Door frame

A door frame and door leaf technology, applied in the direction of window/door frame, etc., can solve the problems of door leaf sinking, easy loosening of screws, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

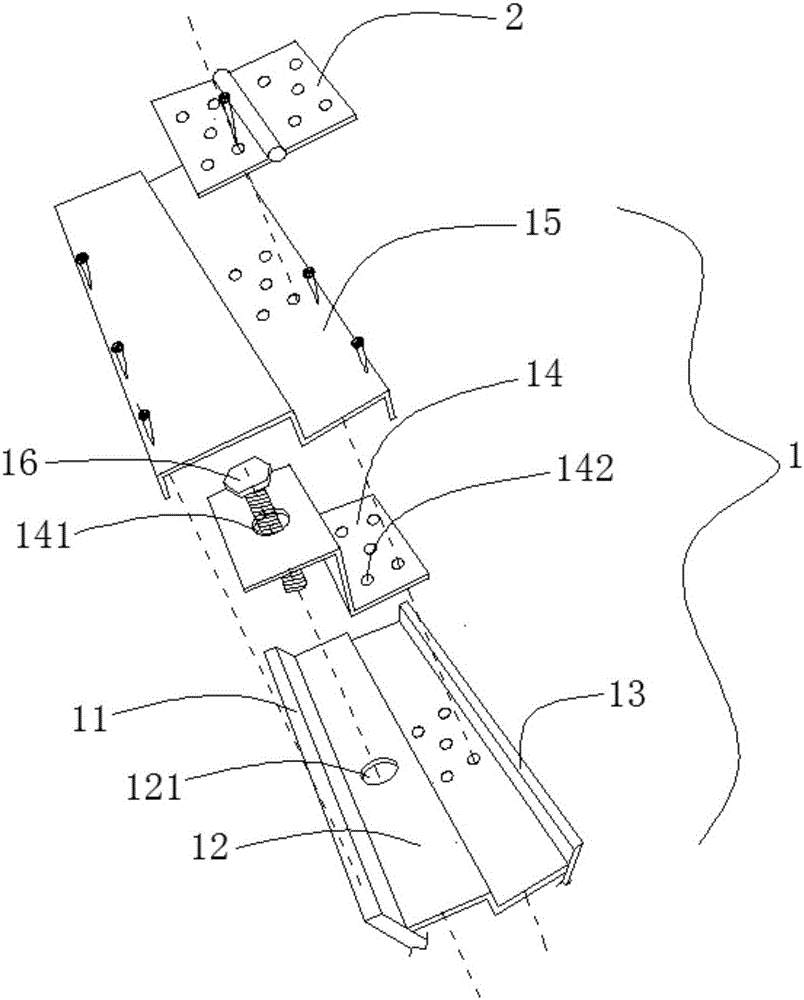

[0017] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0018] Such as figure 1 As shown, a door frame includes a connecting column 1 connected to a door leaf through a hinge 2 . The connecting column 1 is sequentially composed of a first panel 11 , a rib 12 and a second panel 13 along the thickness direction. The rib 12 connects the first panel 11 and the second panel 13 into one body. A fixing piece 14 is also arranged in the connecting column 1 . Two ends of the fixing member 14 are respectively connected to the first panel 11 and the second panel 13 . One of the leaves of the hinge 2 is fixed on a side of the fixing member 14 close to the third panel 13 .

[0019] The fixing part 14 is a Z-shaped plate; the Z-shaped plate is horizontally arranged between the first panel 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com