Patents

Literature

35results about How to "Reduce bending difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

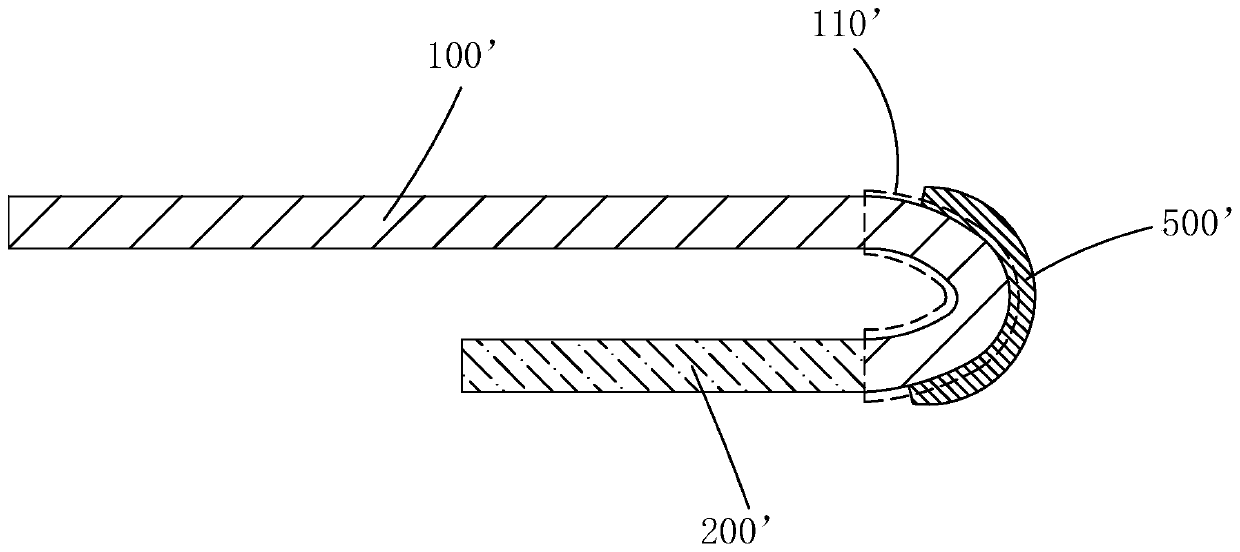

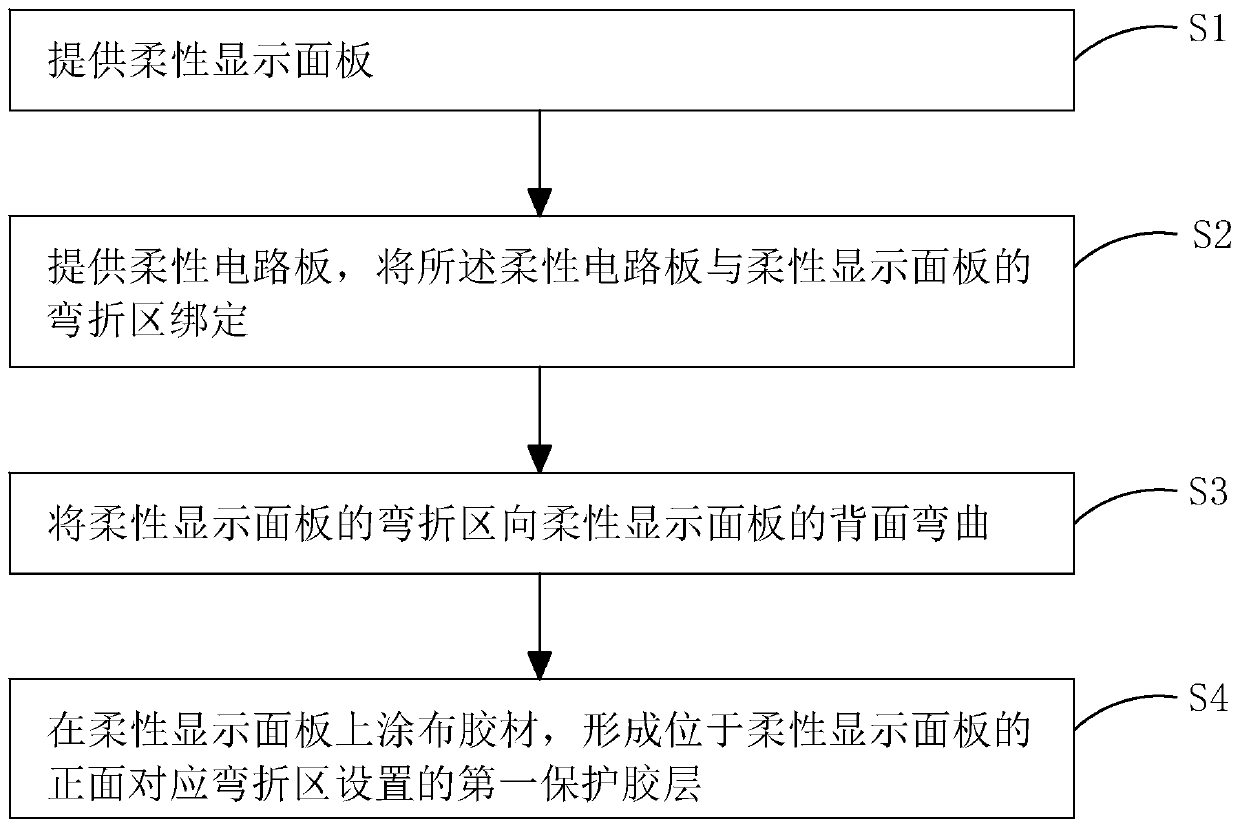

Flexible display device and production method thereof

ActiveCN108281387AReduce difficultyIncrease the difficultyFinal product manufactureSemiconductor/solid-state device detailsFlexible circuitsEngineering

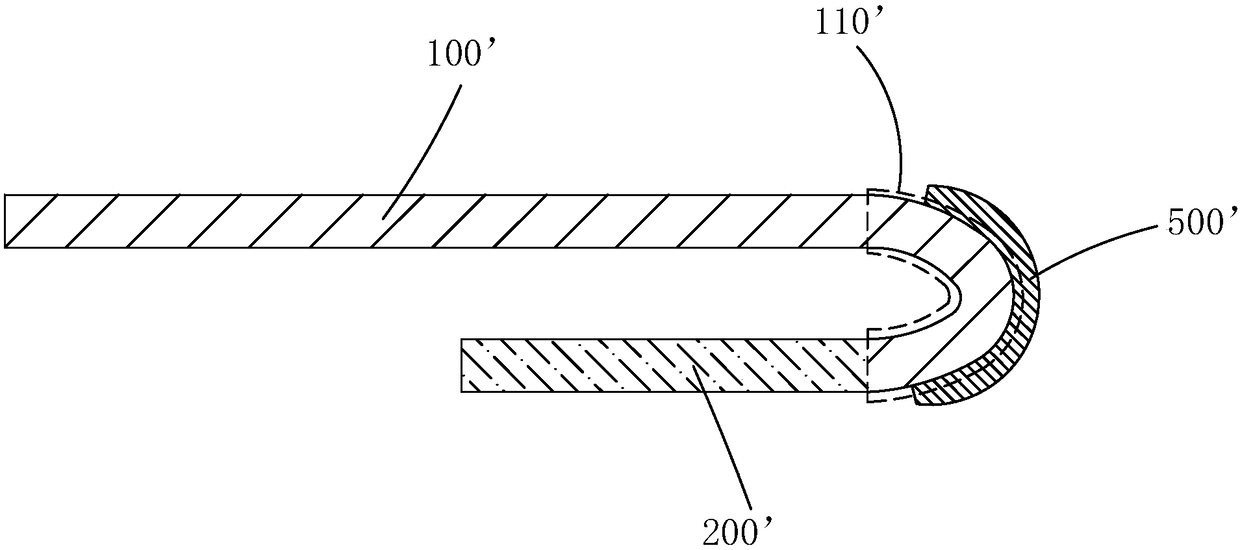

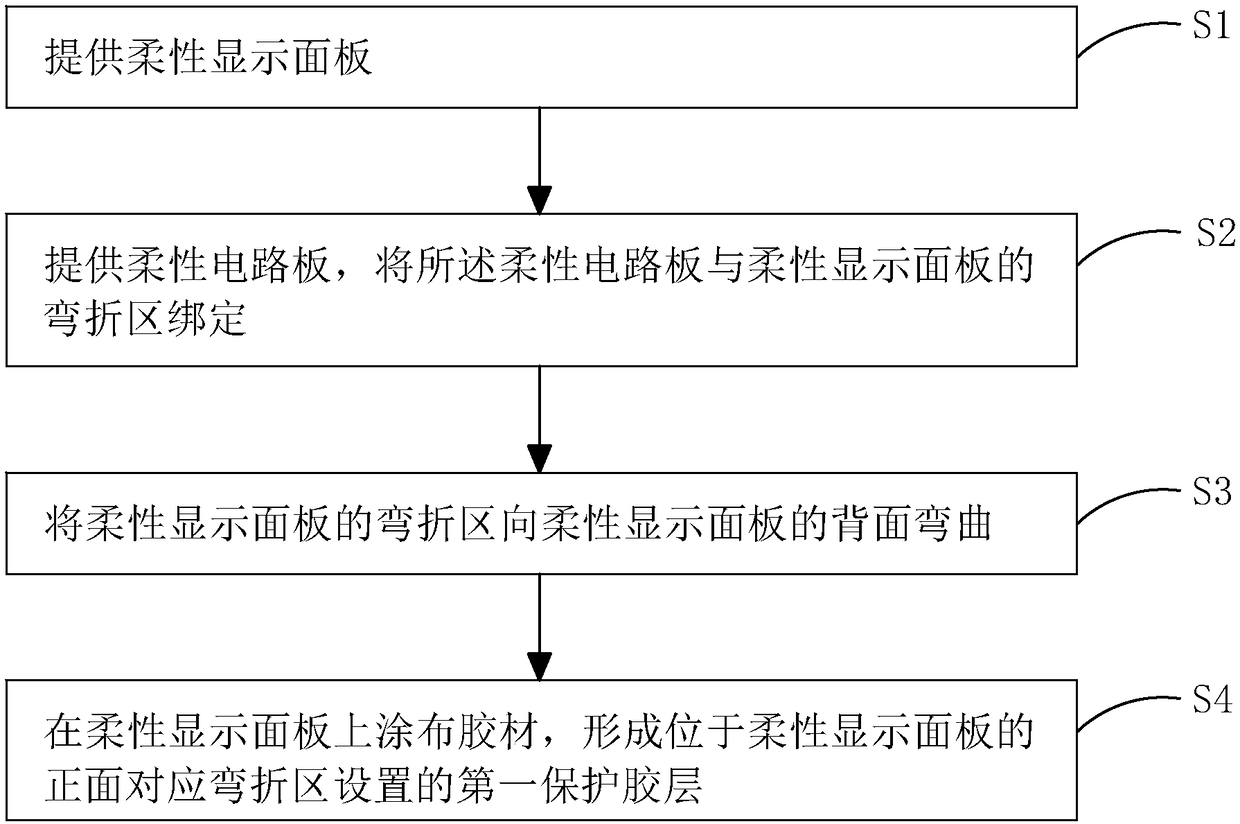

The invention provides a flexible display device and a production method thereof. The production method of the flexible display device includes: firstly, binding the bending area of a flexible displaypanel to a flexible circuit board; secondly, bending the bending area of the flexible display panel to the reverse of the flexible display panel; then making a first protective rubber layer on the front of the flexible display panel corresponding to the setting of the bending area. Compared with the prior art, the flexible display device and the production method thereof have the advantages thatrouting in the bending area is protected by the aid of the first protective rubber layer, difficulty in bending the bending area of the flexible display panel is lowered after the first protective rubber layer is bent on the bending area, the stress on the bending area of the flexible display panel is reduced in bending, and product quality is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

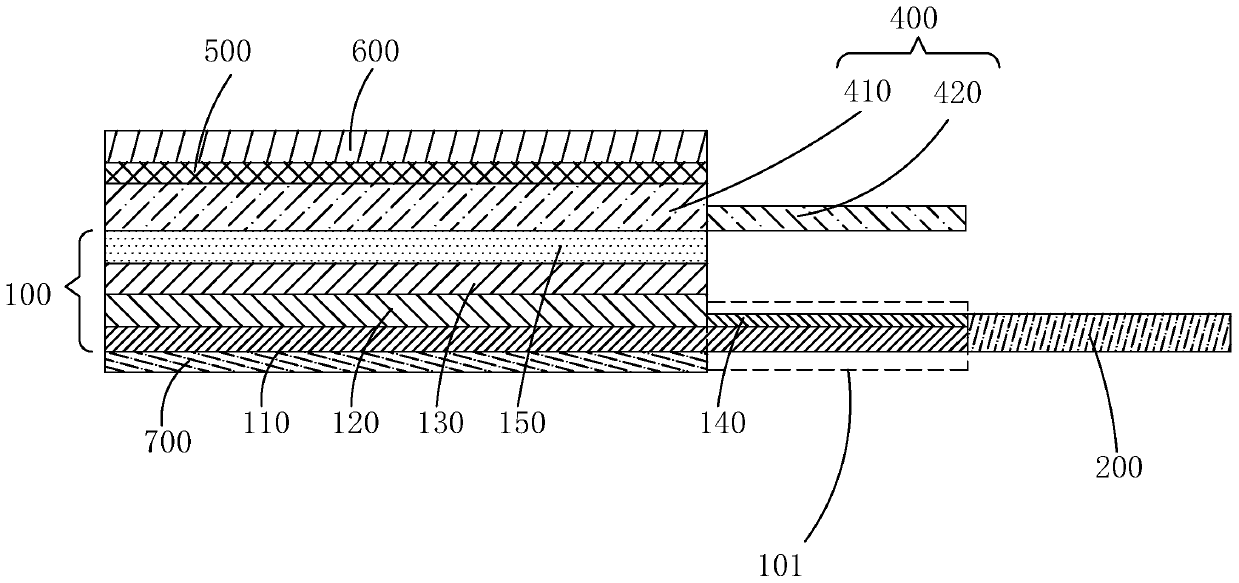

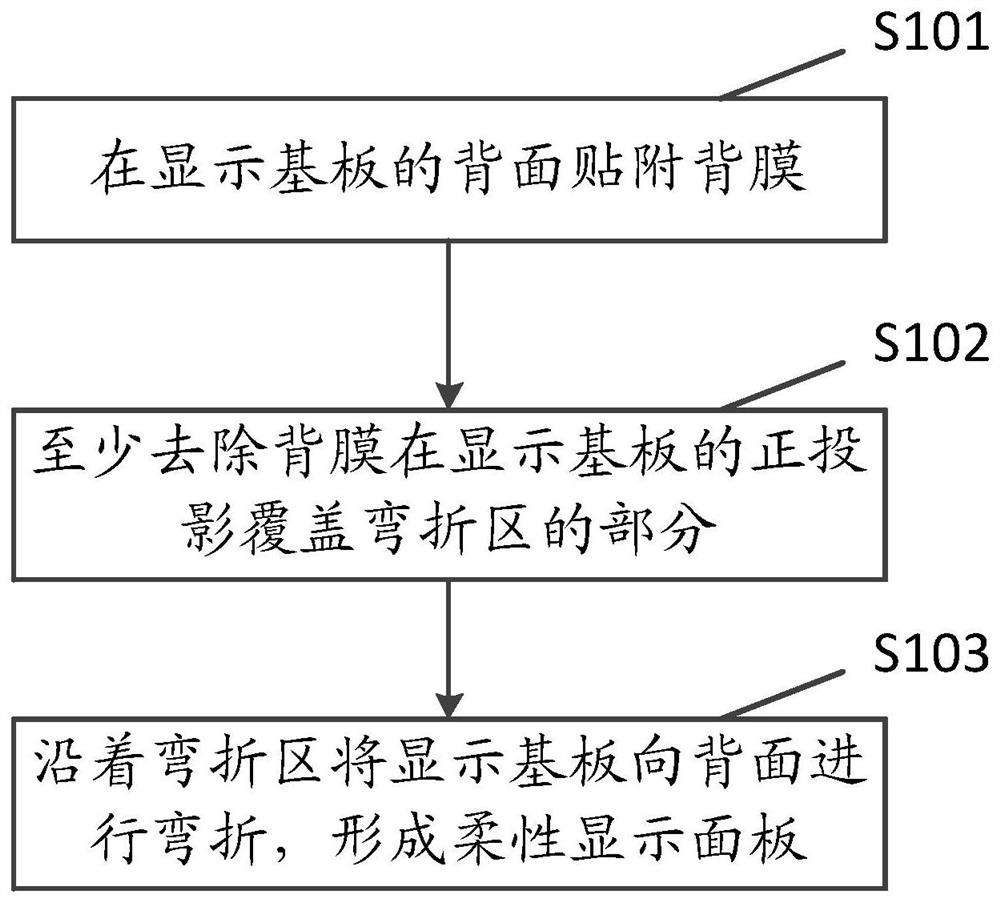

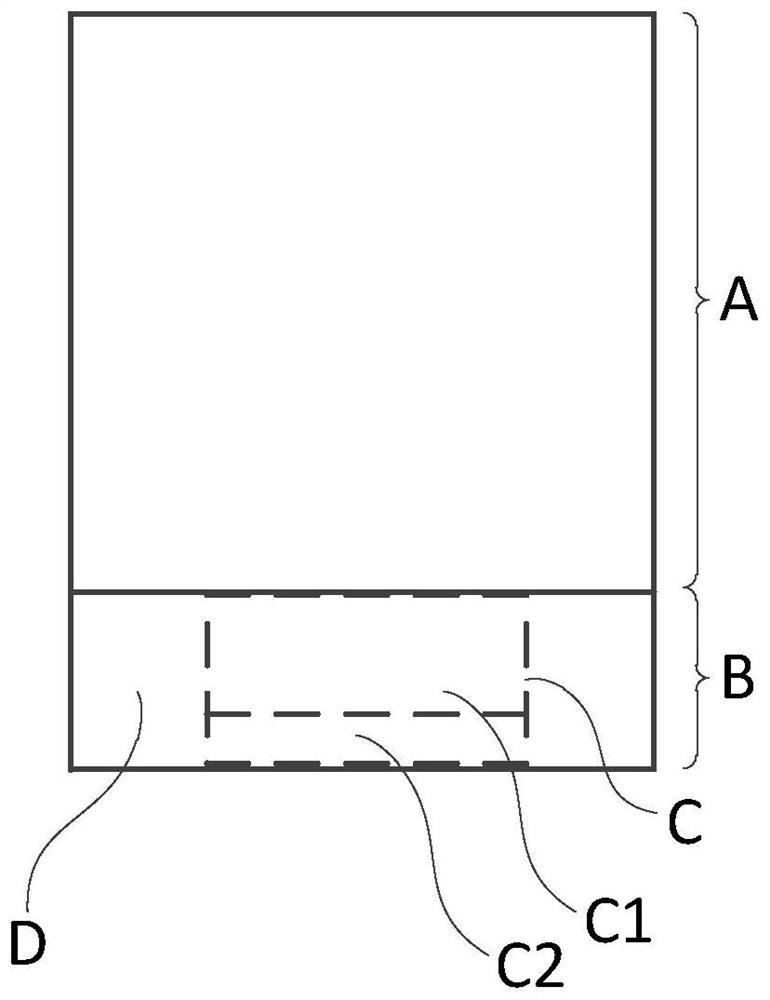

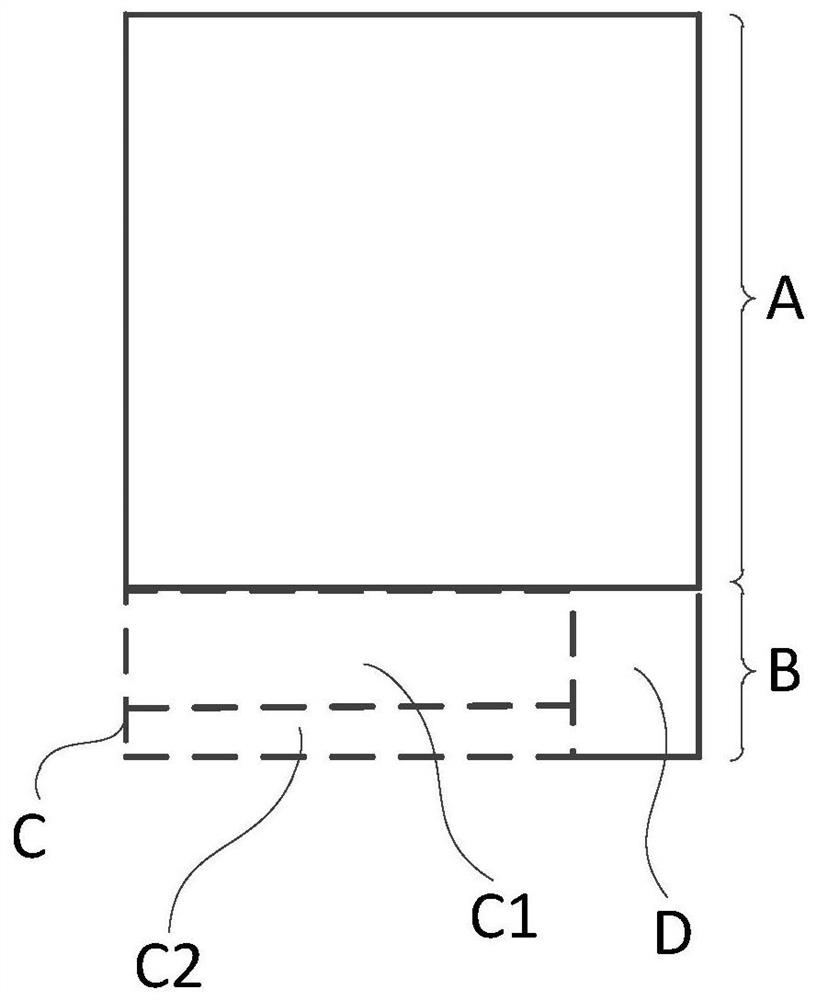

Flexible display panel manufacturing method, flexible display panel and display device

ActiveCN109215511AReduce bending difficultyReduce stressMechanical working/deformationLamination ancillary operationsDisplay deviceFlexible display

