Motor support production equipment

A technology for producing equipment and motor brackets, applied in the field of sheet metal processing, can solve the problems of not being too large in gaps and difficult bending dimensions, and achieve the effect of reducing difficulty and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

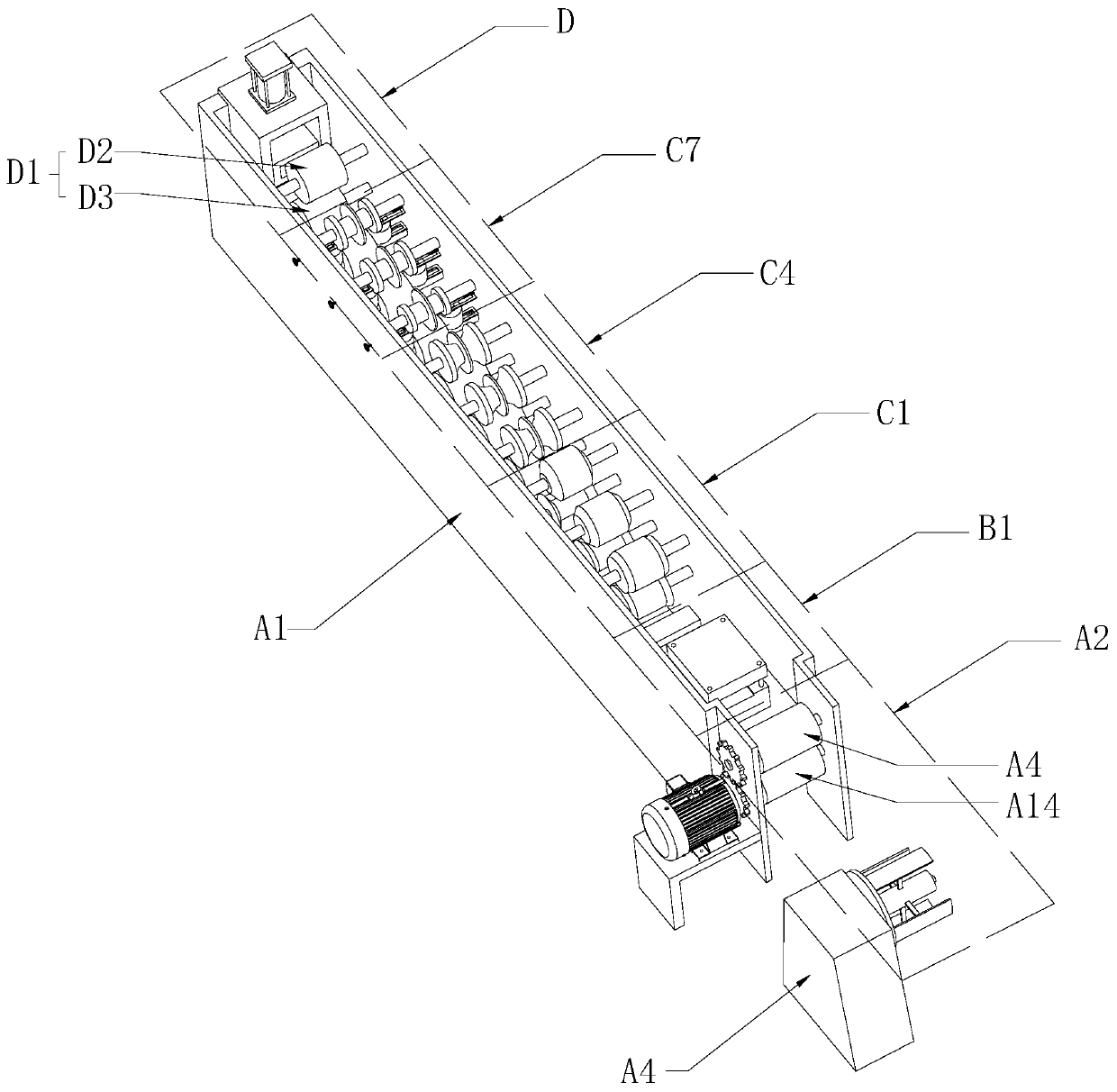

[0047] Such as figure 1 As shown, a motor bracket production equipment includes a frame A1, a feeding unit A2 installed on the frame A1, a bending unit and a discharging unit D. The strip sheet moves along its length on the frame A1, the bending unit squeezes both sides of the width of the strip sheet to bend toward the middle, and the final formed bracket passes through the feeding unit A2, which cuts off the bracket at equal intervals , to achieve the purpose of fast and continuous forming brackets, and improve production efficiency.

