Plate bending device for computer mainframe box production

A technology of bending device and main box, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as increased defective rate, rounded corners that cannot meet production requirements, plate cracks, etc., and achieve good bending quality , Convenient bending processing, reducing the effect of bending difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

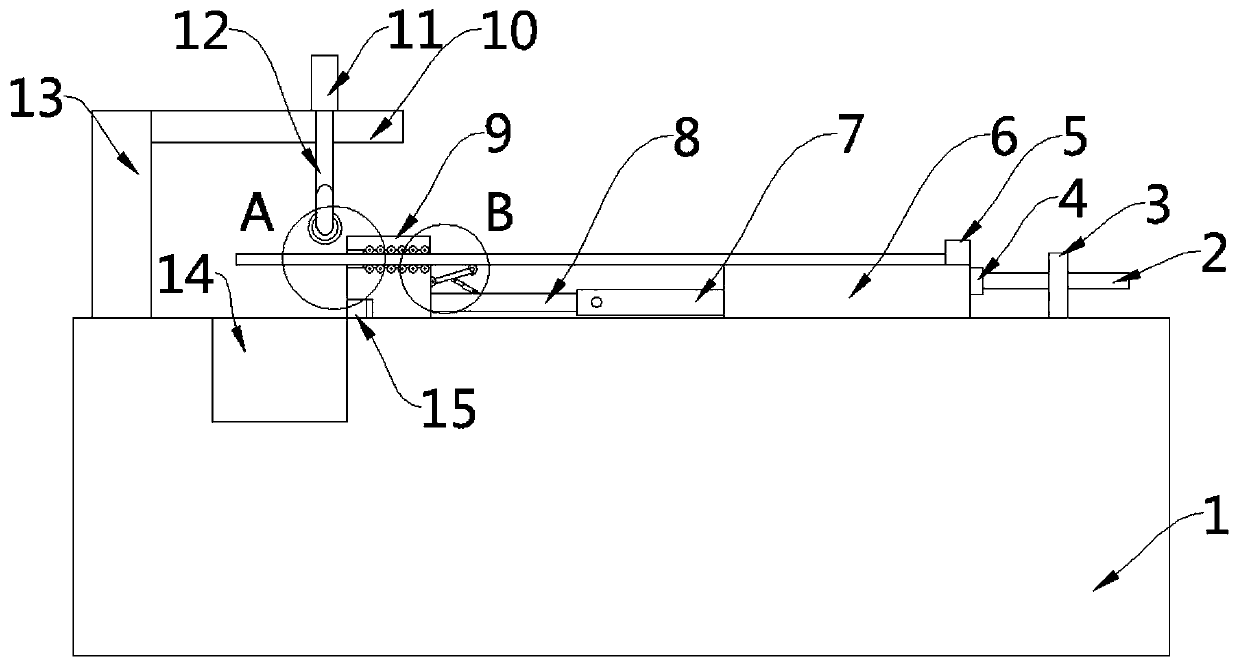

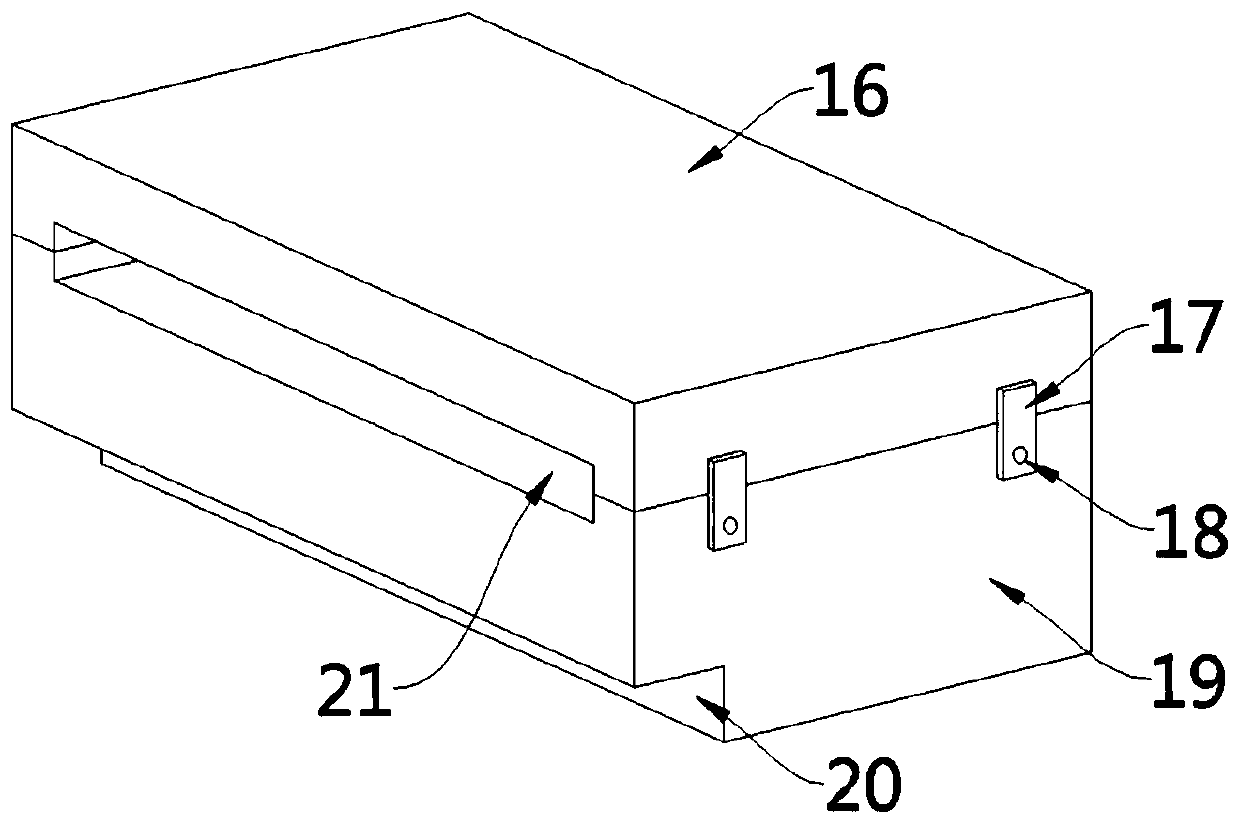

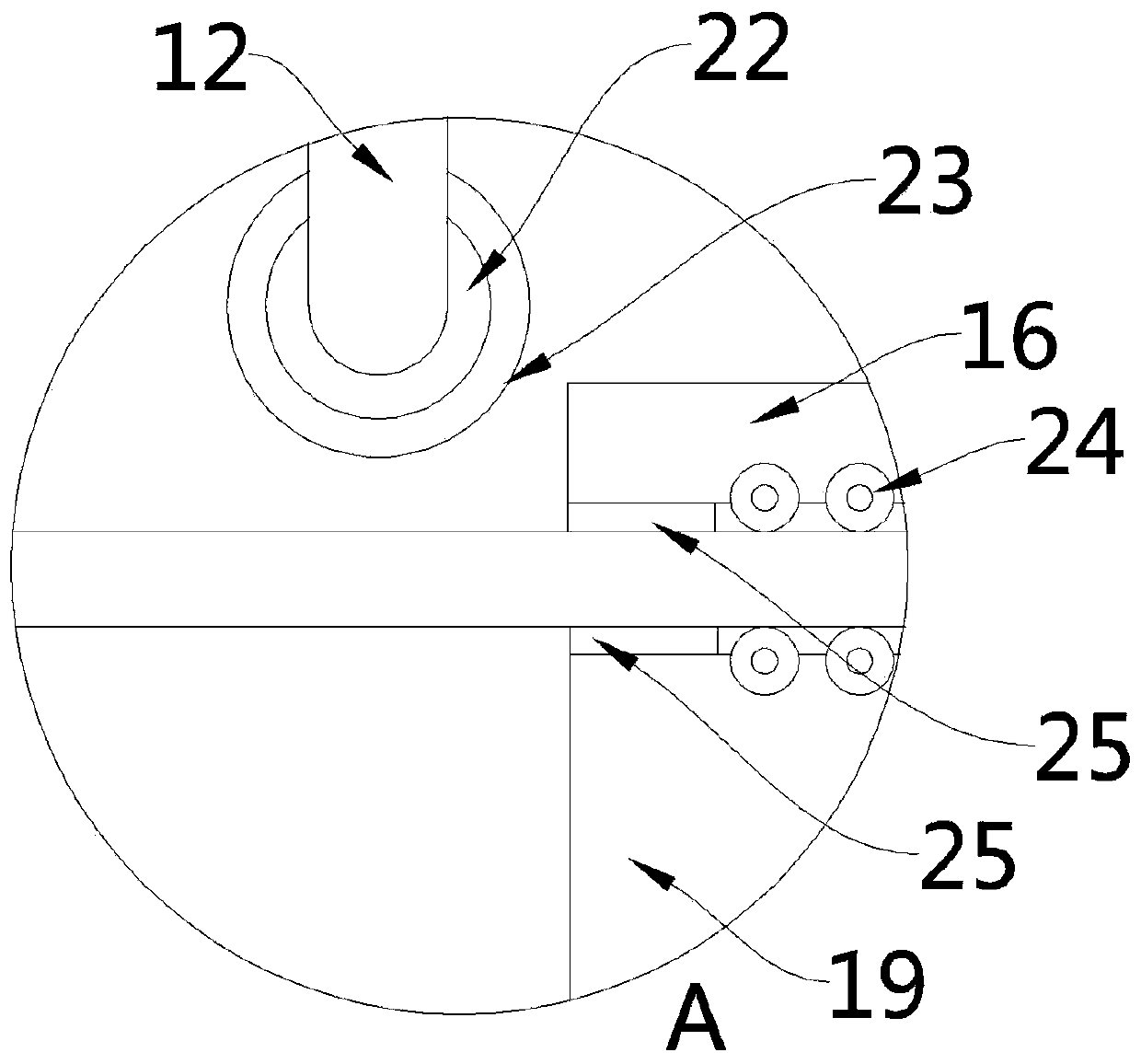

[0027] see Figure 1-4 , this embodiment provides a plate bending device for computer main case production, including a bottom box 1, a support platform 6 is slidably arranged on the upper part of the bottom box 1, and one side of the support platform 6 is connected with a