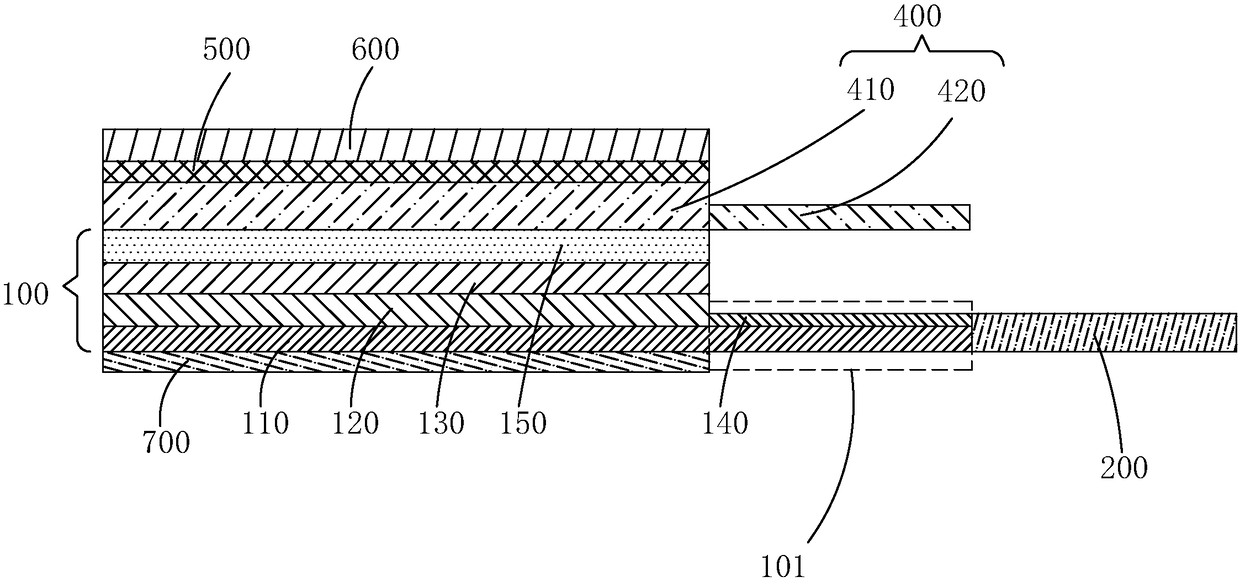

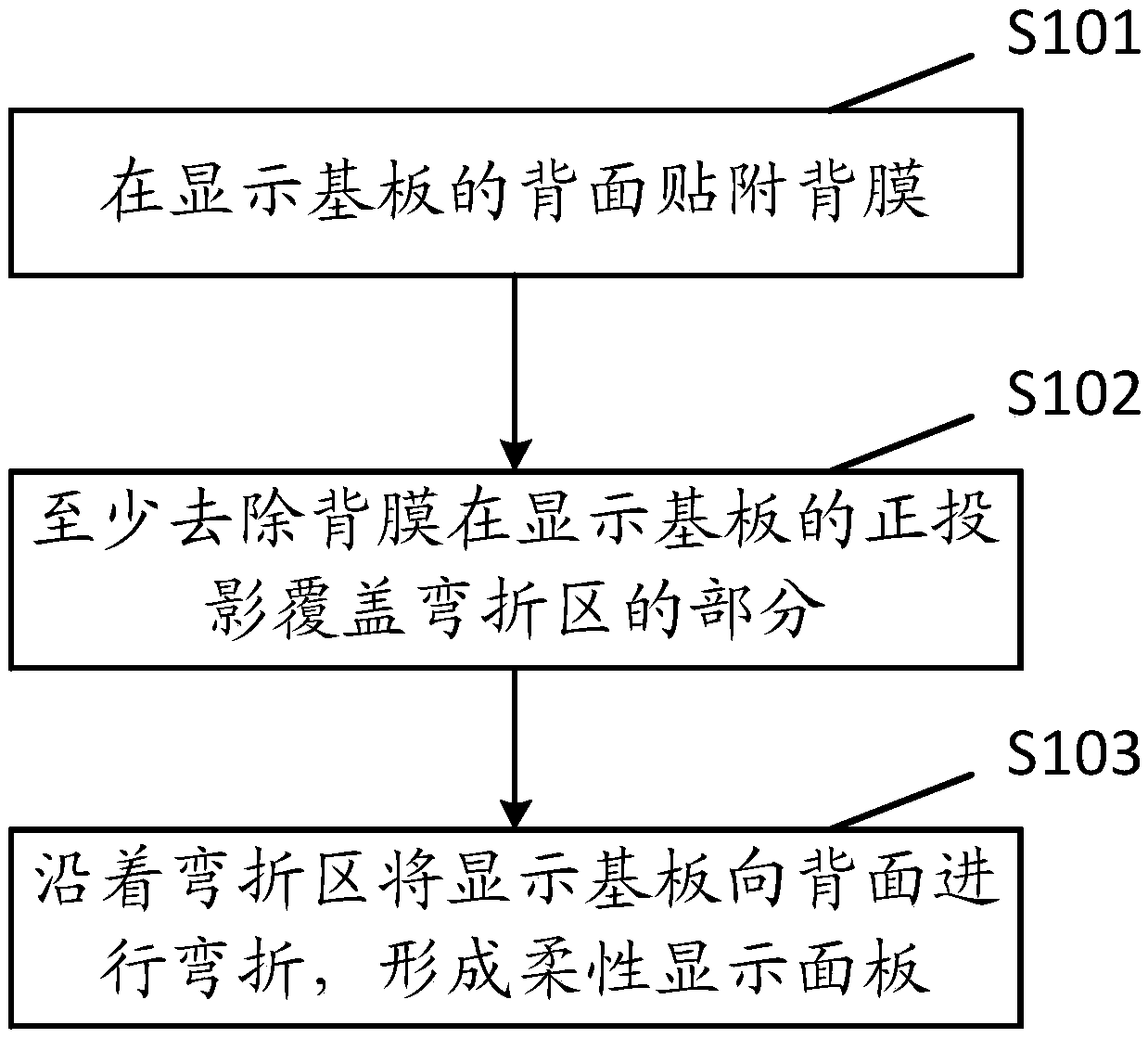

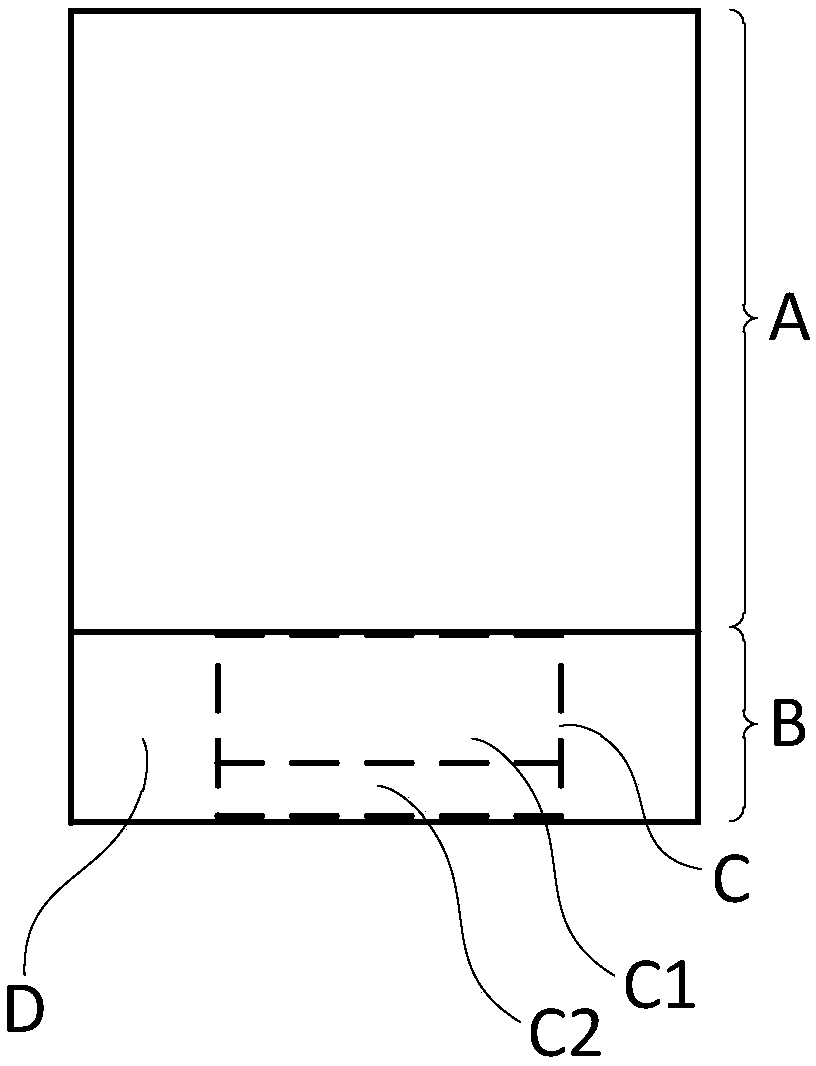

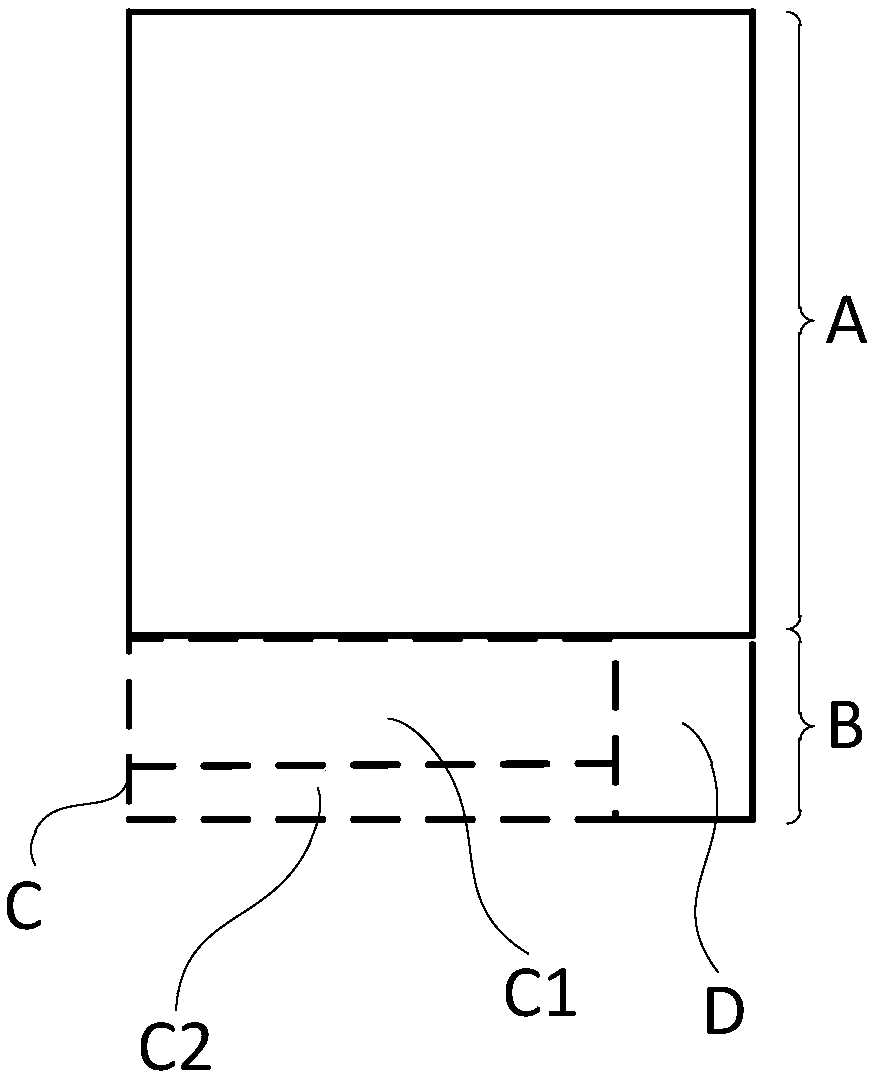

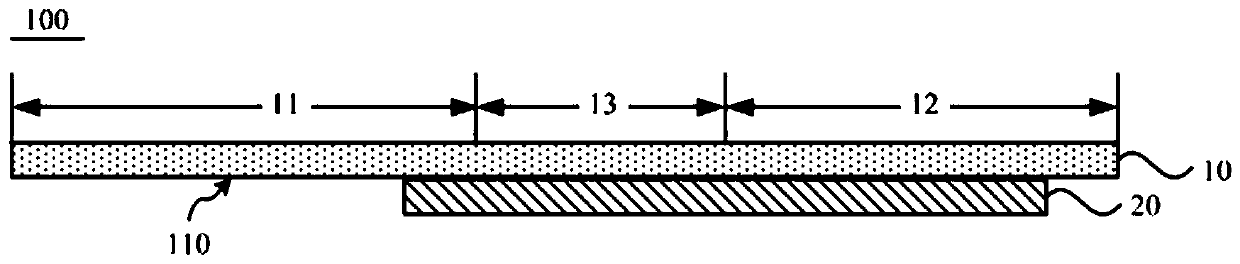

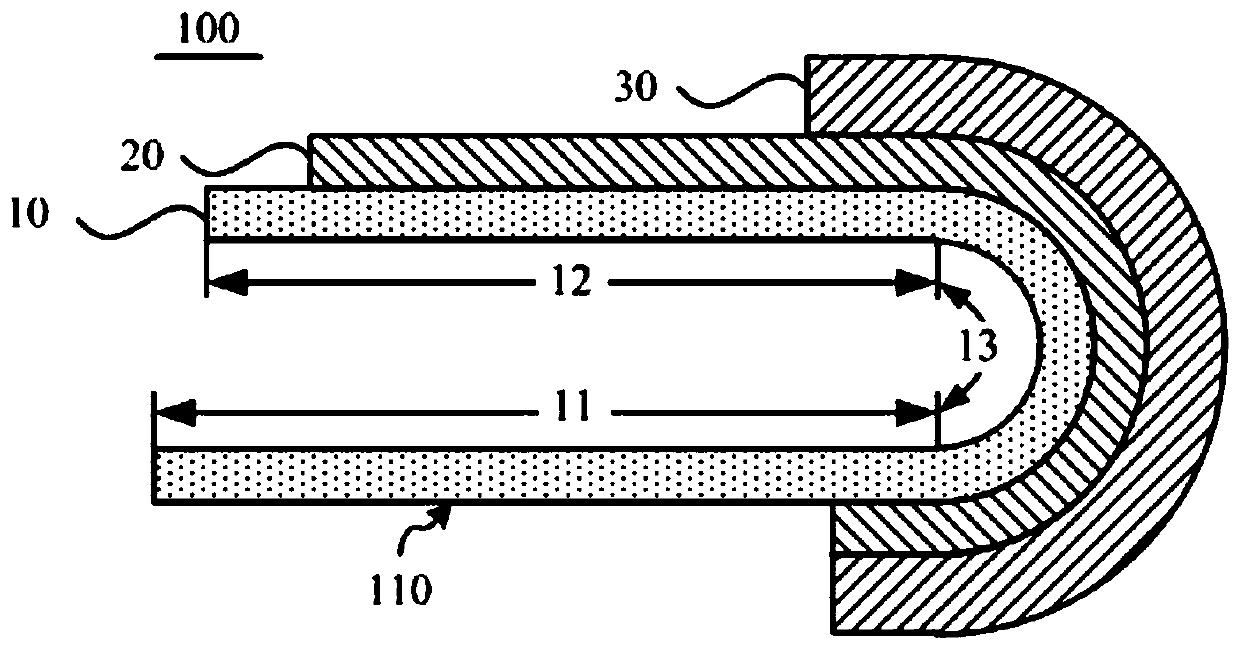

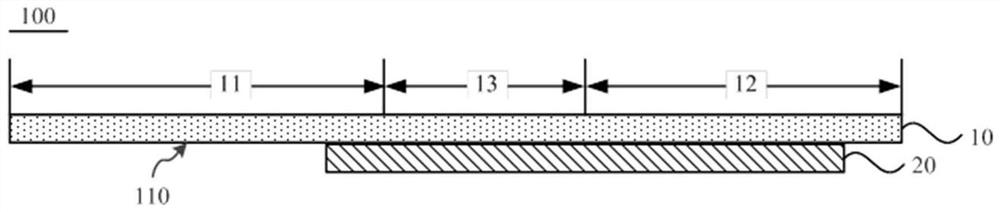

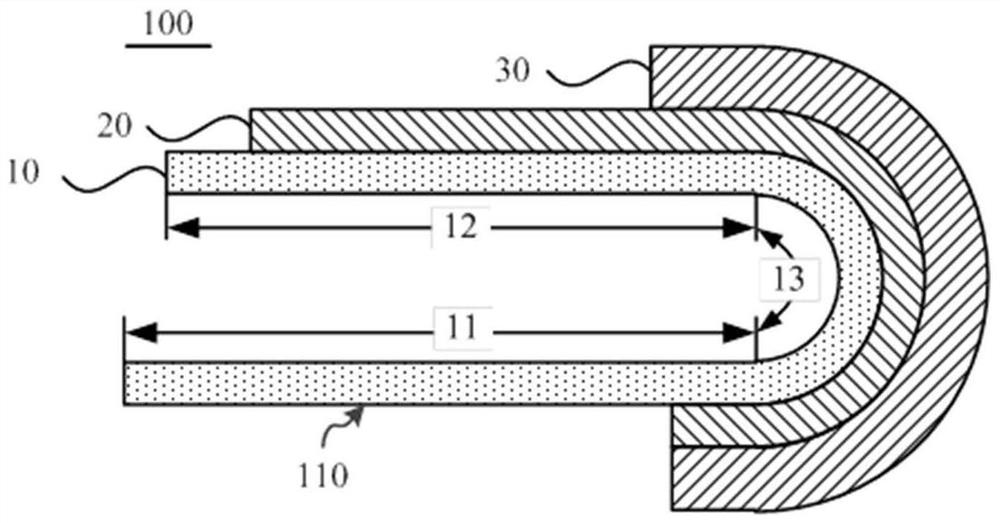

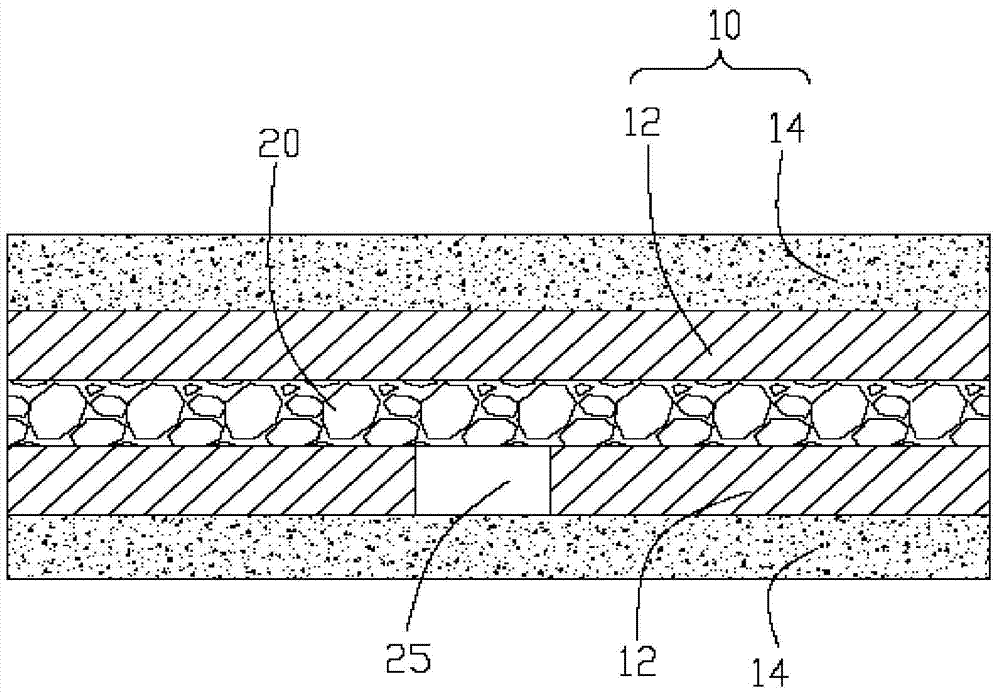

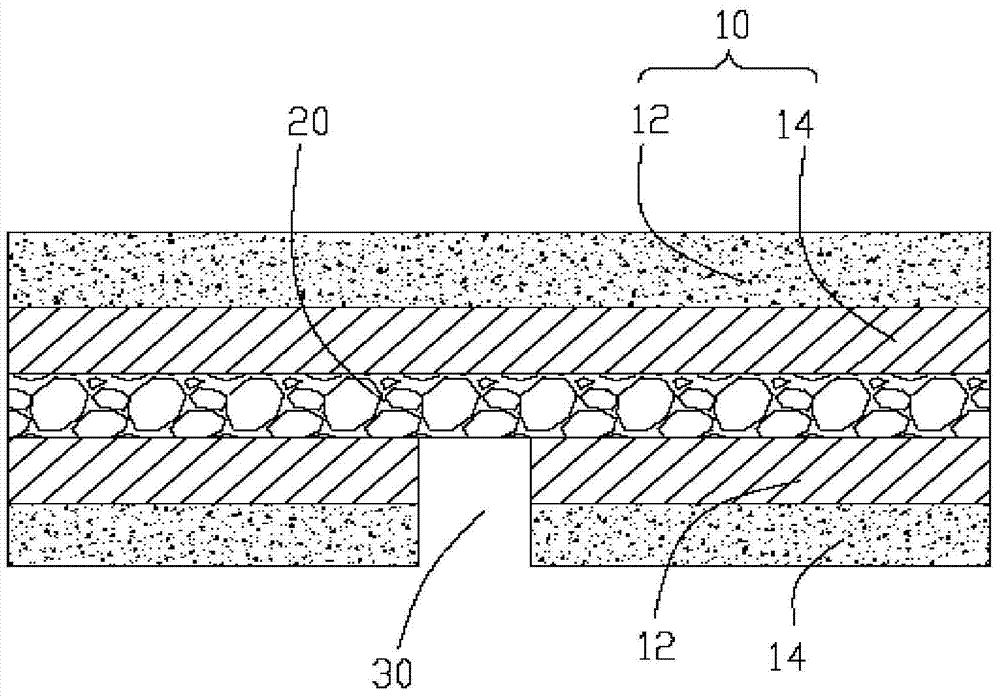

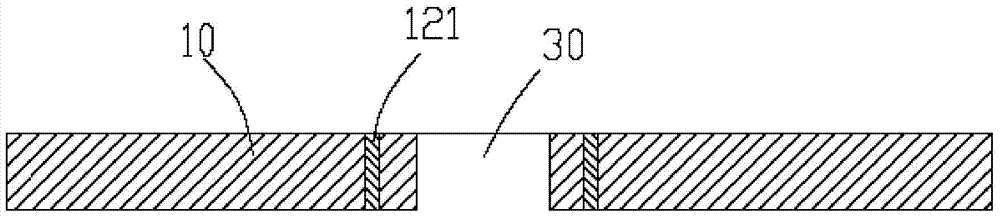

The invention discloses a preparation method of a flexible display panel, a flexible display panel and a display device, which are used for reducing the difficulty of bending a bending region of the flexible display panel, wherein the manufacturing method of the flexible display panel comprises the following steps of: A back film is attached to the back surface of the display substrate, wherein the display substrate is divided into a display area and a non-display area, the non-display area includes a bent area adjacent to the display area, and a binding region adjacent to the bending region,the back film having a continuous pattern covering the display area and extending to the non-display area, the back film having a hollow area in the non-display area, the hollow area covering at leastan area between the binding area and the display area in the bent area in the orthogonal projection of the display substrate; Removing at least a portion of the back film that covers the bent regionby orthographic projection on the display substrate. The flexible display panel is formed by bending the display substrate to a back surface along the bending region.

Owner:BOE TECH GRP CO LTD +1

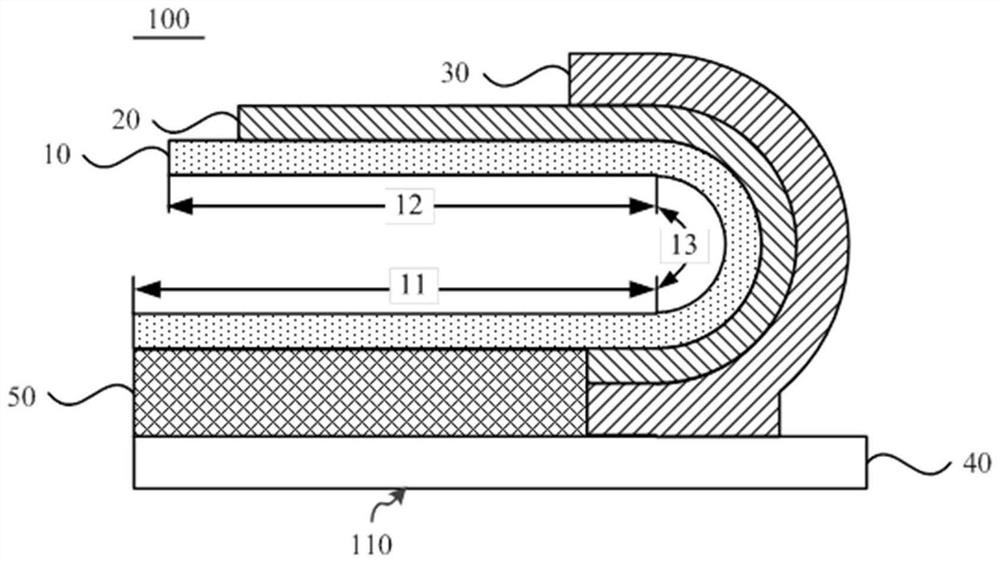

Flexible display device and preparation method thereof

ActiveCN109712530AImprove the display effectPrevent creepIdentification meansEngineeringProtection layer

The embodiment of the invention provides a flexible display device and a preparation method of the flexible display device. A flexible substrate of the flexible display device is provided with a firststraight area, a bent area and a second straight area; before bending, a first bending protecting layer is arranged in a bending area of the flexible substrate, so that the bending difficulty can bereduced, and the bending stress can be reduced; after bending, a second bending protecting layer is arranged in the bending area of the flexible substrate, so that creep occurring after the first bending protecting layer is bent can be prevented, meanwhile, a protection role can be further played on the bending area, so that the phenomenon that cracks occur on the flexible substrate and wires on the flexible substrate due to the fact that the protection capacity of a first bending protecting agent for the flexible substrate and a wiring layer arranged on the flexible substrate is reduced is avoided, and further, the display effect of the flexible display device is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

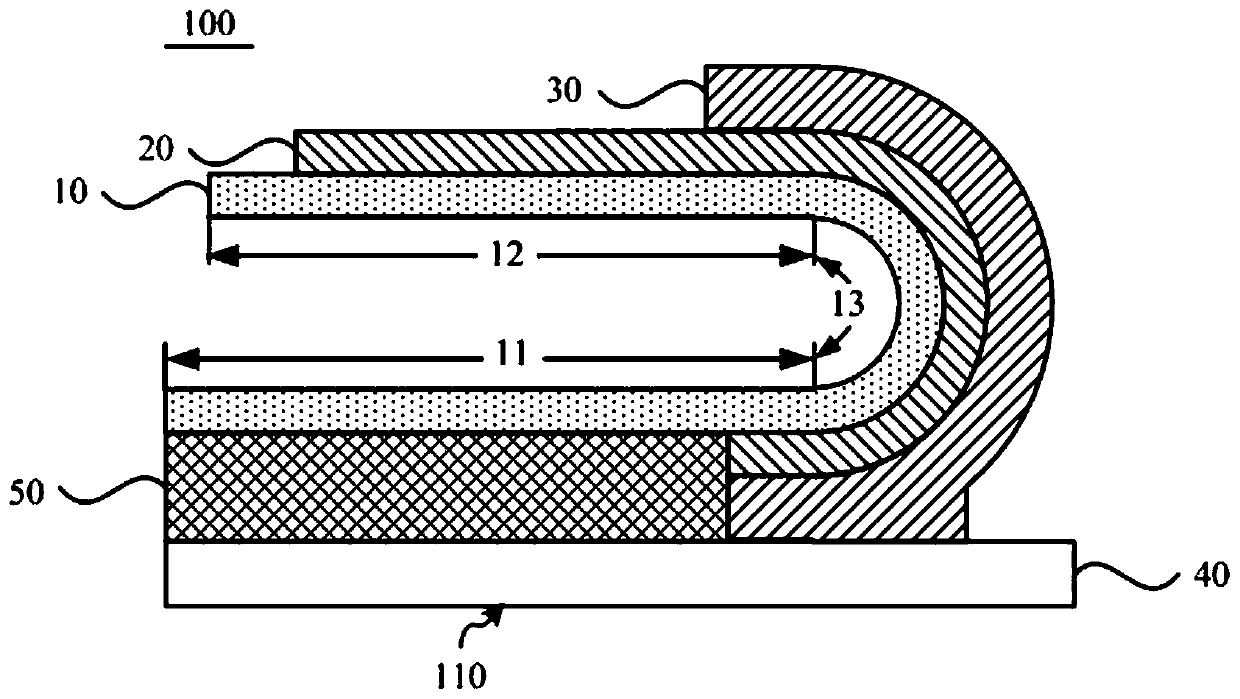

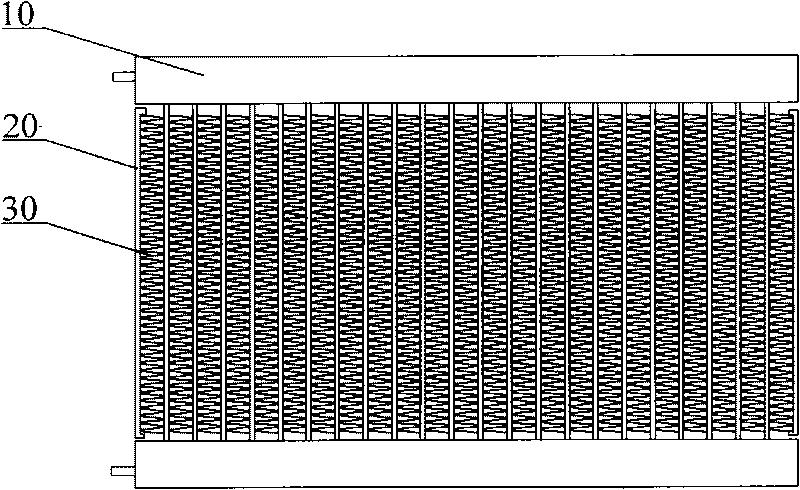

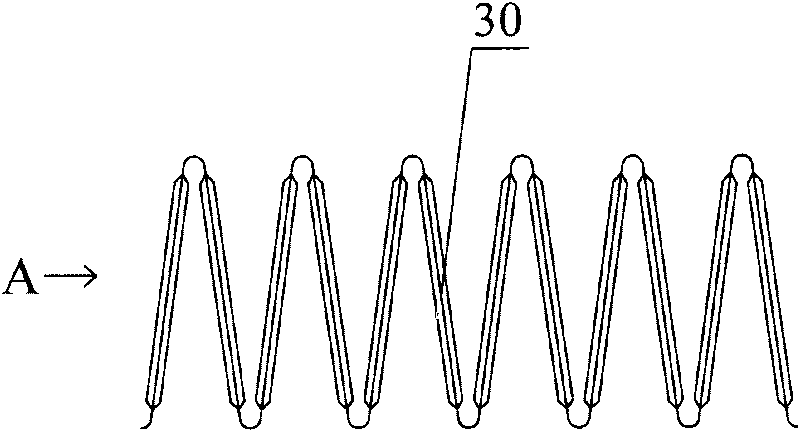

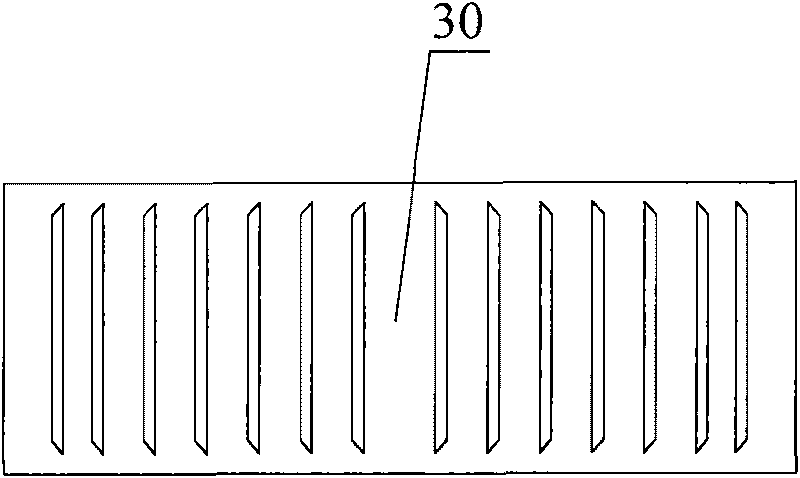

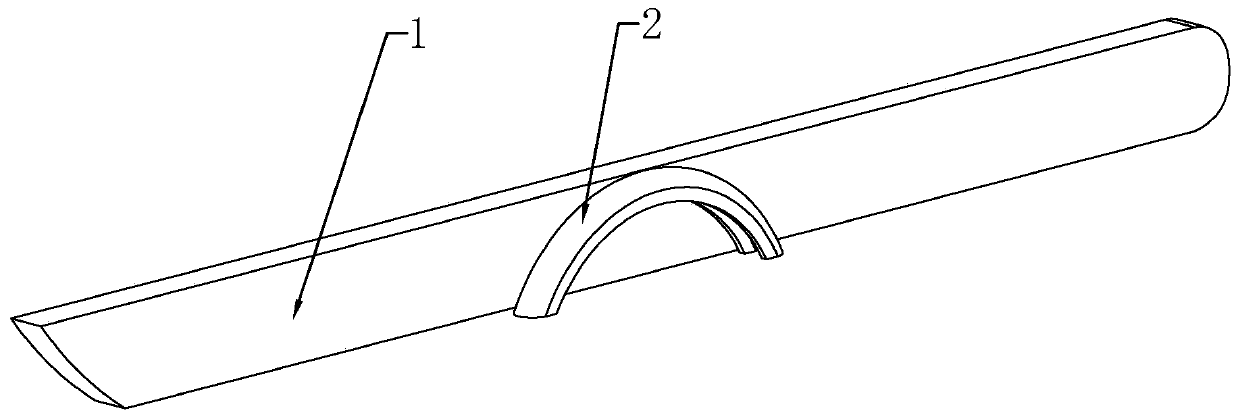

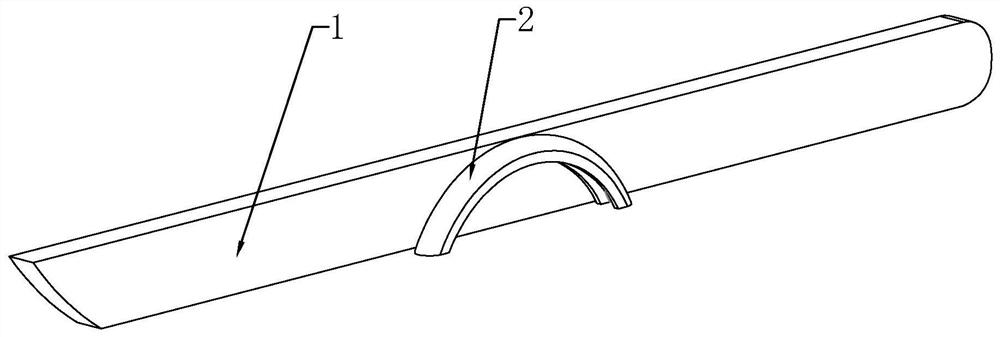

Heat exchanger and fin thereof

InactiveCN101738126AReduce bending difficultyReduce the higher requirements on the bending processLaminated elementsPlate heat exchangerEngineering

The invention discloses a fin of a heat exchanger, which is arranged between neighboring flat pipes on a bent part of the heat exchanger. The fin can be bent on the bent part with the heat exchanger and is provided with a notch. The fin contributes to the reduction of the bending difficulty of the heat exchanger along a flow collecting pipe direction and can reduce the influence of a bending procedure on the heat exchanging performance of the heat exchanger to a minimum degree at the same time so as to still keep a relatively high exchanging performance after the fin is bent. The invention also discloses the heat exchanger with the fin.

