Method for manufacturing high pressure processed food products

a technology of high-pressure processing and food products, which is applied in the field of high-pressure processing of food products, can solve the problems of short shelf life of perishable products, high energy costs associated with freezing and freezing storage, taste and texture, etc., and achieves the effect of high hydrostatic pressure processing and extended shelf li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

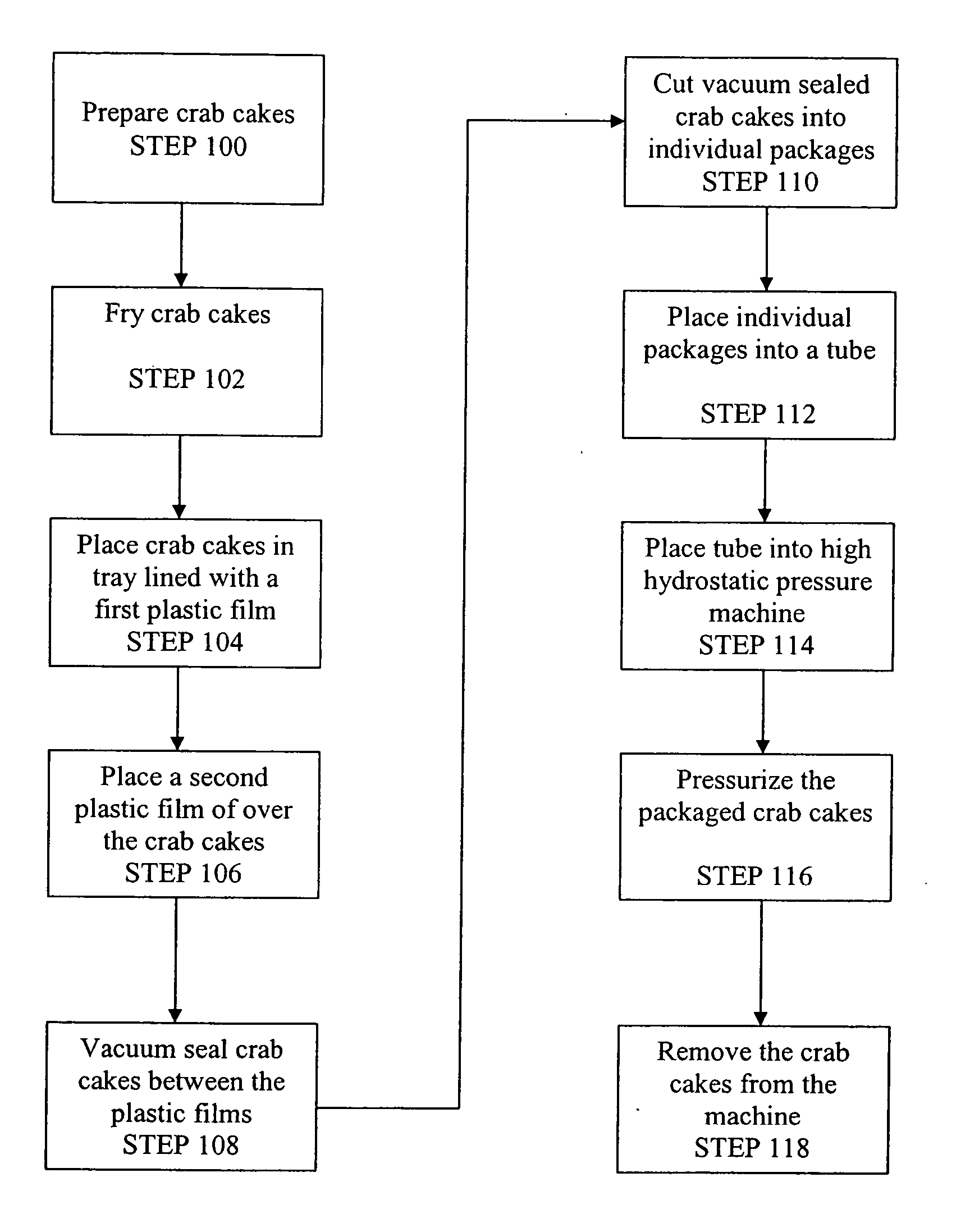

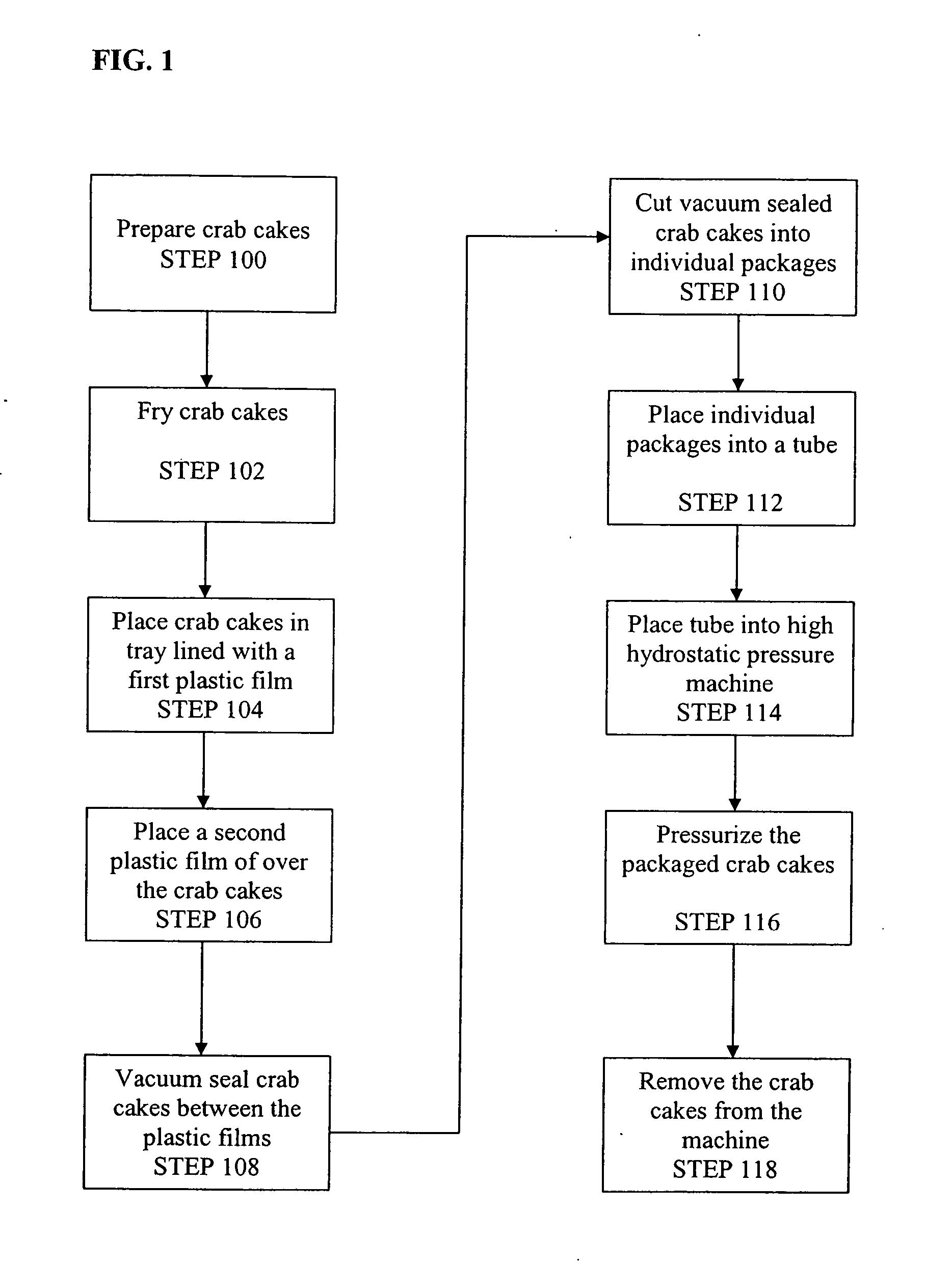

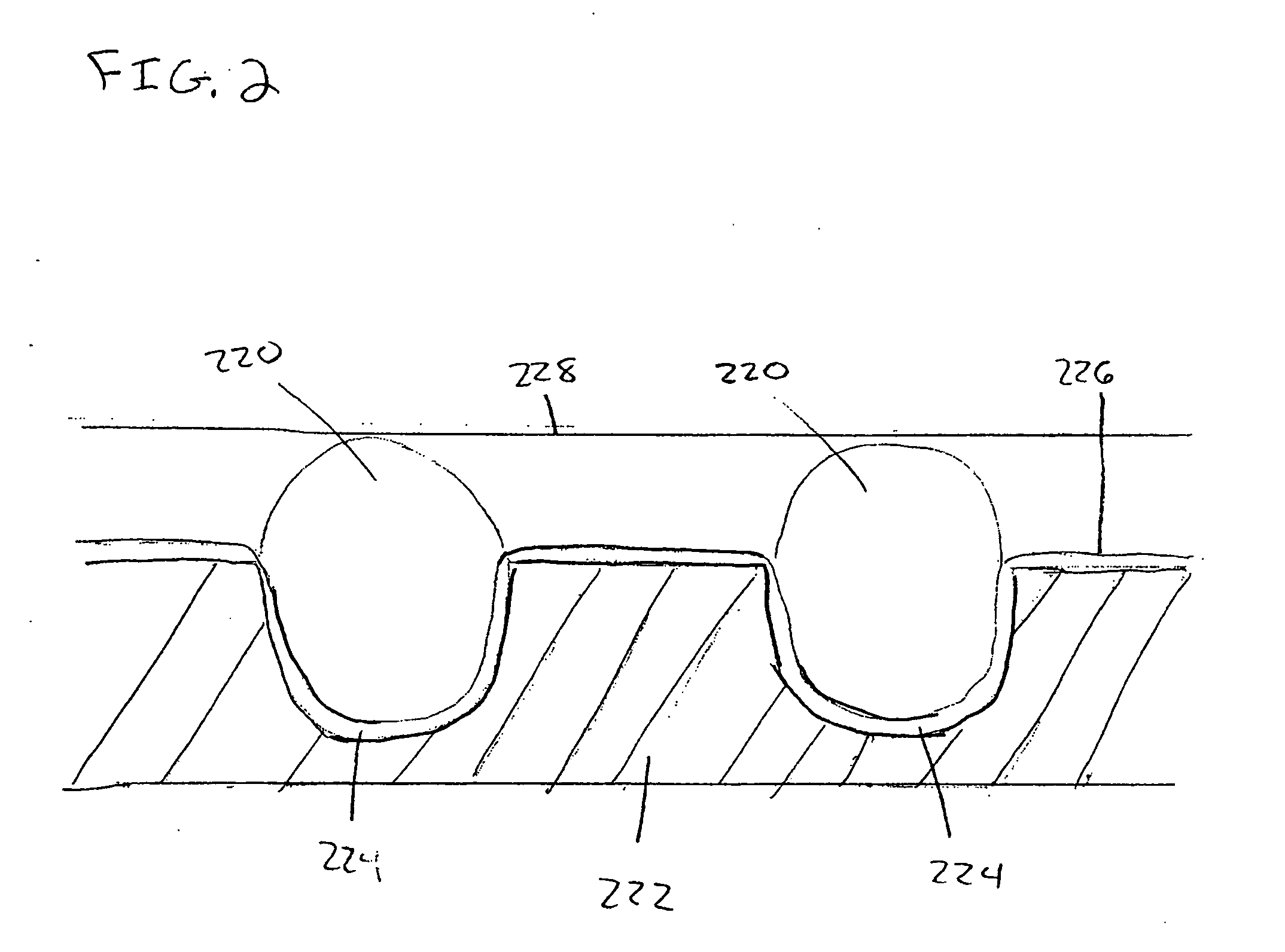

[0029]FIGS. 1, 2, 3A and 3B describe a process for preparing seafood cakes, such as crab cakes. The crab cakes 220 are prepared (STEP 100) and are then pan fried for approximately 