Battery cell, battery and electronic equipment

A cell and battery technology, applied in the field of electrochemistry, can solve the problems of waste of space, reduction of cell packaging space, disadvantages and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

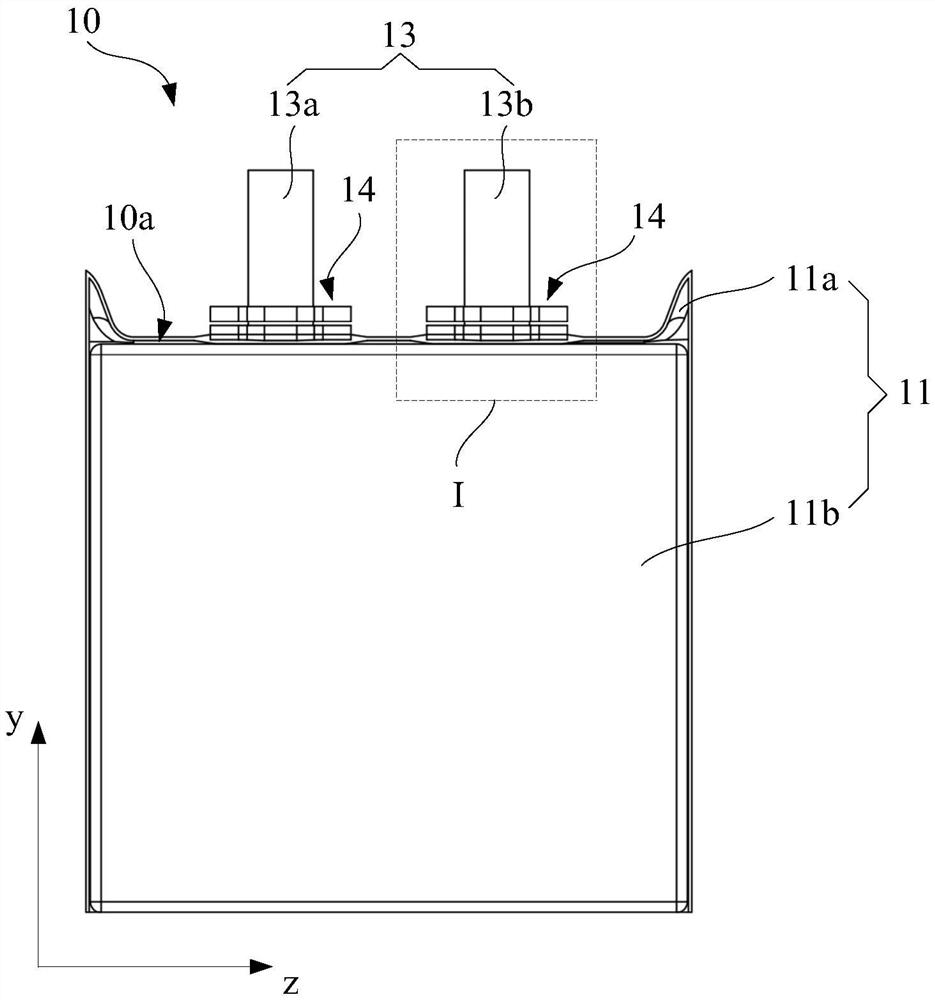

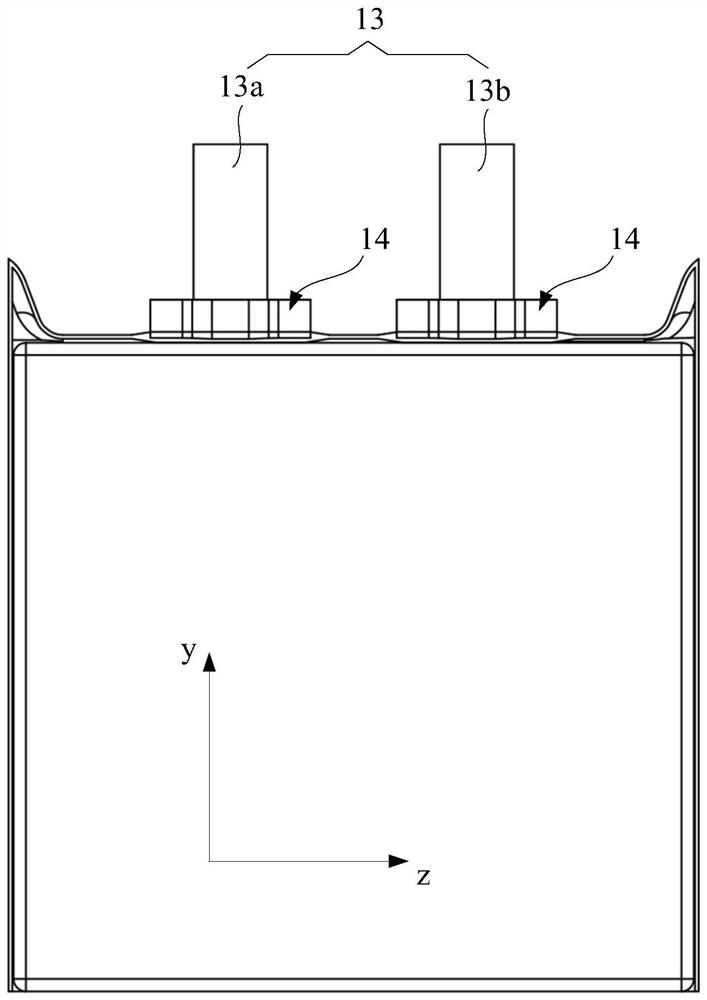

[0043] Please also refer to Figure 1 to Figure 6 As shown, the battery cell 10 of this embodiment includes a packaging bag 11 , an electrode assembly (not shown), tabs 13 , and tab glue 14 .