Owner:SANHUA HLDG GRP +1

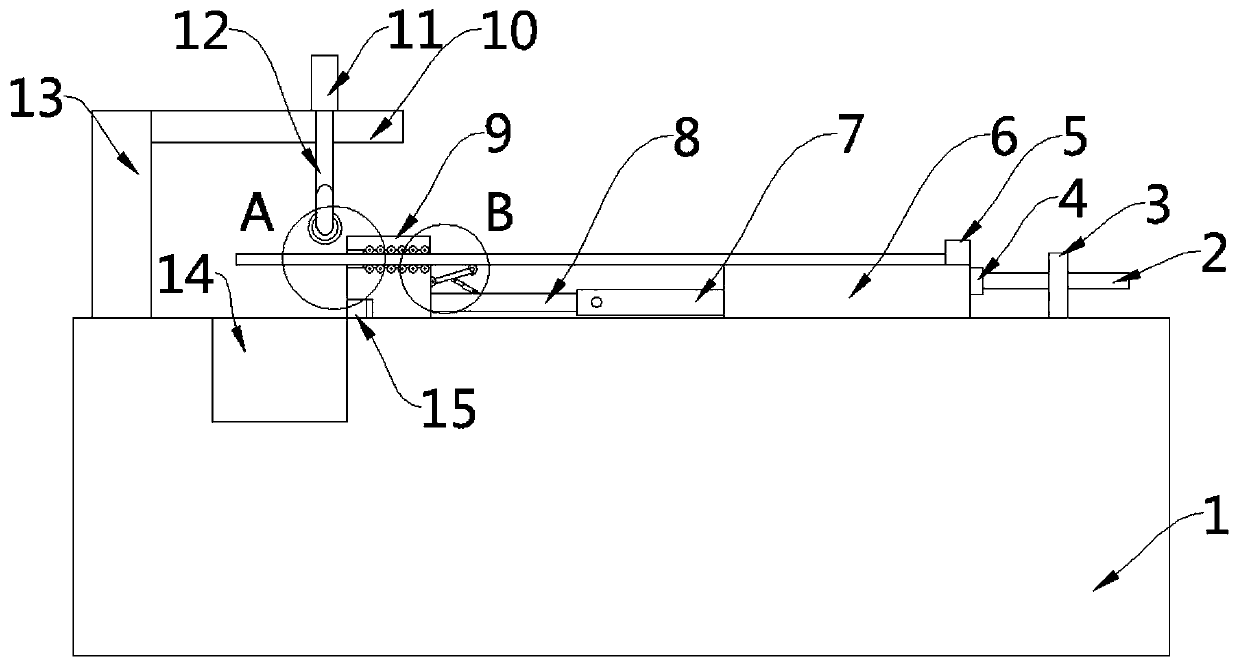

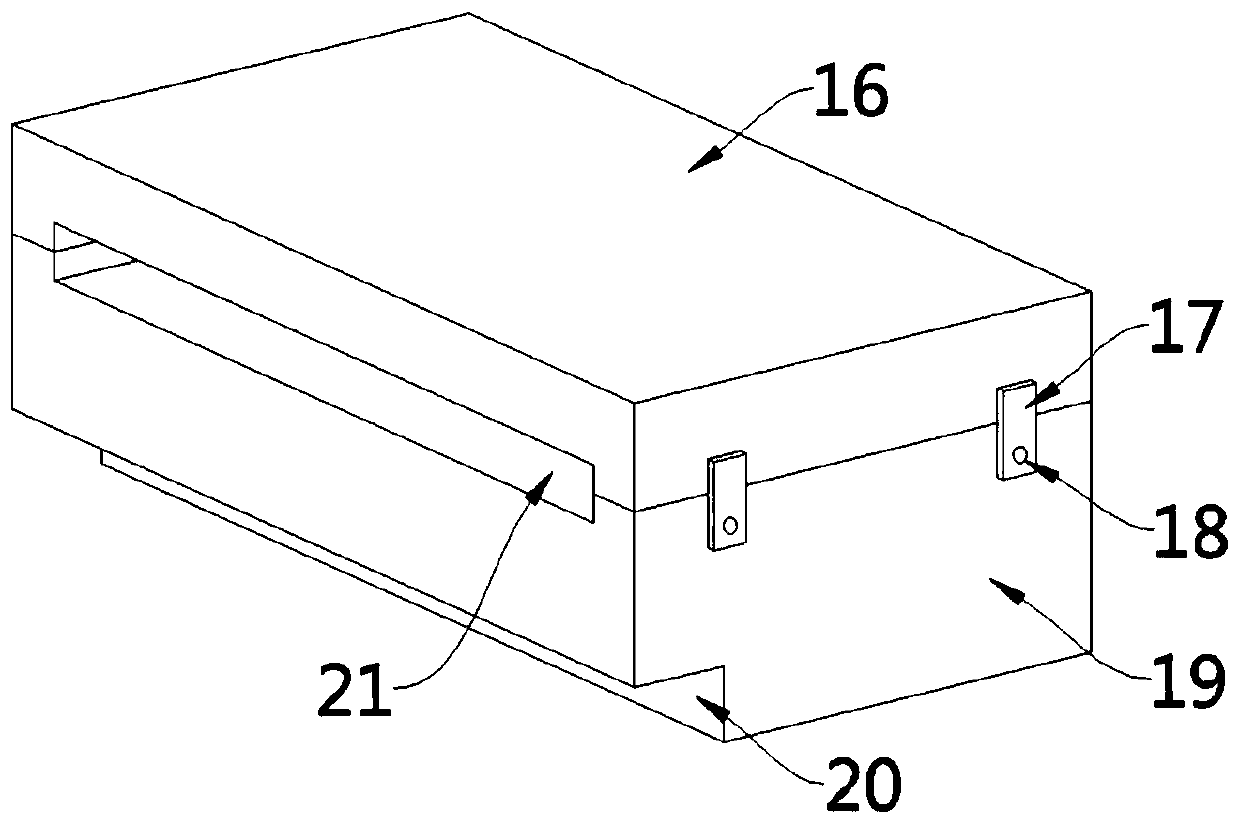

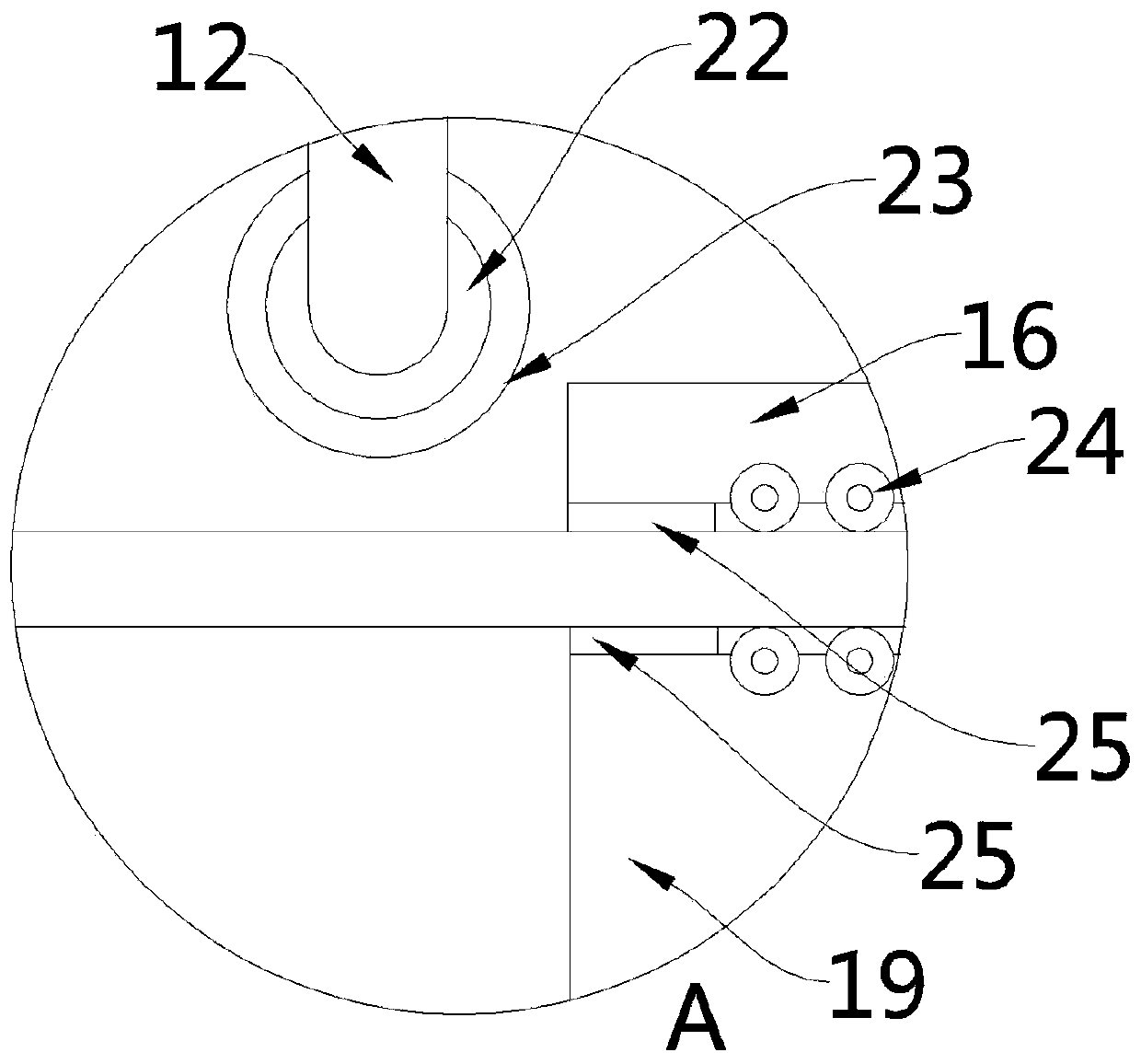

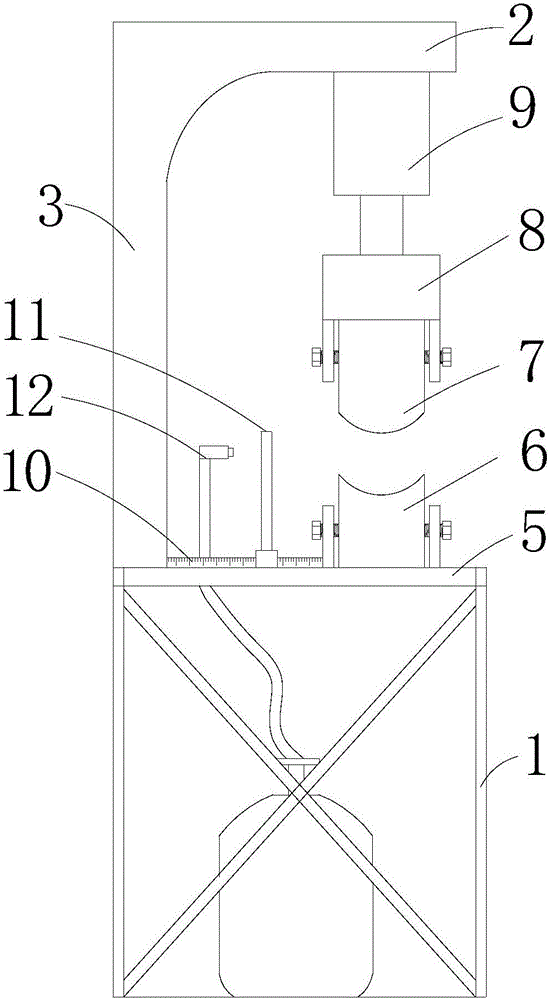

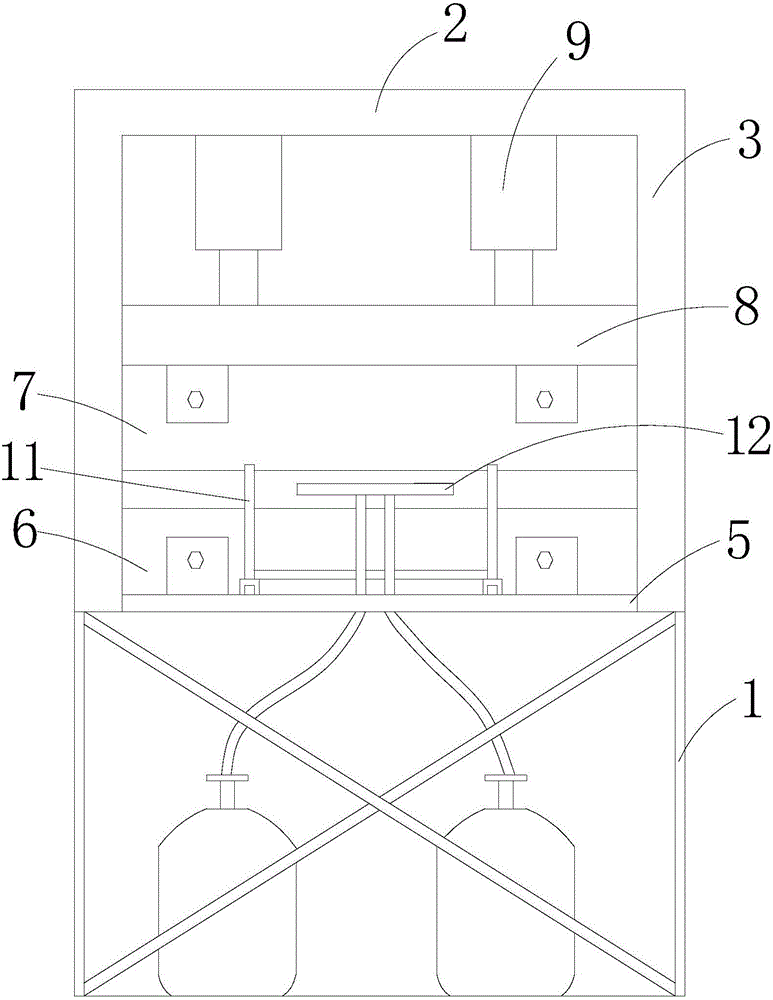

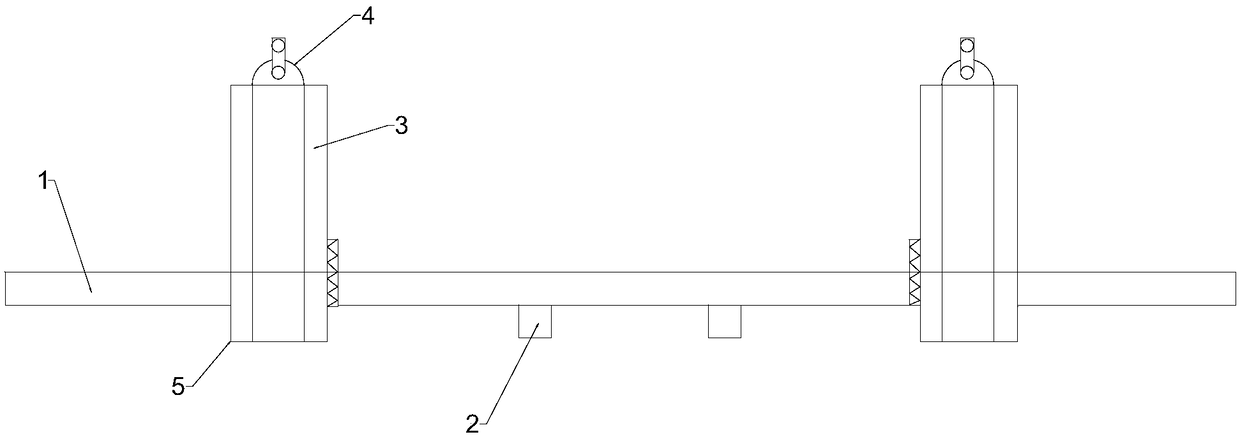

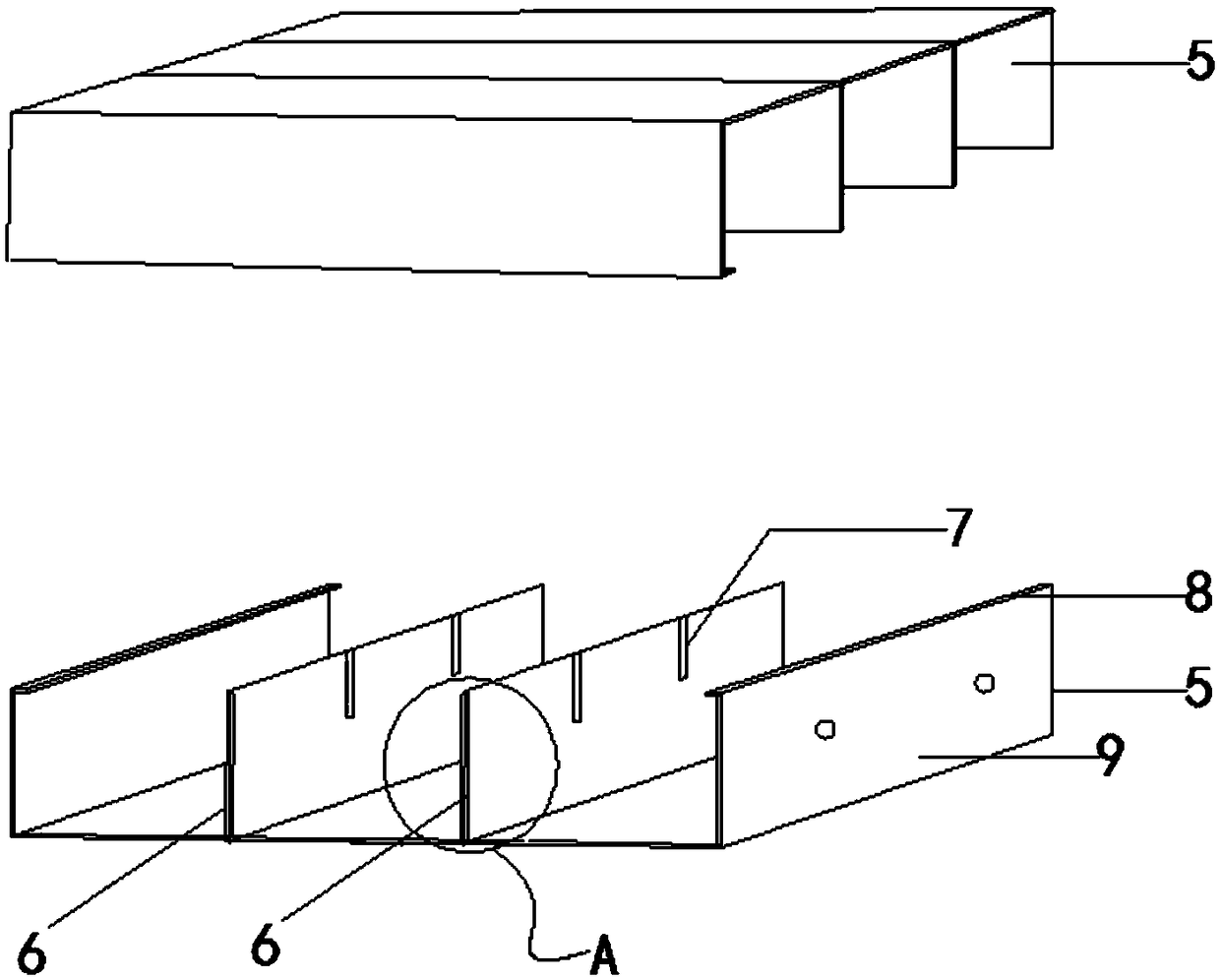

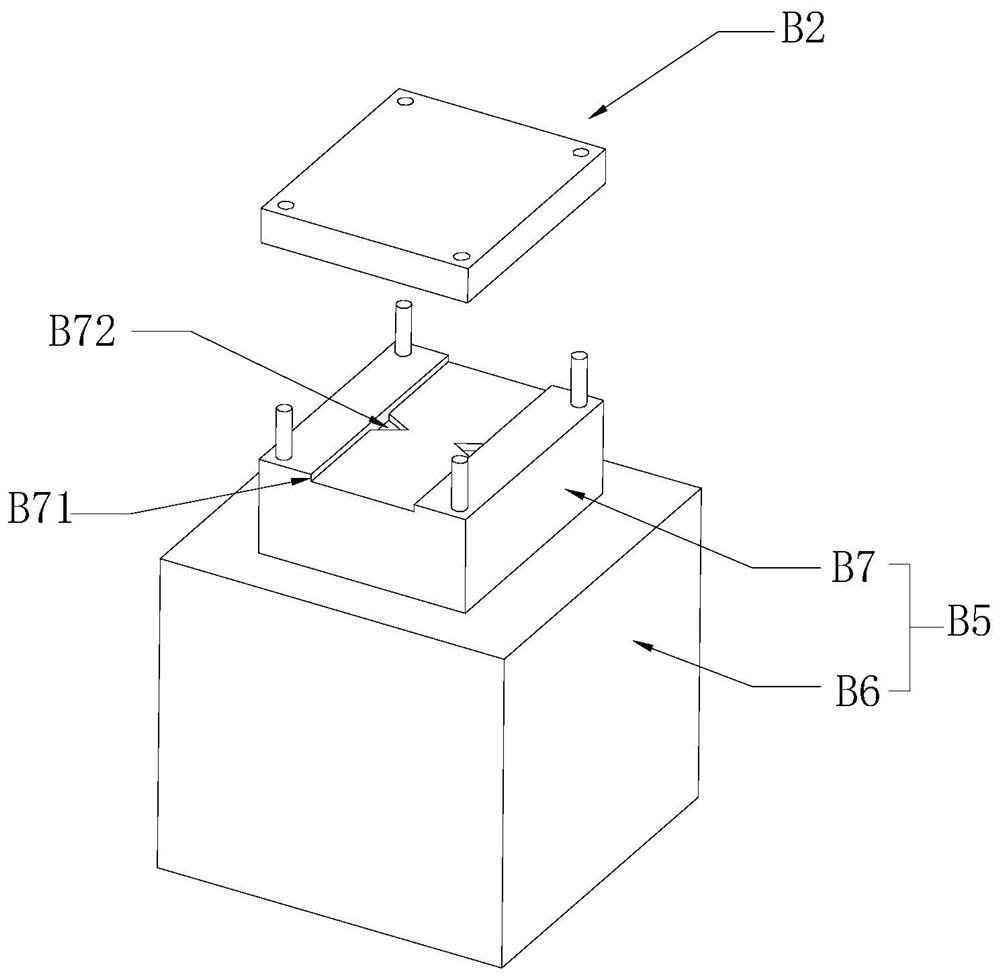

Plate bending device for computer mainframe box production

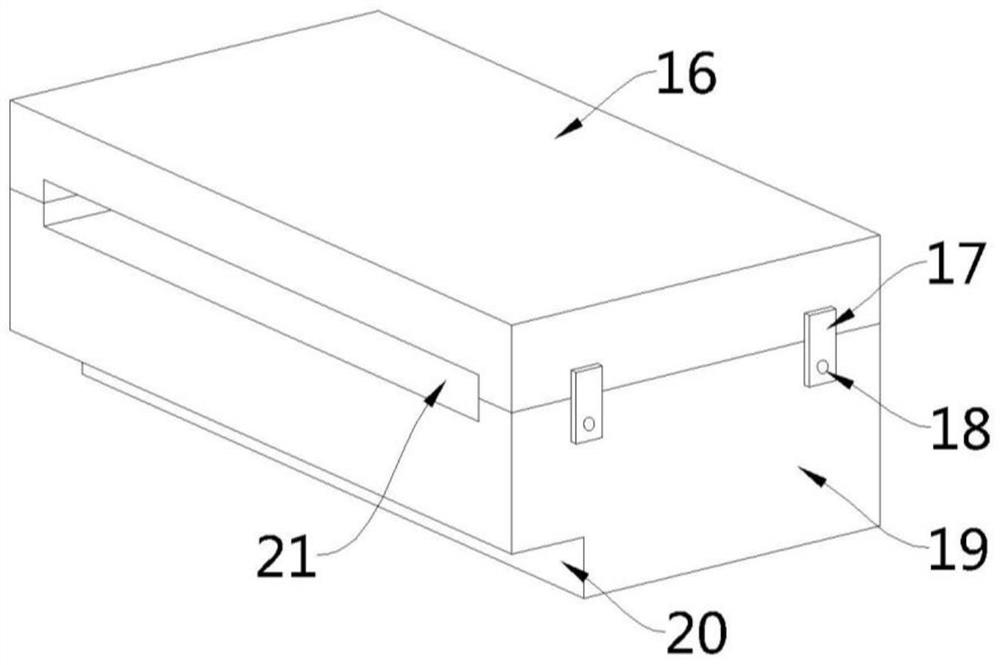

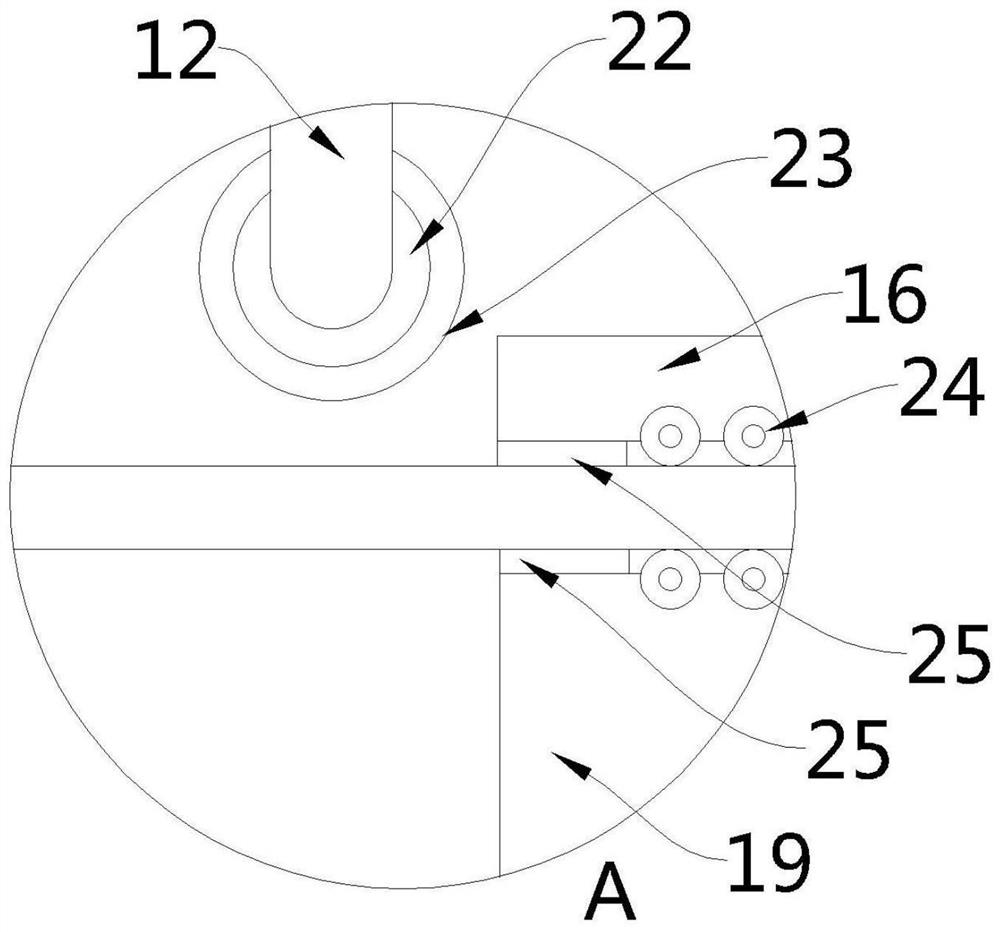

The invention provides a plate bending device for computer mainframe box production, and belongs to the technical field of computer mainframe box production. The plate bending device comprises a bottom box. A supporting table is slidably arranged on the upper portion of the bottom box. One side of the supporting table is connected with a pressing assembly through an adjusting assembly. A bending assembly is arranged above the pressing assembly, the pressing assembly comprises a base body and a cover body hinged to the upper portion of the base body, the cover body is connected with the side face of the base body through a locking assembly, and clamping grooves corresponding to each other are arranged in the side, facing the base body, of the cover body and the side, facing the cover body,of the base body. The plate bending device has the advantages of good bending quality, and the bending part of the plate can be heated to soften the plate by arranging the heating plate so that the bending treatment of the plate by the bending assembly is more convenient, the bending quality of the plate is improved, the bending difficulty of the plate is reduced and the problem that the plate isbroken during cold bending is effectively avoided.

