Manufacturing method of tubular parts

A manufacturing method and technology for parts, applied in the field of machining, can solve the problems of cracked welds, difficult forming of metal plates, inability to manufacture small-diameter thick-walled long tubular parts, etc., so as to avoid weld cracks and solve difficult forming. , effective and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

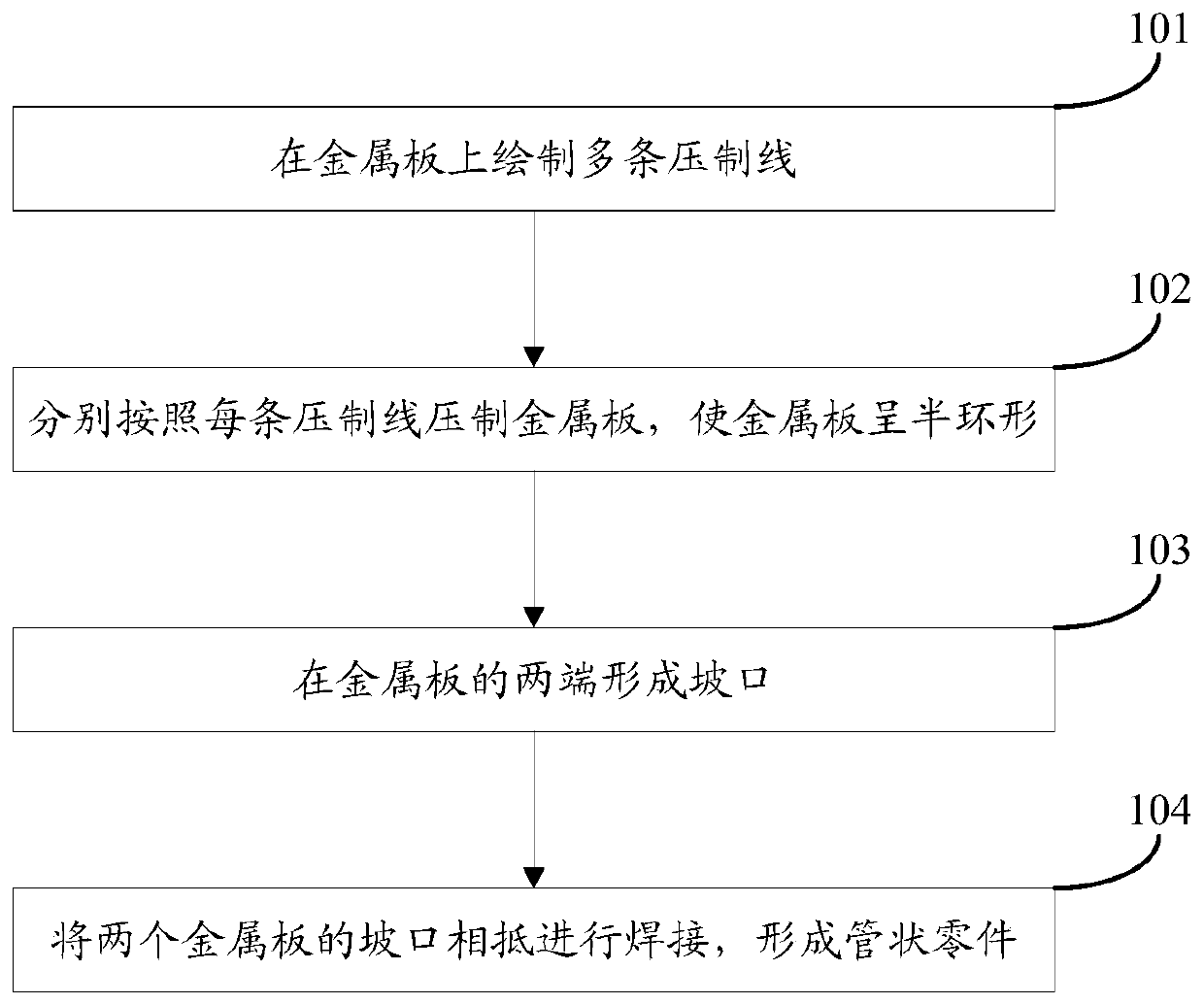

[0054] An embodiment of the invention provides a method for manufacturing a tubular part. figure 1 It is a flowchart of a method for manufacturing a tubular part provided by an embodiment of the present invention. see figure 1 , the manufacturing method includes:

[0055] Step 101: Draw multiple pressing lines on the metal plate.

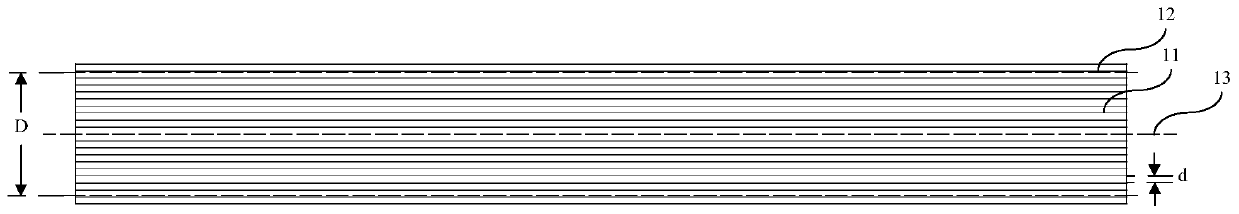

[0056]In this embodiment, the thickness of the metal plate is equal to the wall thickness of the tubular part, and the length of the metal plate is equal to the length of the tubular part. In practical applications, the width of the metal plate can be larger than the outer diameter of the tubular part, and the excess part can be removed during the beveling process.

[0057] figure 2 Schematic diagram o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com