Fast installation fixture for photovoltaic module

A technology of photovoltaic modules and installation fixtures, which is applied to the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation, etc., which can solve the problems of poor applicability and inability to install photovoltaic modules of different thicknesses, and achieve good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

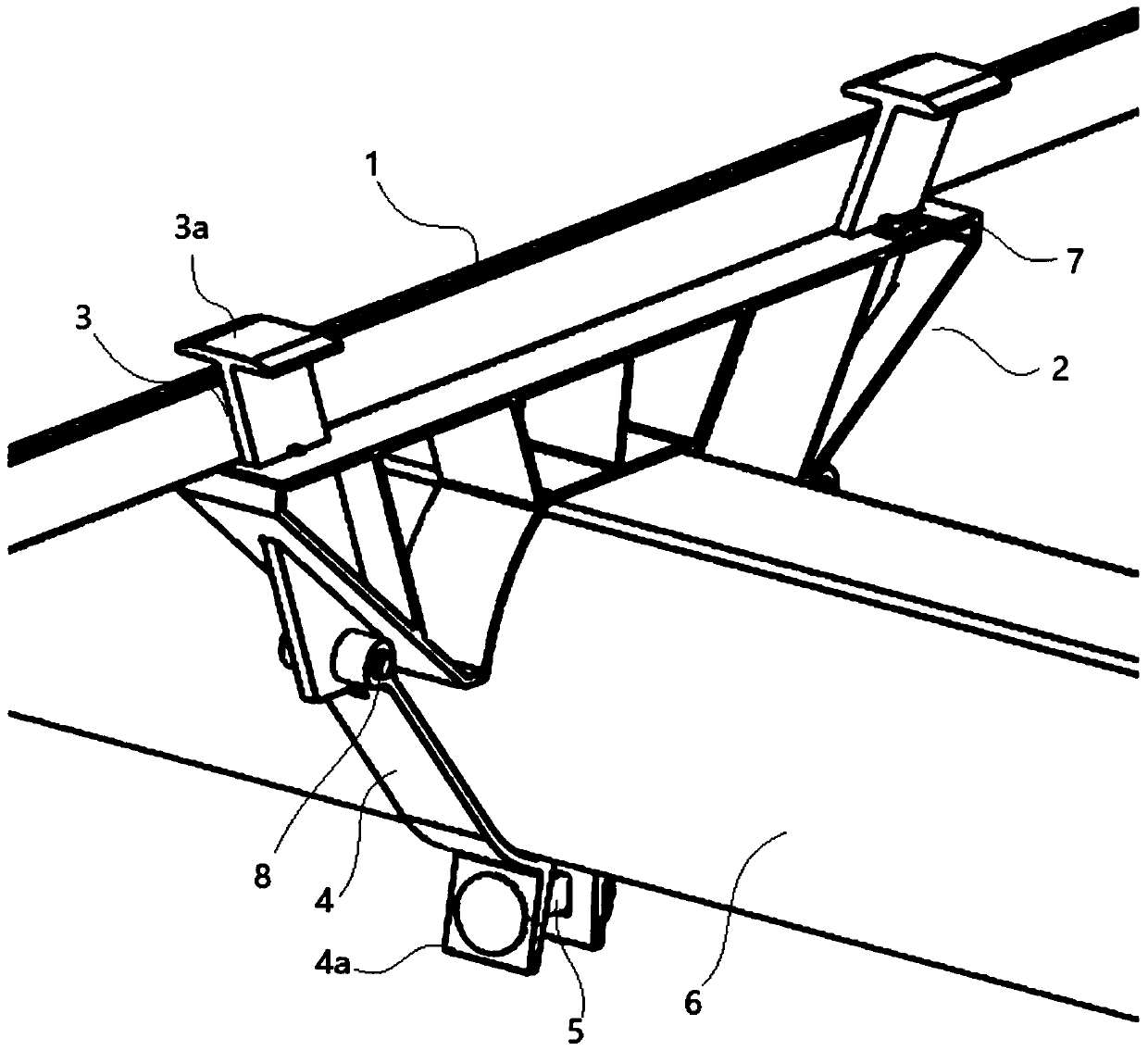

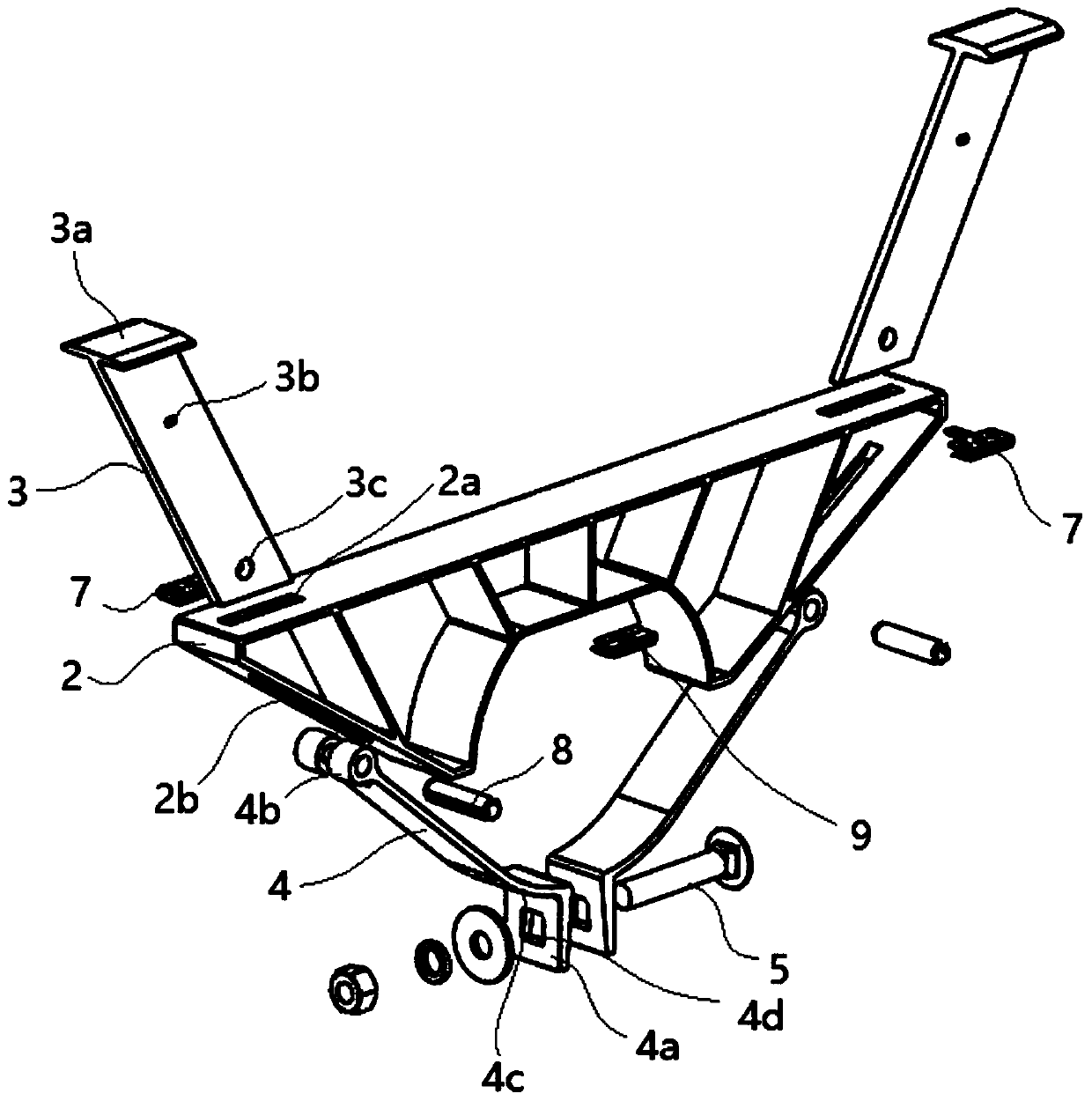

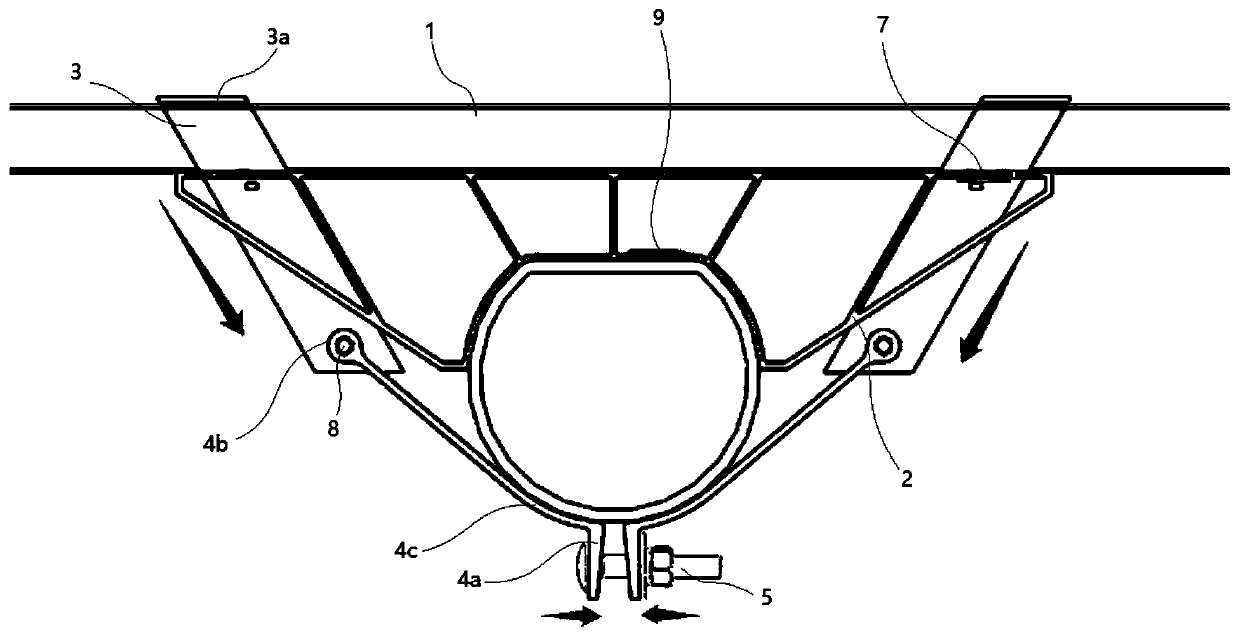

[0045] like Figure 1 to Figure 9 As shown, Embodiment 1 discloses a specific implementation of a quick installation fixture for photovoltaic modules, which can quickly install photovoltaic modules 1 of different thicknesses on the main beam 6 with a D-shaped cross-sectional shape. The board and the flat plate are composed of a purlin 2 placed on the upper end of the main beam 6, two pressing blocks 3 and two connecting plates 4. Specifically, the purlin 2 is placed on the flat plate of the main beam 6, and the purlin 2 is in the form of Arch bridge shape.