Owner:广州市嘉翔电脑设备有限公司

Flexible optical fiber, preparation method and drivable laser scalpel based on optical fiber

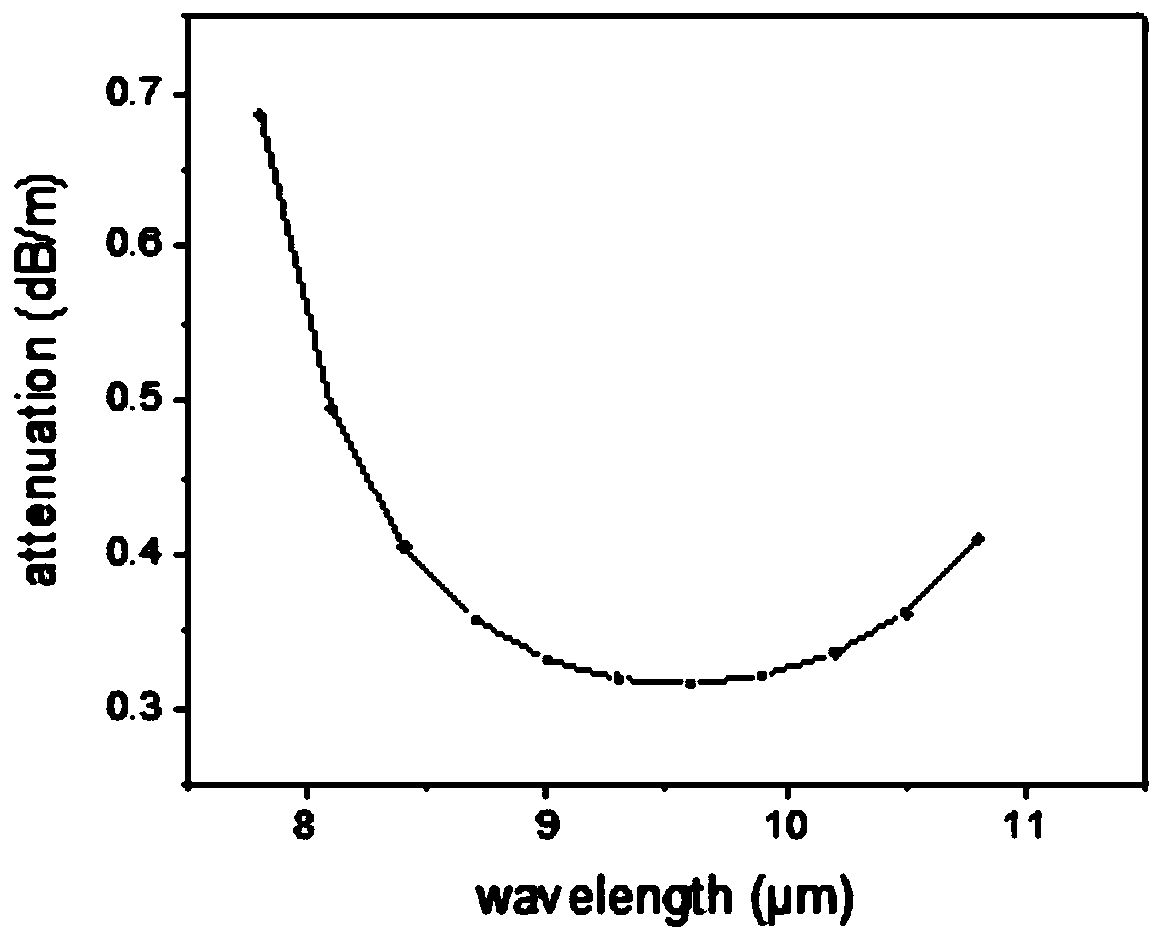

InactiveCN111580230AEasy to bendReduce bending difficultyGlass making apparatusDiagnosticsLaser scalpelEngineering

The invention provides a flexible optical fiber and a drivable laser scalpel based on the optical fiber. The flexible optical fiber comprise an optical fiber structure located on the inner side and aflexible enhancement layer wrapping the optical fiber structure, and the optical fiber structure has the functions of energy transmission and information transmission of a common optical fiber; the flexible enhancement layer comprises at least two layers, and the outermost layer of the flexible enhancement layer has low rigidity. According to the flexible optical fiber, through the design of the flexible enhancement layer, the bending capability of the optical fiber can be improved under the condition that the function of the optical fiber is not obviously influenced, and the selectable rangeof the outermost layer material of the optical fiber is wider. The drivable laser scalpel based on the optical fiber comprises a laser scalpel framework, the flexible optical fiber and a driving wire,the flexible optical fiber and the driving wire are located in the framework, the flexible optical fiber has the energy transmission capacity, and the driving wire is used for controlling movement ofthe framework. The drivable laser scalpel has the functions of high-power laser transmission, form sensing, posture control based on visual servo and the like.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Novel bending machine

InactiveCN105798082ARapid positioningHigh precisionShaping toolsMetal-working feeding devicesEngineeringUltimate tensile strength

The invention relates to the technical field of panel machining machines, and discloses a novel bending machine. The novel bending machine comprises a lower support and an upper support; the upper support is fixedly connected with one side of the upper portion of the lower support through a stand column, a bending table is arranged on the upper surface of the lower support, the bending table is provided with an upper surface, and an angle ranging from 10 degrees to 45 degrees is formed between the horizontal plane and the upper surface; a bending lower mold parallel to the upper surface of the bending table is fixed to the upper surface of the bending table through a bolt, and a bending upper mold matched with the bending lower mold is arranged above the bending lower mold; the bending upper mold is fixedly connected with a pressing head through a bolt, and the pressing head is mounted on the lower portion of the upper support through a hydraulic assembly; a sliding rail is mounted on the bending table, and perpendicular to the bending lower mold; and a positioning plate is arranged on the sliding rail, and a flame heating device is further mounted on the bending table. The novel bending machine is simple in structure, convenient to use and rapid and accurate in positioning, the bending efficiency is improved, labor intensity of workers is reduced, thick panels can be bent, and the bending quality is high.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

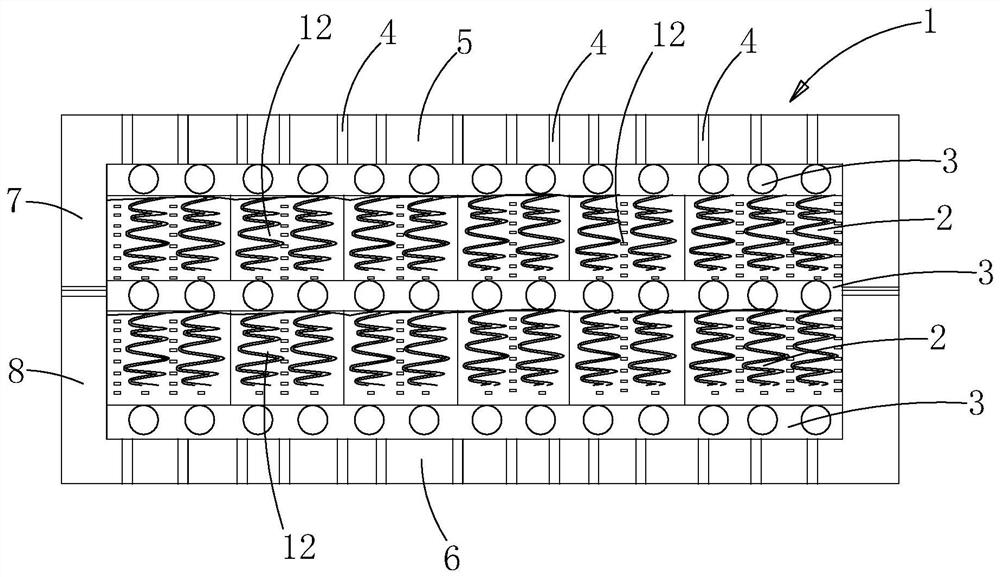

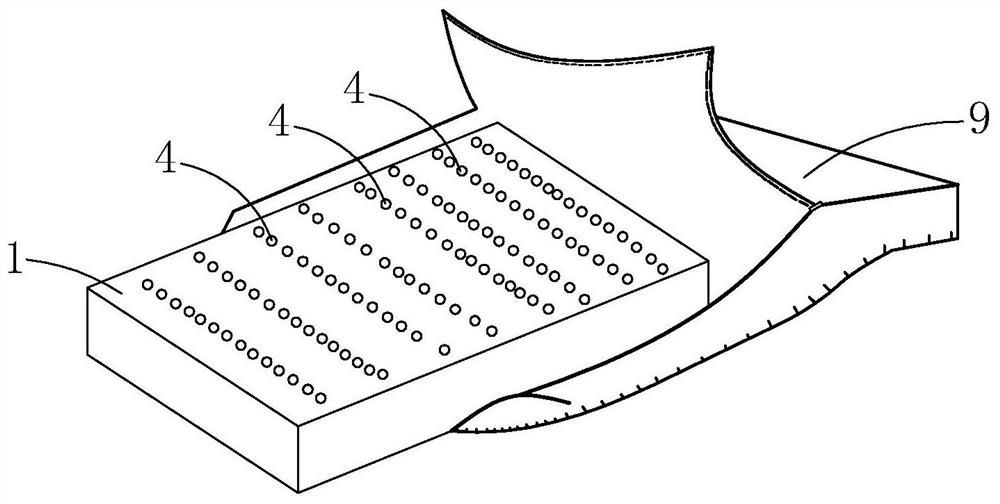

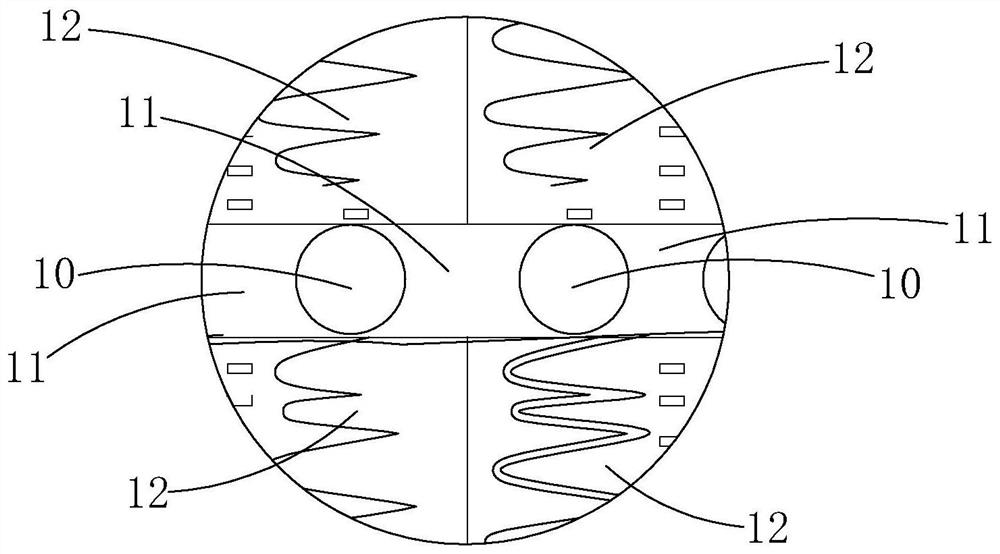

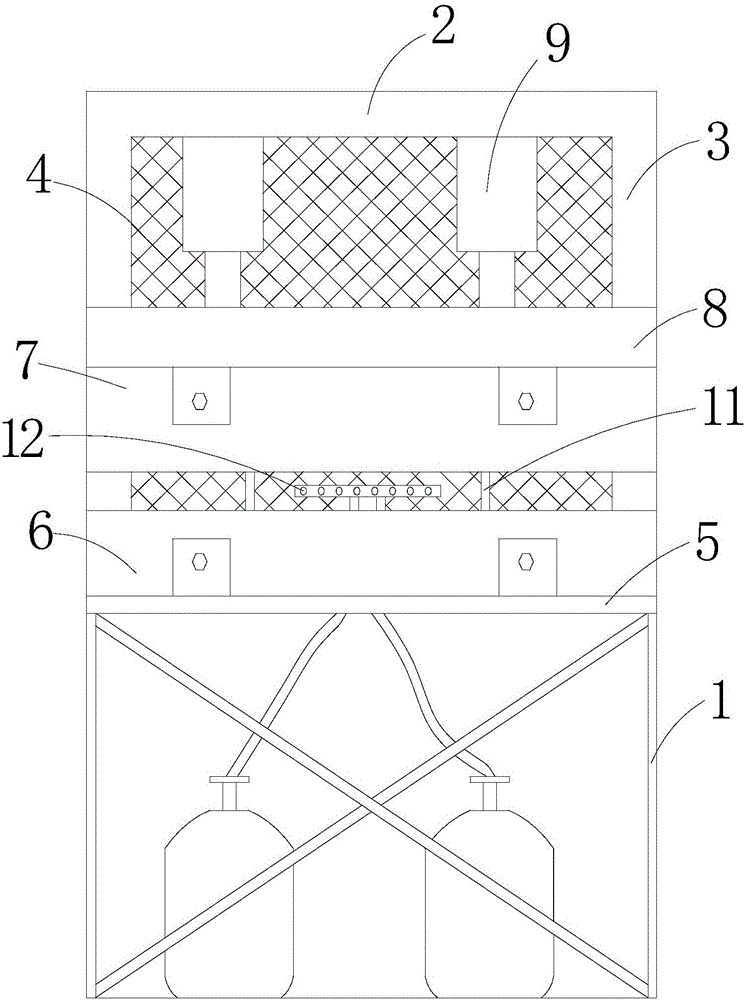

Mattress easy to bend

PendingCN111789446AReduce thicknessGuaranteed stabilityStuffed mattressesSpring mattressesCushionEngineering

The invention relates to a mattress easy to bend. An existing mattress cannot give consideration to both supporting performance and bending performance, and the use experience is affected. The mattress comprises a mattress body, the mattress body comprises at least two vertically stacked elastic layers and a latex sleeve internally provided with an assembly cavity, the elastic layers are vertically stacked in the assembly cavity, an interlayer gap is formed between every two adjacent elastic layers, and every two adjacent elastic layers deviate in a staggered mode through the corresponding interlayer gap and are bent independently, so that the whole mattress body is bent and deformed. The adjacent elastic layers can provide effective vertical support for a user, the bearing stability is guaranteed, large-angle bending can be achieved through relative sliding and staggering, then the cushion body can be bent to form a preset posture meeting ergonomics, and the bearing comfort and the use experience are improved.

Owner:杭州云睡吧健康管理有限公司

Novel bending equipment

InactiveCN105750376APrevent penetrationPrevent false pressureShaping toolsMetal-working feeding devicesEngineering

The invention relates to the technical field of plate processing machinery, and discloses novel bending equipment. The novel bending equipment comprises a lower support and an upper support, wherein the upper support is fixedly connected with one side of the upper part of the lower support through two columns; a protective net is mounted between the columns; a bending platform is mounted on the upper surface of the lower support, a lower bending mold is fixed to the upper surface of the bending platform through bolts, and an upper bending mold adapted to the lower bending mold is arranged above the lower bending mold, and is fixedly connected with a pressing head through bolts; the pressing head is mounted at the lower part of the upper support through hydraulic devices; a sliding rail is mounted on the bending platform and is arranged perpendicularly to the lower bending mold; locating plates are arranged on the sliding rail; a flame heating device is further arranged on the bending platform. The novel bending equipment has the advantages that the structure is simple, the application is easy and safe, the plate bending precision and efficiency are improved, plates with relatively high thickness can be bent, and the bending quality is high.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

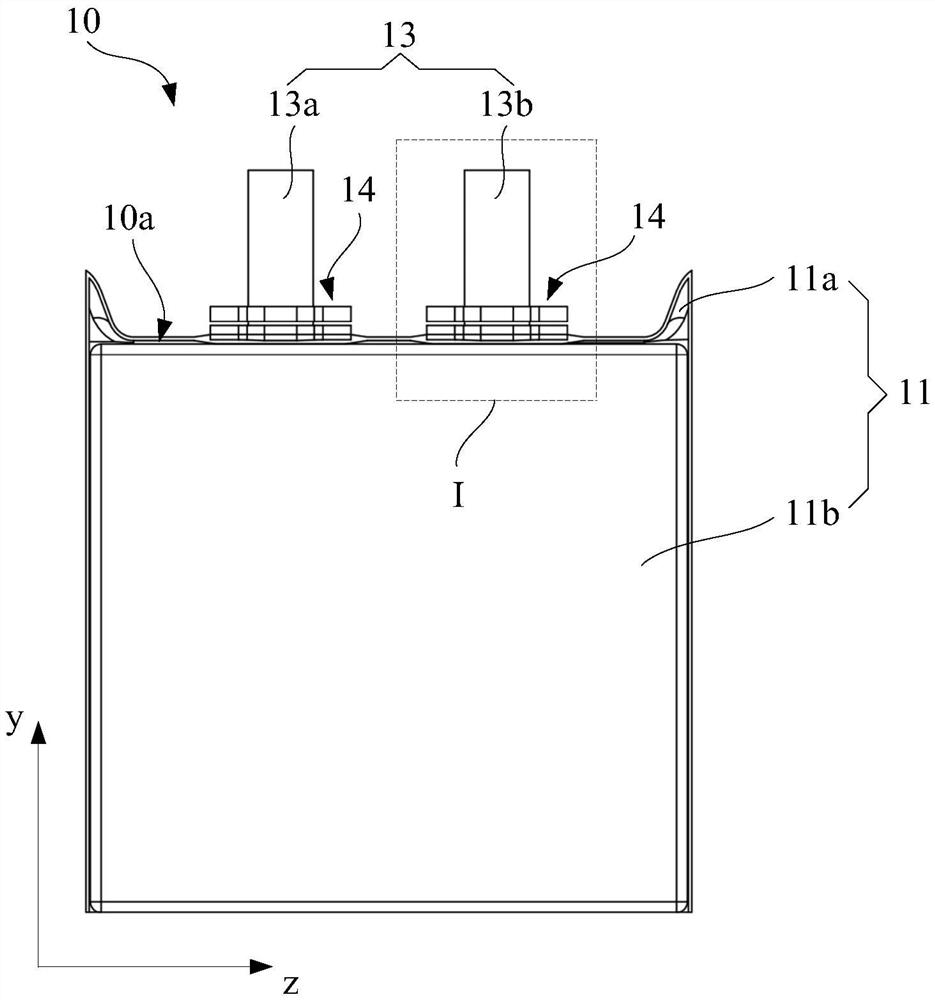

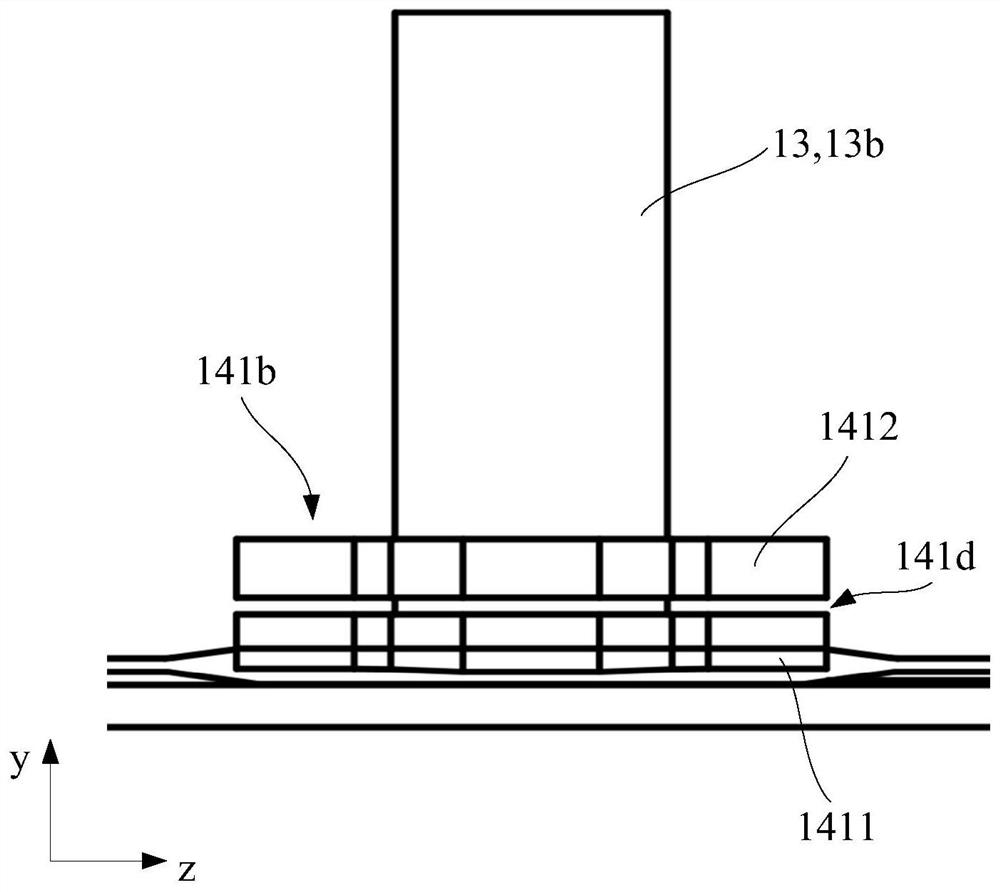

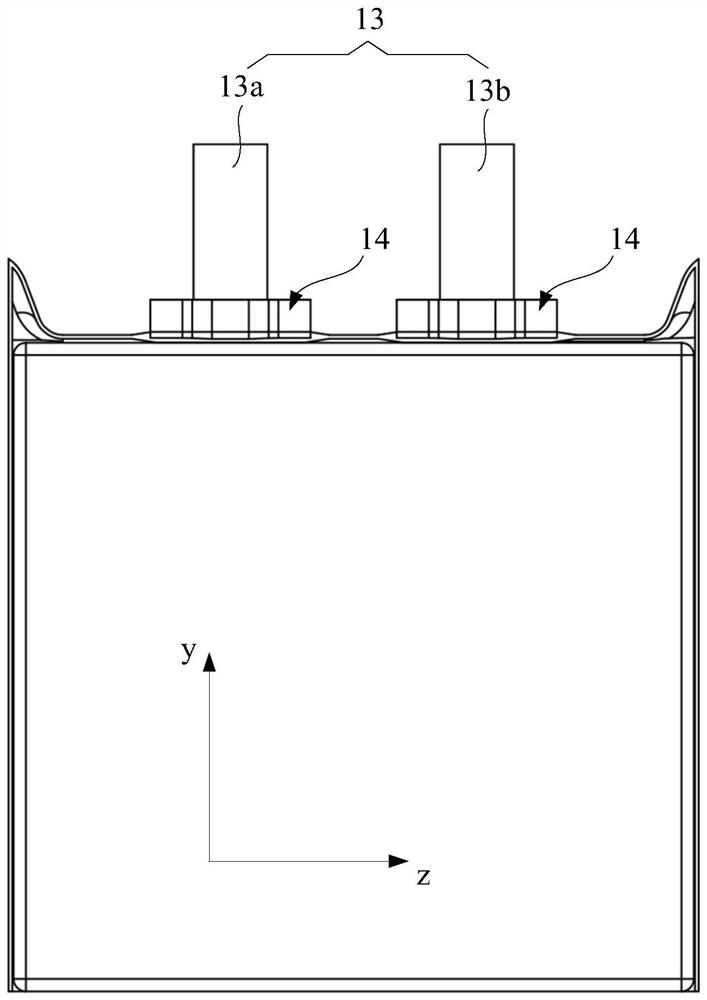

Battery cell, battery and electronic equipment

ActiveCN113611986ASave packing spaceIncrease capacityCell component detailsEngineeringStructural engineering

The invention discloses a battery cell, a battery and electronic equipment. Tab glue comprises an exposed part extending out of a packaging part, the exposed part is provided with a clearance area, and the clearance area forms an easy folding line perpendicular to the extending direction of a tab on the tab glue. The clearance area can reduce the bending difficulty of the tab glue, and the length of a bent part in the length direction of the battery cell is reduced after the bent part is bent, so that the packaging space of the battery cell is reduced, and the capacity of the battery cell and the battery is improved.

