LC type polarization-maintaining connector

A connector, all-in-one technology, used in instruments, optics, light guides, etc., can solve problems such as loosening and limited connection stability, and achieve the effect of reducing loosening, avoiding excessive bending of optical fibers, and reducing installation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-8 The application is described in further detail.

[0040] The embodiment of the present application discloses an LC type polarization maintaining connector.

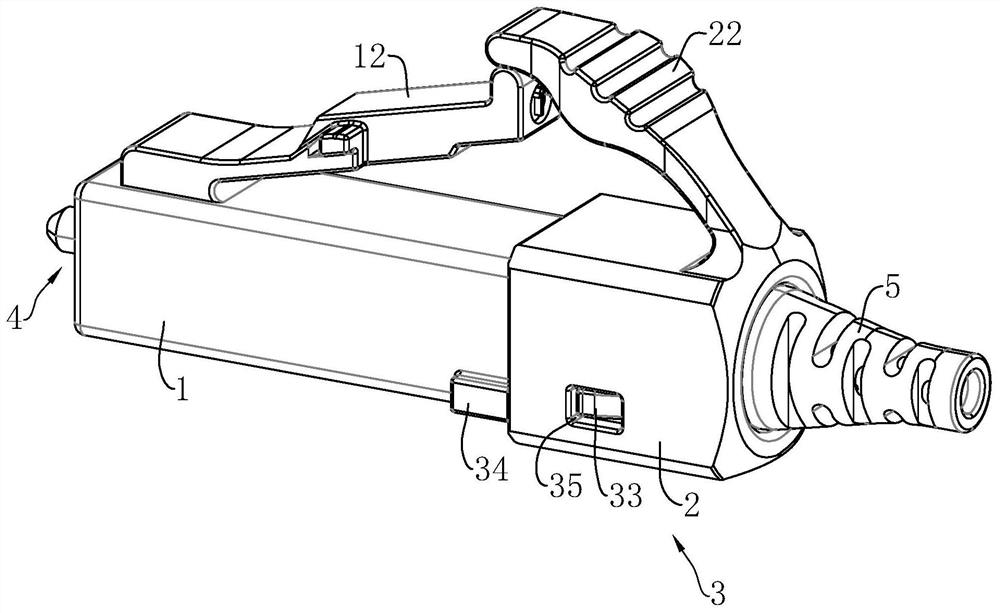

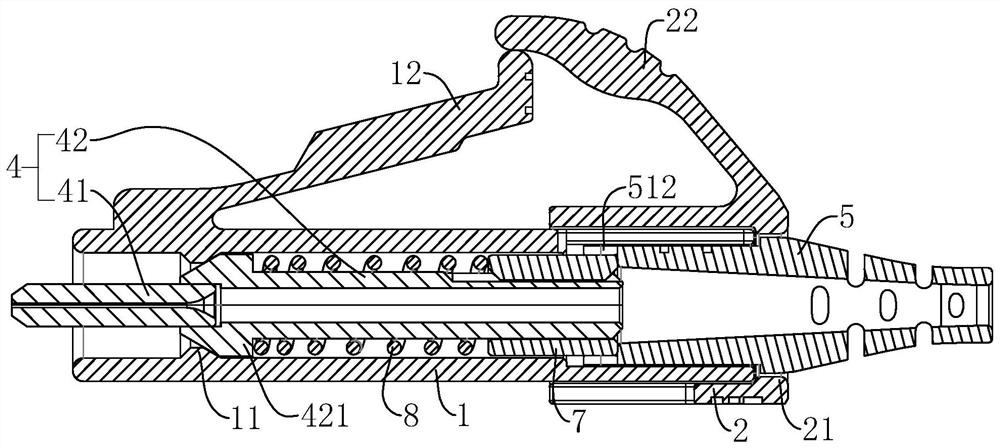

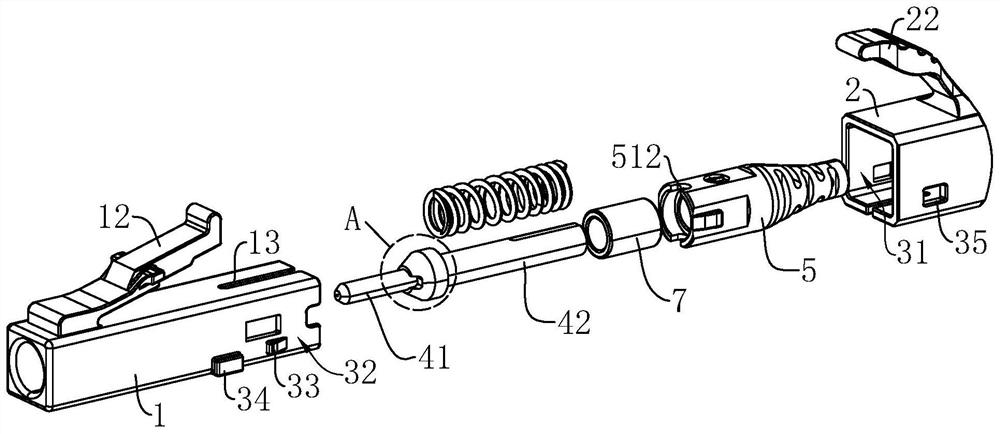

[0041] combine figure 1 , figure 2 and image 3 , an LC type polarization maintaining connector, comprising an outer frame sleeve, a ferrule assembly 4 slidingly fitted in the outer frame sleeve, an integrated boot 5 arranged at the end of the outer frame sleeve, and used to connect the integrated boot 5 and The angle fixing ring 7 of the ferrule assembly 4, the spring 8 arranged on the outside of the ferrule assembly 4, the ferrule assembly 4, the angle fixing ring 7 and the integrated boot 5 are connected to form an optical fiber channel through which the optical fiber passes.

[0042] The outer frame cover includes a front frame cover 1 and a handle frame cover 2 snapped to the outside of the rear end of the front frame cover 1 through an outer buckle structure 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com