Efficient silicon steel sheet cross line shearing device

A technology of cross-cutting line and silicon steel sheet, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of cumbersome operation mode, high labor cost, prone to human error, etc., and reduce the possibility of loosening. , Improve work efficiency and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

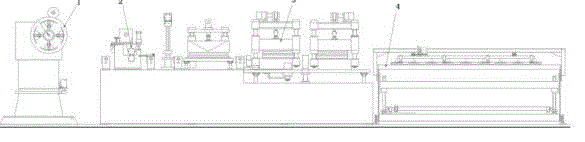

[0027] Such as figure 1 Shown: the present invention comprises: winding device 1, feeding device 2, shearing device 3 and unloading device 4; The structural relation between each device is: described winding device 1 connects described feeding device 2; The feeding device 2 is connected to the shearing device 3, and the sheet material is sent into the shearing device 3 for processing; the shearing device 3 cuts and processes the sheet material, and sends the processed sheet material into the discharging device. device 4.

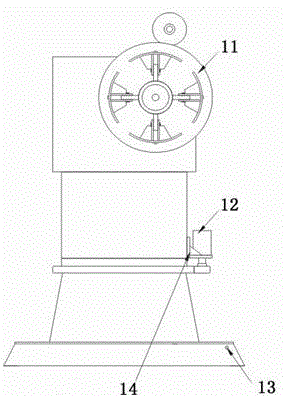

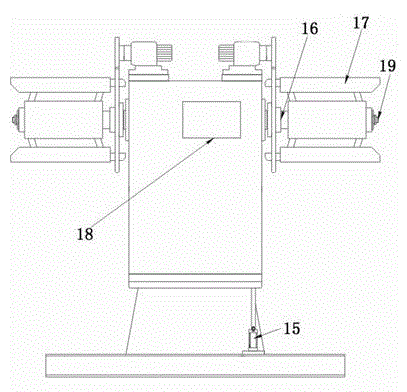

[0028] Such as figure 2 , image 3 Embodiment 1 shown: the winding device 1 includes a winding shaft 11, a hydraulic motor 12, a photoelectric sensor switch 13, a photoelectric proximity switch 14 and a cylinder 15, the number of the winding shafts 11 is at least two, and the photoelectric The induction switch 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com