Bending mechanism for reinforcing steel bar truss web rib

A technology of steel truss and abdominal reinforcement, applied in the direction of online network, other household appliances, household appliances, etc., can solve the problems of affecting the next process, uneven abdominal reinforcement, low efficiency, etc., to improve bending quality, high degree of automation, installation and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

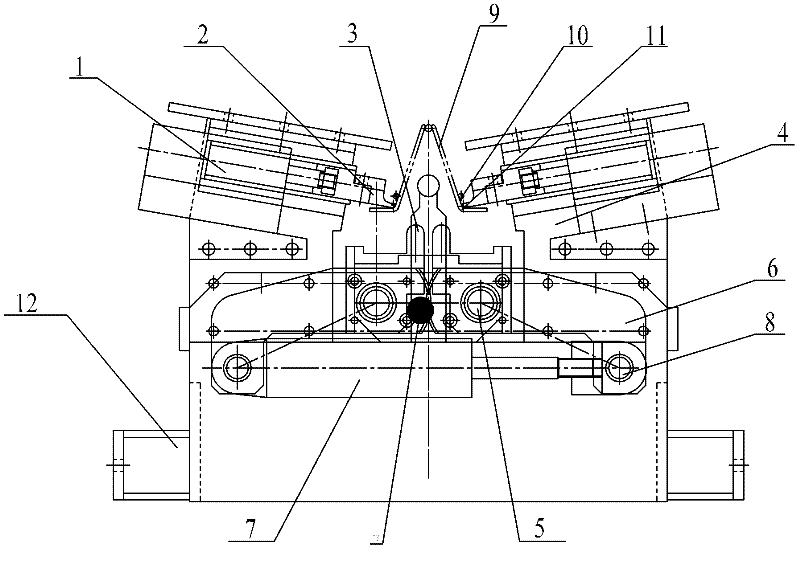

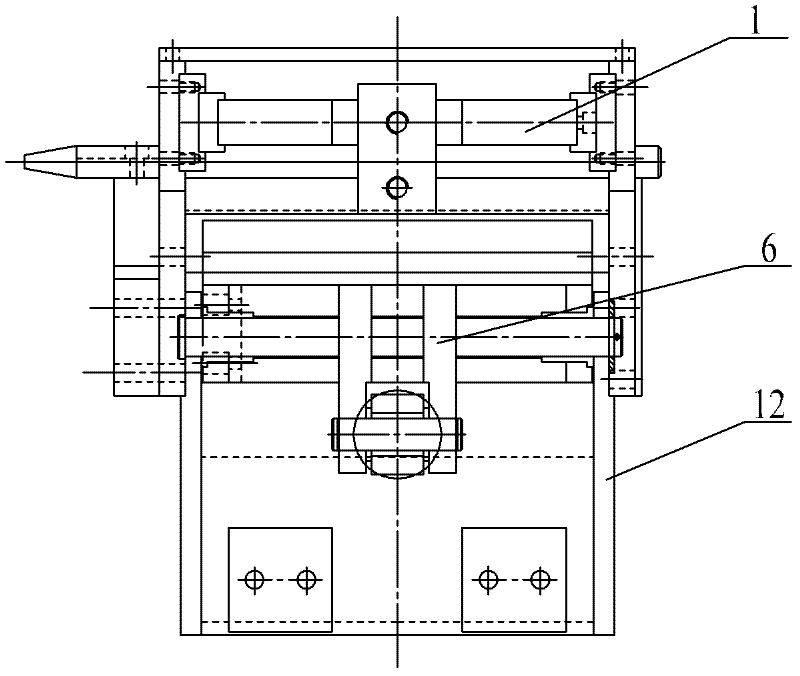

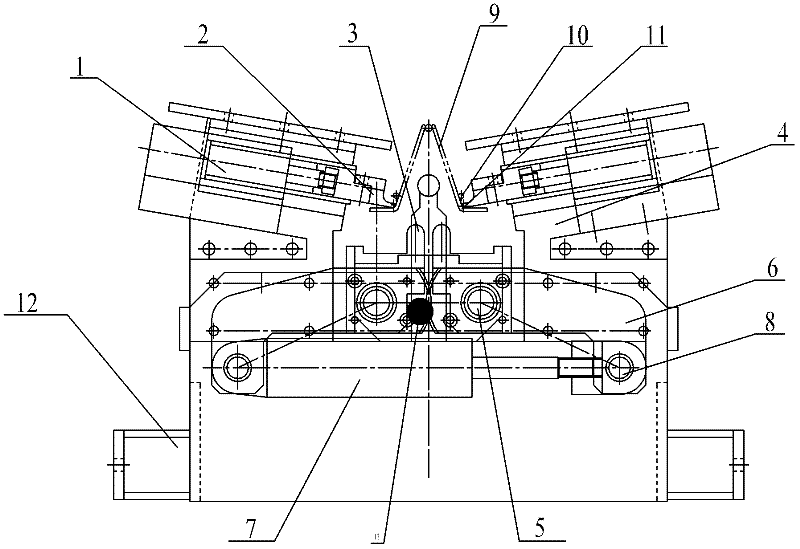

[0011] Such as Figure 1~Figure 2 Shown: the present invention comprises support oil cylinder 1, support block 2, rotating block 3, support oil cylinder mounting bracket 4, rotating shaft 5, rotating block mounting bracket 6, rotating oil cylinder 7, support mounting shaft 8, steel bar truss 9, lower chord bar 10, Bending 11, frame 12 and synchronous gear 13.

[0012] Such as figure 1 and figure 2 As shown: the frame 12 is provided with symmetrically distributed support cylinder installation brackets 4 , and the support cylinder installation brackets 4 protrude from the frame 12 . The supporting oil cylinder mounting bracket 4 is provided with a supporting oil cylinder 1, and the piston rod of the supporting oil cylinder 1 is provided with a fixedly connected supporting block 2, and the supporting oil cylinder 1 and the supporting block 2 symmetrically dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com