Anti-sinking door

An anti-sinking, door leaf technology, applied in the layout of wing leaves, door/window accessories, switches with brakes, etc. , the effect of reducing the chance of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

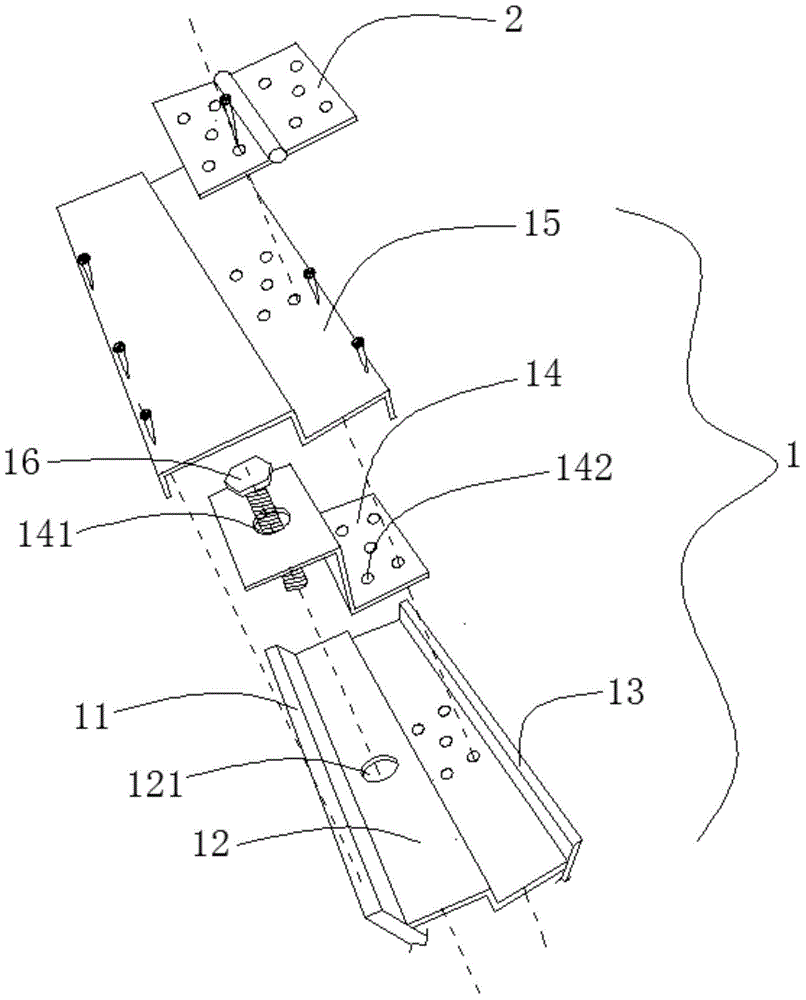

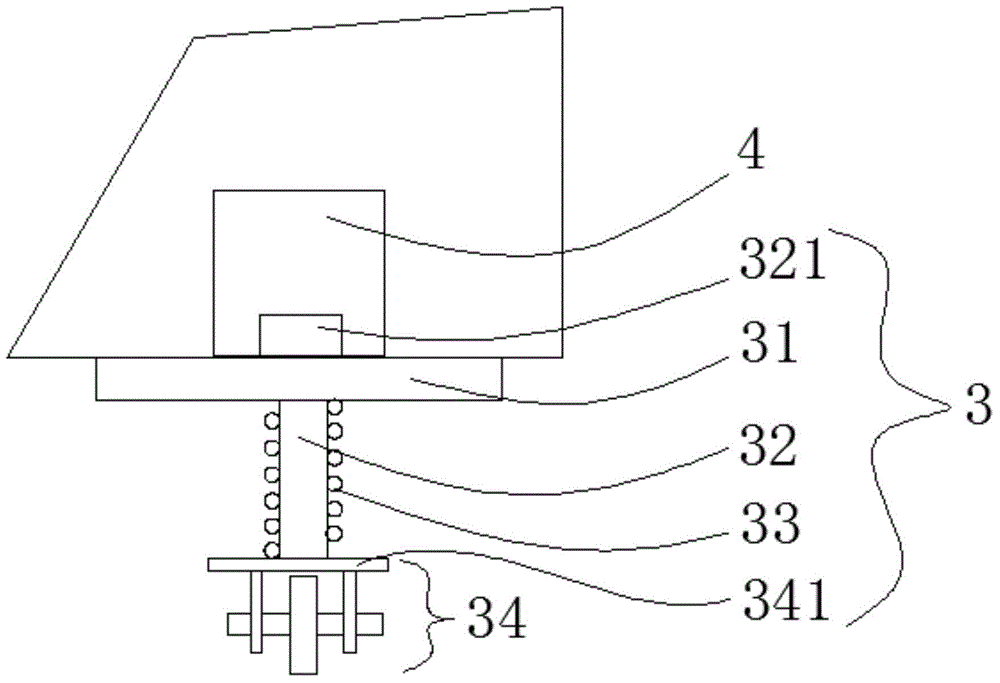

[0021] Such as figure 1 As shown, an anti-sinking door includes a door leaf and a door frame. The door frame includes a connecting column 1 connected to the door leaf through a hinge 2 . The connecting column 1 is sequentially composed of a first panel 11 , a rib 12 and a second panel 13 along the thickness direction. The rib 12 connects the first panel 11 and the second panel 13 into one body. A fixing piece 14 is also arranged in the connecting column 1 . Two ends of the fixing member 14 are respectively connected to the first panel 11 and the second panel 13 . One of the leaves of the hinge 2 is fixed on a side of the fixing member 14 close to the third panel 13 .

[0022] The fixing part 14 is a Z-shaped plate; the Z-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com