One-time molding and stamping process of a storage rack for ashes

A technology for storing racks and ashes, which is applied to the stamping and forming of ashes storage racks and urn storage racks. It can solve the problems of difficult assembly, complicated process, and insufficient strength, and achieve the effect of improving quality and reducing process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

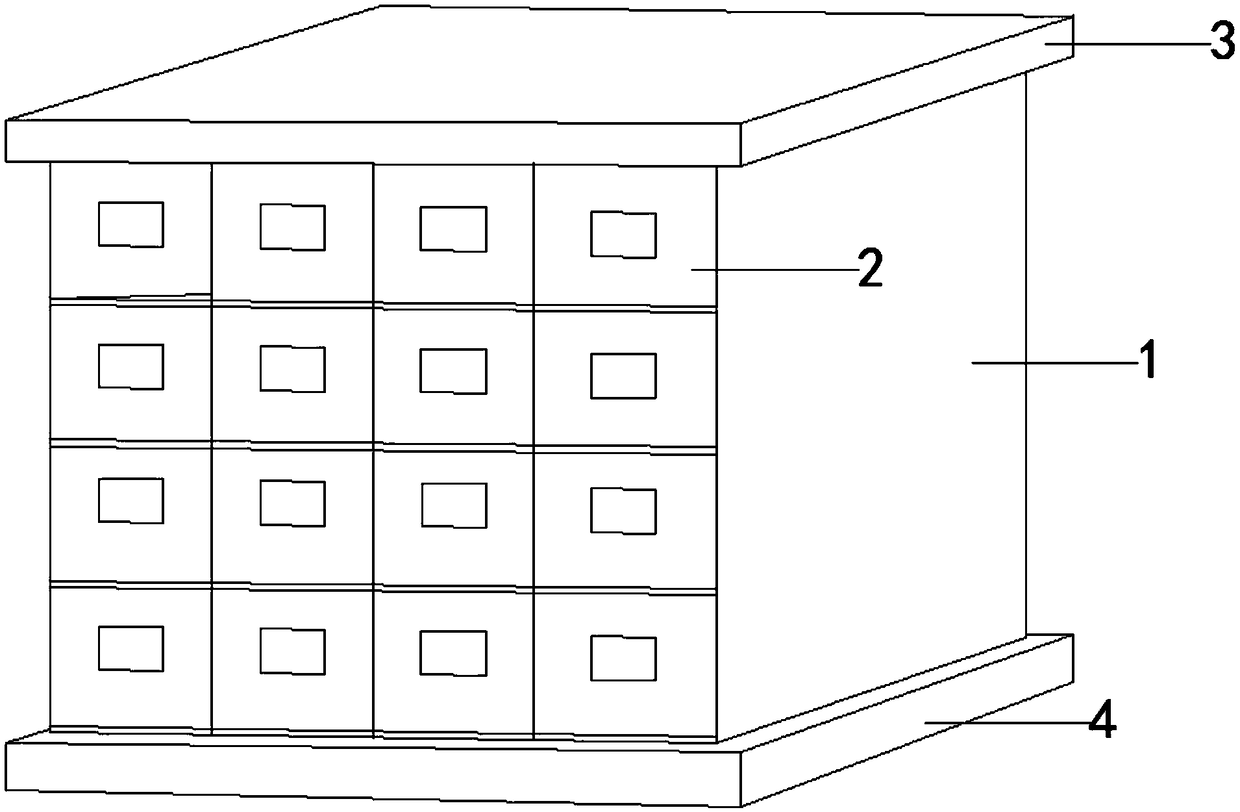

