Manufacturing method of flexible display device and flexible display device

A flexible display device and flexible display technology, which are applied in identification devices, final product manufacturing, climate sustainability, etc., can solve the problems of increasing the difficulty of bending, line damage, and increasing the stress of the bending area 110', and reduce the Difficulty of bending, stress prevention, stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

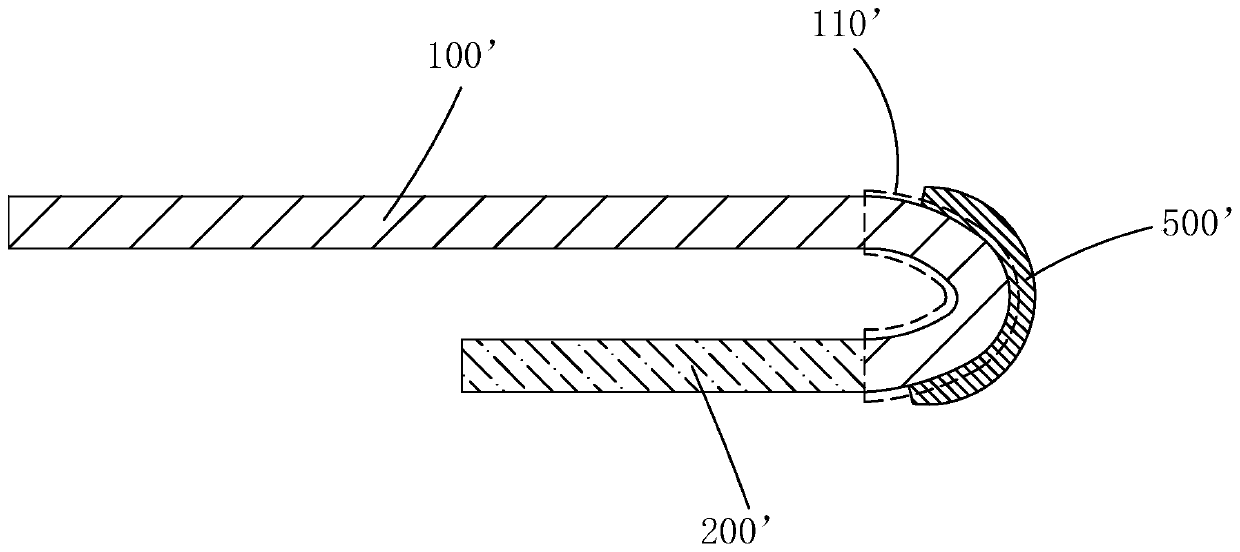

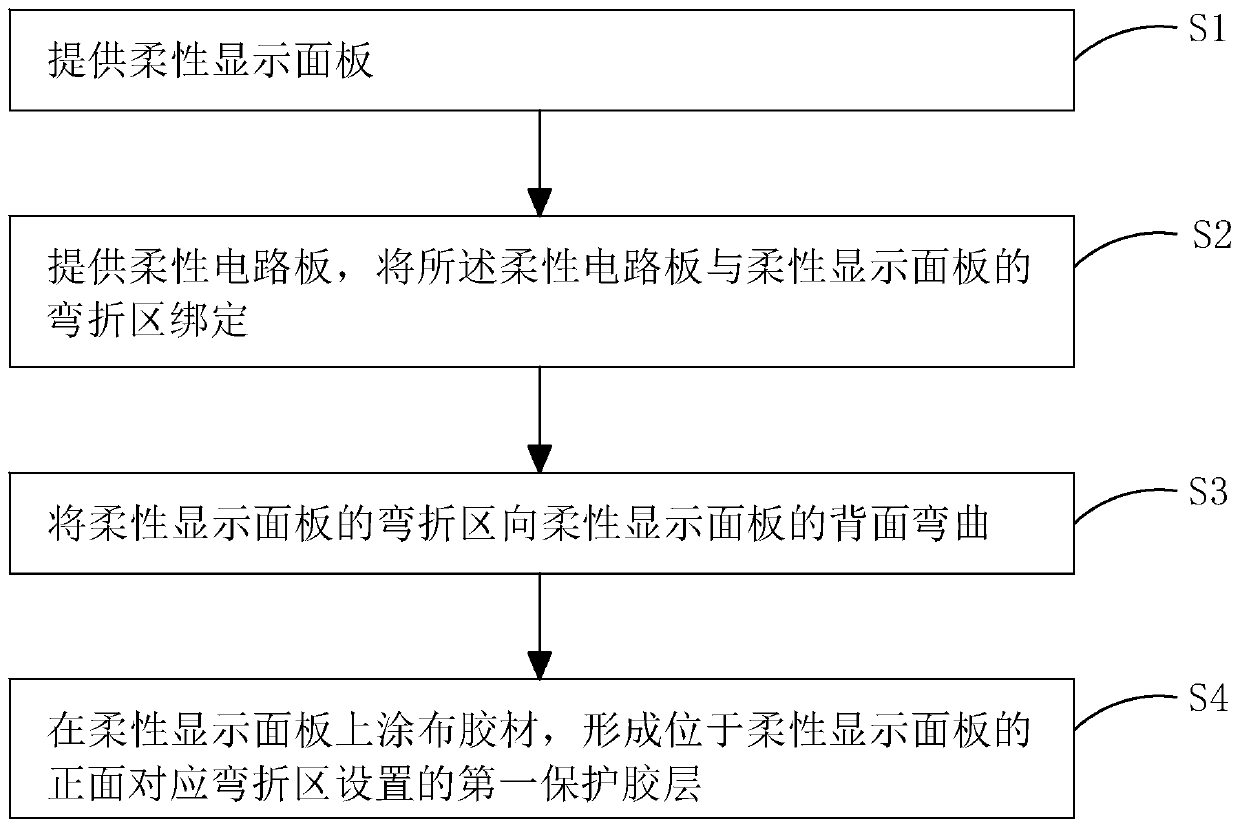

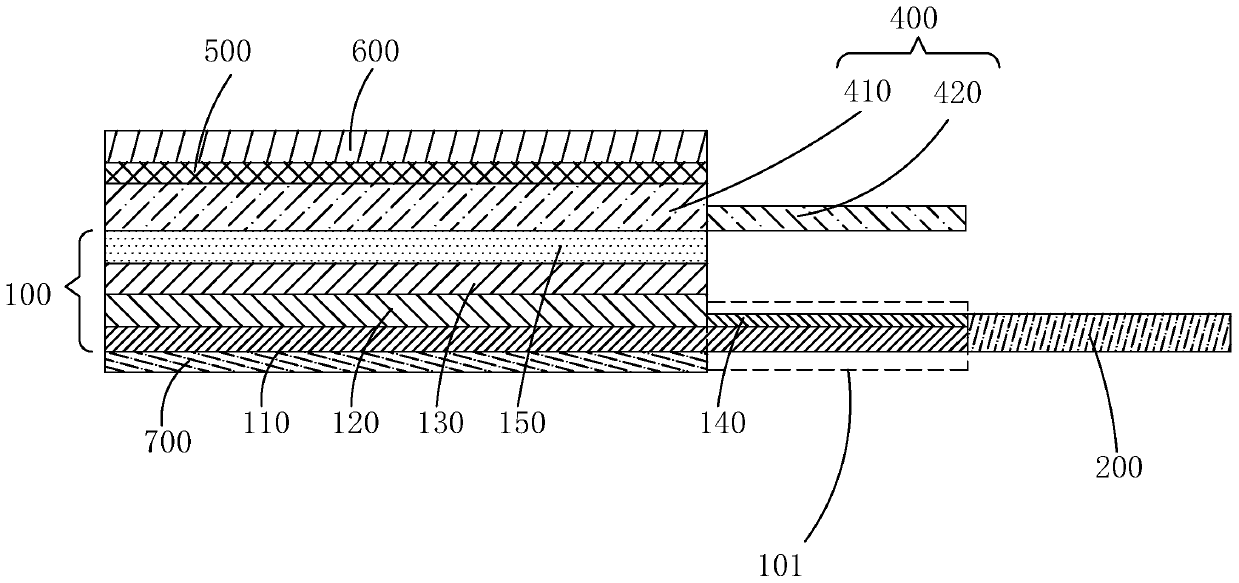

[0056] Based on the same inventive concept, the present invention also provides a flexible display device manufactured by the above-mentioned manufacturing method of the flexible display device, please refer to Figure 5 , is the first embodiment of the flexible display device of the present invention, and the flexible display device includes: a flexible display panel 100, a flexible circuit board 200 bound to the flexible display panel 100, and a first protective glue disposed on the flexible display panel 100 Layer 310;

[0057] The flexible display panel 100 has a bending area 101 at one end thereof, and the flexible circuit board 200 is bound to the bending area 101 of the flexible display panel 100; the bending area 101 of the flexible display panel 100 faces the flexible display panel The back side of the flexible display panel 100 is curved; the first protective adhesive layer 310 is located on the front side of the flexible display panel 100 corresponding to the bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com