3 minutes at approximately 350° F. (STEP 102). A tray 222 is provided with a plurality of cavities 224. The tray 222 may be pre-formed or formed in-line. While pan frying is utilized in this example, the crab cake may be prepared through other methods, for example, such as by broiling or baking. A first plastic film 226 is placed over the tray 222 and each of the cavities 224 is filled with a prepared crab cake 220 (STEP 104). The first plastic film 226 is preferably a 3 to 12 mil durable plastic, more preferably a 10 ml durable plastic, and functions as the top surface 332 of the ultimate vacuum sealed package 330. A second plastic film 228 is placed over the crab cakes 220 (STEP 106). The second plastic film 228 can be either a perforated durable plastic, of preferably 10 mil, or an oxygen permeable film...

example 2

[0031] A salmon steak is steamed for 5 minutes at 165° F. and then vacuum sealed in a oxygen permeable plastic film with an oxygen transmission rate greater than 10,000 cc / m2 / 24 hrs. The vacuum sealing process involved pulling a vacuum for 3 seconds and then sealing for 3 seconds. Afterwards, the packaged salmon steak was loaded into a pressure vessel for HPP. The water was pressurized to 45,000 psi for approximately 3 minutes.

example 3

[0032] A cut of tenderloin was seared and then sauteed for 3 minutes on each side such that the core temperature of the tenderloin was 45° F. The tenderloin was then vacuum sealed between two barrier films by applying vacuum for 5 seconds and HPP was performed for 180 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com