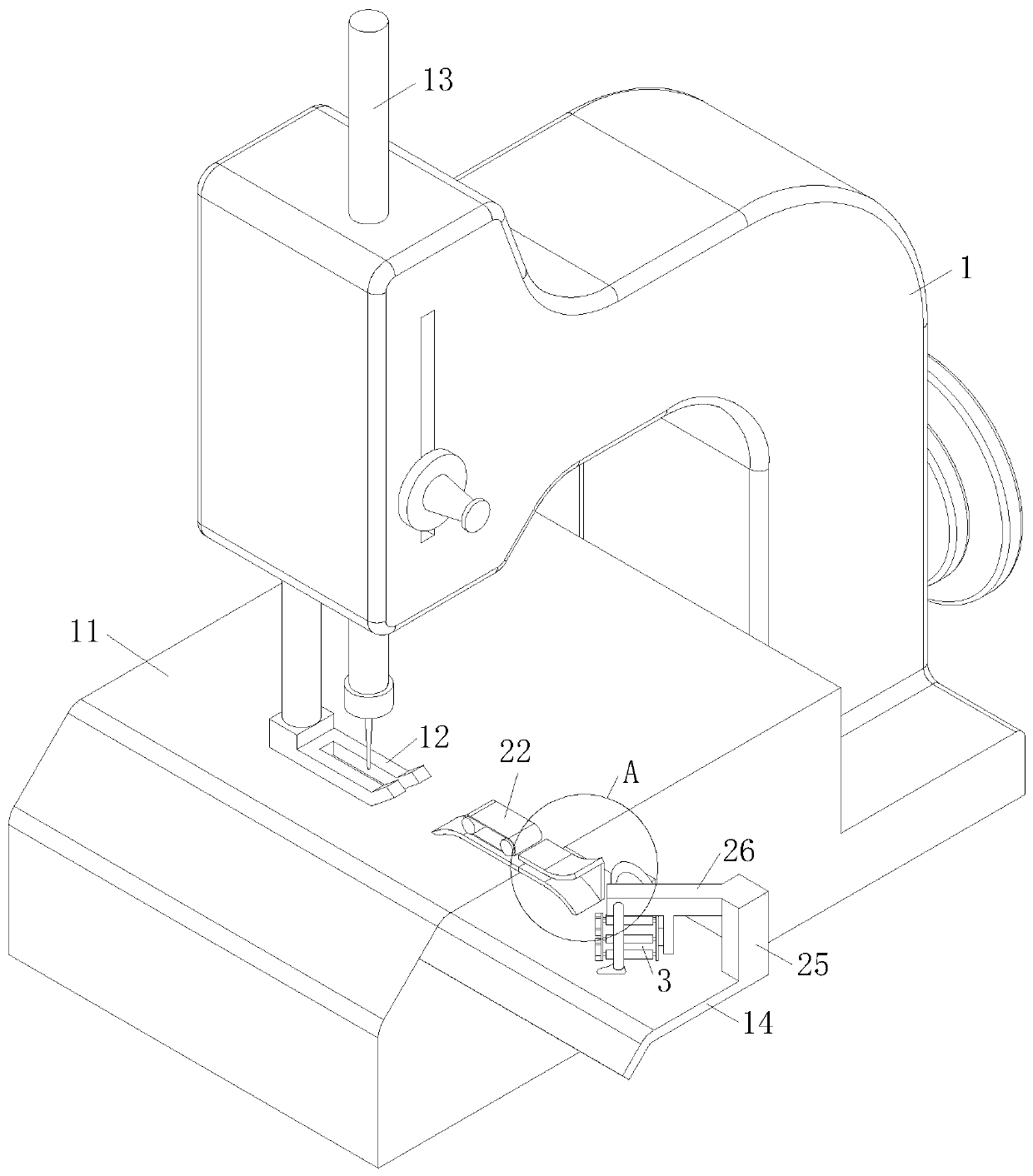

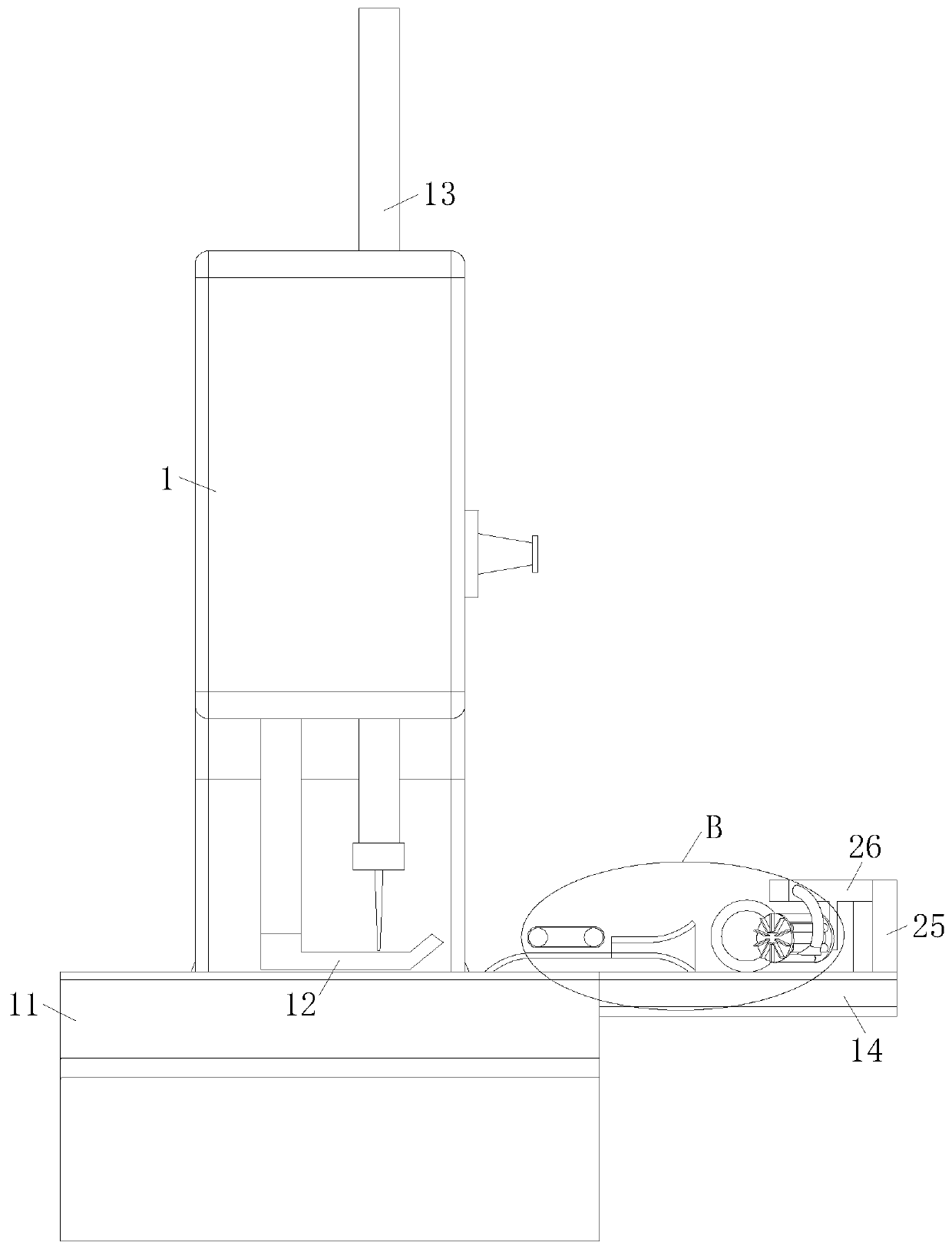

Woven bag covering machine

A technology for woven bags and hemming machines, which is applied in the direction of fabric edging, cloth feeding mechanism, sewing machine components, etc. Production and other problems, to avoid re-threading, increase sewing efficiency, and reduce re-breaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

