Flexible optical fiber, preparation method and drivable laser scalpel based on optical fiber

An optical fiber and flexible technology, applied in the field of optical fiber and its preparation, which can solve the problems of wire drawing speed limitation, difficulty in achieving high-precision surgery, and poor controllability of the thickness of the coating layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The preparation method of the flexible optical fiber: comprises the following steps:

[0085] S1, preparing a preform structure of an optical fiber structure;

[0086] S2, preparing the innermost layer of the flexible reinforcement layer on the outside of the preform structure to obtain an inner layer preform;

[0087] S3, preparing at least one hollow sleeve, which is another layer in the flexible reinforcing layer, and nesting the hollow sleeve outside the inner layer preform to obtain the final optical fiber preform; the at least one hollow sleeve The material of the outermost layer has lower rigidity, and the outermost layer in the optical fiber structure, the innermost layer in the flexible reinforcing layer and at least one hollow sleeve have similar rheological properties between adjacent layers;

[0088] S4, drawing the optical fiber preform, the drawing temperature of the optical fiber preform is 60°C-600°C.

[0089] If the optical fiber structure is a step-r...

Embodiment 1

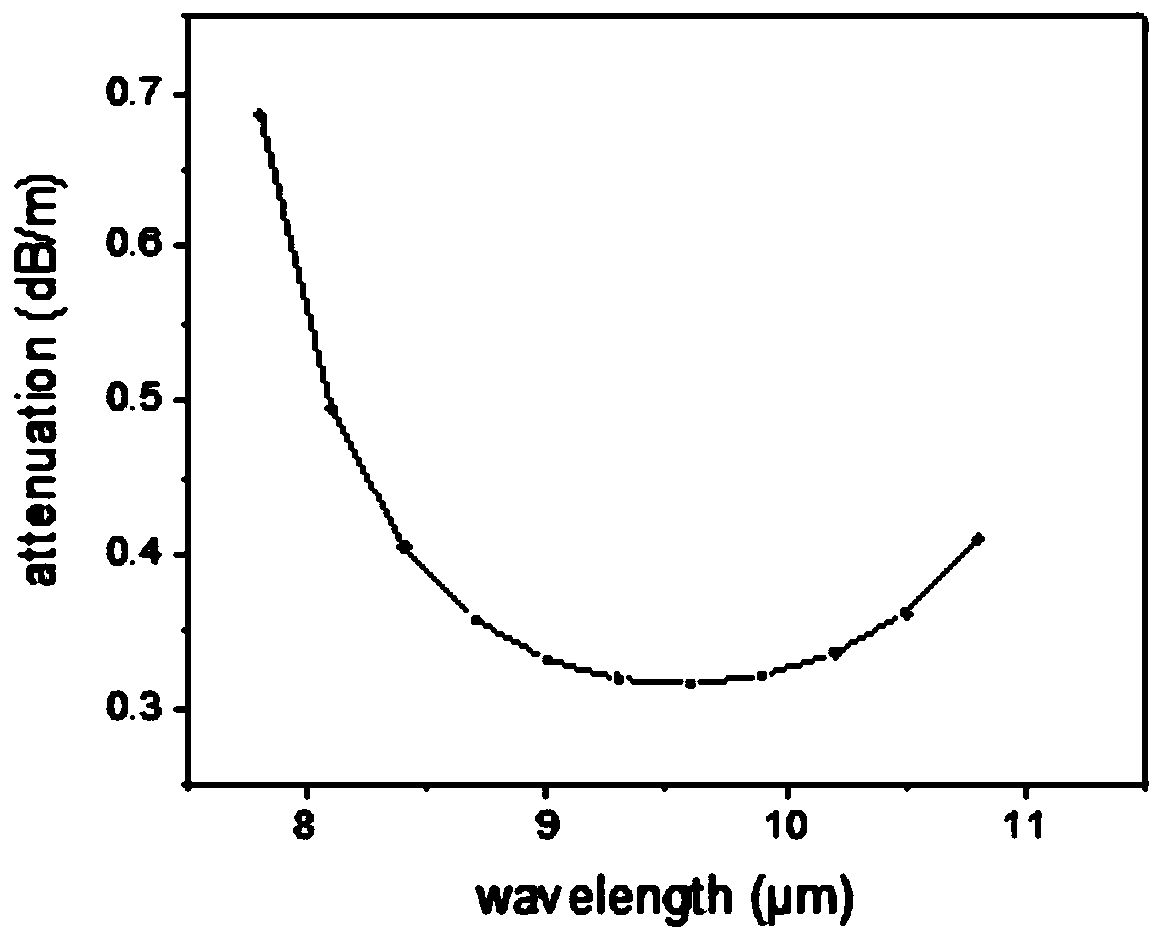

[0110] In the optical fiber in this embodiment, the central optical fiber structure is a photonic bandgap optical fiber, that is, it includes an air core at the center, and the diameter of the air core is 500 μm. The outer side of the air core is cladding, and the cladding includes a first cladding and a second cladding that are periodically and alternately stacked, and the first cladding is As 2 Se 3 Glass, ie high refractive index material, and the second cladding layer is PPSU, ie low refractive index material. The first cladding layer is located on the innermost side, and the first cladding layer and the second cladding layer are stacked alternately, each having 12 layers. The thicknesses of the first cladding layer and the second cladding layer were 1.2 μm and 2.4 μm, respectively.

[0111] The flexible reinforcement layer includes an innermost layer, which is composed of multiple layers of PPSU film. The thickness of the innermost layer is 1-20 times the thickness of ...

