Solid electrolyte aluminium electrolytic capacitor and method for manufacturing same

A technology of aluminum electrolytic capacitors and solid electrolytes, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of increased product process and cost, damage to the conductive tin layer, and low process efficiency, so as to reduce the time and cost of carbonization The number of times, avoiding damage to the coating, and shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

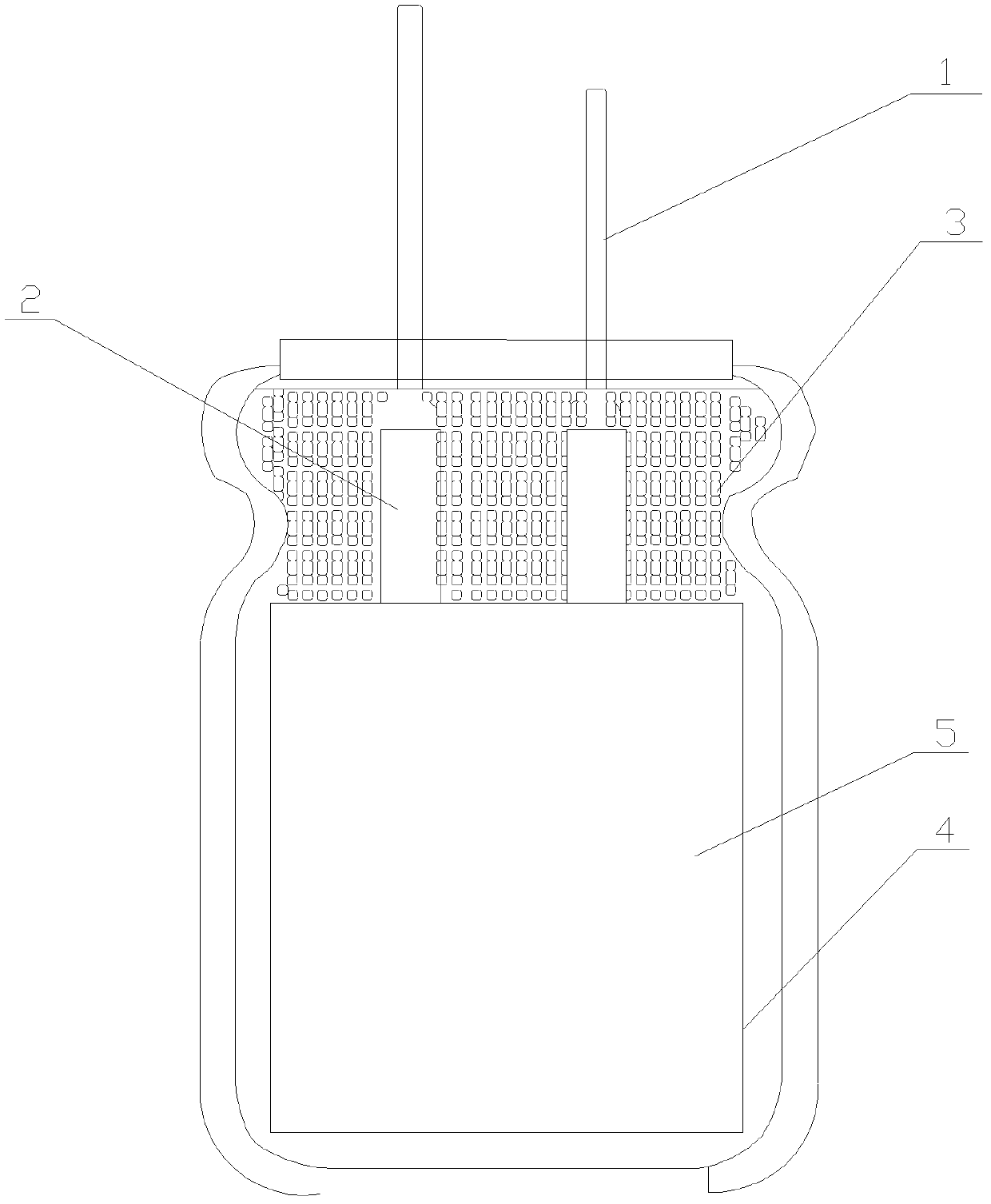

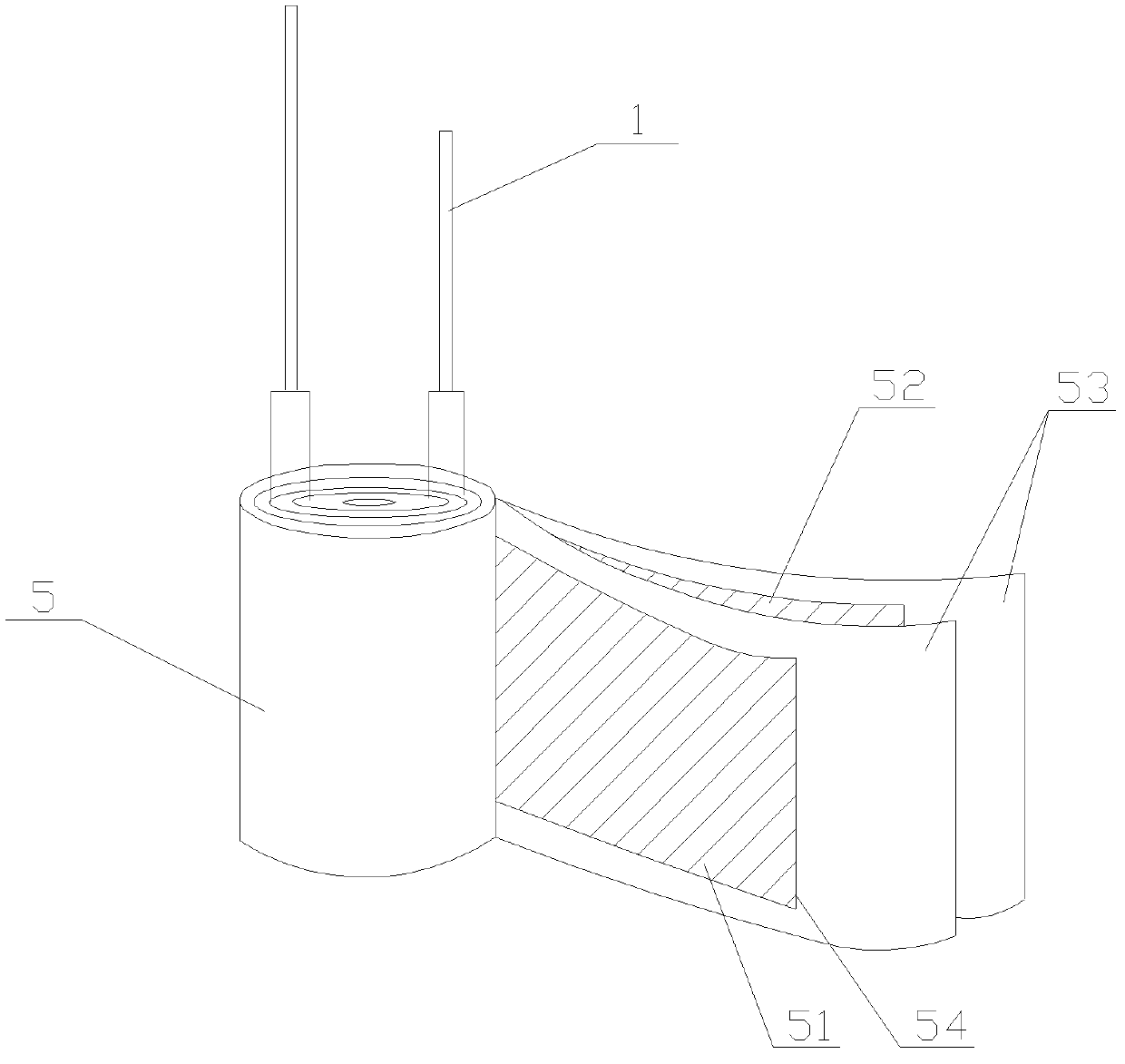

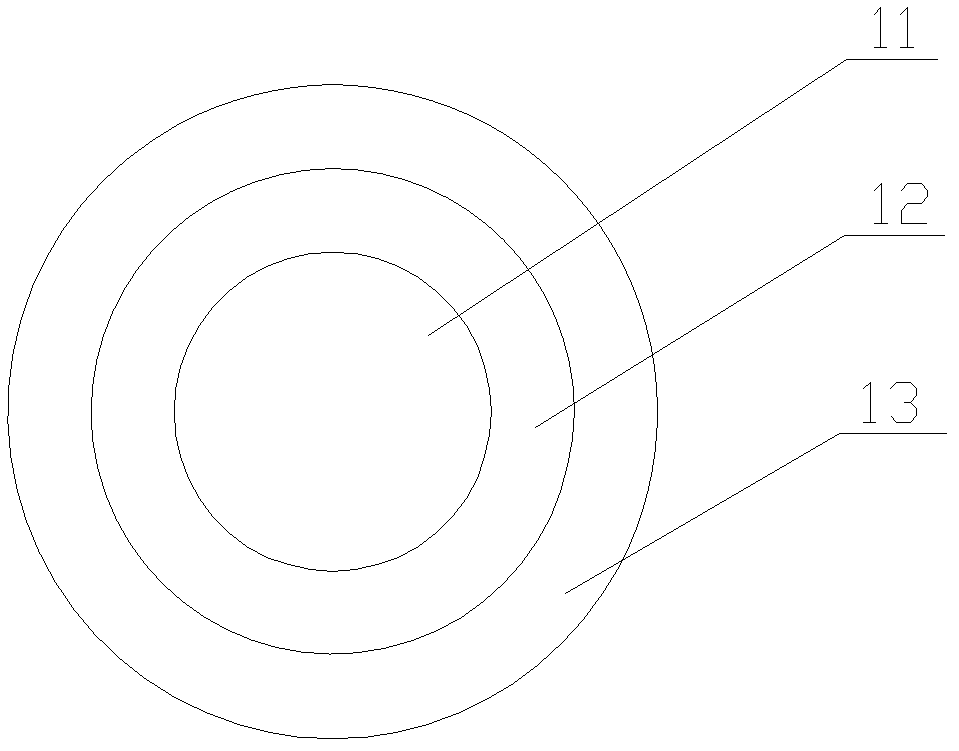

[0041] refer to Figure 1 to Figure 3 , a polymer solid electrolyte aluminum electrolytic capacitor according to the present invention, the specification is 6.3V820μF, the production quantity is 5000, it includes a core package 5, the core package 5 is composed of anodized aluminum