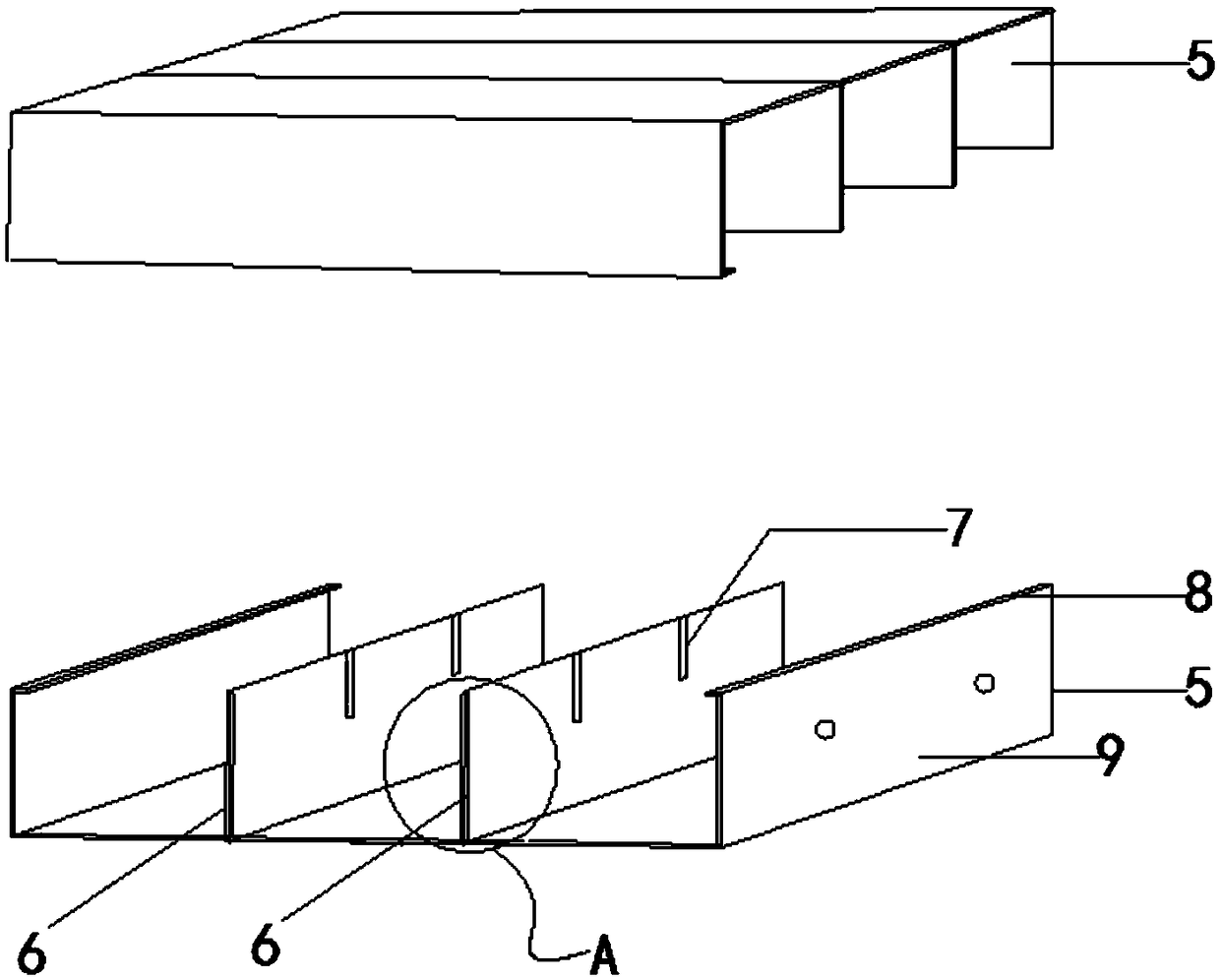

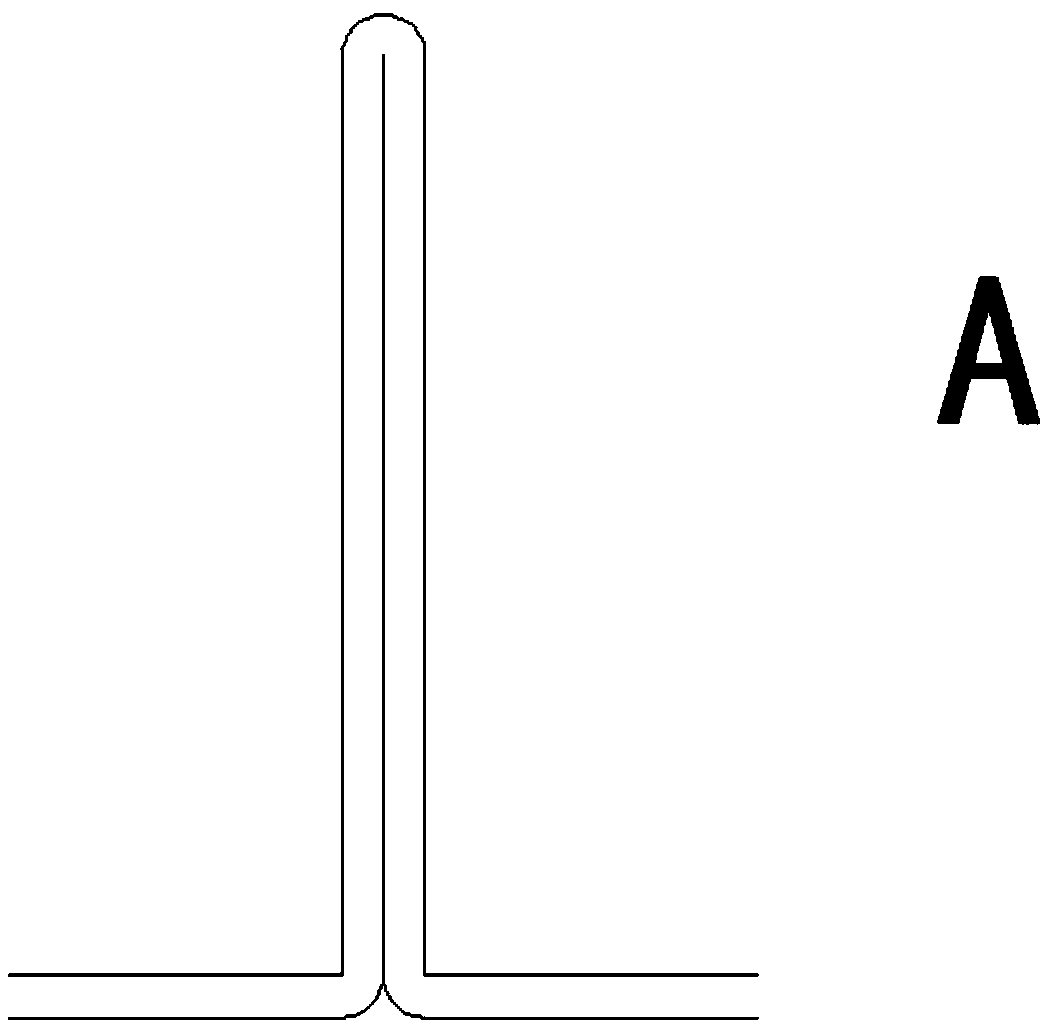

[0032] Refer to attached Figure 1-5 , a one-time forming stamping process for a storage rack for ashes, the storage rack for ashes includes a frame 1, a door leaf 2, a top cover 3 and a base 4, the middle part of the door leaf 2 has a quadrilateral opening, and the sheet material at the opening is folded by stamping Two upper and lower W-shaped structures 10 are located inside the door leaf; the pallet is composed of two pallet plates 5 that are fastened together, the pallet plate is square, and the front and rear sides of the pallet plate are both It is a two-fold structure, and the left and right sides of the pallet are not provided with folds, and there is at least one bent reinforcing rib 6 in the middle of the pallet, and the bent reinforcing rib is formed by the plate used to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com