[0046] like figure 1 and Figure 4 As shown, along the extension direction perpendicular to the main girder 6, the two ends of the upper end surface of the purlin 2 are symmetrically provided with the first chute hole 2a, and the two ends of the lower end surface of the purlin 2 are symmetrically provided with the second chute hole 2b , the first chute hole 2a and the second chute hole 2b on the same side of the purlin ...

Embodiment 2

[0055] like Figure 1 to Figure 14 As shown, Embodiment 2 discloses another specific implementation of a quick installation fixture for photovoltaic modules, which can quickly install photovoltaic modules 1 of different thicknesses on the main beam 6 with a D-shaped cross-sectional shape. The main beam 6 consists of a circle The arc plate is composed of a flat plate, which specifically includes: a purlin 2 placed on the upper end of the main beam 6, two pressing blocks 3 and two connecting plates 4, specifically, the purlin 2 is placed on the flat plate of the main beam 6, and the purlin 2 In the shape of an arch bridge.

[0056] like figure 1 and Figure 4 As shown, along the extension direction perpendicular to the main girder 6, the two ends of the upper end surface of the purlin 2 are symmetrically provided with the first chute hole 2a, and the two ends of the lower end surface of the purlin 2 are symmetrically provided with the second chute hole 2b , the first chute ho...

Embodiment 3

[0067] like Figure 1 to Figure 14 As shown, Embodiment 3 discloses another specific implementation of a quick installation fixture for photovoltaic modules, which can quickly install photovoltaic modules 1 of different thicknesses on the main beam 6 with a D-shaped cross-sectional shape. The main beam 6 is formed by a circle The arc plate is composed of a flat plate, which specifically includes: a purlin 2 placed on the upper end of the main beam 6, two pressing blocks 3 and two connecting plates 4, specifically, the purlin 2 is placed on the flat plate of the main beam 6, and the purlin 2 In the shape of an arch bridge.

[0068] like figure 1 and Figure 4 As shown, along the extension direction perpendicular to the main girder 6, the two ends of the upper end surface of the purlin 2 are symmetrically provided with the first chute hole 2a, and the two ends of the lower end surface of the purlin 2 are symmetrically provided with the second chute hole 2b , the first chute h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com