Embodiment 2

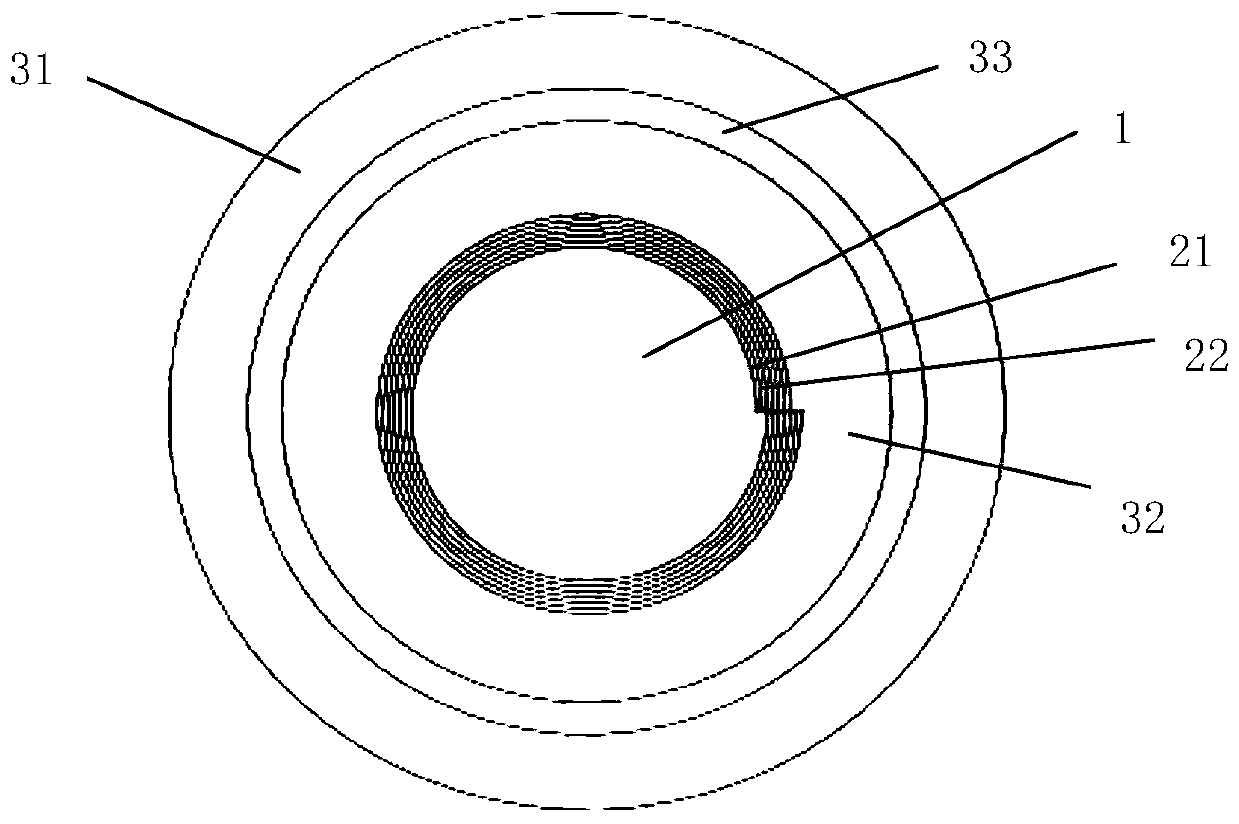

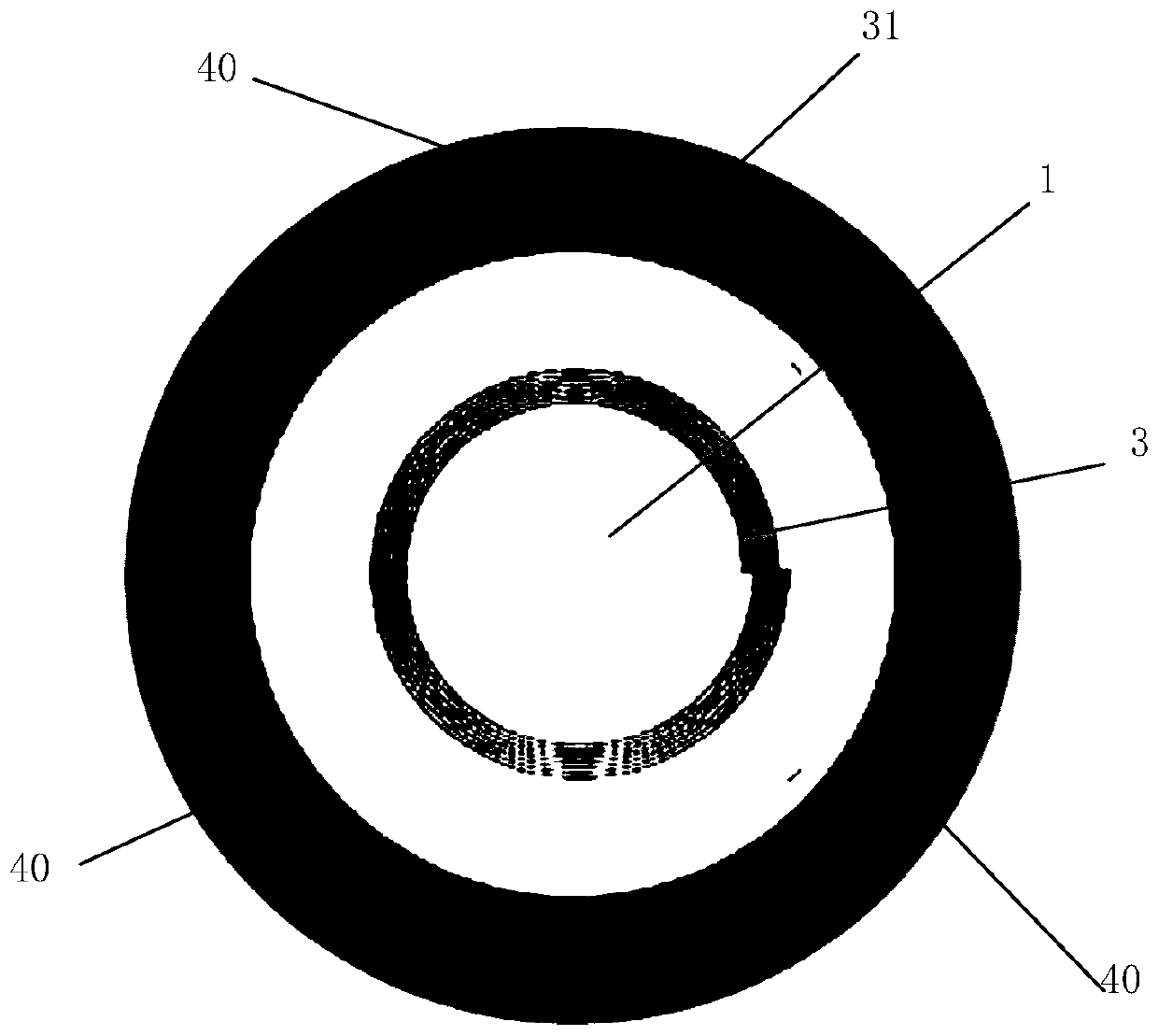

[0120] The fiber in this embodiment, as figure 1 As shown, the optical fiber structure in the center is a photonic bandgap optical fiber, and the air core 1 is in the center, and the diameter of the air core 1 is 500 μm. The outer layer of the air core 1 is a cladding, the cladding includes a first cladding 21 and a second cladding 22, the first cladding 21 is As 2 Se 3 glass, the second cladding 22 is PPSU. The first cladding layer 21 is located on the innermost side, and the first cladding layer 21 and the second cladding layer 22 are alternately stacked, 15 layers each. The thicknesses of the first cladding layer 21 and the second cladding layer 22 are 0.75 μm and 1.75 μm, respectively.

[0121] The flexibility enhancement layer comprises an innermost layer 32 which is a multilayer PPSU film. The thickness of the innermost layer 32 is 25 μm, and the outer side of the PPSU film layer is successively provided with an intermediate layer 33 and an outermost layer 31, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com