Preparation method of silicon-carbon composite material, silicon-carbon composite material and application thereof

A silicon-carbon composite material and composite material technology, applied in the field of lithium-ion batteries, can solve the problems of deterioration of capacity and cycle performance in the first cycle, complicated process flow, large economic cost, etc., to avoid loss of electrical contact, simple process, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

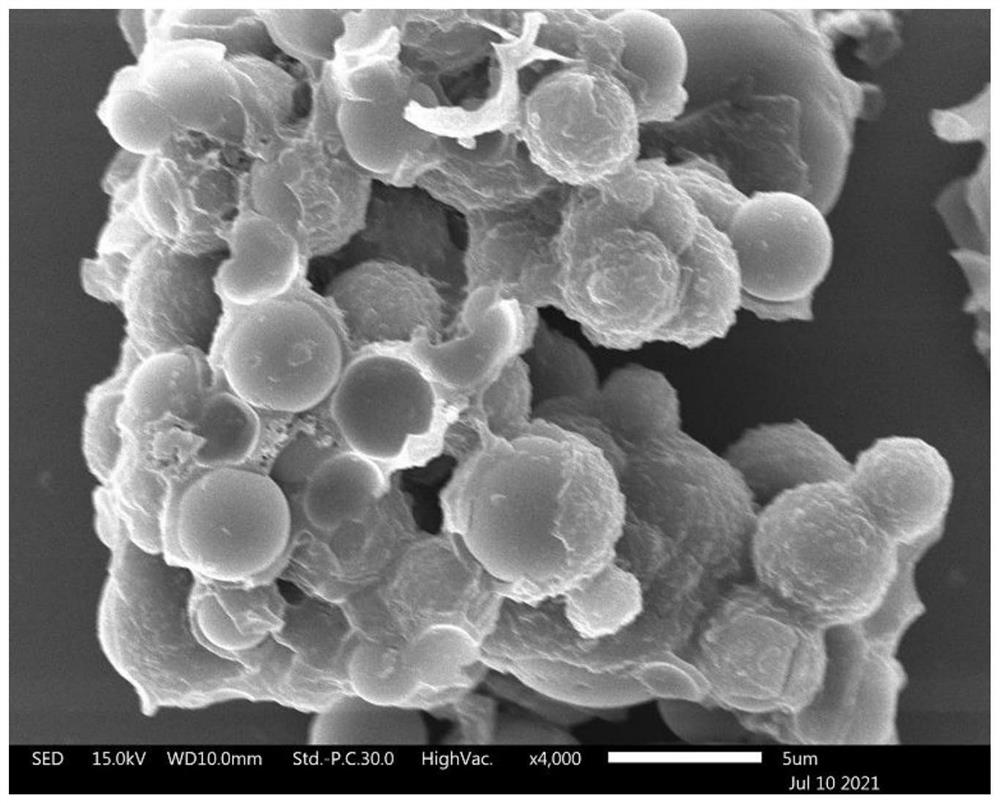

[0044] A method of preparing a silicone composite material, prepared by the following steps:

[0045] S1, carbon layer cover: The carbon source and silicon source are mixed in a certain proportion, and the carbon source is covered with the silicon source; that is, the SiO coated with a carbon layer 2 / C composite material;

[0046] The carbon layer is covered by a liquid phase method or a gas phase method, wherein the liquid phase includes the following steps:

[0047] a. Preparation of a carbon source solution having a concentration of 200 to 500 g / L (carbon source is sucrose, glucose, starch, citric acid, ascorbic acid one or several), the mass fraction of 0.045 to 0.075 is 98% Preparation of concentrated sulfuric acid;

[0048] b. Add a silicon source to the solution (commercial silica or natural mineral, such as kaolinite, diatomaceous earth, such as kaoli, diatomaceous earth, such as kaolinite, diatomaceous earth, such as kaolinite, diatomaceous) One or several composition...

Embodiment 1

[0059] Silicon source selection montmorillonite, carbon source selects sucrose, metal reducing agent to select aluminum powder;

[0060] S1 carbon layer cover:

[0061] a. Preparation of 200 g / l sucrose solution, concentrated sulfuric acid is added thereto in a volume ratio of 0.061;

[0062] b. Take a certain solution to add silicon sources to the obtained S1 solution in montmorillonite: sucrose mass ratio of 1: 1, stir for 2 h, heating in an oven to 100 ° C, heat insulation for 5 h, then continues to heat up to 160 ° C , Heat insulation 7h, natural cooling after cooling;

[0063] c. Take the amount of B in argon under argon under argon to heat up to 700 ° C, after holding up for 6 hours, obtain SiO 2 / C composite material;

[0064] S2 low temperature reduction: in a glove box (argon atmosphere), 1G SiO 2 / C, 0.6 g Al, 8 g of anhydrous aluminum chloride is loaded into the reactor, then placed in an oven, 250 ° C for 5 h, natural cooling to obtain product SiO x / C;

[0065] S3...

Embodiment 2

[0072] Silicon source selects kaolin, carbon source selects sucrose, metal reducing agent to select magnesium powder;

[0073] S1 carbon layer cover:

[0074] a. Preparation of 300 g / L of sucrose solutions, concentrated sulfuric acid is added thereto in a volume ratio of 0.051;

[0075] b. Take a certain solution, in kaolin: Citricate ratio is 1: 0.05 to the obtained S1 solution, after stirring for 4 h, heating to 110 ° C in an oven, heat insulation for 4 h, then continues to heat up to 165 ° C, Insulation for 6 h, naturally cooling after cooling;

[0076] c. Take the B-producing product by 8 ° C / min at a rate of 8 ° C / min under nitrogen protection to 900 ° C, after holding it for 5 h, obtain SiO 2 / C composite material;

[0077] S2 low temperature reduction: in a glove box (argon atmosphere), 1.4g SiO 2 / C, 0.7 g mg, 7 g of anhydrous aluminum chloride is placed in the reactor, then placed in an oven, 230 ° C for 7 h, natural cooling to obtain product SiO x / C;

[0078] S3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com