Single-driven omni-directional type AGV device

A vehicle body, single-drive technology, applied in motor vehicles, steering mechanisms, vehicle components, etc., can solve problems such as inability to solve problems, and achieve the effect of high mechanical transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

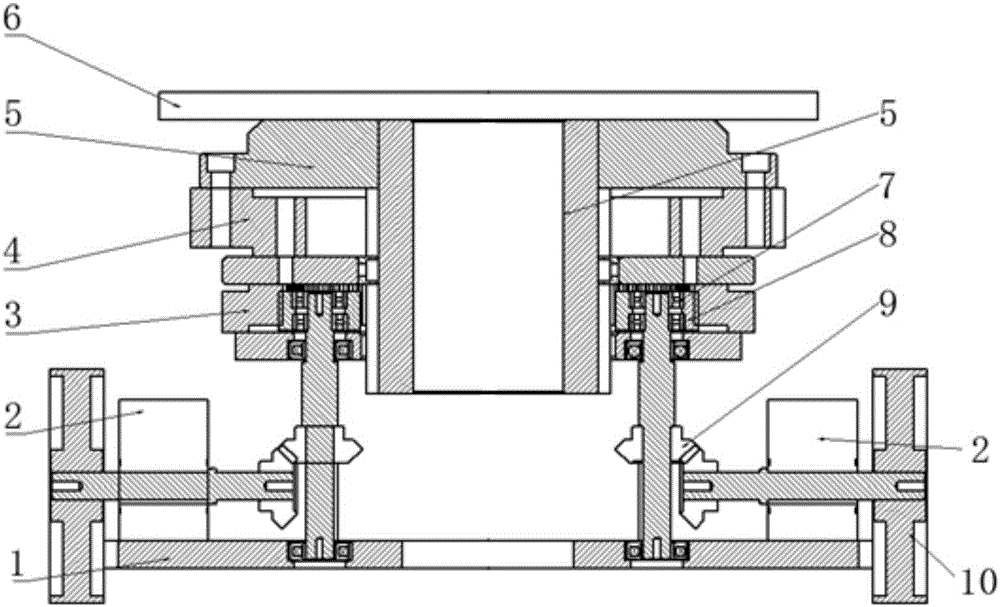

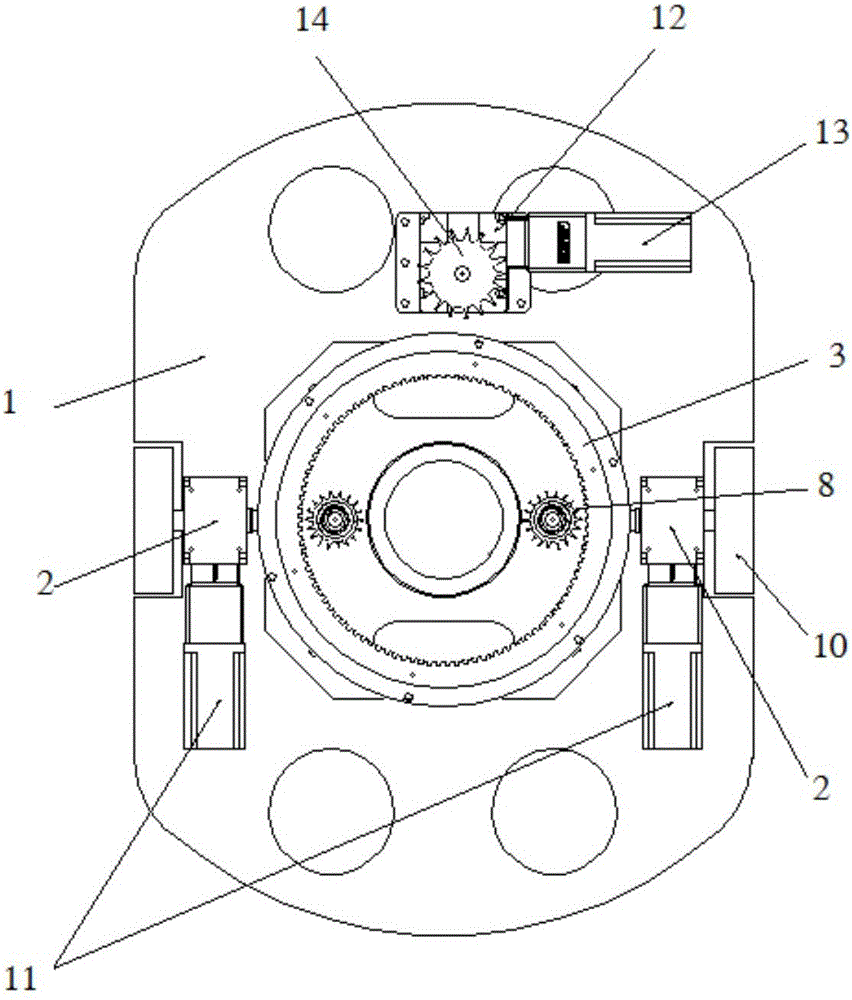

[0022] A single-drive omnidirectional AGV car body device, figure 1 , figure 2 They are the schematic diagram of the front view and the top view of the car body respectively. The car body device is composed of a moving unit and a lifting unit, wherein the moving unit includes a driving wheel 10, a driving motor 11, a first reducer 2, a bevel gear 9, The driving gear 8 and the overrunning clutch 7, the driving wheel 10 is installed on the first reducer 2, the first reducer 2 is composed of a planetary reducer and a worm gear reducer, the first reducer 2 is connected with a drive motor 11, and the drive motor 11 drives The first speed reducer 2 and the driving wheel 10 rotate, and drive the overrunning clutch 7 to rotate through the transmission of the transmission gear assembly. Symmetrical setting. Overrunning clutch 7 left and right respectively is provided with 2 pairs.

[0023] The lifting unit includes a servo motor 13, a second speed reducer 12, a second transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com