Wood veneer internal corner connecting structure, forming process of wood veneer internal corner connecting structure and wood cabinet with wood veneer internal corner connecting structure

A technology of wood veneer and connecting structure, which is applied in the direction of connecting member, thin plate connection, wood processing appliance, etc., can solve the problems of cracking and deformation of the joint, reducing the stability of the first wood veneer and the second wood veneer, etc. Achieve the effect of reducing fracture and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

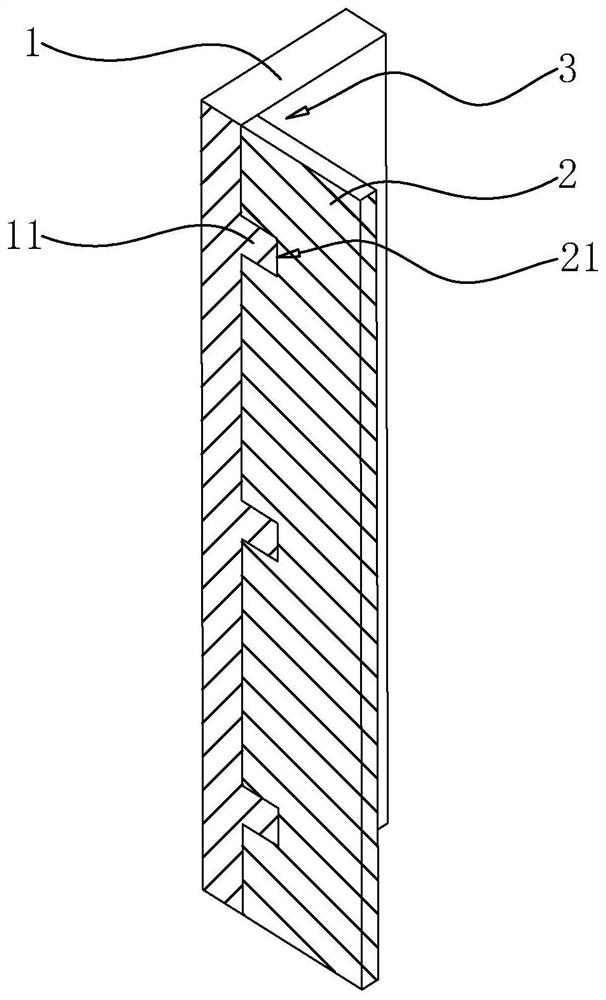

[0045] refer to figure 1 , in the existing internal corner connection structure of wood veneer panels, including a first wood veneer panel 1 and a second wood veneer panel 2 . An inner angle 3 is formed between the first wood veneer 1 and the second wood veneer 2 .