Owner:DONGGUAN NVT TECH

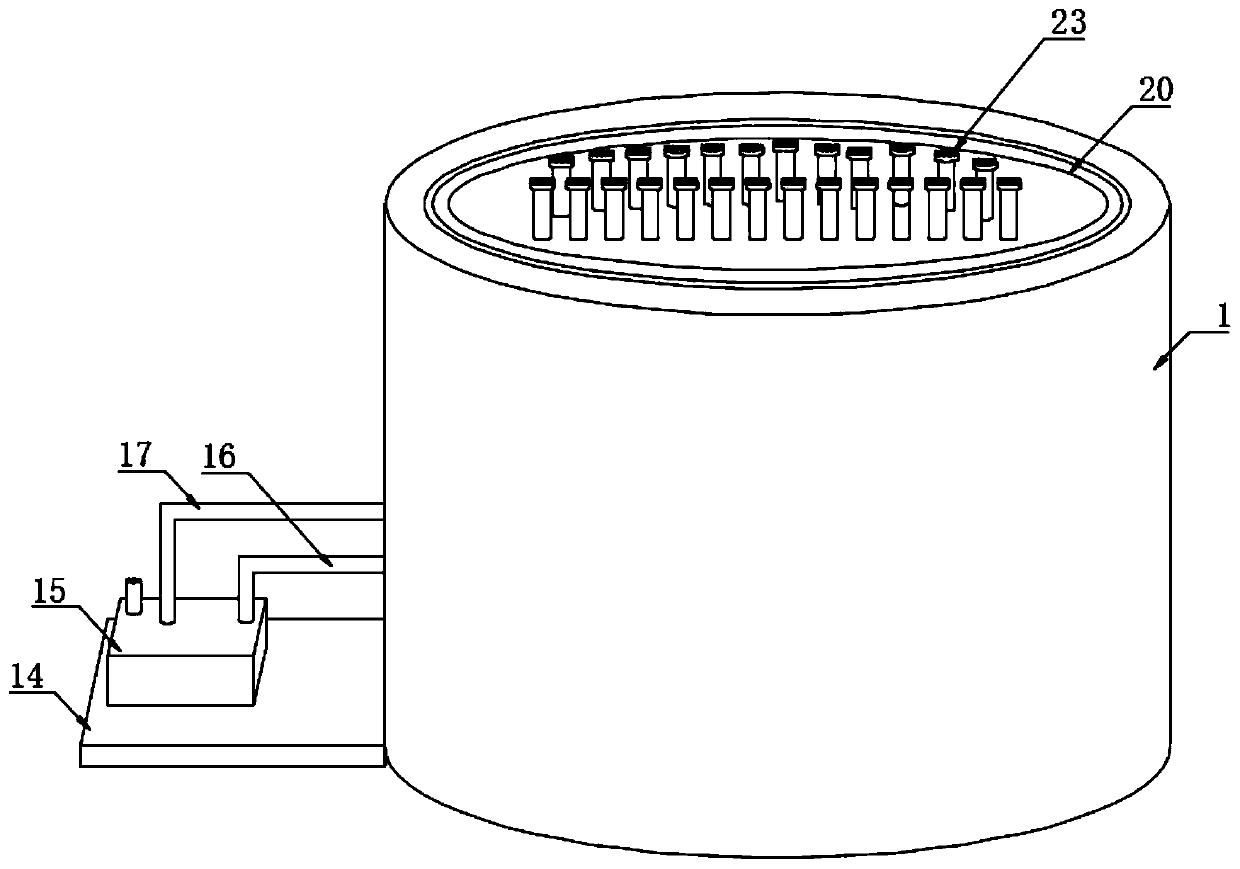

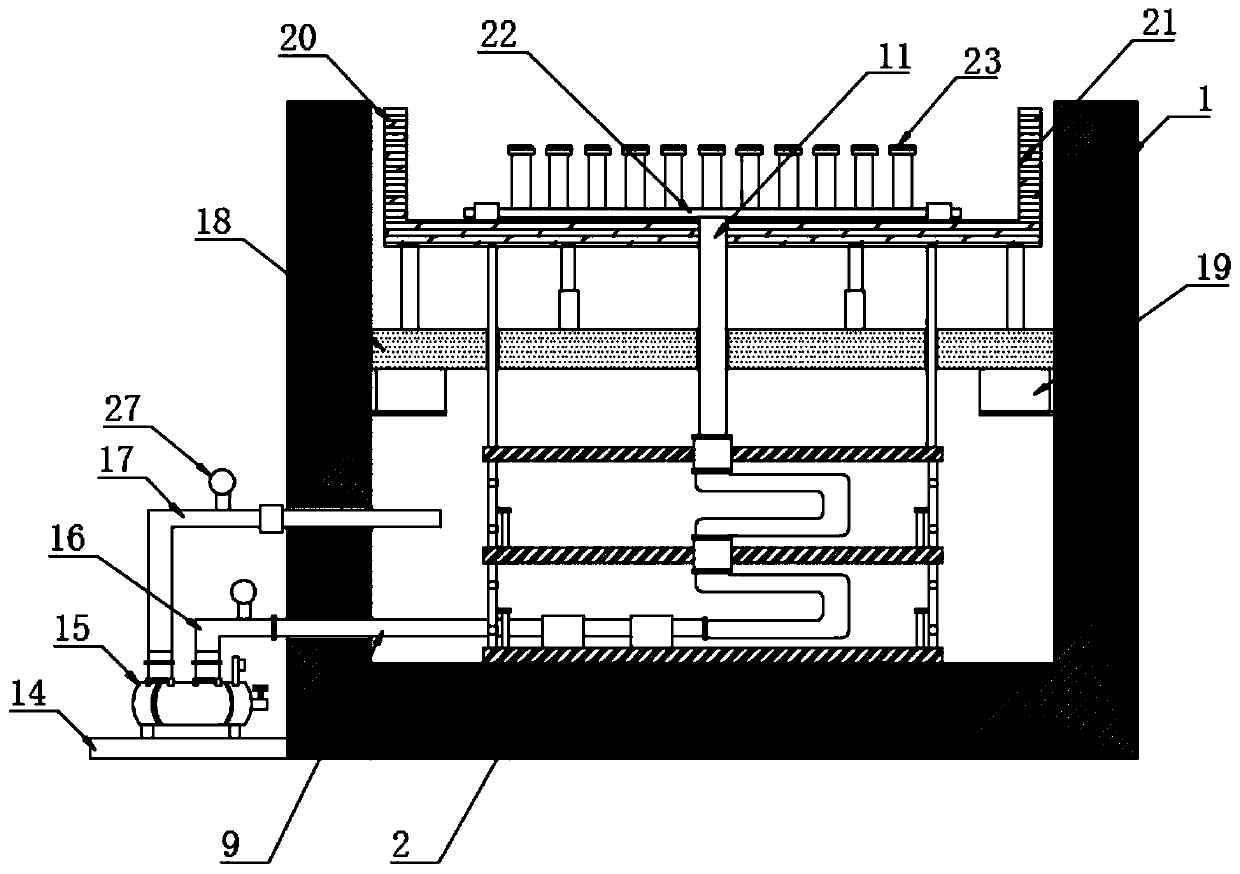

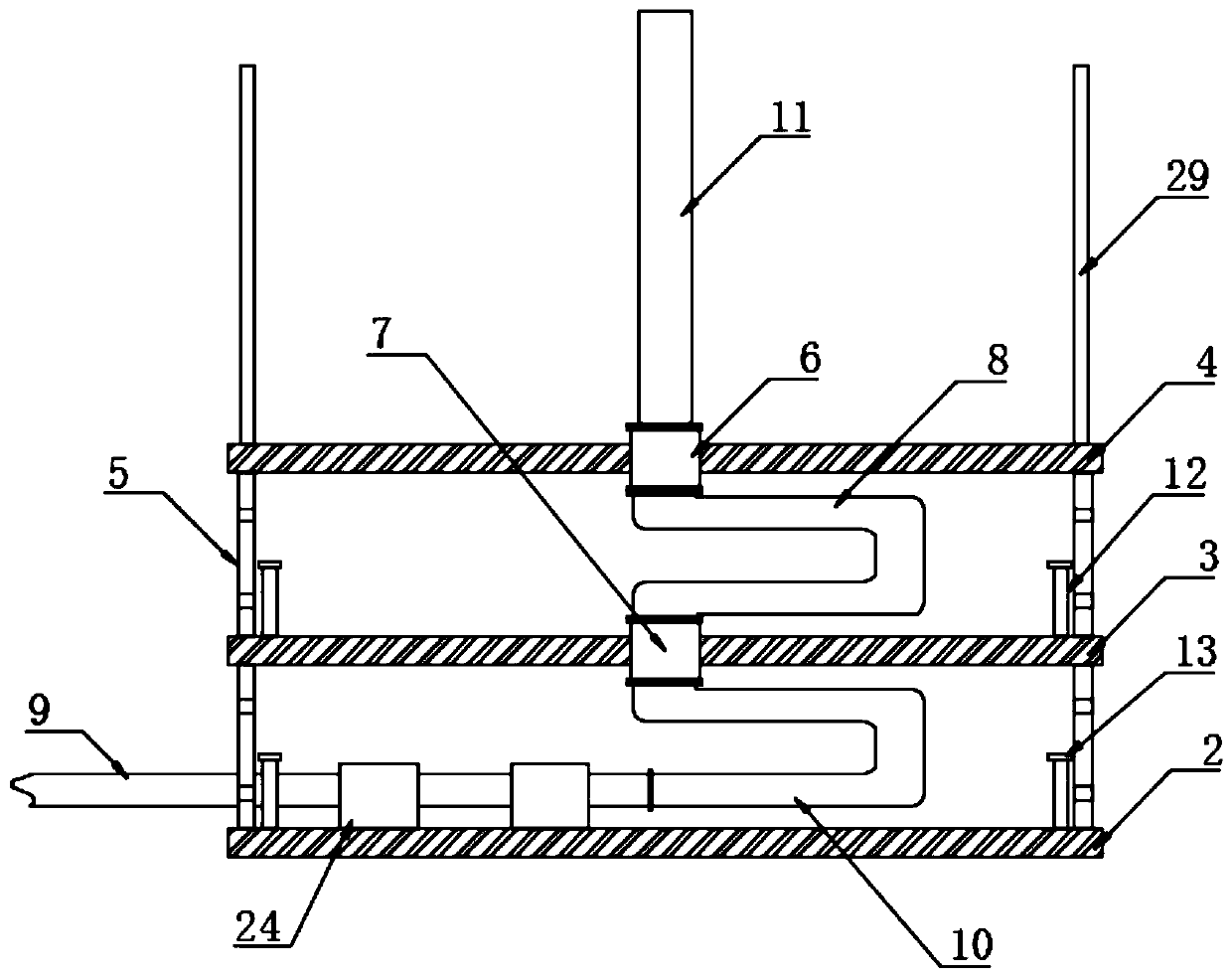

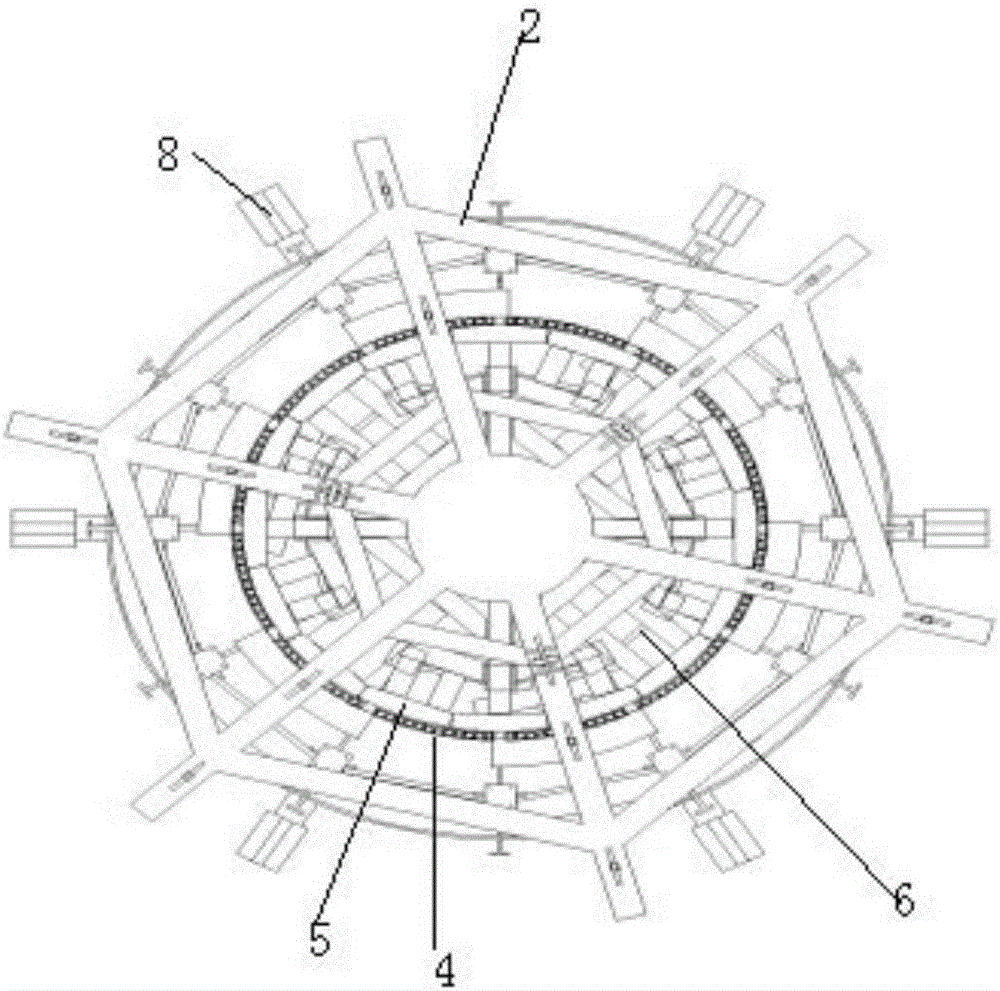

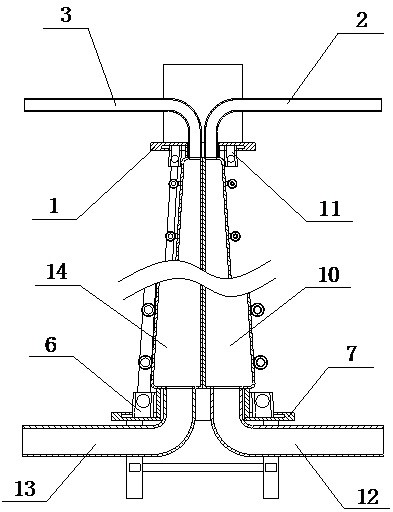

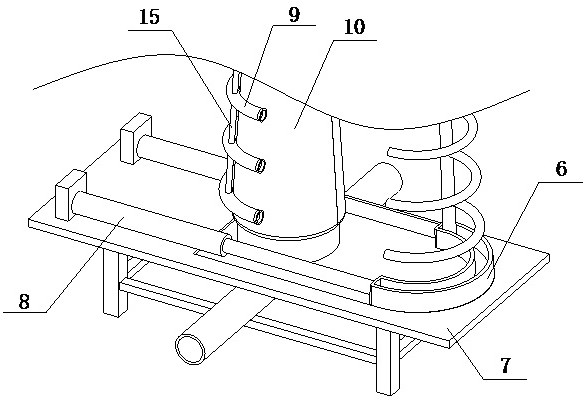

Lifting fountain device

PendingCN110465440ALimit the range of activitiesAvoid damageLiquid spraying apparatusEngineeringMotion range

The invention discloses a lifting fountain device and particularly relates to the technical field of fountain equipment. The lifting fountain device comprises a performance pool. A fountain mechanismis arranged in the performance pool. A lifting mechanism is arranged on the bottom of the fountain mechanism. A pipeline folding mechanism is arranged on the bottom of the lifting mechanism. A power mechanism is arranged on one side of the performance pool. According to the lifting fountain device, the pipeline folding mechanism is arranged, the ascending track of a third connecting plate and a second connecting plate can be limited, thus the motion range of hoses can be limited, damage to other equipment by the hoses is effectively prevented, a pipeline needing to be bent is partitioned intothe first hose and the second hose, and the bending difficulty of the bent pipeline is reduced; and by arranging a bearing rod and a bearing plate, the distance between the adjacent connecting platesis effectively controlled, the situation that the hoses are pressed by the connecting plates and damaged is effectively prevented, compared with the prior art, the motion range in the hose bending process is narrowed, and the service life of the device is prolonged.

Owner:合肥仁泰科技发展有限公司

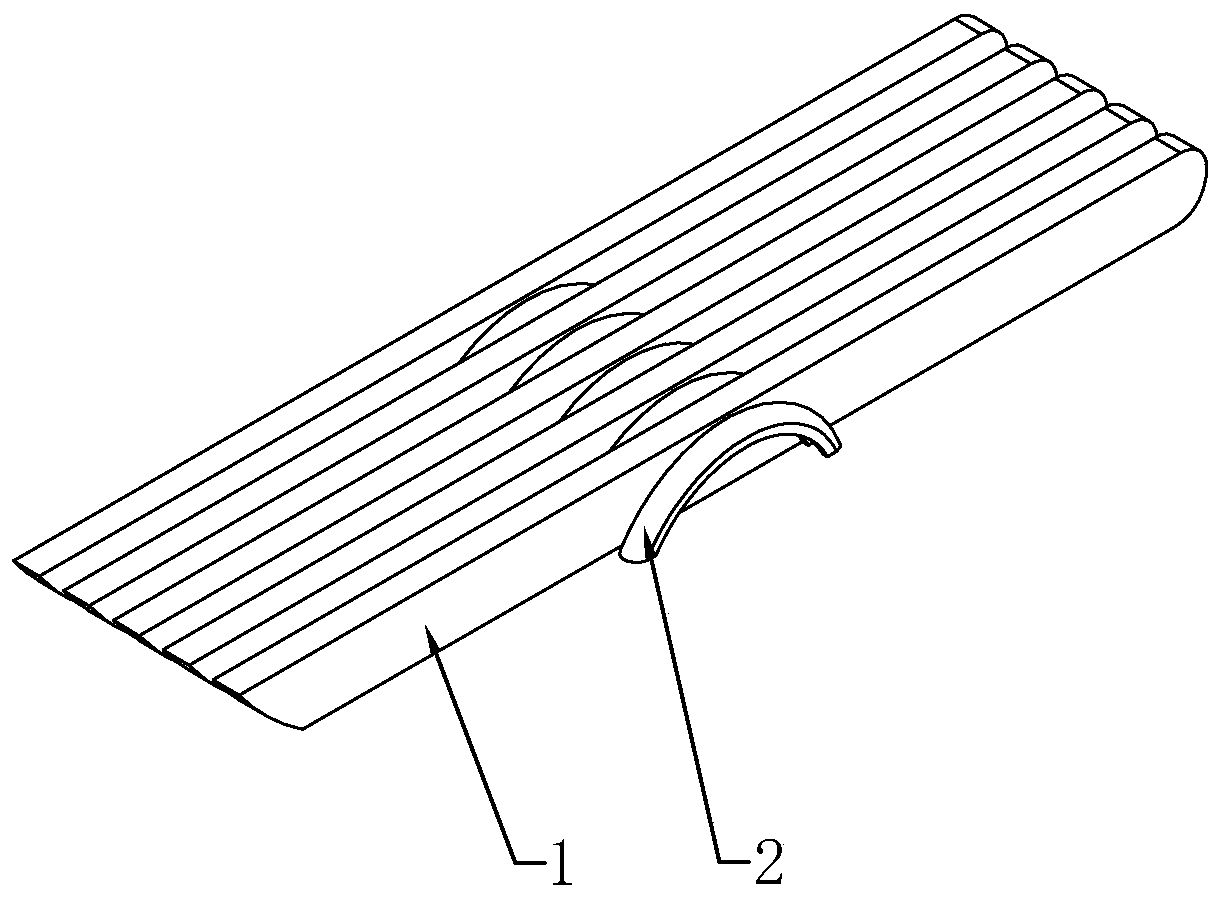

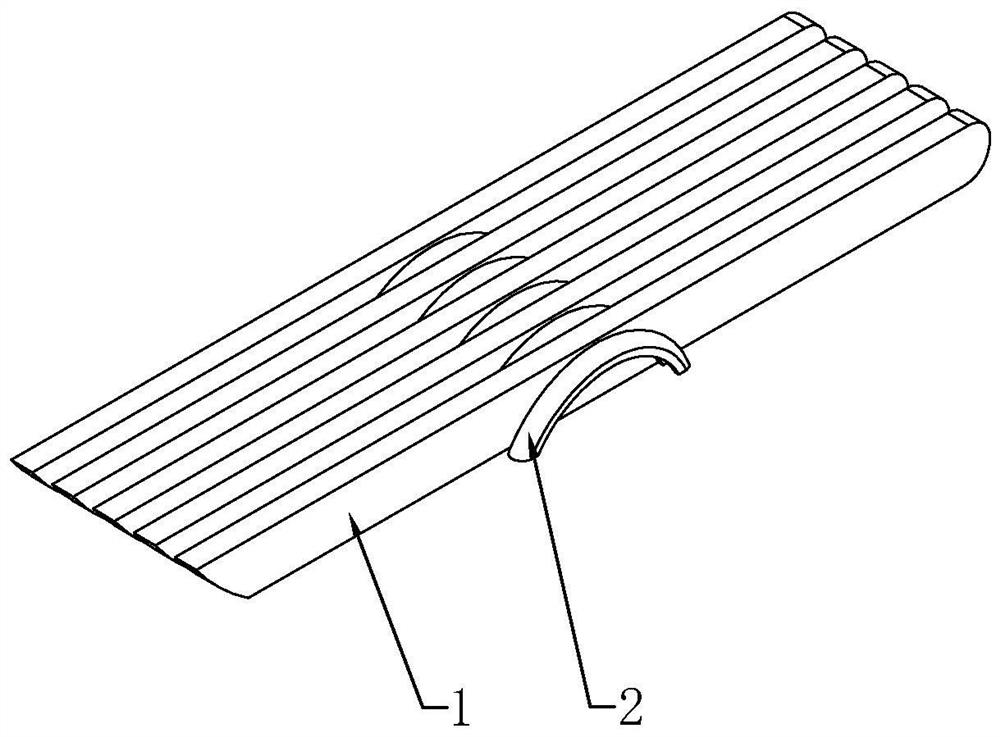

Paper straw bending and skew notch cutting process method

ActiveCN110450212AIncrease productivityDoes not significantly affect hardnessMetal working apparatusPulp and paper industryDrinking straw

The invention discloses a paper straw bending and skew notch cutting process method. The paper straw bending and skew notch cutting process method includes the following steps that 1, paper straws areconveyed; 2, the paper straws are impressed, according to an impressing method, an impressing knife and round groove blocks fixedly connected with the impressing knife cooperate with multiple impressing assemblies for impressing, and every two impressing assemblies are seamlessly connected and fixed; 3, skew notches of the paper straws are cut, the tail ends of the paper straws are obliquely cutthrough the obliquely-arranged impressing knife, and the skew notches are formed; and 4, collecting is completed. The paper straw bending and skew notch cutting process method has the following beneficial effects that the bending difficulty of the paper straws is reduced, and bent portions are not likely to be broken.

Owner:庄孔庆

Simple wrist arm recovery device for orthopedics department

InactiveCN108295419AReduce bending difficultyEasy to resume trainingRoller massageMuscle exercising devicesOrthopedic departmentPressure sensor

The invention discloses a simple wrist arm recovery device for the orthopedics department. The device comprises a bracket, forearm clamping slots, hand placement devices and big arm clamping slots. The middle of the bracket is provided with baffling rods, the inner walls of the forearm clamping slots are provided with forearm massage pads, the side faces of the forearm clamping slots are providedwith first pressure sensors, the first pressure sensors are provided with compression springs, and placement pieces are fixedly arranged on the hand placement devices. The upper surfaces of the placement pieces are provided with horizontal rockers, vertical grip bars are vertically arranged at the left ends of the horizontal rockers, second pressure sensors are fixedly disposed at the lower ends of the vertical grip bars, springs are connected to the second pressure sensors, and big arm massage pads are fixedly disposed on the inner walls of the big arm clamping slots. Sliding sleeves are fixedly disposed at the lower ends of the big arm clamping slots, and two rows of rollers are arranged on the upper and lower segments of the inner wall of each sliding sleeve respectively. A segmented movable device is adopted, arms and wrists can be separately exercised, a massage system is added, and the recovery speed is increased.

