Tube bending forming processing device

A technology of bending forming and processing equipment, applied in the field of material processing, can solve the problems of increasing the cost of mold design, new product production cycle, deformation process and degree, and can not alleviate the thinning of the pipe wall, so as to aggravate inner wall wrinkling and outer wall collapse The resultant force is reduced and the effect of improving the metal flow condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

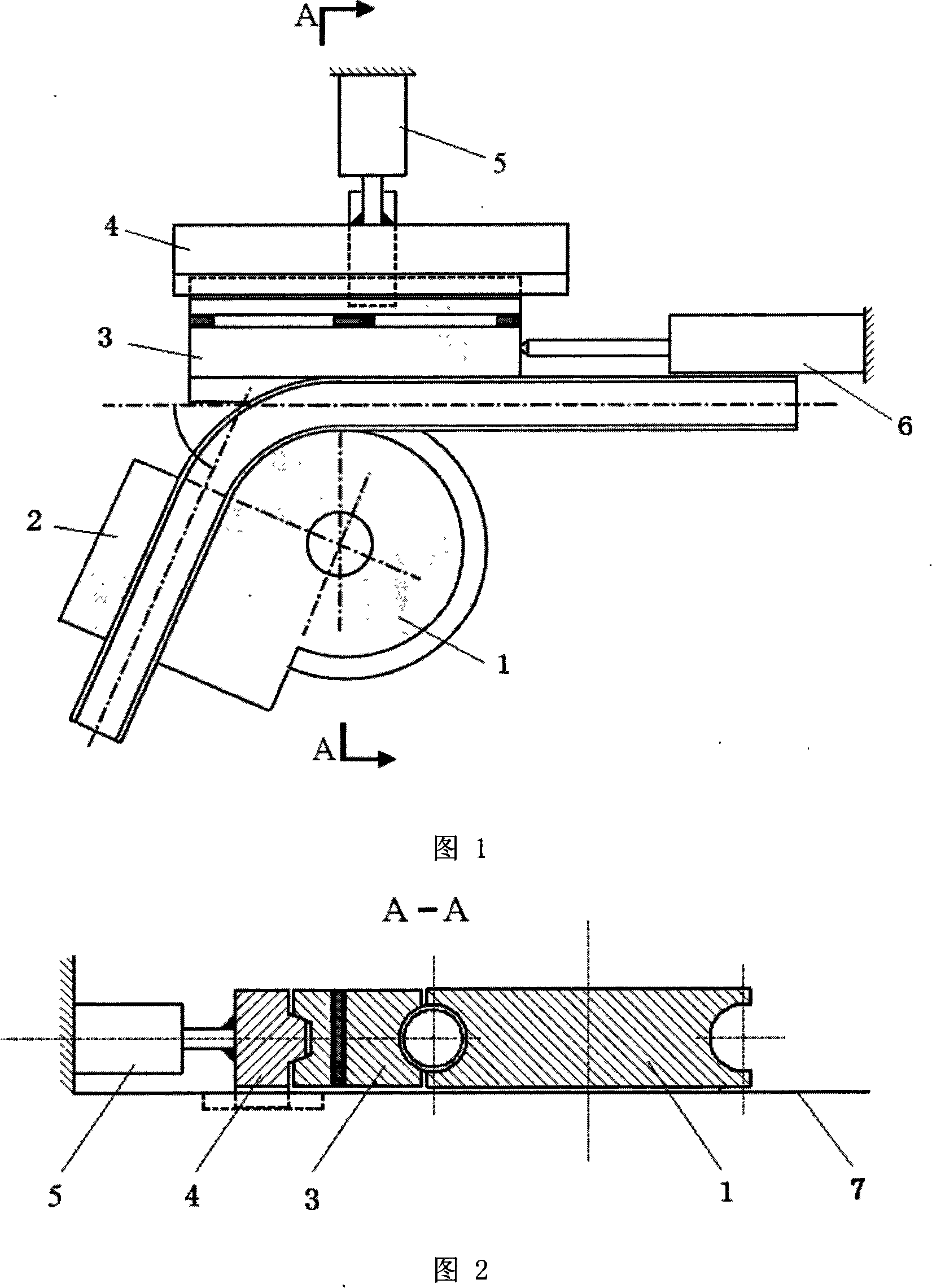

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

[0020] As shown in FIG. 1 , this embodiment includes: a bending die 1 , a clamping die 2 , a pressing die 3 , a booster plate 4 , a circumferential pressure hydraulic cylinder 5 , an axial propulsion hydraulic cylinder 6 and a bending machine table 7 . The bending die 1 is fixed on the bending machine table 7 through the bending center. The bending die 1, the pressing die 3 and the clamping die 2 are all provided with grooves matching the outer diameter of the pipe. The push rod of the circumferentially pressurized hydraulic cylinder 5 is rigidly connected with the booster plate 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com