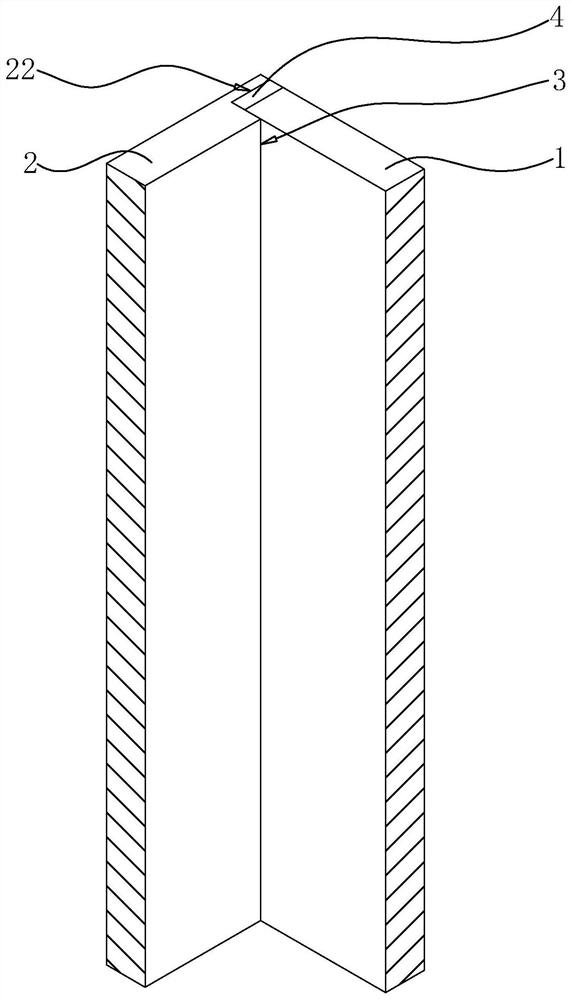

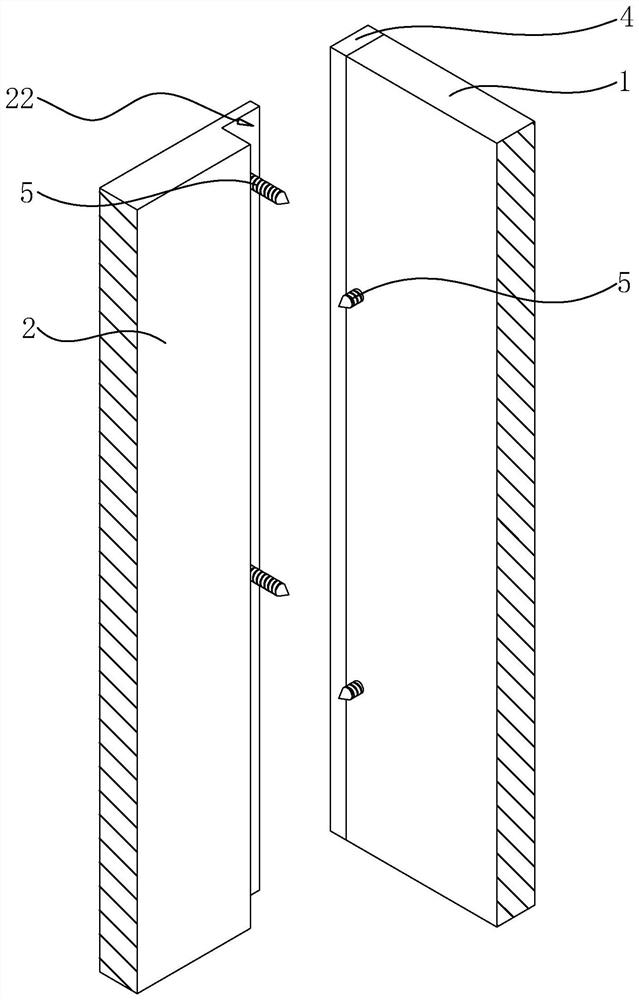

[0046] The embodiment of the present application discloses a connection structure for internal corners of wood veneer panels. refer to figure 2 and image 3 , the connection structure includes a first wood veneer 1 and a second wood veneer 2 . Both the first wood veneer 1 and the second wood veneer 2 are arranged in a rectangular parallelepiped, and the width direction of the first wood veneer 1 is perpendicular to the width direction of the second wood veneer 2 . One side of the second wood veneer 2 thickness direction is provided with a positioning groove 22, the length direction of the positioning groove 22 is parallel and equal to the length of the second wood veneer 2, and the positioning groove 22 is posi...

Embodiment 2

[0055] The embodiment of the present application discloses a molding process of the internal corner connection structure of wood veneer panels, which adopts the following steps:

[0056] S1, designing and drawing the first wood veneer panel 1 and the second wood veneer panel 2, and making the first wood veneer panel 1 and the second wood veneer panel 2 according to the drawings;

[0057] S2, using a milling machine to mill out a positioning groove 22 in the side of the second wood veneer 2 for abutting against the first wood veneer 1;

[0058] S3, the worker paints the surfaces of the first wood veneer 1 and the second wood veneer 2;

[0059] S4, the staff cleans up the corners of the first wood veneer 1 and the second wood veneer 2 and removes the burrs;

[0060] S5, the worker coats the glue layer 4 on the groove wall in the positioning groove 22 and the side where the first wood veneer 1 needs to be plugged and matched with the positioning groove 22;

[0061] S6, one side...

Embodiment 3

[0067] Embodiment 1 of the present application discloses a wooden cabinet with an internal corner connection structure of wood veneer panels. The wooden cabinet includes the internal corner connection structure of wood veneer panels in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com