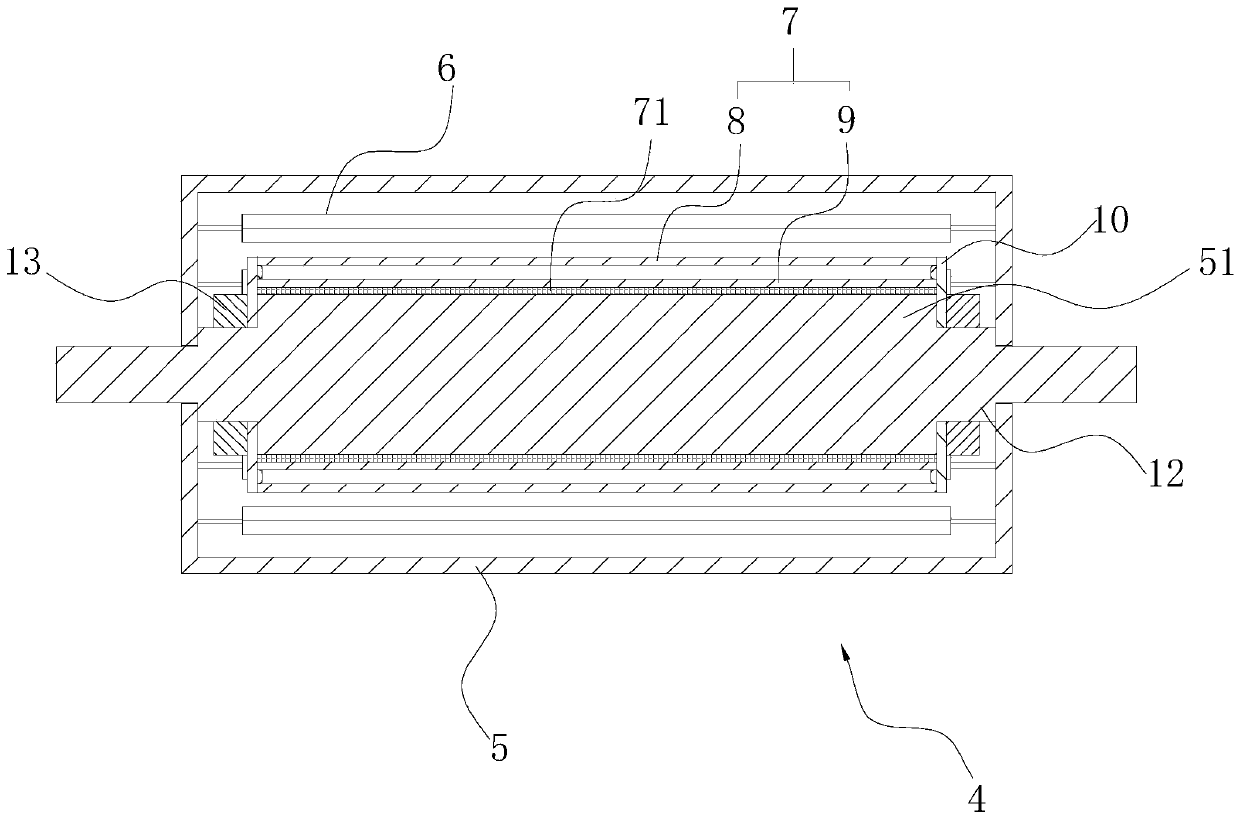

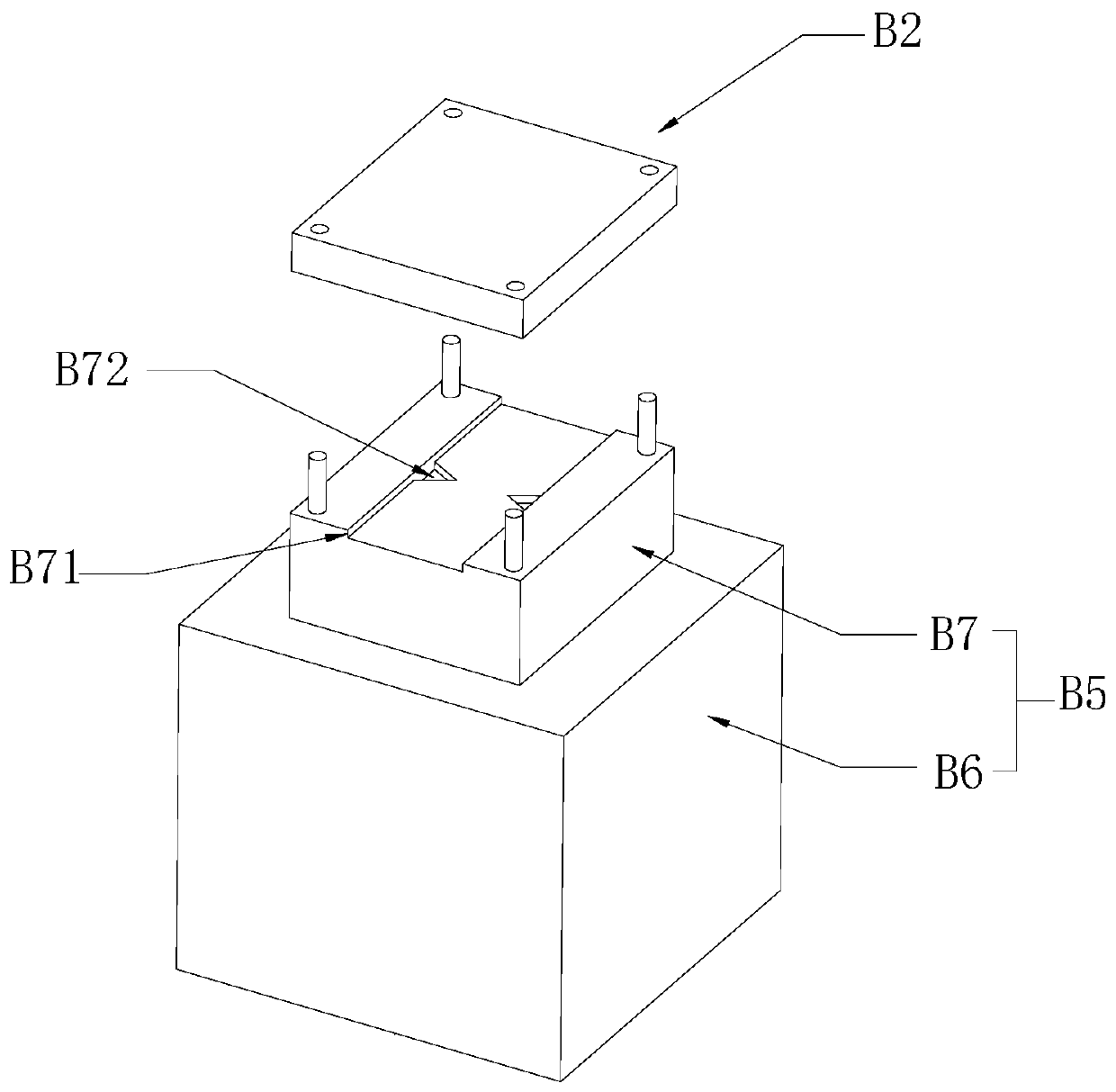

[0048] Such as figure 1 and figure 2 As shown, the feeding unit A2 includes a winding machine A3 and a set of feeding rollers installed on the frame A1. The winding machine A3 includes a support frame and a winding disk, and the strip-shaped sheet material is wound on the winding disk. The feeding roller group is rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com