[0044] The packaging bag 11 surrounds the shape of the electric core 10, and can also be used to define the appearance of the electric core 10. For example, the packaging bag 11 includes a packaging part 11a and a main body part 11b, and the electrode assembly is arranged in the main body part 11b. The packaging part 11a and the main body part 11b The tab 13 extends from the first end surface of the main body 11b. The first end surface of the main body 11b can be regarded as the first end surface 10a of the battery cell 10 , which will be described below as an example. The main body part 11b is formed with a housing cavity, and the internal components of the battery cell 10 (such as electrode assembly and electrolyte) are contained in the housing cavity, and the internal components are...

no. 2 example

[0065] The various embodiments of the present application use the same reference numerals to identify structural elements with the same names.

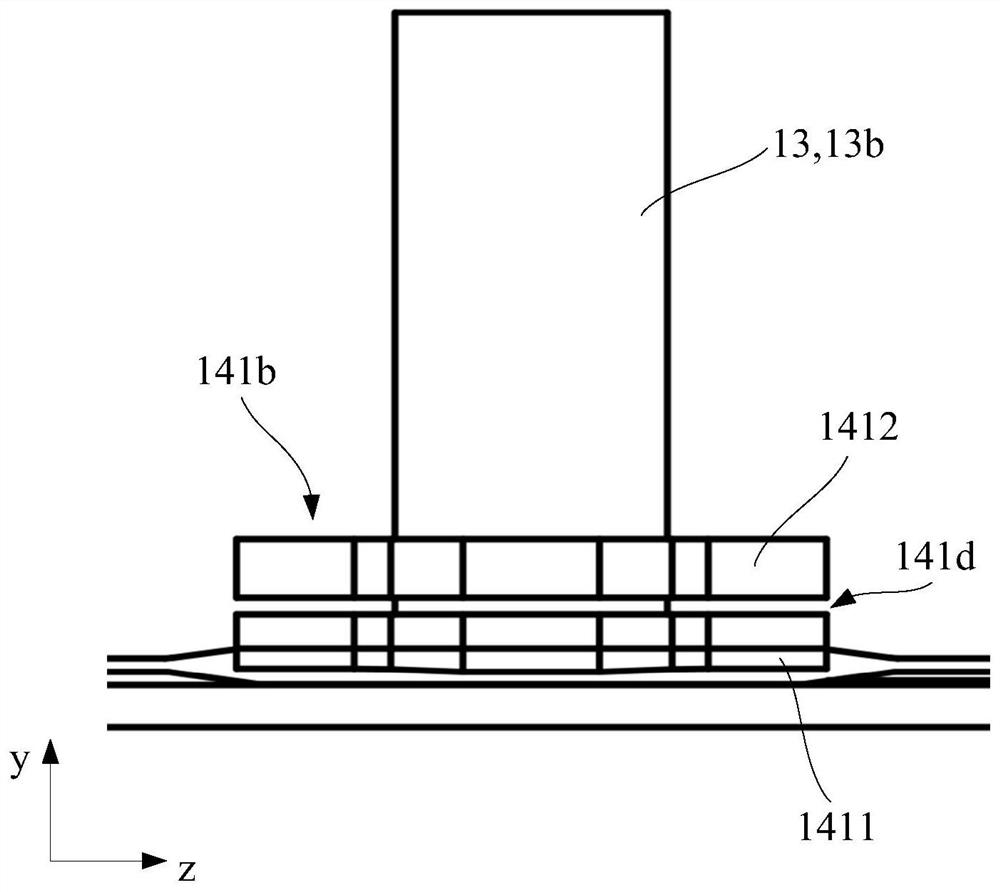

[0066] On the basis of the description of the previous embodiment, but different from it, such as Figure 8 and Figure 9 As shown, it is a structural schematic diagram of the tab glue 14 in an unbent state. In the battery cell 10 of this embodiment, when the battery cell 10 is in an unbent state, the space-avoiding areas 141d are distributed at intervals on the exposed portion 141 perpendicular to the direction in which the tabs 13 extend; when the battery cell 10 is in a bent state, The avoidance areas 141d are distributed at intervals along the third direction z on the bending portion 141b. The first bending part 141e and the second bending part 141f are still connected, but not completely disconnected, which is beneficial to improve the structural strength of the bending part 141b, improve the protection effect of the tab 13, an...

no. 3 example

[0070] On the basis of the description of the foregoing first embodiment, but different from it, please refer to Figure 10 and Figure 11 As shown, it is a structural schematic diagram of the tab glue 14 in an unbent state. Along the third direction z, the length of the first bending portion 141e remains constant before and after bending, and the length of the second bending portion 141f also remains constant before and after bending. For ease of description, this embodiment is in the unbent state Figure 10 and Figure 11 The middle indicates the difference between the lengths of the first bent portion 141e and the second bent portion 141f.

[0071] In the cell 10 of this embodiment, when the cell 10 is in an unbent state, along the direction y perpendicular to the extension of the tab 13, at least one side of the tab (such as Figure 11 the left side and the right side shown), the length of the first part 1411 is smaller than the length of the second part 1412, when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com