foil 51, cathode foil 52 and electrolytic paper 53 , the core package 5 is connected to the positive and negative terminals 1, the core package is provided with a plastic cover 3 and an aluminum shell 4, the positive and negative terminal 1 includes an iron core 11, and the outer surface of the iron core 11 is sequentially plated with a copper-plated layer 12 and a silver-plated layer 13 .

[0042] Its production steps are as follows:

[0043] 1. Select an iron core 11 with a diameter of 500 μm, plate a copper layer 12 with a thickness of 60 μm, and then plate a silver layer 13 with a thickness of 40 μm to form a positive and negative terminal 1 with a wire diameter of 600 μm, and spot weld an alum...

Embodiment 2

[0058] A polymer solid electrolyte aluminum electrolytic capacitor, the specification is 25V47μF, and the production quantity is 5000 pieces. The production steps are as follows:

[0059] 1. Select a copper lead wire with a diameter of 560 μm, and then plate a silver-plated layer 13 with a thickness of 40 μm to form a positive and negative terminal 1 with a wire diameter of 600 μm. One end is spot-welded with an aluminum lead 2, and the positive and negative terminals 1 are connected by a nail coiler. Respectively riveted on the anodized aluminum foil 51 and cathode foil 52 with a VF value of 54V, sandwiched electrolytic paper 53 and wound it with a nail roll machine to make a core package 5, and the electrolytic paper 53 was inserted between the anodized aluminum foil 51 and the cathode aluminum foil. The two foils are separated without forming a short circuit, and the cathode foil 52 wraps the core package 5 after winding.

[0060] 2. Send the wound core package 5 to a speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com