Medical titanium/magnesium composite material and preparation method thereof

A composite material and magnesium alloy technology, applied in the field of biological materials, can solve the problem of not being able to meet all the requirements of bone implantation, and achieve the effects of facilitating bone conduction, avoiding stress shielding, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

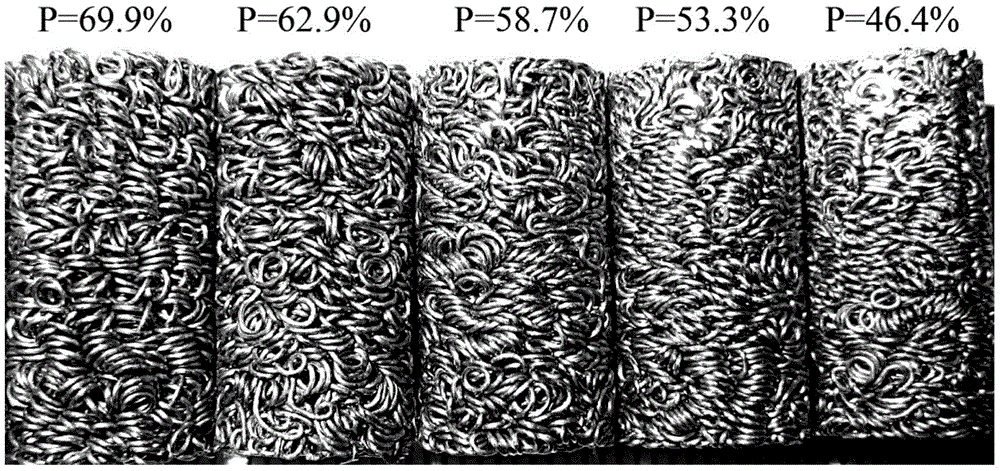

example 1

[0028] Using medical-grade medical titanium wire with a diameter of 0.005mm, a porous titanium skeleton with a set shape and porosity is prepared by a braiding machine, and the porosity is 90%. Then, the medical Mg- The RE alloy solution is injected into the pores of the porous titanium framework, and a composite material is formed after cooling; the compressive strength of this composite material is 400MPa, and its elastic modulus reaches 45GPa, which is suitable for bone repair occasions that require high bone.

example 2

[0030] Medical grade medical titanium alloy wire with a diameter of 3mm is used to prepare a porous titanium skeleton with a set shape and porosity by conventional winding, and its porosity is 20%. Through negative pressure suction casting technology, the medical Mg- The Ca alloy solution is injected into the pores of the porous titanium skeleton to form a composite material, and finally the micro-arc oxidation surface treatment is performed on the formed medical titanium / magnesium composite material; the compressive strength of the composite material is 50MPa, and the elastic modulus is 1GPa. It is conducive to osteogenesis and is suitable for bone repair occasions that require high bone.

example 3

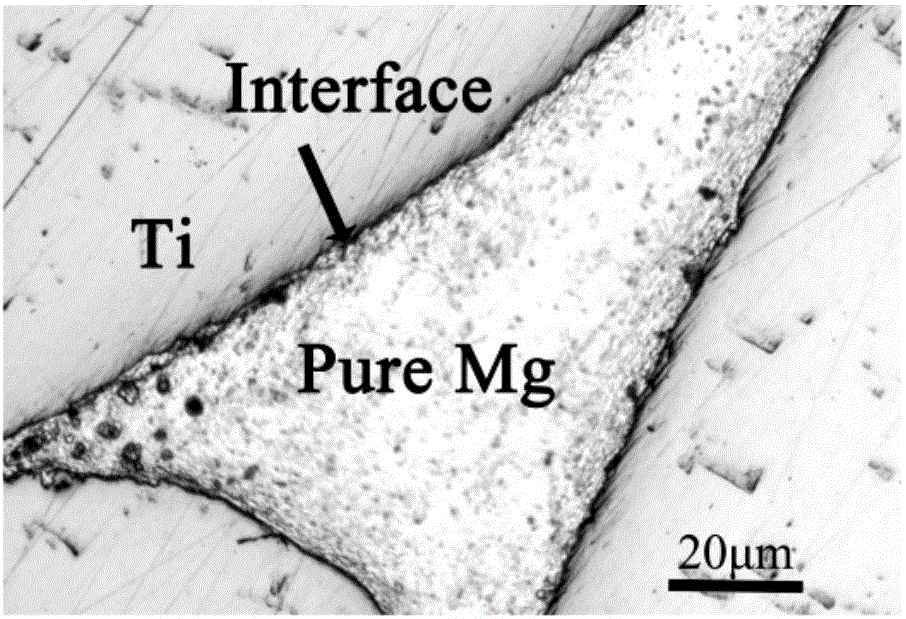

[0032] Using medical-grade medical titanium wire with a diameter of 0.27mm, a porous titanium skeleton with a set shape and porosity is prepared by a braiding machine, and the porosity is 63%; through pressureless infiltration technology, the medical-grade pure magnesium The metal solution is added with Ag and Sr elements and injected into the pores of the porous titanium skeleton to form a composite material. Finally, anodic oxidation surface treatment is performed on the formed medical titanium / magnesium composite material; the compressive strength of this composite material is 228MPa, and the elastic modulus The content is 9.22GPa, which is beneficial to the bactericidal effect and osteogenic effect, and is suitable for bone repair occasions with high bone requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive modulus of elasticity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com