Preparation method by employing double-face coated jacketing plates to roll foil

A double-bread and foil technology, applied in the field of pressure processing, can solve the problems that rolling equipment cannot meet large-scale and large-volume production, and achieve the effect of facilitating machinability, improving machinability, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

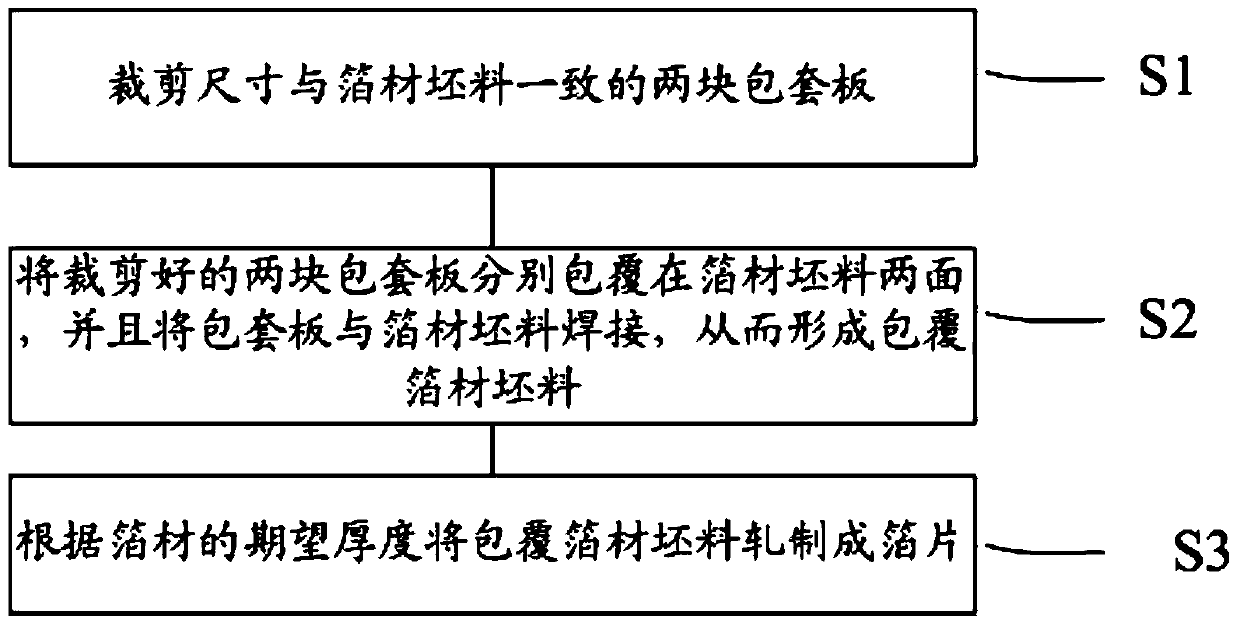

[0020] Specifically, as figure 1 As shown, the method for preparing rolled foil using a double-sided cladding plate according to a preferred embodiment of the present invention comprises:

[0021] The first step S1 is to cut two wrapping plates whose size is consistent with that of the foil blank; for example, the thickness of the foil blank is 1-0.05 mm; preferably, the thickness of the wrapping plate is 1.0-2.0 mm.

[0022] Preferably, the material of the foil blank is tungsten-nickel-iron, tungsten-nickel-copper, tungsten-copper, molybdenum-copper, pure molybdenum, pure tungsten and other materials. For example, the foil stock can also be a copper alloy stock.

[0023] Preferably, the cladding plate is an economical plate with good welding performance, such as iron plate, copper plate, aluminum plate, stainless steel plate, etc. For example, the cladding plate is a cladding iron plate.

[0024] In the second step S2, the two cut-out wrapping plates are respectively wrapp...

Embodiment 1

[0030] The 85Mo-Cu composite material with a size of 0.1mm*149*150 is double-sided coated with a sheathed iron plate. The thickness of the sheathed iron plate is 1.5mm. It is 1000r / min, the pressure is within 30t, and the pass reduction is 0.002-0.005mm. When the length is extended to 600mm, stop rolling. According to the principle of constant volume, the thickness of molybdenum-copper is 0.025mm at this time. The actual measured thickness is 0.024mm, and the thickness tolerance is within ±0.002mm. The surface of the style is smooth, without waves and cracks.

Embodiment 2

[0032] Cover the iron plate with pure Mo with a size of 0.05*175*192mm, the thickness of the iron plate is 2mm, and wrap it on a two-roll rolling mill. The diameter of the roll is 300mm, the speed of the roll is 1500r / min, and the pressure is Within 30t, the pass reduction is 0.002-0.005mm. When the length is extended to 385mm, stop rolling. According to the principle of constant volume, the thickness of molybdenum-copper should be 0.025mm at this time. The actual measured thickness is 0.026mm, and the thickness tolerance is within ±0.002mm. The surface of the style is smooth, without waves and cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com