Hoisting equipment for green building assembly type prefabricated wall panel

A prefabricated wall panel and green building technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as low safety, inability to realize automatic adjustment of wire ropes, and inability to realize automatic locking of hooks, etc., to achieve reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

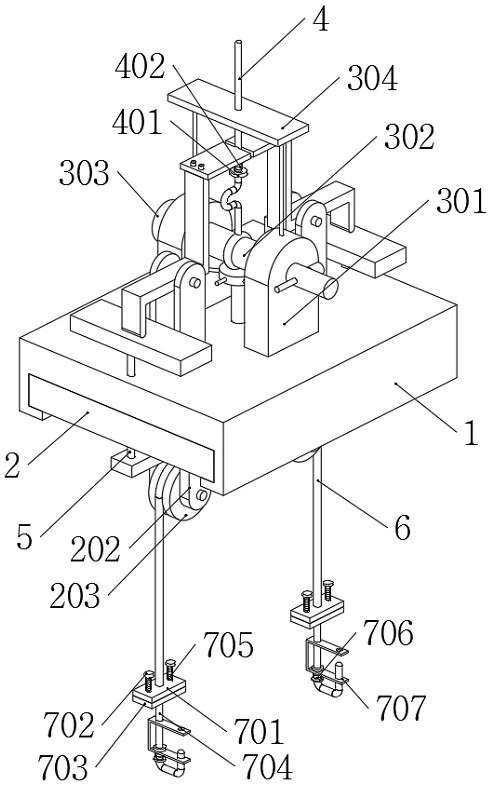

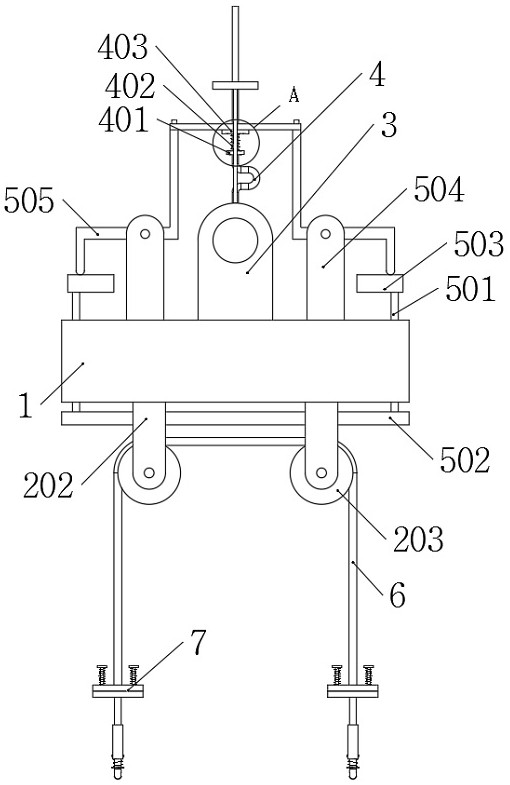

[0040] Example: Please refer to Figure 1 to Figure 9 :

[0041] The present invention proposes a hoisting device for prefabricated prefabricated wall panels in green buildings, including: a seat body 1, a connecting part 3, an auxiliary part 5 and a hanging part 7;

[0042] A connecting seat A2 is installed on the seat body 1; two rotating seats A202 are welded on the bottom of the connecting seat A2, and each rotating seat A202 is rotatably connected with a roller 203, and a steel wire rope 6 is wound on the two rollers 203;

[0043] The connecting part 3 is composed of a connecting seat B301, a sleeve 302, a bolt 303 and an auxiliary seat A304, and the connecting seat B301 is welded on the seat body 1; the connecting seat B301 is inserted with a bolt 303, and the connecting seat B301 is connected with a traction rope 4 ;

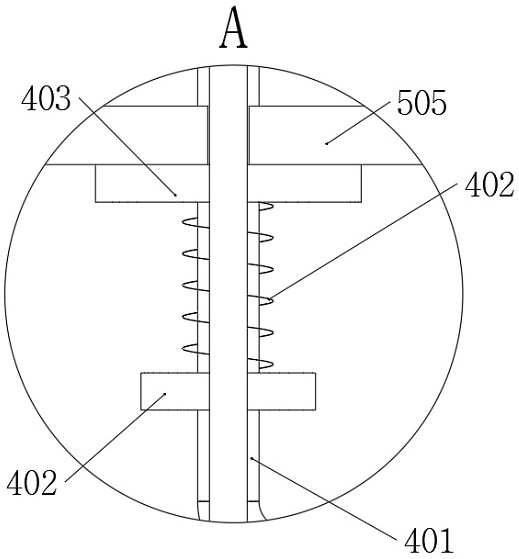

[0044] The auxiliary part 5 is composed of a sliding rod A501, a locking block 502, a force receiving block 503, a rotating seat B504 and a toggle bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com