Owner:WUXI HOSPITAL OF CHINESE MEDICINE

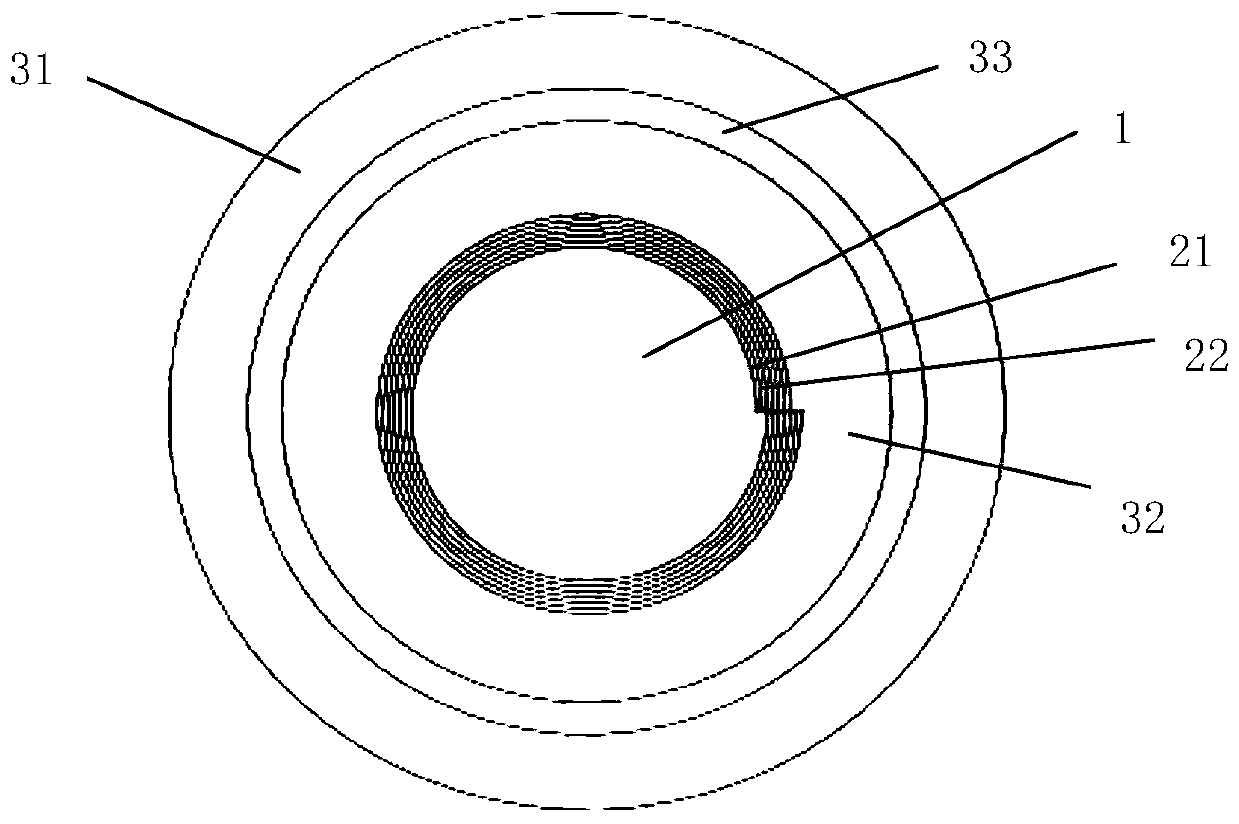

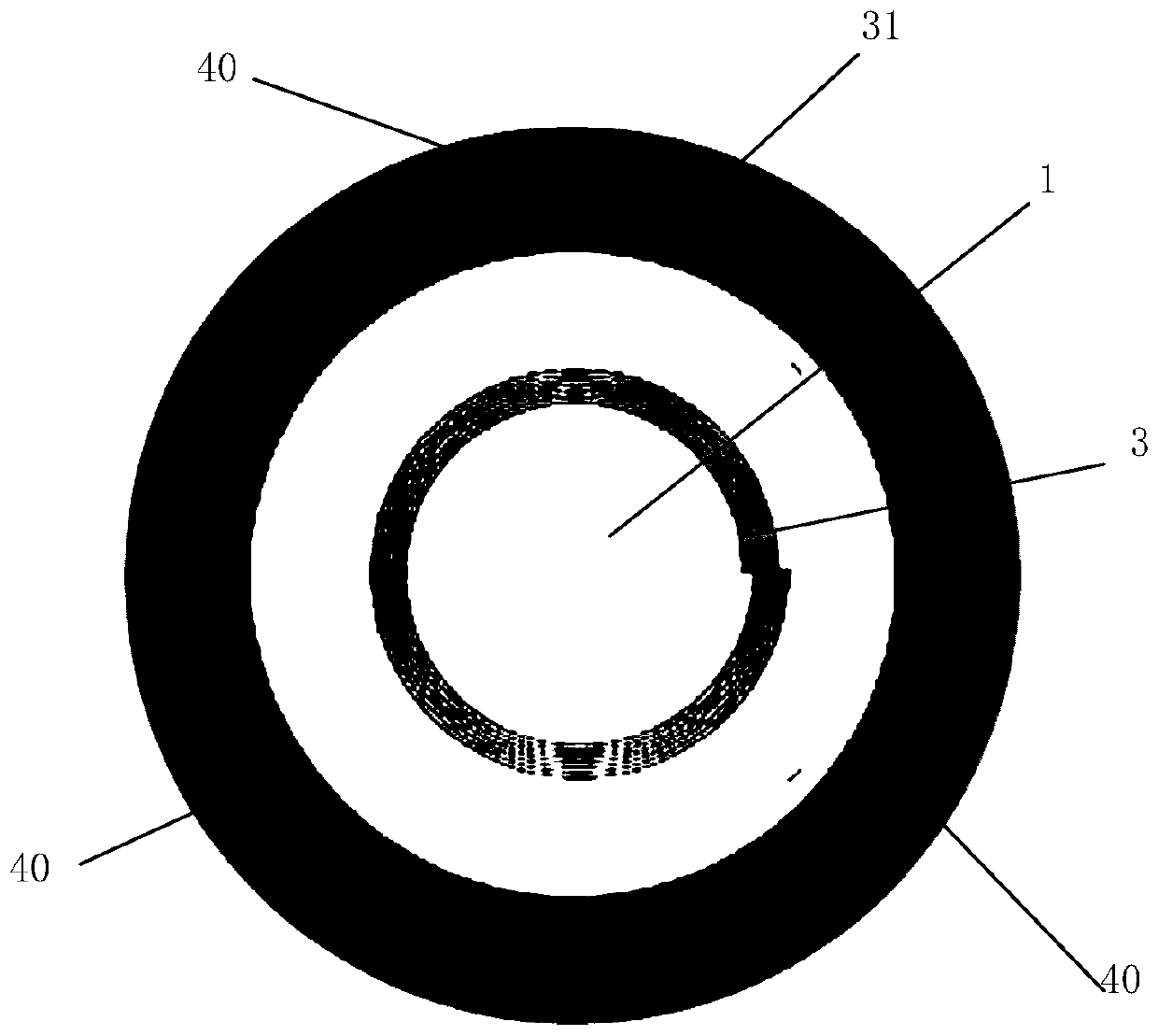

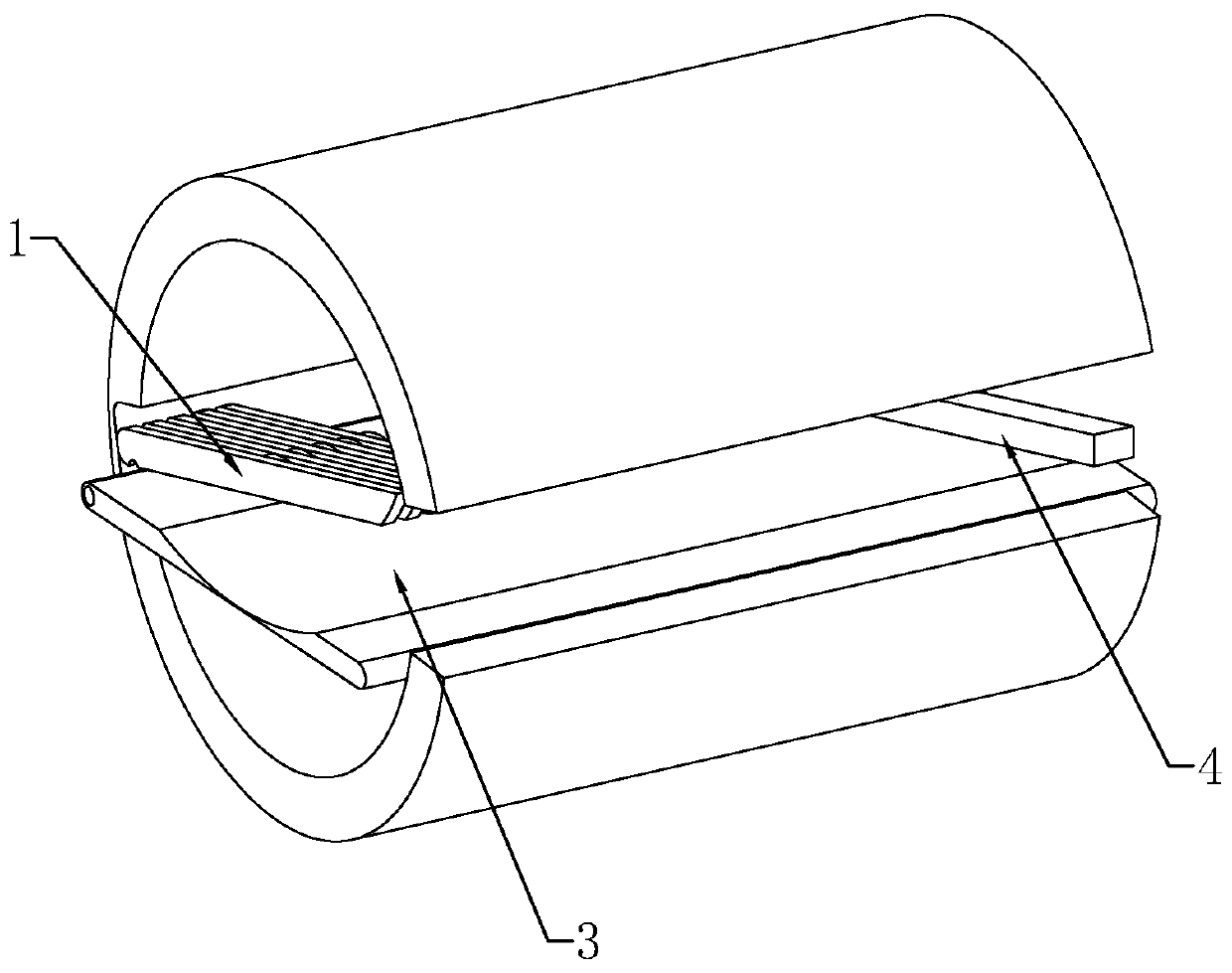

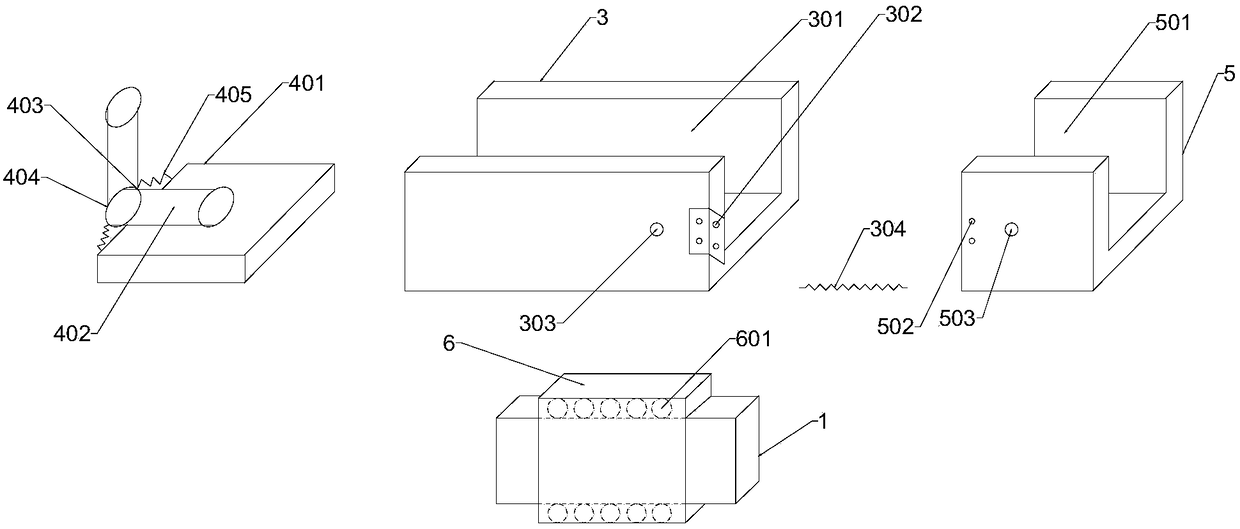

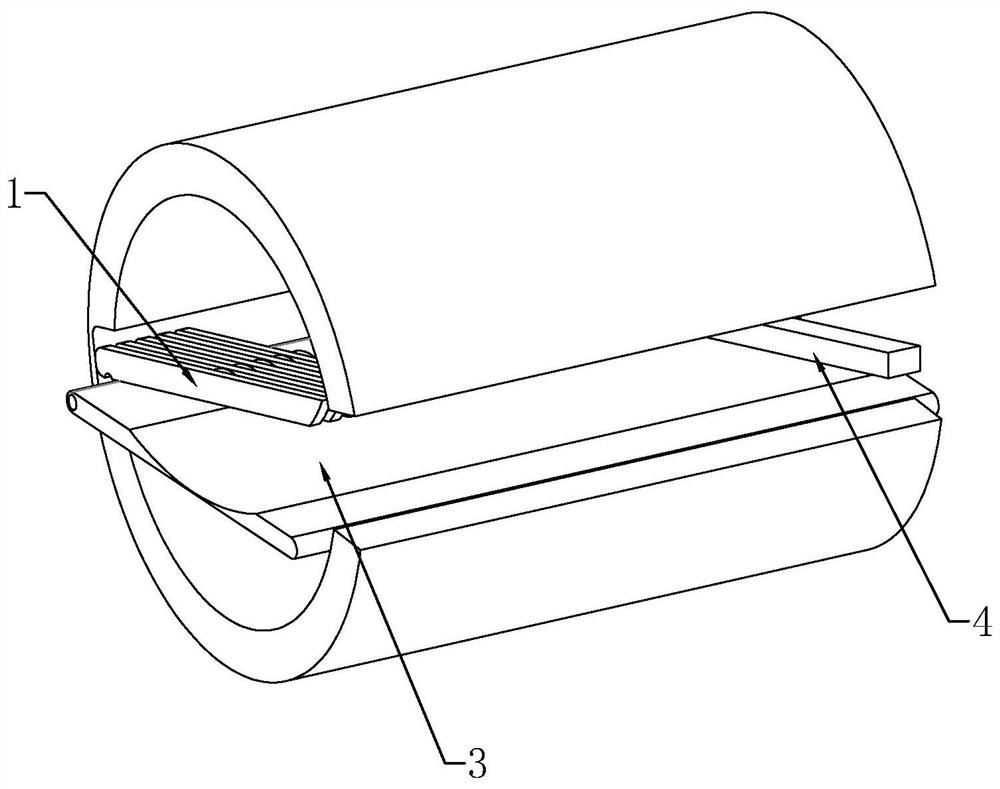

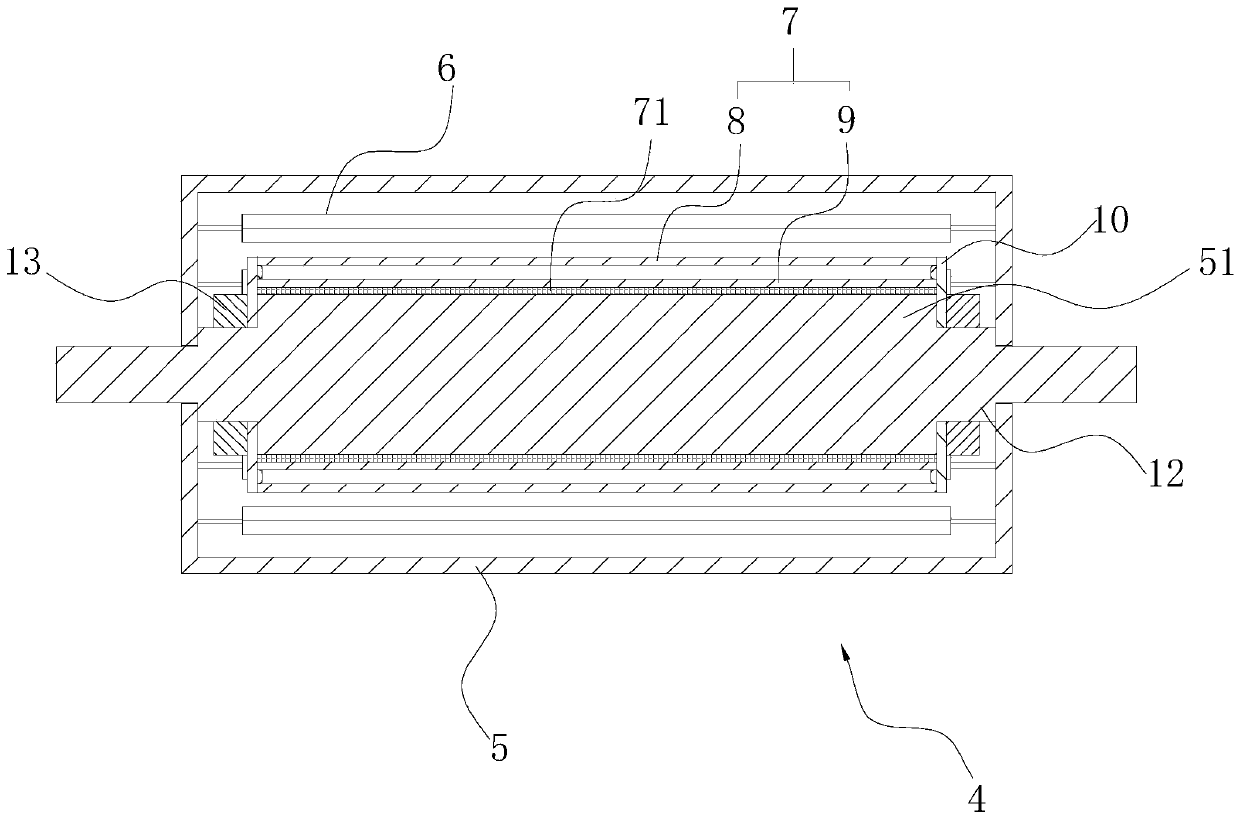

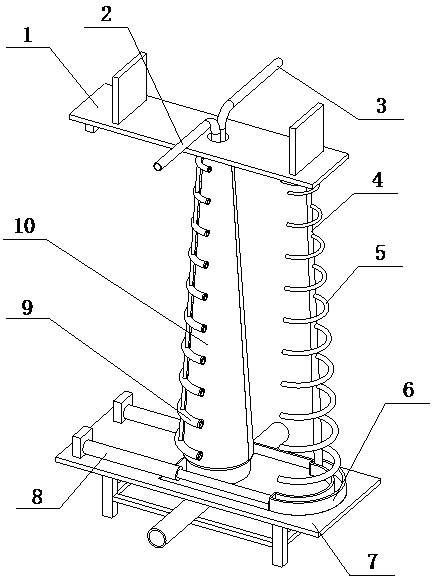

Smoothing reactor coil winding device

ActiveCN106158354AReduce bending difficultyReduce manufacturing costInductances/transformers/magnets manufactureBusbarEngineering

The invention relates to a smoothing reactor coil manufacturing device, which comprises a glue plate, a support body placed above the glue plate, a winding die arranged on the periphery of the support body for coil winding, and a coil hanger above it; An upper busbar and a lower busbar are respectively welded to the upper and lower coil outlets of the winding die, and the lower busbar is installed on the glue-connecting tray and a suspension is provided on the glue-connecting tray. The invention has a simple structure, the winding mold is spliced by steel pipes, and the production cost is low; the inner diameter of the coil and the tension force requirements during winding can be guaranteed; and the internal steel pipe is removed after the coil winding is completed, and the inner steel pipe does not need to be entered for internal operation, and the operation is convenient. At the same time, the coil sling and the crane are used for hoisting, the connection strength is reliable, and it is suitable for large-tonnage coils.

Owner:SHANDONG POWER EQUIP

A kind of technological method of bending and cutting oblique opening of paper straw

ActiveCN110450212BIncrease productivityDoes not significantly affect hardnessMetal working apparatusPulp and paper industryIndustrial engineering

The invention discloses a process method for bending and cutting a paper straw, which comprises the following steps: step 1: conveying the paper straw; step 2: indenting the paper straw, and the indentation method is an indentation knife and fixing with the indentation knife The connected circular groove blocks are indentation components for indentation; there are multiple indentation components, and the two indentation components are seamlessly connected and fixed; The set creasing knife obliquely cuts the end of the paper straw to form an oblique incision; step 4: receiving. The invention has the following beneficial effects: the paper straw bending and bevel cutting process can reduce the bending difficulty of the paper straw, and the bent part is not easy to break.

Owner:庄孔庆

A plate bending device for computer main case production

The invention provides a plate bending device for computer main box production, which belongs to the technical field of computer main box production, and includes a bottom box, the upper part of the bottom box is slidably provided with a support platform, and one side of the support platform is connected by an adjustment component. A pressing assembly, a bending assembly is arranged above the pressing assembly, the pressing assembly includes a base body and a cover hinged on the upper part of the base body, and the side between the cover body and the base body is also connected by a locking assembly, The side of the cover body facing the base body and the side of the base body facing the cover body are both provided with engaging slots corresponding to each other. The embodiment of the present invention has the advantage of good bending quality. By setting the heating plate, the bending part of the plate can be heated to soften the plate, so that the bending process of the plate by the bending assembly is more convenient, and the bending of the plate is improved. The bending quality reduces the bending difficulty of the plate, and effectively avoids the problem of breaking when the plate is cold bent.

Owner:广州市嘉翔电脑设备有限公司

Flexible display device and manufacturing method thereof

ActiveCN109712530BImprove the display effectPrevent creepIdentification meansEngineeringFlexible display

Embodiments of the present invention provide a flexible display device and a manufacturing method thereof. The flexible substrate of the flexible display device has a first straight region, a bending region and a second straight region; The first bending protective layer is set in the bending area to reduce the bending difficulty and the bending stress; the second bending protective layer is set in the bending area of the flexible substrate after bending, which can prevent the first bending protective layer from bending Creep that occurs after bending, and can further provide protection for the bending area, thereby preventing the flexible substrate and the wiring layer on the flexible substrate from being reduced due to the first bending protectant. The wiring provided on the flexible substrate cracks, thereby improving the display effect of the flexible display device.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

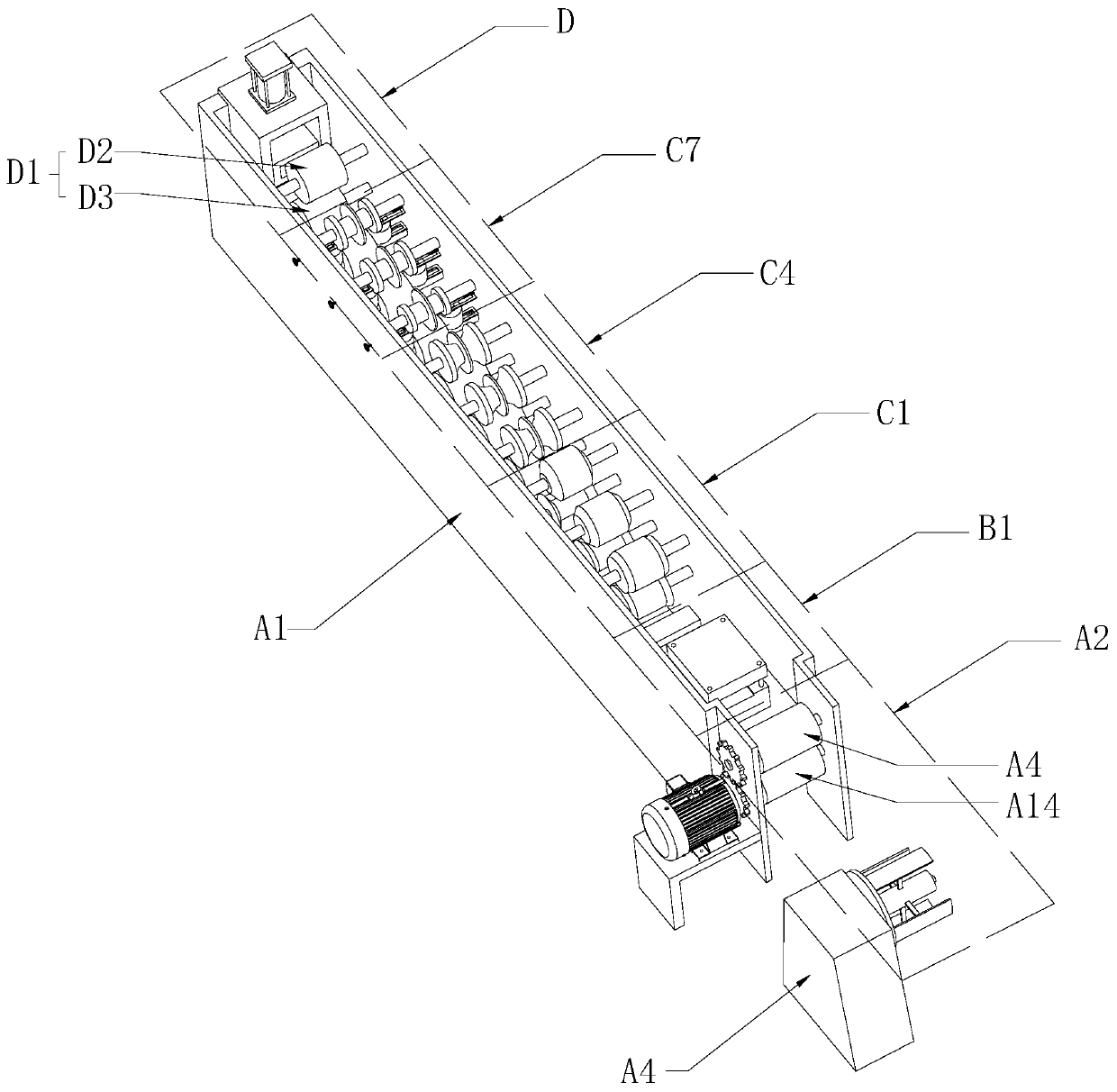

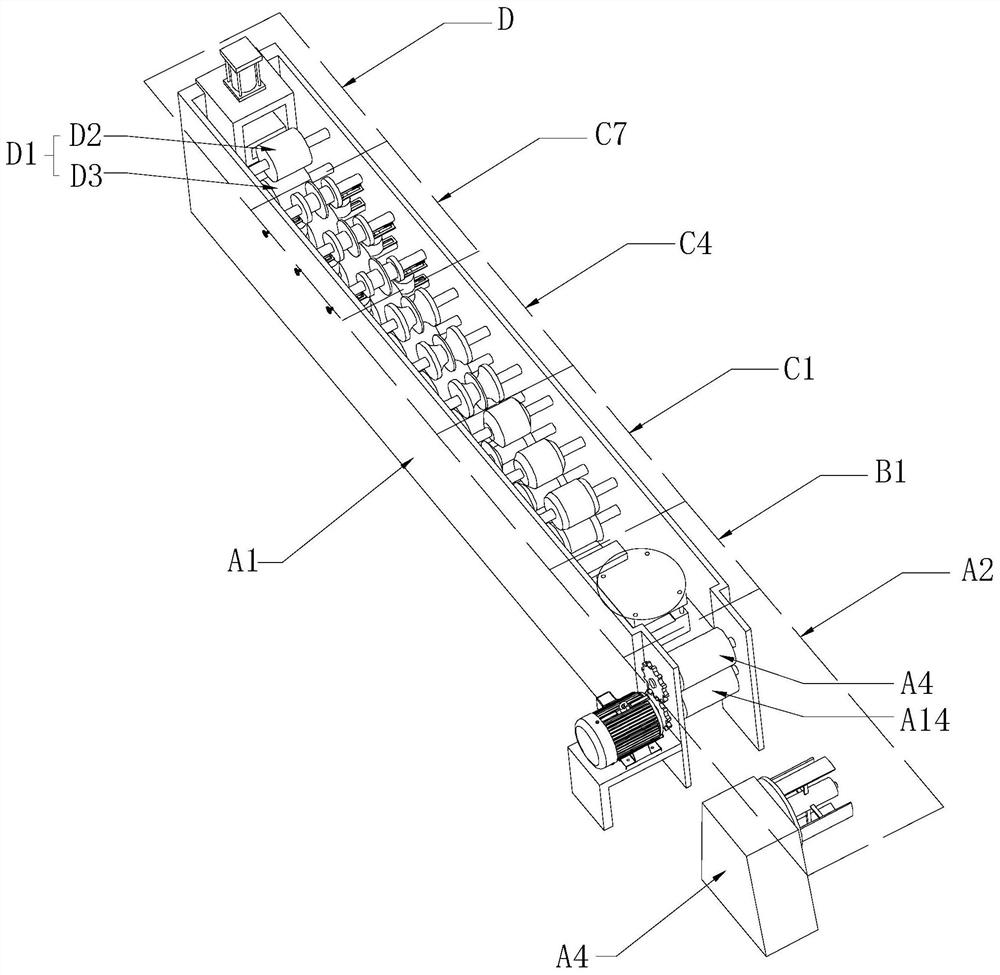

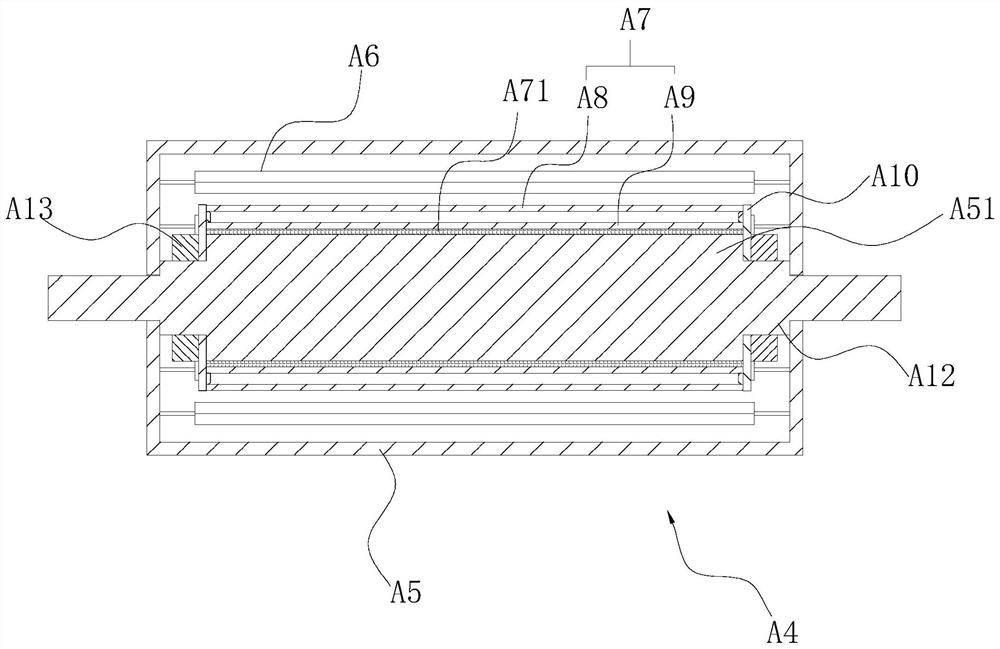

Motor support production equipment

ActiveCN109968034AReduce intensityEasy to cutShearing machinesOther manufacturing equipments/toolsEngineeringMachining

The invention relates to the field of machining of sheet metal, and discloses motor support production equipment. The motor support production equipment comprises a rack, a feeding unit installed on the rack, a bending unit and a discharging unit; the feeding unit comprises a rolling machine with strip-shaped board materials rolled and a feeding roller set installed on the rack; the bending unit comprises a primary bending roller set, a secondary bending roller set and a final bending roller set which are arranged in sequence; the discharging unit comprises a discharging roller set and a cutting-off device for cutting of the strip-shaped board materials; the discharging roller set comprises a lower discharging roller supported on a bottom board and an upper discharging roller abutting against a top board; and the cutting-off device comprises a supporting table and a cutting-off tool moving in the vertical direction. The motor support production equipment has the effects that the strip-shaped board materials move in the length direction of the rack, the bending unit extrudes the two sides of the strip-shaped board materials in the width direction to be bent to the middle, a final finished support passes through the feeding unit, the feeding unit cuts off the support at equal intervals, the purpose of rapidly and continuously forming the support is achieved, and the production efficiency is improved.

