Cylinder housing of lightweight/hybrid construction and method for the production thereof

A technology of hybrid structure and composite structure, which is applied in the direction of cylinders, other household appliances, fluid pressure actuators, etc., and can solve problems such as difficulties in the working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] First of all, it should be determined that in differently described implementation forms, the same components have the same reference signs or the same component names, and the disclosure contained in the entire specification can be reasonably transferred to have the same reference signs or the same component names. The same part of the component name. The position descriptions selected in the description, such as upper, lower, side, etc., also refer to the current description and the illustrated drawings, and can be reasonably transferred to a new position when the position is changed.

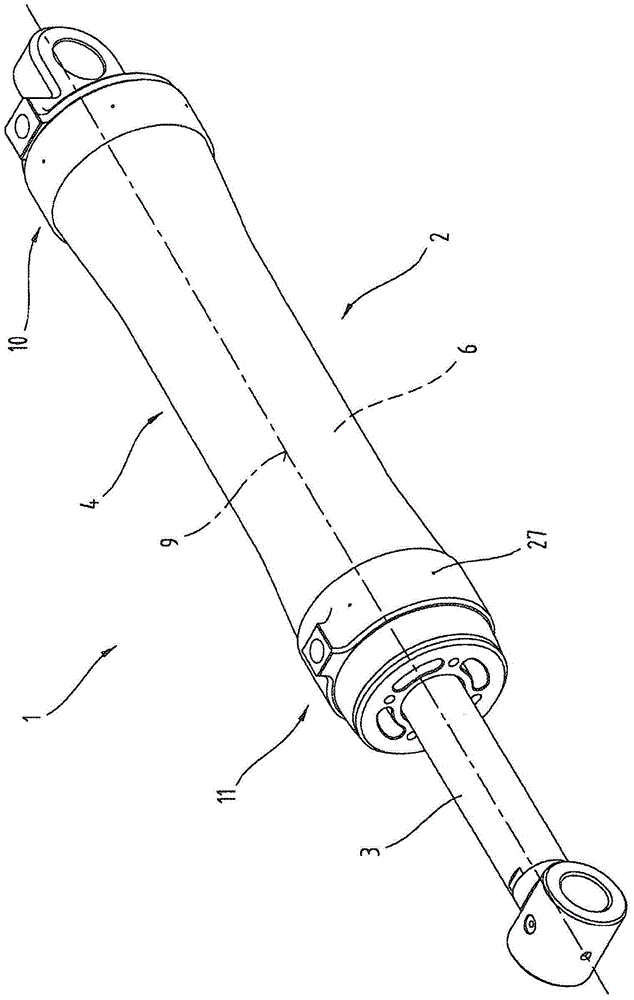

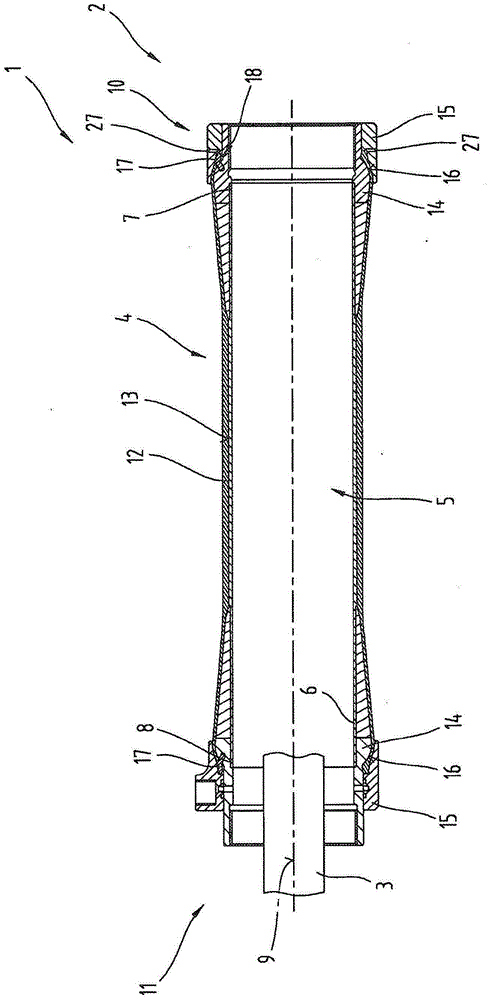

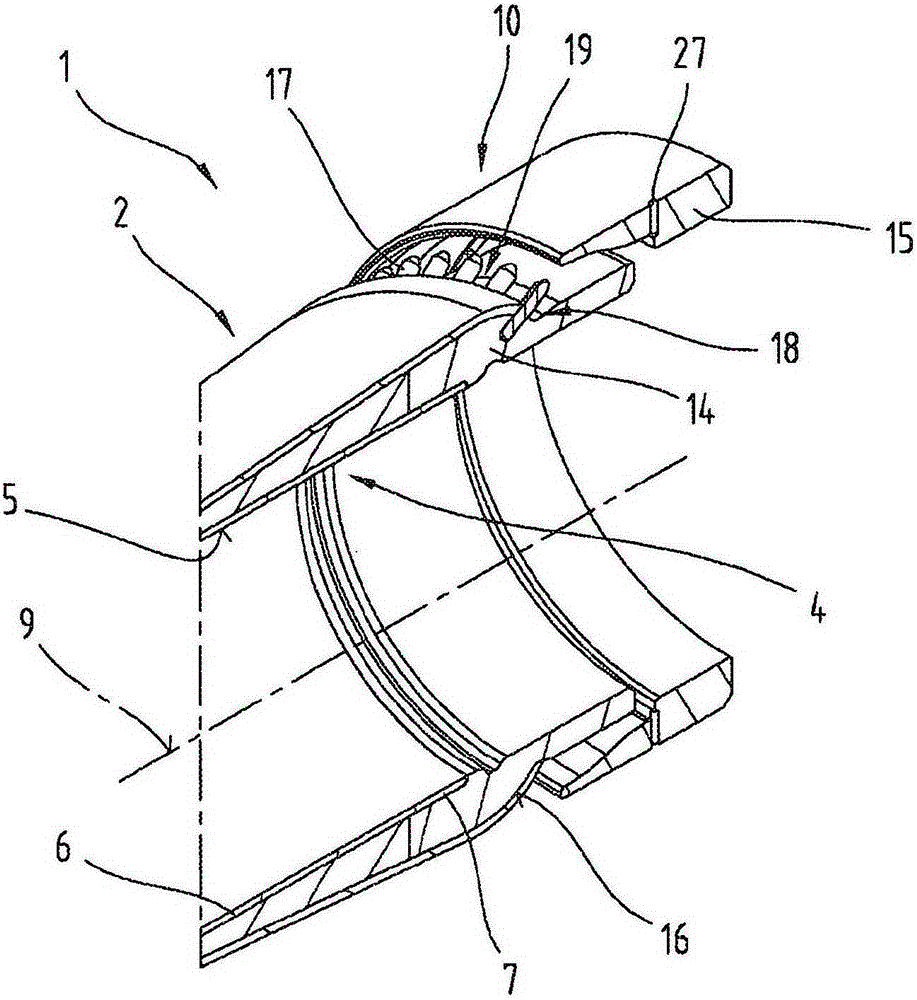

[0037] in figure 1 A working cylinder in the form of a pressure cylinder 1 is shown in simplified form. The pressure cylinder includes a cylinder housing 2 in the form of a hybrid light-weight structure and a piston not shown in detail here and a piston rod 3 connected thereto. The pressure cylinder may be, for example, a hydraulic cylinder, a pneumatic cylinder or a hydropneumatic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com