two connectors are used for being communicated with two sections of pipe bodies of the drainage pipe respectively. And the corrugated pipe is connected between the two connectors so as to communicate the two connectors. An inner cavity is formed in one end of the first reference rod, and one end of the second reference rod is slidably matched with the inner cavity. The first reference rod is in spherical hinge connection with one connector, and the second reference rod is in spherical hinge connection with the other connector. The supporting piece is attached to the inner side of the corrugated pipe. The first reference rod and the second reference rod are both fixedly connected with positioning pieces, the multiple positioning pieces are evenly distributed in the circumferential direction of the first reference rod and the circumferential direction of the second reference rod at intervals, and each positioning piece is fixedly connected with one supporting piece. The probability of structural collapse of the flexible connection part can be reduced, and the probability of loosening, water leakage and other problems of the flexible connection part can be reduced.

Owner:江西嘉特信工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com