Owner:浙江理通风机科技股份有限公司

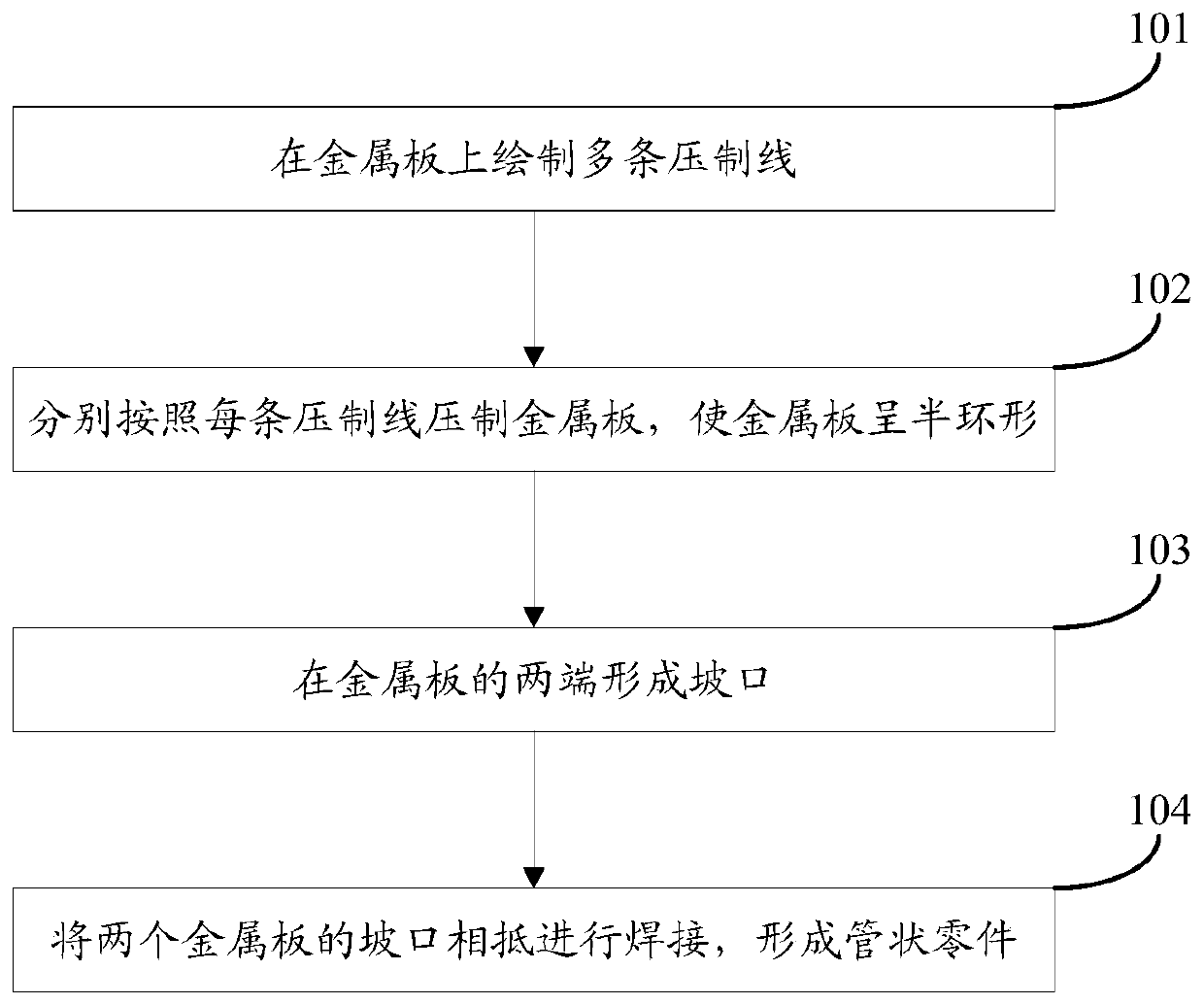

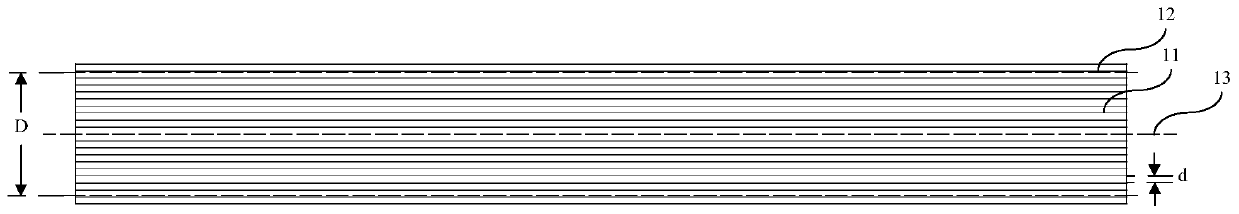

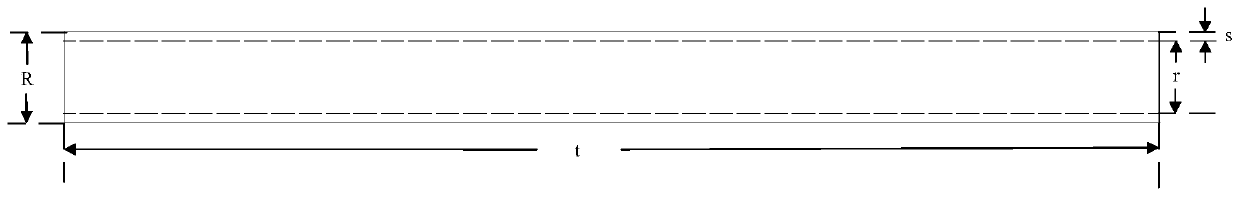

Manufacturing method of tubular parts

The invention discloses a manufacturing method of tubular parts, and belongs to the field of machining. The manufacturing method comprises the following steps that a plurality of pressing lines are drawn on metal plates, thicknesses of the metal plates are equal to the wall thicknesses of the tubular parts, and the lengths of the metal plates are equal to the lengths of the tubular parts; each pressing line is parallel to the length direction of the metal plate, and the pressing lines are arranged at intervals in the width direction of the metal plates; the metal plates are pressed according to each pressing line to enable each metal plate to be in a semi-ring shape, grooves are formed at the two ends of the metal plates, and the grooves of the two metal plates are abutted against each other for welding to form the tubular parts. According to the manufacturing method, and the manufacturing of the small-caliber thick-wall long tubular parts is realized by multiple times of pressing.

Owner:WUHAN MARINE MACHINERY PLANT

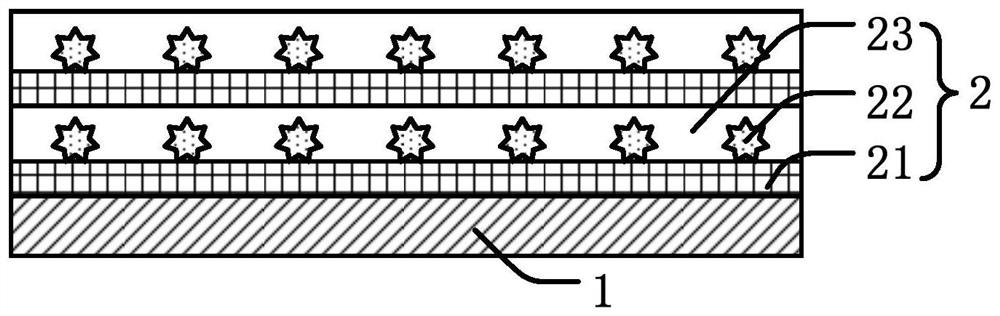

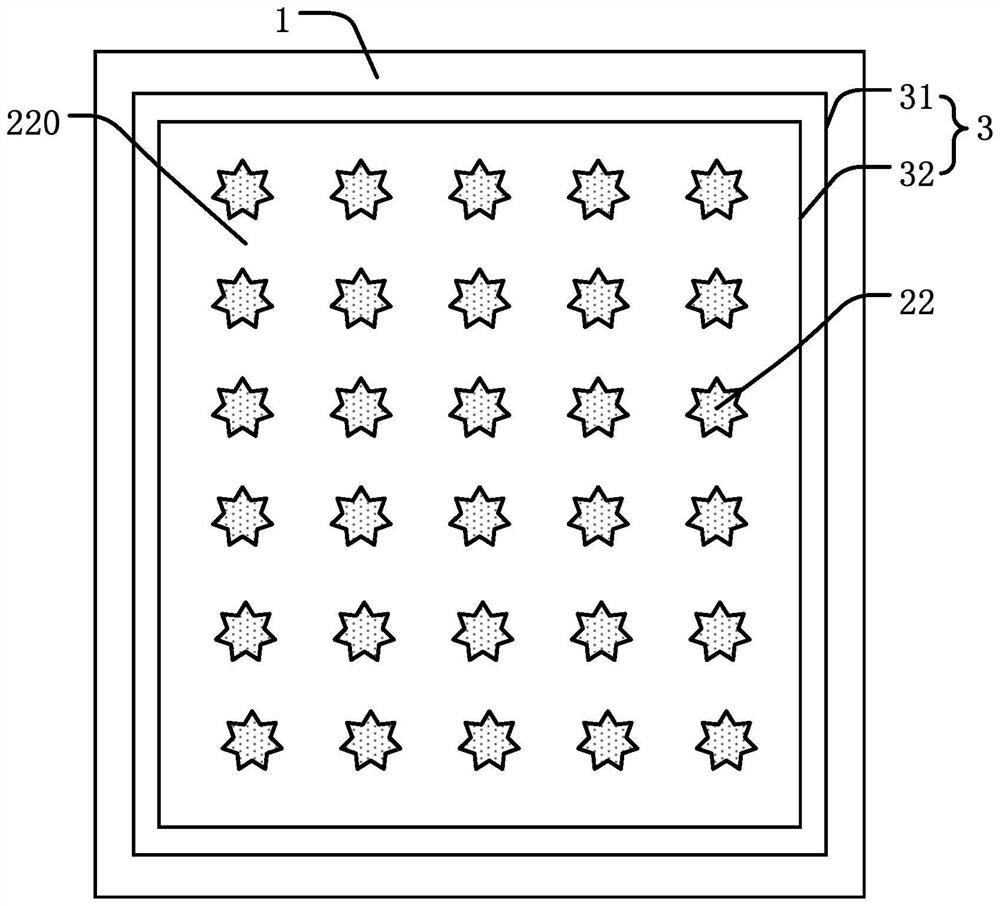

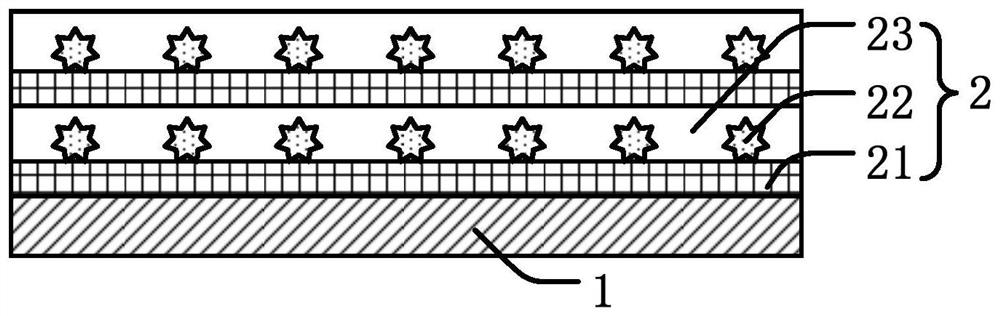

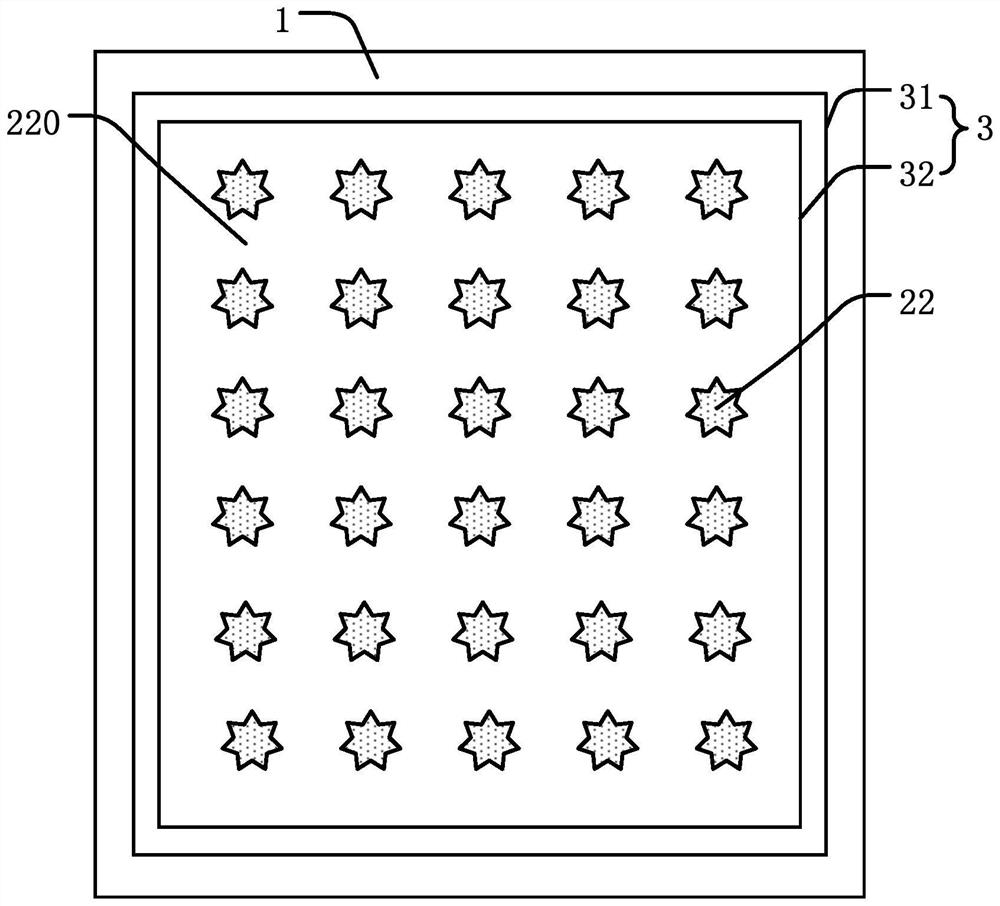

Display panel, method for producing the same, and display device

ActiveCN111864104BEasy to spreadImprove the level ofSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display panel, a preparation method thereof, and a display device. The display panel includes a substrate and an encapsulation layer, wherein the encapsulation layer is a stacked film layer formed by stacking an inorganic layer and an organic layer; the inorganic layer faces One side of the organic layer is evenly distributed with a layer of rough particles. The technical effect of the present invention is that a layer of rough particles is formed on the surface of the inorganic layer, the roughness of the surface of the inorganic layer is improved, the subsequent organic layer can be better spread and leveled, and the thickness of the organic layer is reduced, Further reduce the thickness of the encapsulation layer and the display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

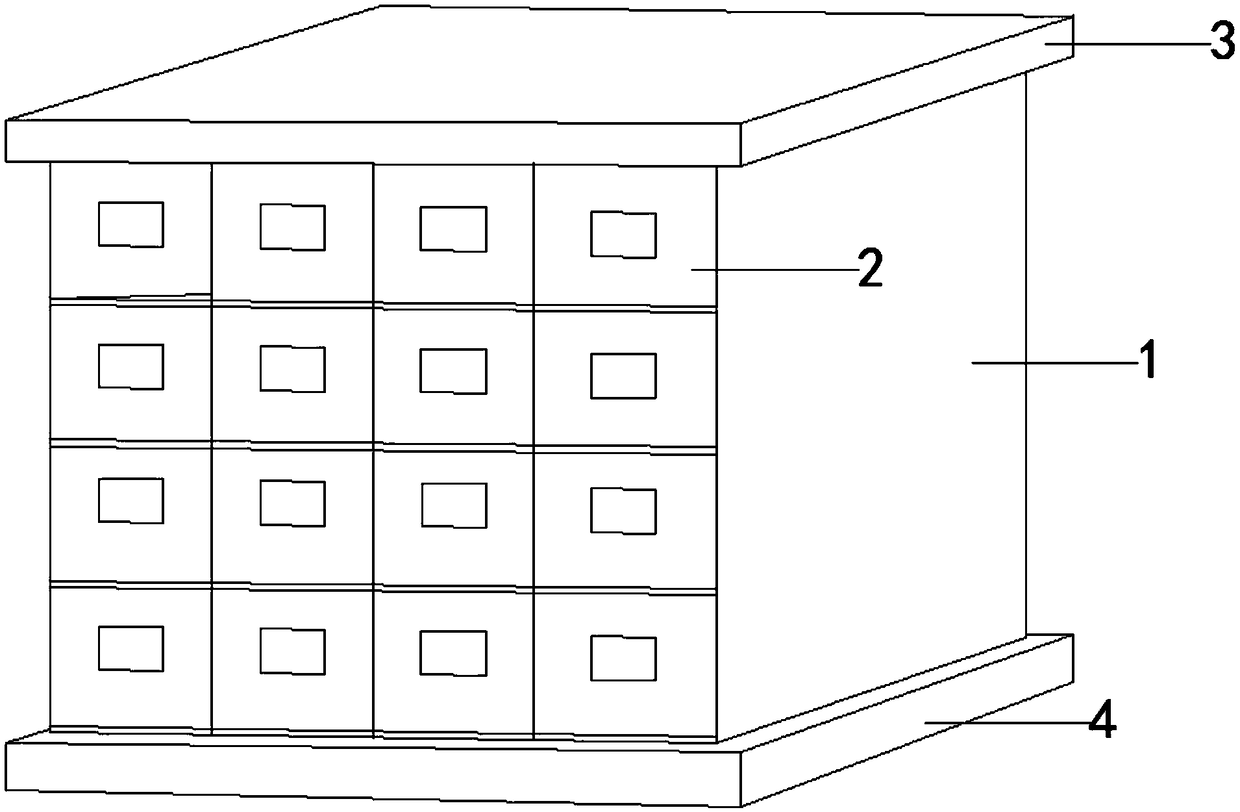

One-time molding and stamping process of a storage rack for ashes

ActiveCN108505815BSolve the problem of scattered storageReduce convenienceBurial vaultsMonumentsEdge structureEngineering

Owner:江西天境精藏科技有限公司

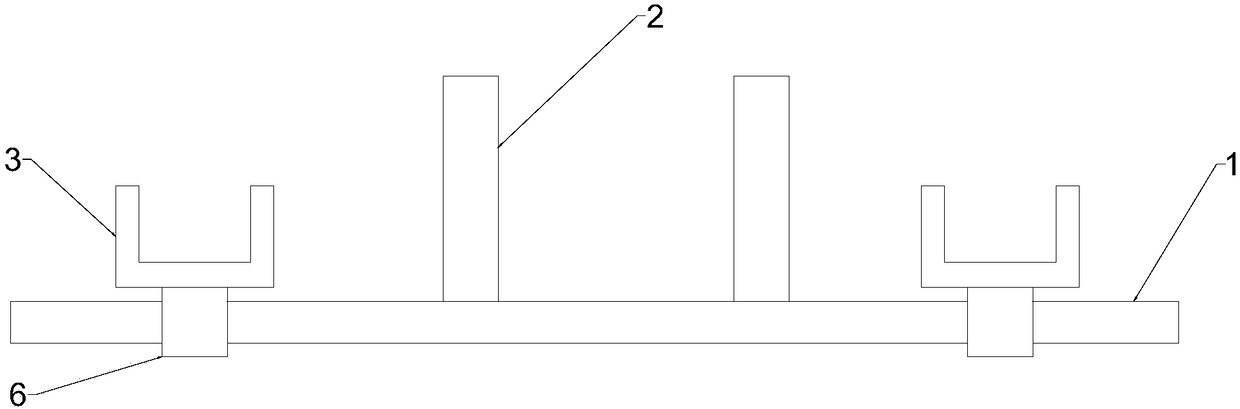

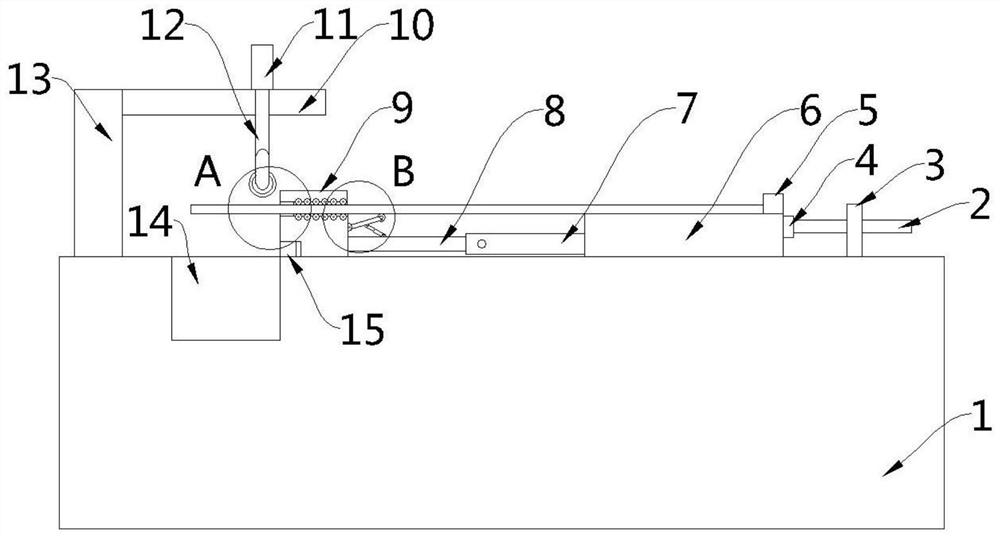

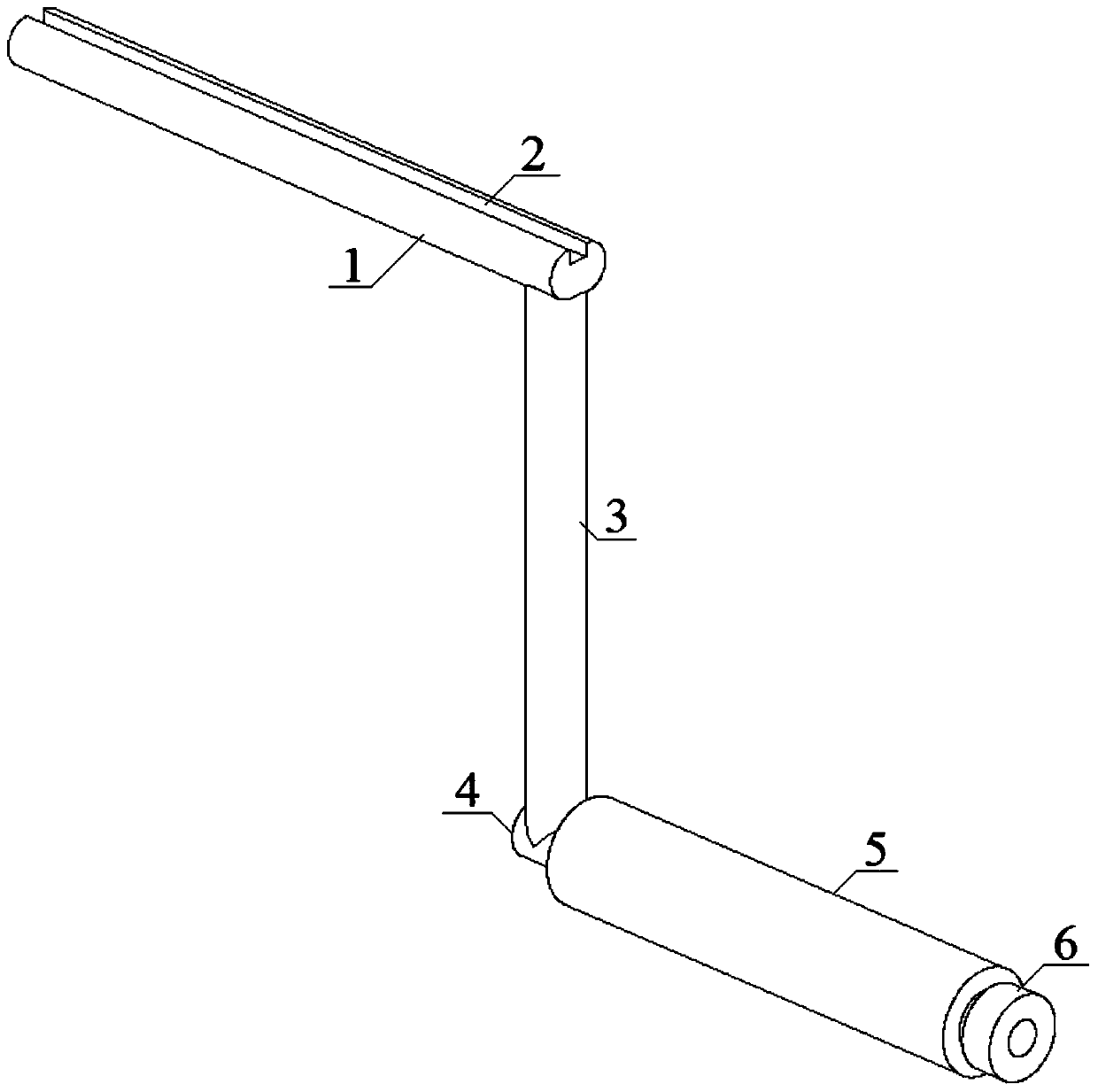

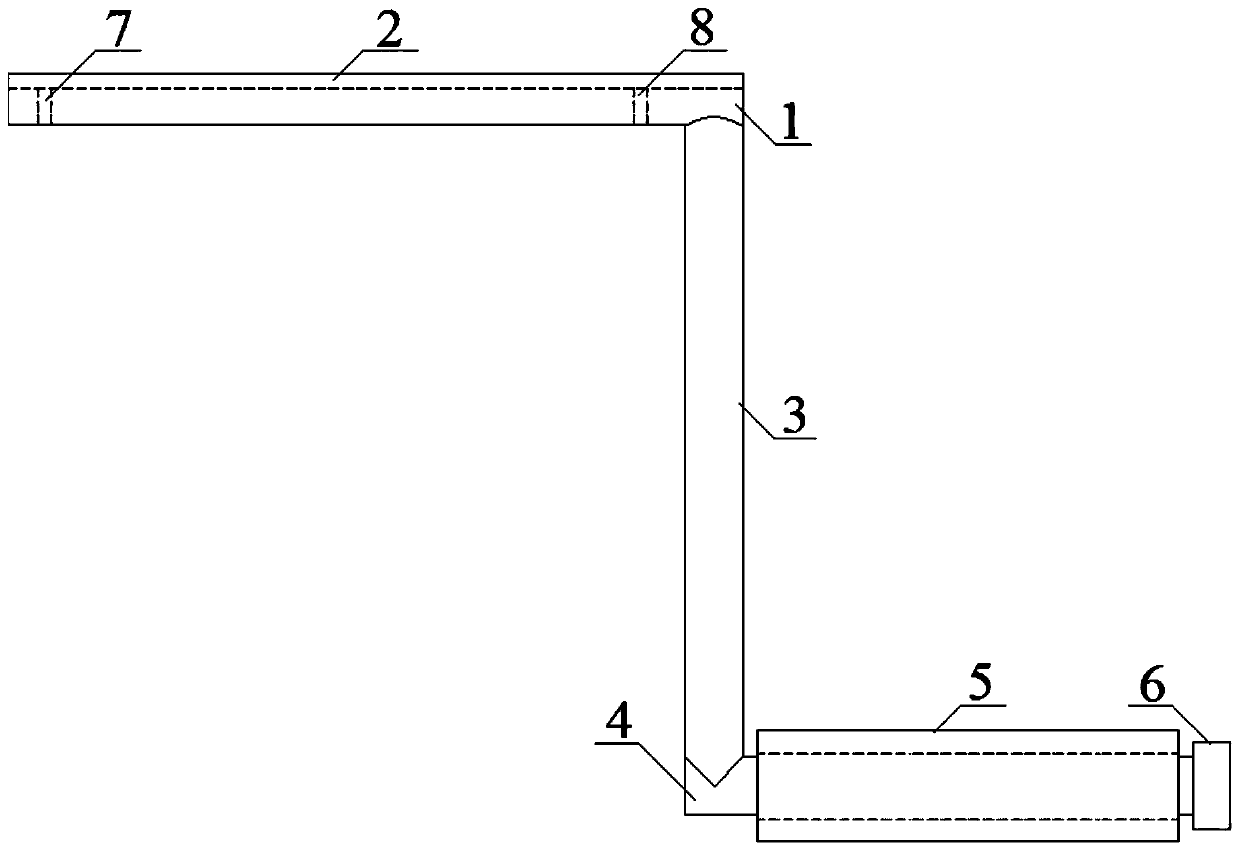

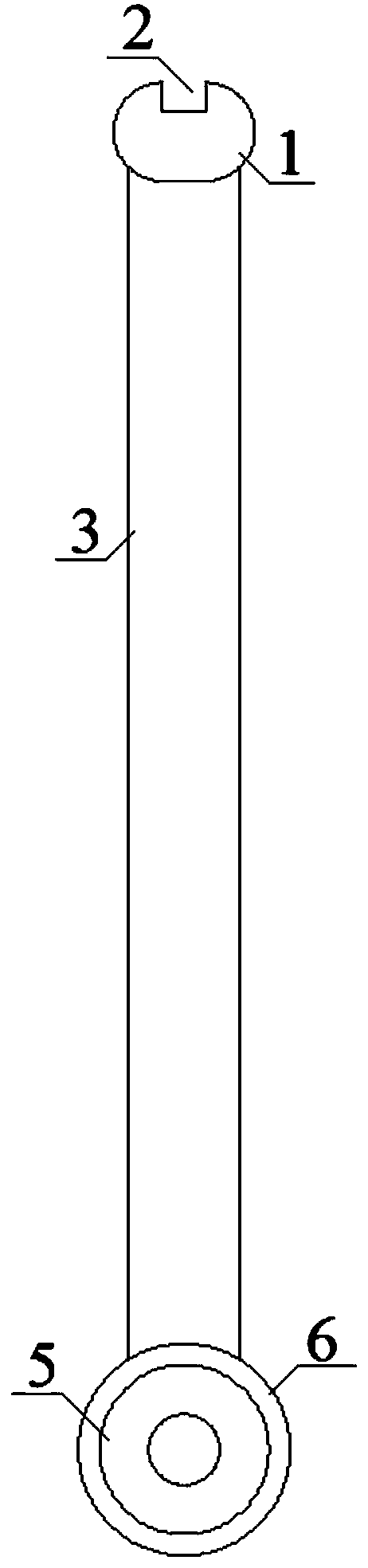

Small-diameter and small-size chain ring manual bending tool and forming method

The invention belongs to the technical field of metal piece machining, and discloses a small-diameter and small-size chain ring manual bending tool which comprises a core bar and a handle. The radialsection of the core bar is elliptical. A groove is formed in the side wall of the core bar in the axial direction of the core bar. A first through hole running through the core bar in the radial direction is formed in the groove. The handle is fixed to the core bar. By means of the small-diameter and small-size chain ring manual bending tool, the efficient and high-quality manual bending machiningof a small-diameter and small-size chain ring can be realized.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

