Light steel house connecting structure

A technology for connecting structures and houses, which is applied in the direction of building components, building structures, and residential buildings. The effects of detachment, tight connection, and improved connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

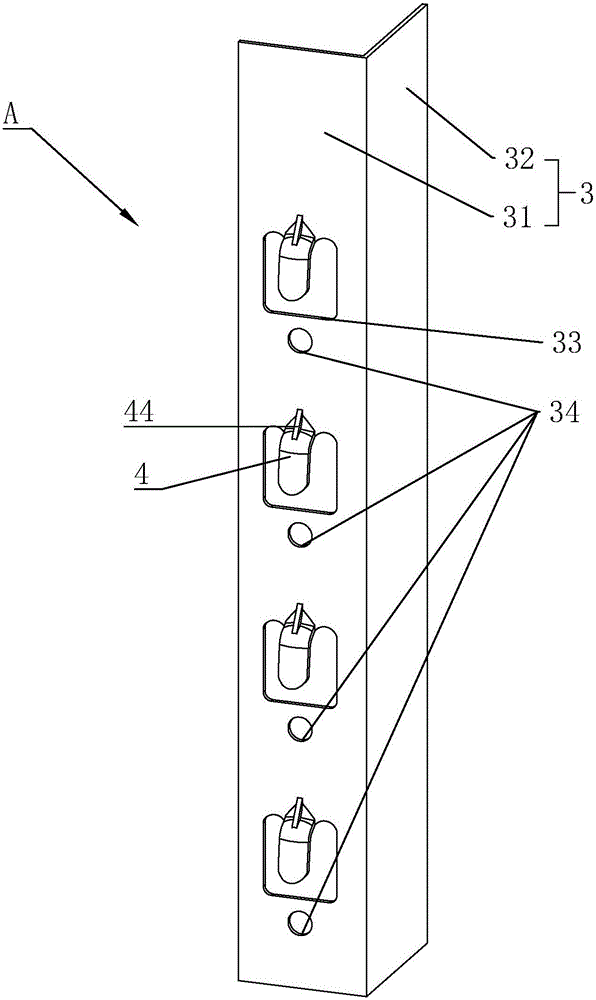

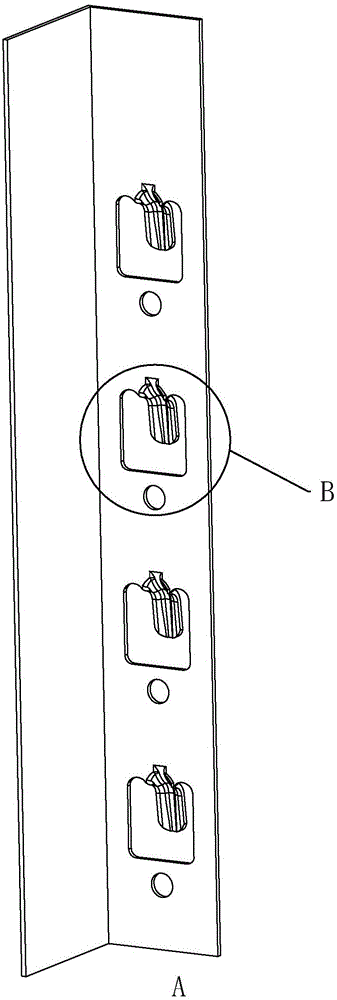

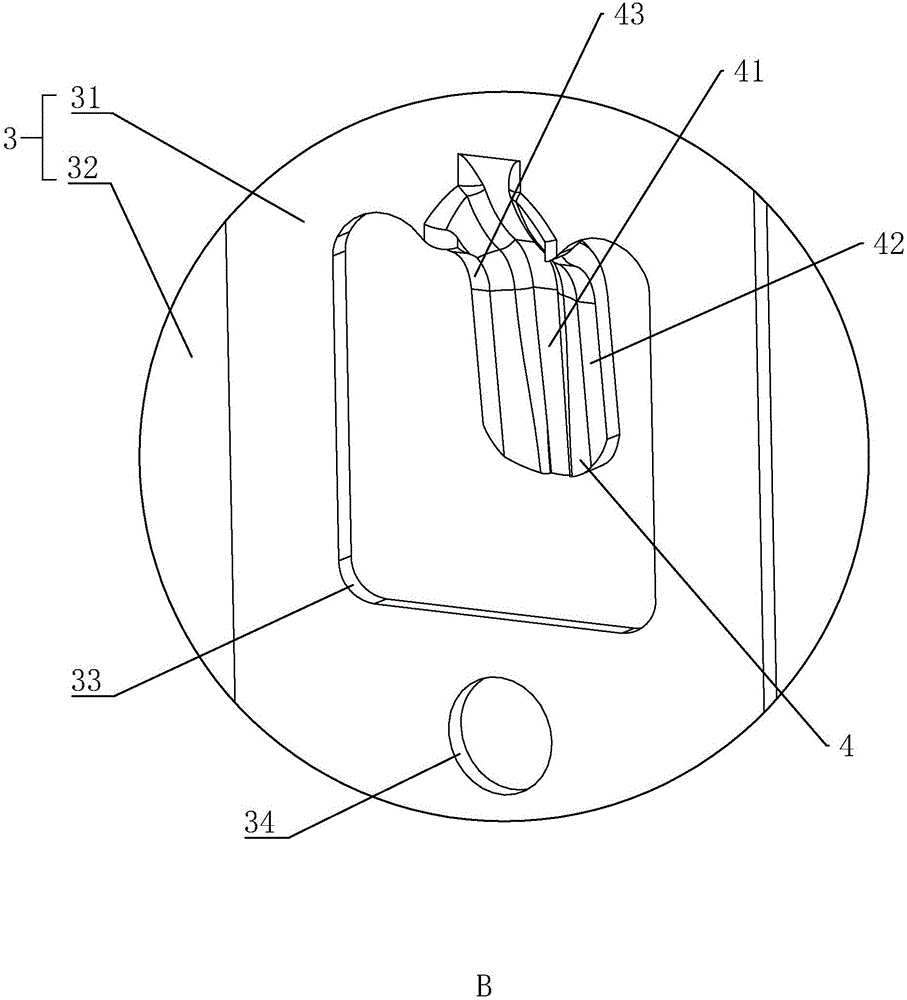

[0044] Embodiment 1: A connection structure of a light steel house, such as figure 1 and Figure 4 As shown, a supporting plate 3 and a fixing plate 5 are included. The support plate 3 is elongated and its length direction is set along the vertical direction, including an integrated connection part 32 and a mounting part 31. The width direction of 31 is arranged vertically.

[0045] Such as figure 1 and Figure 5 As shown, the end of the beam 1 is welded to the connecting portion 32 . Four support blocks 4 are integrally connected to the installation part 31 , and the four support blocks 4 are arranged along the length direction of the installation part 31 , and the distances between adjacent support blocks 4 are equal.

[0046] Such as figure 2 and image 3 As shown, one end of the support block 4 is connected to the installation part 31, and the other end is suspended. The end of the support block 4 away from the installation part 31 is inclined downward in the vert...

Embodiment 2

[0056] Embodiment 2: A connection structure of a light steel house, such as Figure 10 to Figure 13 As shown, the difference with embodiment 1 is that the fixed plate 5 is removed (see Figure 6 )setting.

[0057] Such as Figure 11 and Figure 12 As shown, the column 2 is a hollow quadrangular prism, and each face of the column 2 is provided with sixteen fixing holes 53 and the second positioning holes 52, see Figure 10 , with eight fixing holes 53 and the second positioning hole 52 as a group, which are respectively placed at the upper and lower ends of the column 2, see Figure 11 , the four fixing holes 53 and the second positioning holes 52 in each group form a row, that is, the end of each column 2 is provided with two rows of fixing holes 53 and the second positioning holes 52, and the fixing holes 53 and the second positioning holes of each row The positioning holes 52 are arranged along the length direction of the column 2 .

[0058] As described in Embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com