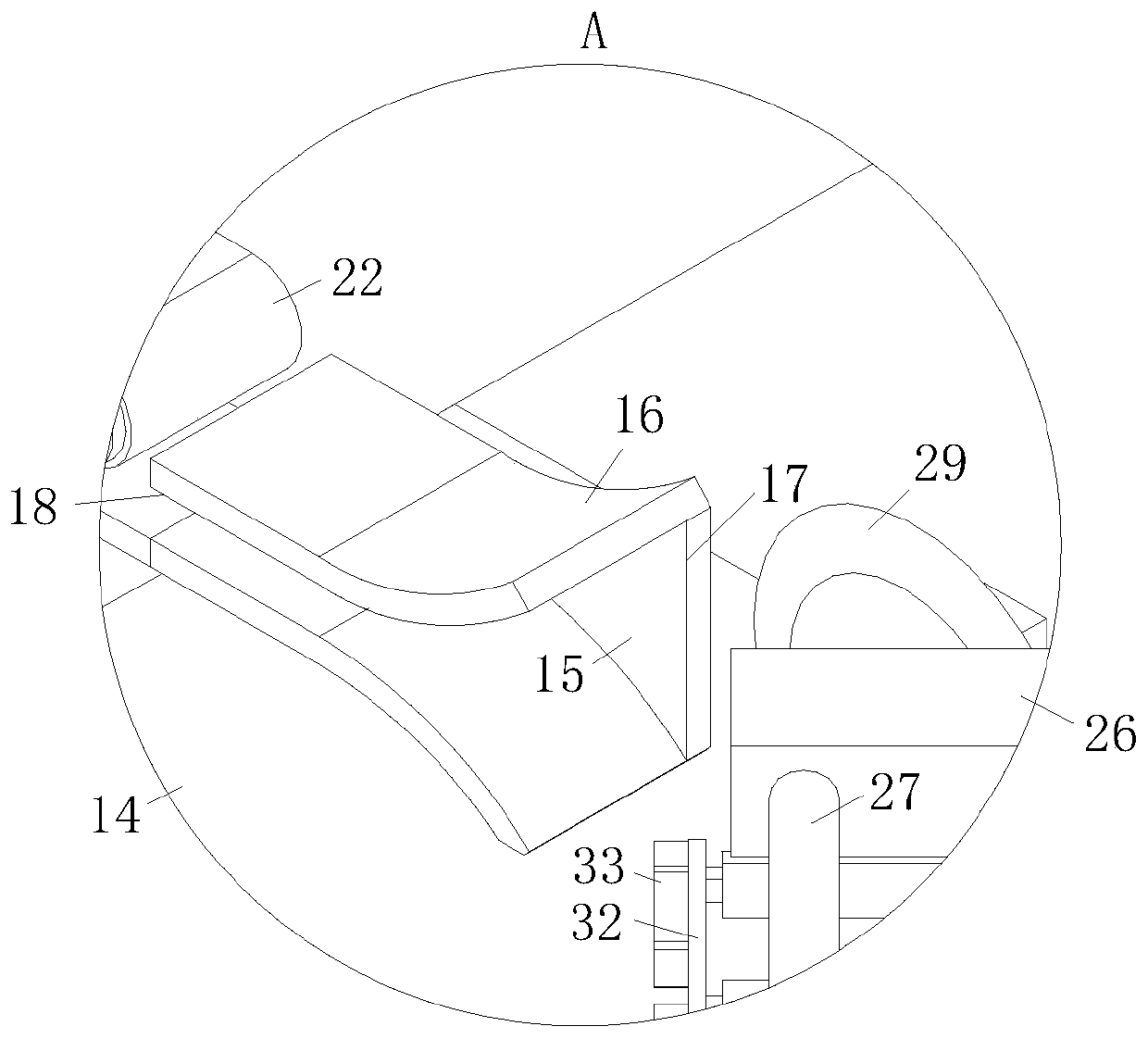

[0024] As an embodiment of the present invention, the extension plate 14 on the side of the guide plate 16 close to the presser foot plate 12 is rotatably connected with the driving roller 2 and the driven roller 21 through a bracket, the driving roller 2 is driven by a servo motor, and the servo motor passes The controller is connected to the power supply; a conveyor belt 22 is sleeved between the driving roller 2 and the driven roller 21, and the bottom of the conveyor belt 22 is provided with a support plate 23 that is fixedly connected with the extension plate 14, and the linear speed of the conveyor belt 22 is the same as The feeding speed of the presser foot plate 12 is the same; the tension force on the woven bag is increased through the cooperation of the conveyor belt 22 with the support plate 23, thereby reducing the wrinkles of the woven bag and ensuring the smooth feeding of the woven bag; the driving roller 2 is driven by a servo motor, and then Drive the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com