pressing device through an adjustment assembly. Assembly 9, a bending assembly is arranged above the pressing assembly 9, specifically, the pressing assembly 9 includes a base 19 and a cover 16 hinged on the upper part of the base 19, the cover 16 and the base 19 The two sides are also connected by locking components. The side of the cover body 16 facing the base body 19 and the side of the base body 19 facing the cover body 16 are provided with corresponding card slots 21, and the upper and lower sides of the card slots 21 are rotated. There are a number of rotating rods 24, a heating plate 25 is provided at the end of the card slot 21 away from the support platform 6, and a swing rod 26 is installed on the...

Embodiment 2

[0046] see figure 1 , a plate bending device for computer mainframe production. Compared with Embodiment 1, the upper part of the bottom box 1 is provided with a groove 14 corresponding to the bending assembly. Through the setting of the groove 14, the The sheets bent by the bending assembly are accommodated, so that the bending assembly is convenient for bending sheets of different sizes.

[0047] The embodiment of the present invention has the advantage of good bending quality. By setting the heating plate 25, the bending part of the plate can be heated to soften the plate, so that the bending process of the plate by the bending assembly is more convenient, and the bending of the plate is improved. The bending quality reduces the bending difficulty of the plate, and effectively avoids the problem of breaking when the plate is cold bent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com