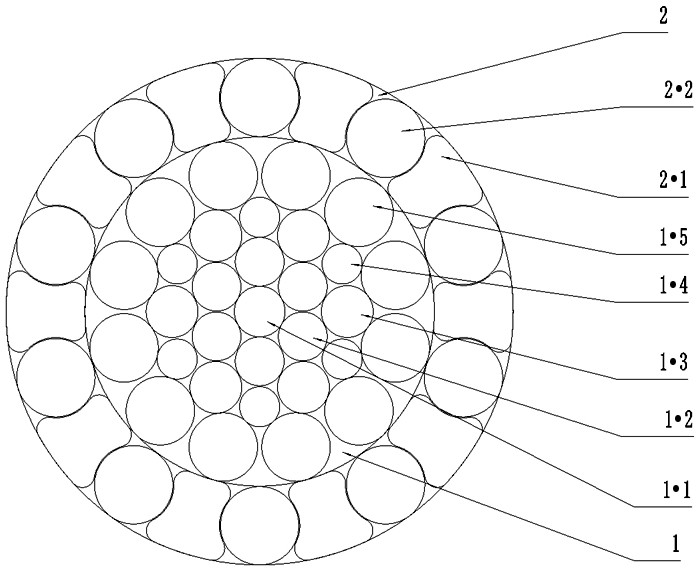

Sealed steel wire rope with diameter of 42 mm and manufacturing method thereof

InactiveCN111648149AGuaranteed general soft and flexible capabilitiesImprove wear resistanceTextile cablesBreaking strengthMaterials science

The invention discloses a sealed steel wire rope with a diameter of 42 mm and a manufacturing method thereof. The sealed steel wire rope with the diameter of 42 mm consists of inner layer strands andan outer layer from inside to outside; and the outer layer is composed of H-shaped steel wires and round wires. The inside of the steel wire rope is in a point-line contact state, which can maintain the necessary flexibility of the steel wire rope; the external surface is sealed, the metal fill factor is increased, and the effective metal cross-sectional area is increased; and therefore, the wearresistance, fatigue resistance and breaking strength are improved.

Owner:GUIZHOU WIRE ROPE

Manufacturing method of flexible display device and flexible display device

ActiveCN108281387BReduce difficultyIncrease the difficultyFinal product manufactureSemiconductor/solid-state device detailsFlexible circuitsEngineering

The invention provides a manufacturing method of a flexible display device and the flexible display device. In the manufacturing method of the flexible display device of the present invention, the bending area of the flexible display panel is first bound to the flexible circuit board, then the bending area of the flexible display panel is bent toward the back of the flexible display panel, and then the flexible display panel Making the first protective adhesive layer on the front side of the flexible display panel corresponding to the bending area. The first protective adhesive layer is used to protect the wiring in the bending area, and at the same time, since the first protective layer is formed after the bending area is bent, compared with the prior art, the bending area of the flexible display panel is reduced. Difficulty, reduce the stress on the bending area of the flexible display panel during bending, and improve product quality.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

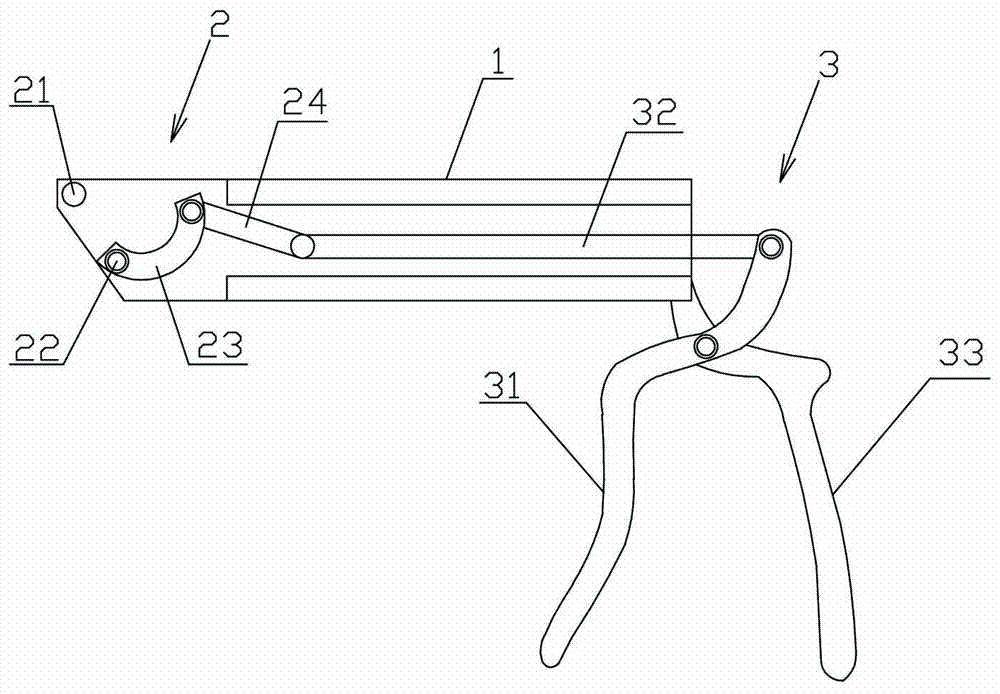

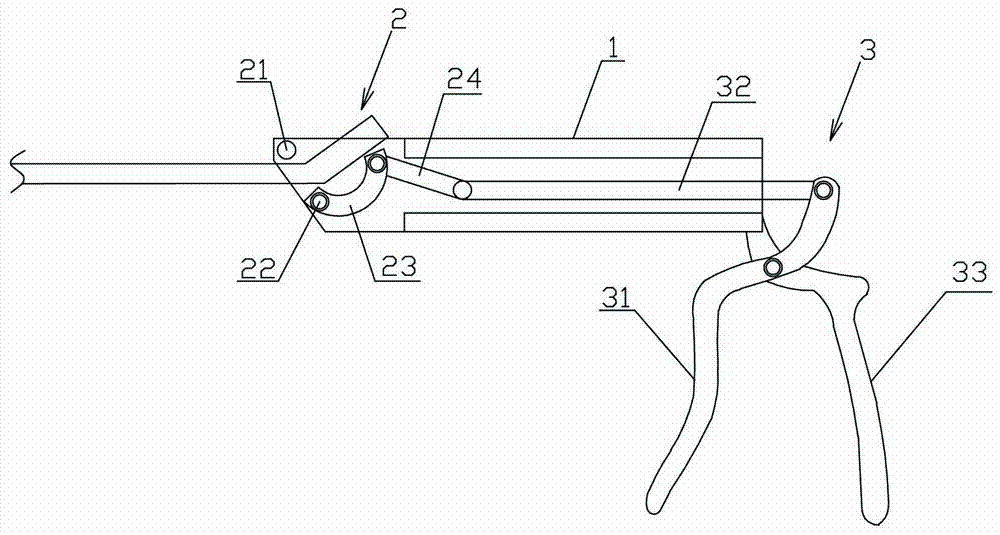

A special Kirschner wire bending device for orthopedics and its application method

ActiveCN105496542BEasy to useBending stabilityOsteosynthesis devicesArthroscopic procedureEngineering

The invention discloses a Kirschner wire bending device dedicated to orthopedics and its use method. A pushing device for braking and controlling the bending angle is provided at the rear of the bending gun frame body, and the bending part is driven and connected with the power output end of the pushing device. The present invention can not only complete the bending and use of the Kirschner wire very easily, and will not cause the Kirschner wire to move during the bending process, causing damage to other tissues, but also can be operated very conveniently during operation; on the other hand , the present invention bends the Kirschner wires by using a connecting bar push structure and a two-step bending method. The structure is more reasonable and convenient, and the working method of bending is more clever and practical; It is more suitable for narrow operating space, such as in the joint cavity, making it better used in arthroscopic surgery.

Owner:浙江西塘实业有限公司

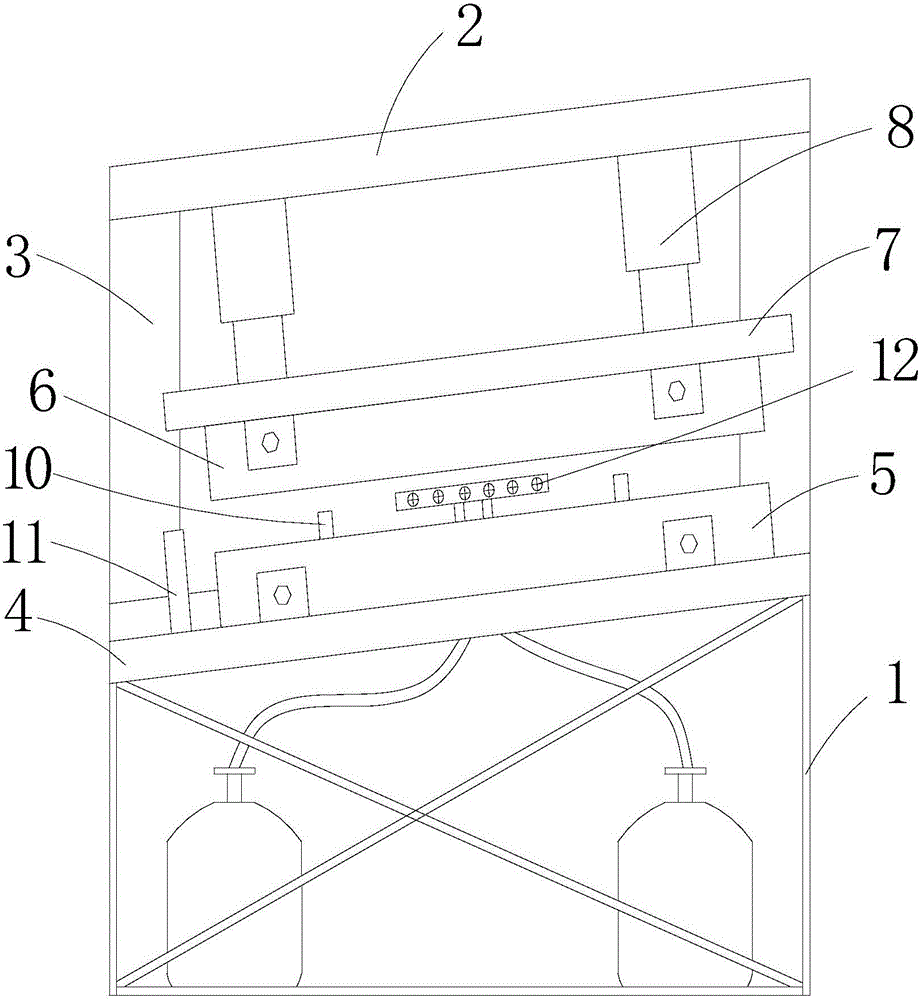

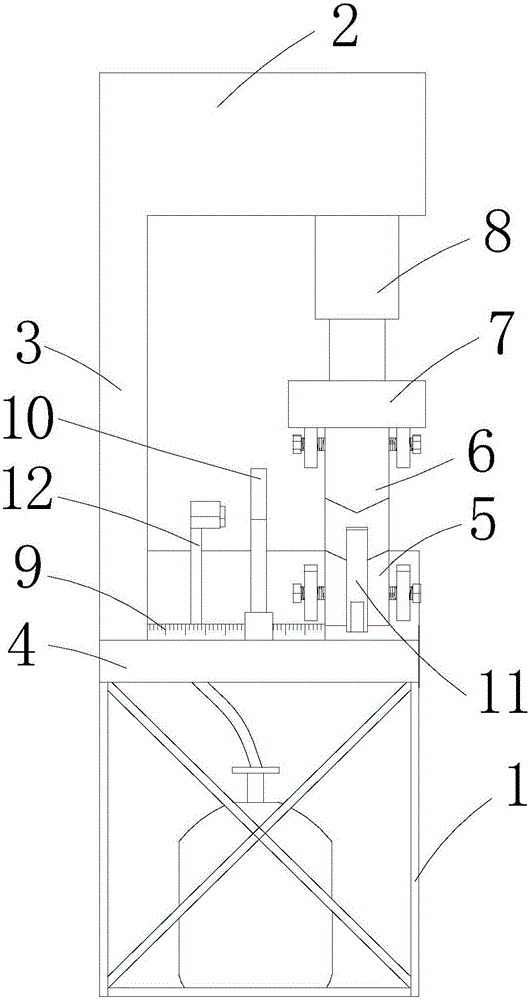

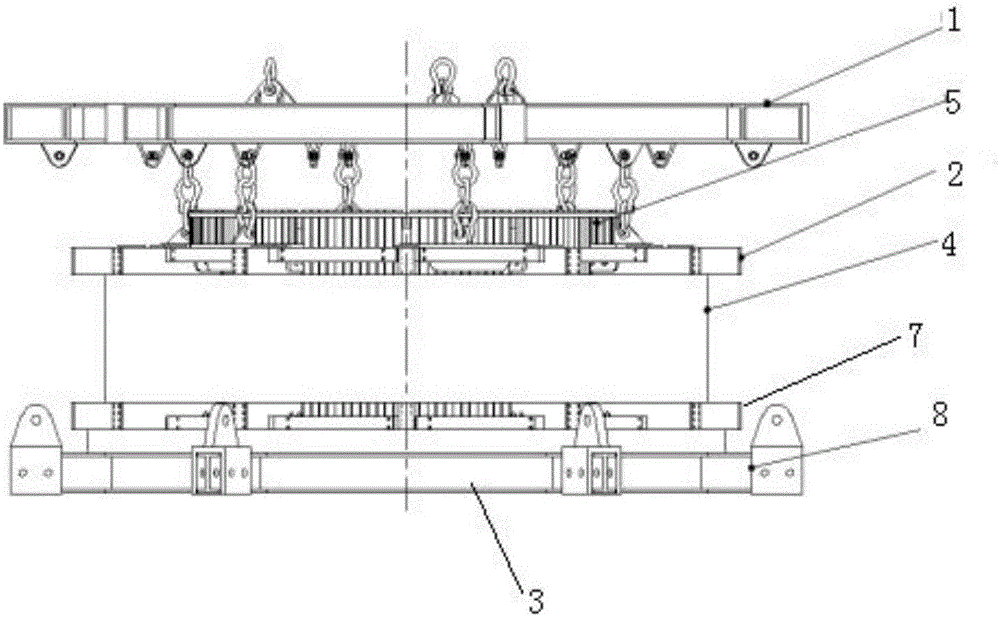

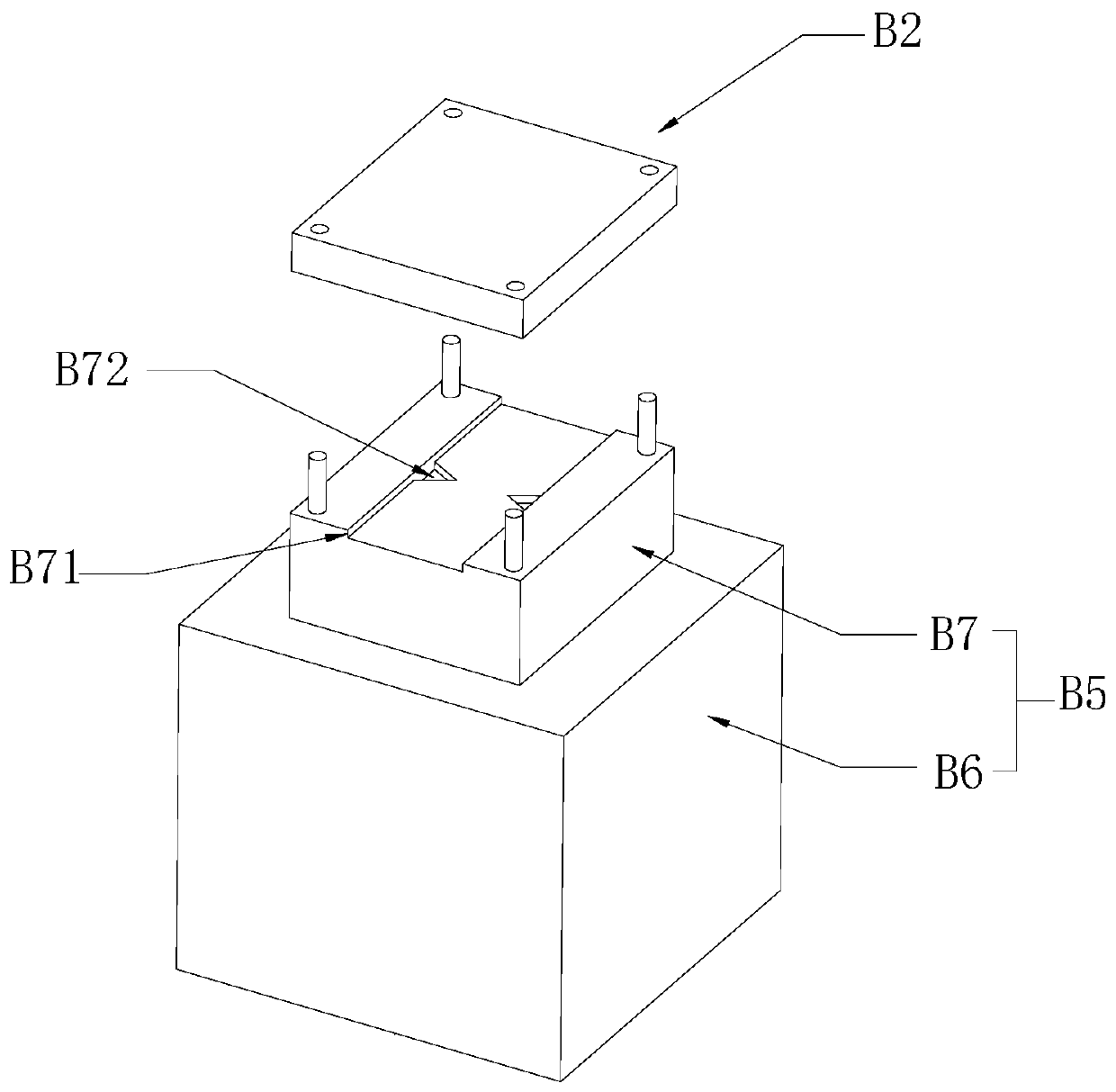

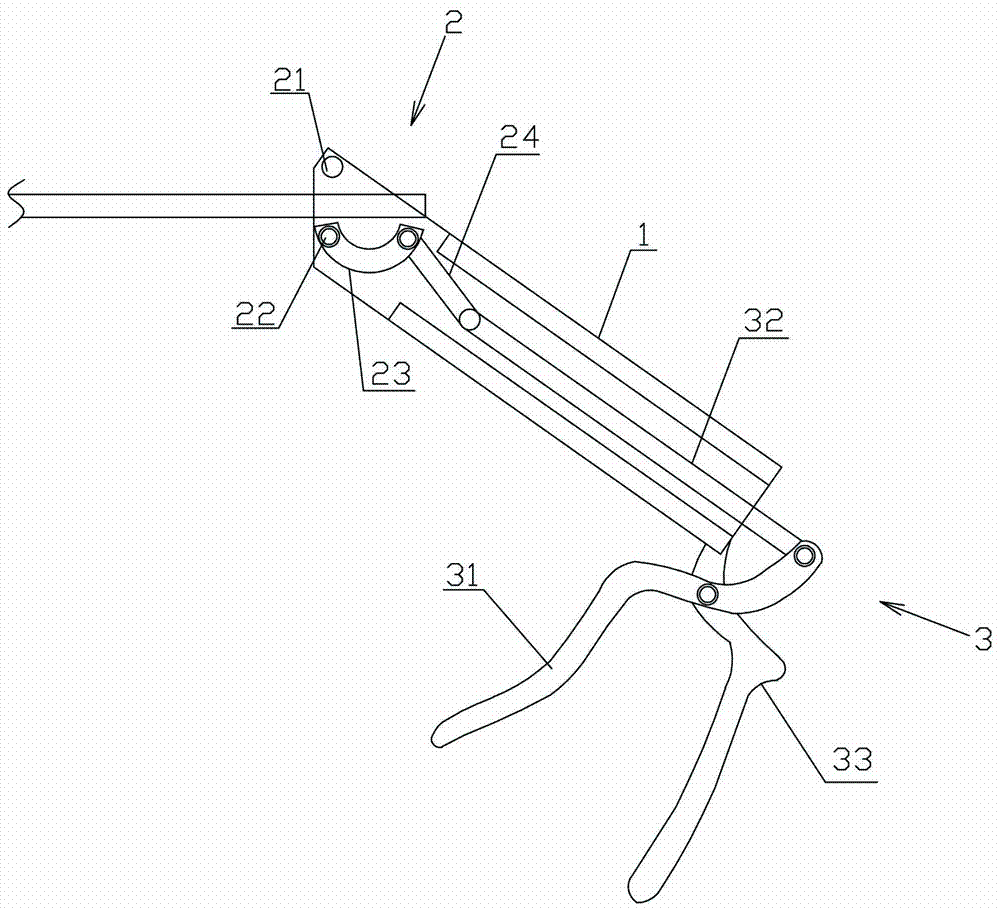

Medical suture needle bending device and using method thereof

InactiveCN114309346AReduce intensityReduce bending difficultyWire articlesNeedlesSuturing needleEngineering

The invention relates to a medical suture needle bending device and a use method thereof, and discloses a bending device for carrying out heat treatment on straight needles through a heat storage cylinder and then carrying out one-time concentrated bending on the straight needles with different sizes through cooperation of a plurality of bending pipes with different sizes and a needle pushing assembly, and a use method of the bending device. The upper fixing plate is located above the supporting platform, the bending assembly is arranged between the supporting platform and the upper fixing plate, the push rod assembly is arranged between the supporting platform and the upper fixing plate in a sliding mode, a lower hydraulic rod is arranged on the supporting platform, and an upper hydraulic rod corresponding to the lower hydraulic rod is arranged on the upper fixing plate. The push rod assembly slides under the action of the upper hydraulic rod and the lower hydraulic rod to push the straight needle into the bending assembly, and the bending assembly heats and bends the straight needle.

Owner:江苏侎医特信息科技有限公司

A kind of motor bracket production equipment

ActiveCN109968034BReduce intensityEasy to cutShearing machinesOther manufacturing equipments/toolsElectric machineryMachining

Owner:浙江理通风机科技股份有限公司

Method for preparing flexible display panel, flexible display panel and display device

ActiveCN109215511BReduce bending difficultyReduce stressMechanical working/deformationLamination ancillary operationsDisplay deviceFlexible display

The invention discloses a preparation method of a flexible display panel, a flexible display panel and a display device, which are used for reducing the difficulty of bending a bending area of the flexible display panel. The preparation method of the flexible display panel includes: attaching a back film on the back of the display substrate, wherein the display substrate is divided into a display area and a non-display area, and the non-display area includes a curved panel adjacent to the display area. A folding area, and a binding area adjacent to the bending area, the back film has a continuous pattern covering the display area and extending to the non-display area, and the back film has a hollow area in the non-display area , the orthographic projection of the hollow area on the display substrate at least covers the area between the binding area and the display area in the bending area; at least remove the back film on the front of the display substrate Projecting the part covering the bending area; bending the display substrate toward the back along the bending area to form the flexible display panel.

Owner:BOE TECH GRP CO LTD +1

Flexible circuit board and optical module with said flexible circuit board

ActiveCN103957657BGood flexibilityGuaranteed connectivityPrinted circuit detailsOptical ModuleFlexible circuits

The present invention provides a flexible circuit board. The flexible circuit board includes at least two circuit layers and an insulating layer between every two circuit layers. Each circuit layer includes a metal layer and a cover film covering the metal layer. The insulating layer is stacked with the metal layers of every two circuit layers, at least one of the circuit layers is recessed with a bending area, and the bending area is formed on the metal layer or the circuit layer. The invention also provides an optical module with the flexible circuit board.

Owner:HUAWEI MACHINERY

Display panel, preparation method thereof and display device

ActiveCN111864104AEasy to spreadImprove the level ofSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceStructural engineering

The invention discloses a display panel, a preparation method thereof and a display device. The display panel comprises a substrate and a packaging layer, the packaging layer is a laminated film layerformed by stacking an inorganic layer and an organic layer, and a layer of coarse particles are uniformly distributed on one surface, facing the organic layer, of the inorganic layer. The display panel has the technical effects that a layer of coarse particles is formed on the surface of the inorganic layer, the roughness of the surface of the inorganic layer is improved, the subsequent organic layer can be better spread and leveled, the thickness of the organic layer is reduced, and the thickness of the packaging layer and the thickness of the display panel are further reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com