Sealed steel wire rope with diameter of 42 mm and manufacturing method thereof

A steel wire rope and rope strand technology, which is applied in the field of metal product processing, can solve the problems of low breaking force and low wear resistance and fatigue resistance of steel wire ropes, and achieve the effects of increasing breaking force, increasing plasticity, and eliminating wire looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A 42mm-diameter sealing steel wire rope and its manufacturing method of the present invention will be further described in detail below in conjunction with the accompanying drawings. Including the following implementation steps:

[0016] 1) Steel wire rope structure design:

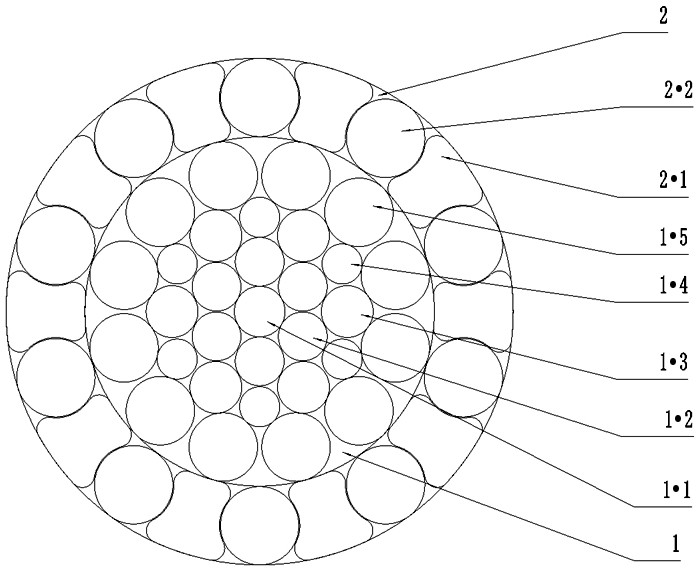

[0017] figure 1 Shown in is a sealed steel wire rope with a diameter of 42mm of the present invention, which includes an inner layer strand 1 and an outer layer 2 from the inside to the outside; wherein, the inner layer strand includes a central wire 1.1 and an inner layer wire 1.2 from the inside to the outside. , sub-layer size wire, outer layer wire 1.5; said sub-layer size wire includes sub-layer large wire 1.3, sub-layer small wire 1.4, all in one layer; said outer layer includes H-shaped wire 2.1, round wire 2.2, All within one layer.

[0018] 2) Wire rope matching wire design:

[0019] The process parameters of steel wire rope matching are: central wire 1.1 diameter 4.2mm, quantity 1; in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com