Femoral head support frame and manufacturing method thereof

A manufacturing method and support frame technology, which is applied in the field of human implants, can solve the problems of high cost, physical processing of support frames, lack of uniformity of product pores, etc., and achieve the effect of high porosity, large pore diameter, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

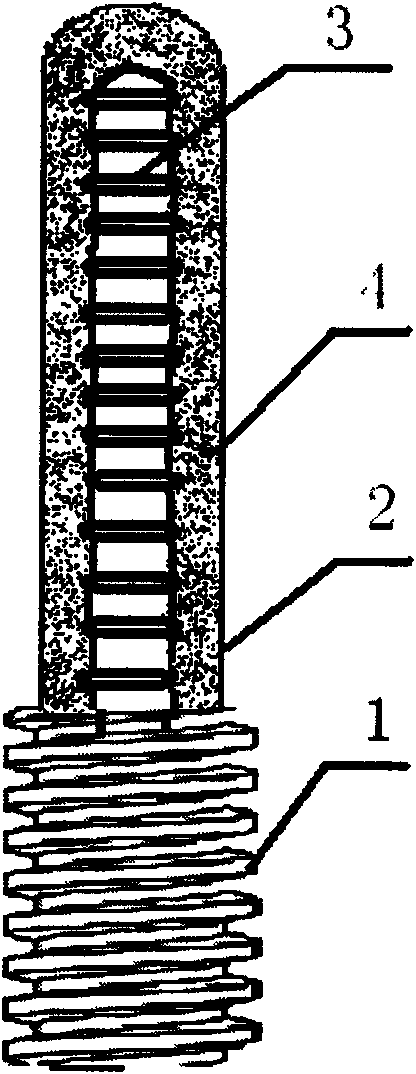

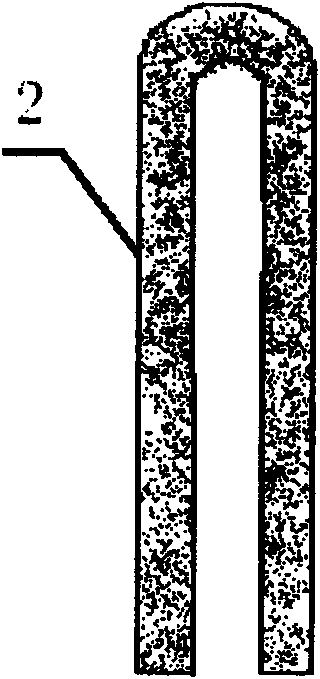

[0017] like figure 1 As shown, the overall shape of the femoral head support frame of the present invention is cylindrical, and is divided into a body part 4 and a tail part 1 . The body part 4 is composed of a stem 3 located on the central axis and a hemispherical cylindrical shell 2 on the outer periphery of the stem 3; the tail part 1 of the support frame is a cylinder provided with external threads. The core column 3 of the support frame body and the support frame tail 1 are made of solid metal, and the hemispherical cylindrical shell 2 of the support frame body 4 is made of porous metal.

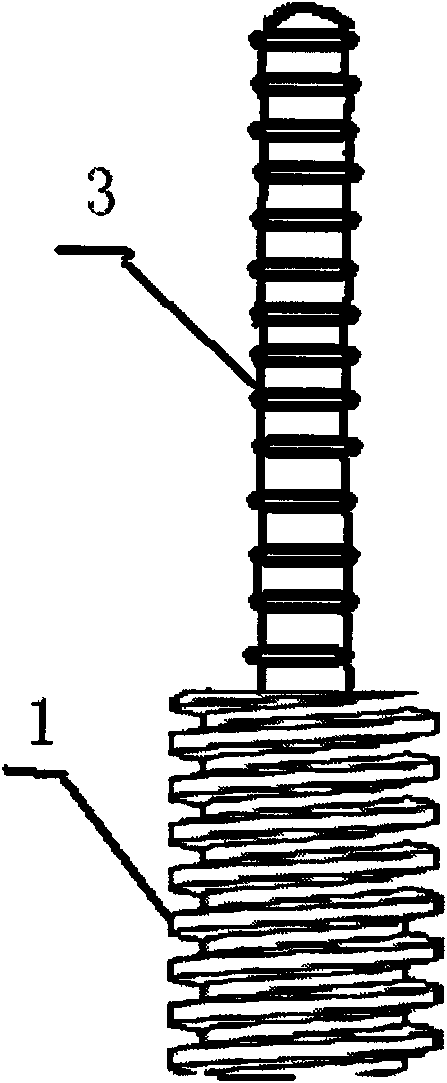

[0018] Figure 2A and Figure 2B Shown is an embodiment of the fabrication and assembly of the composite structure femoral head support frame of the present invention:

[0019] Using solid metal materials, using mechanical processing methods such as Figure 2A The stem 3 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com