Saw blade for a machine tool

A technology for machine tools and saw blades, applied in the field of rotary oscillating saw blades, to achieve the effects of improving chip export, uniform load and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

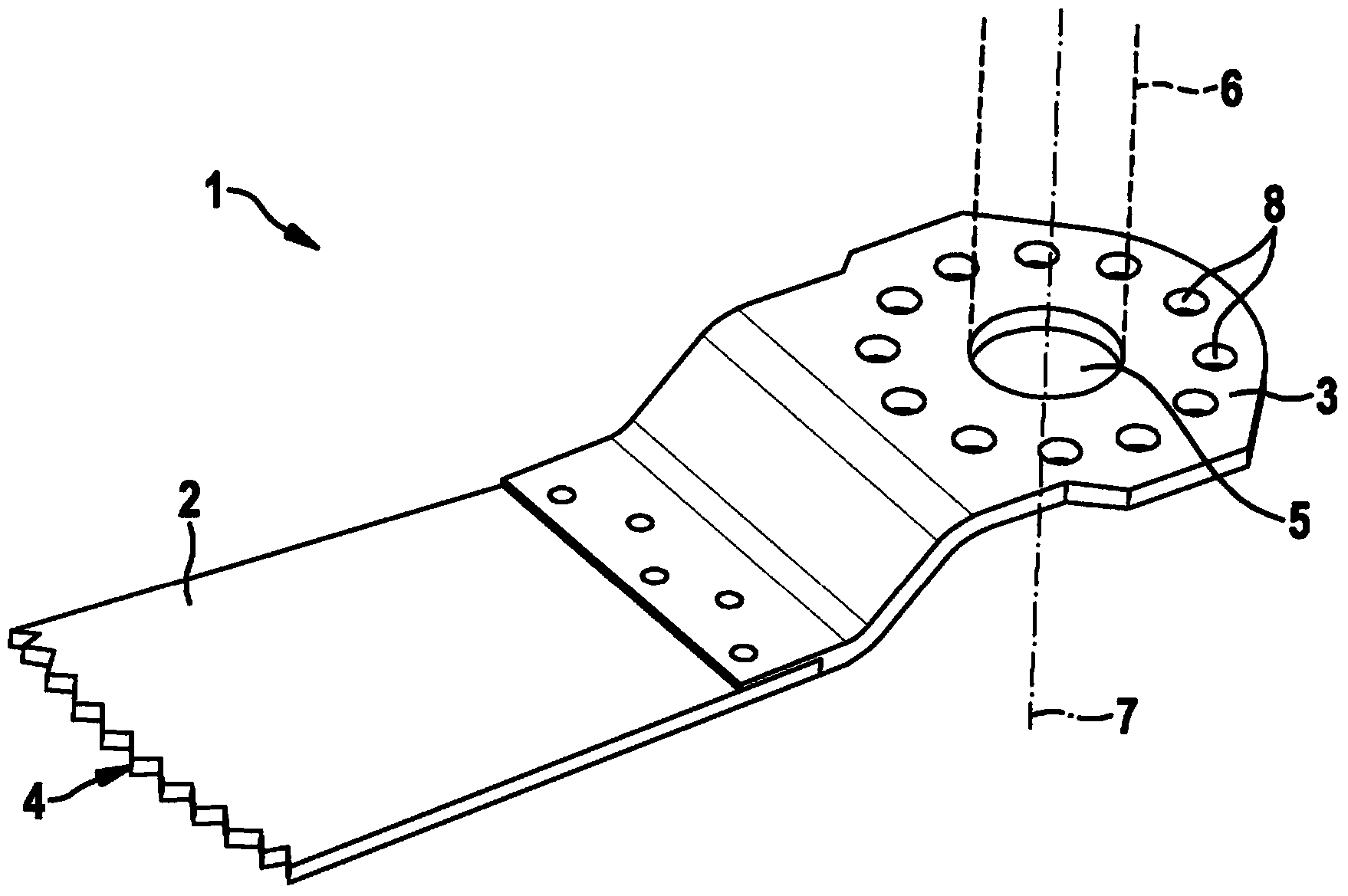

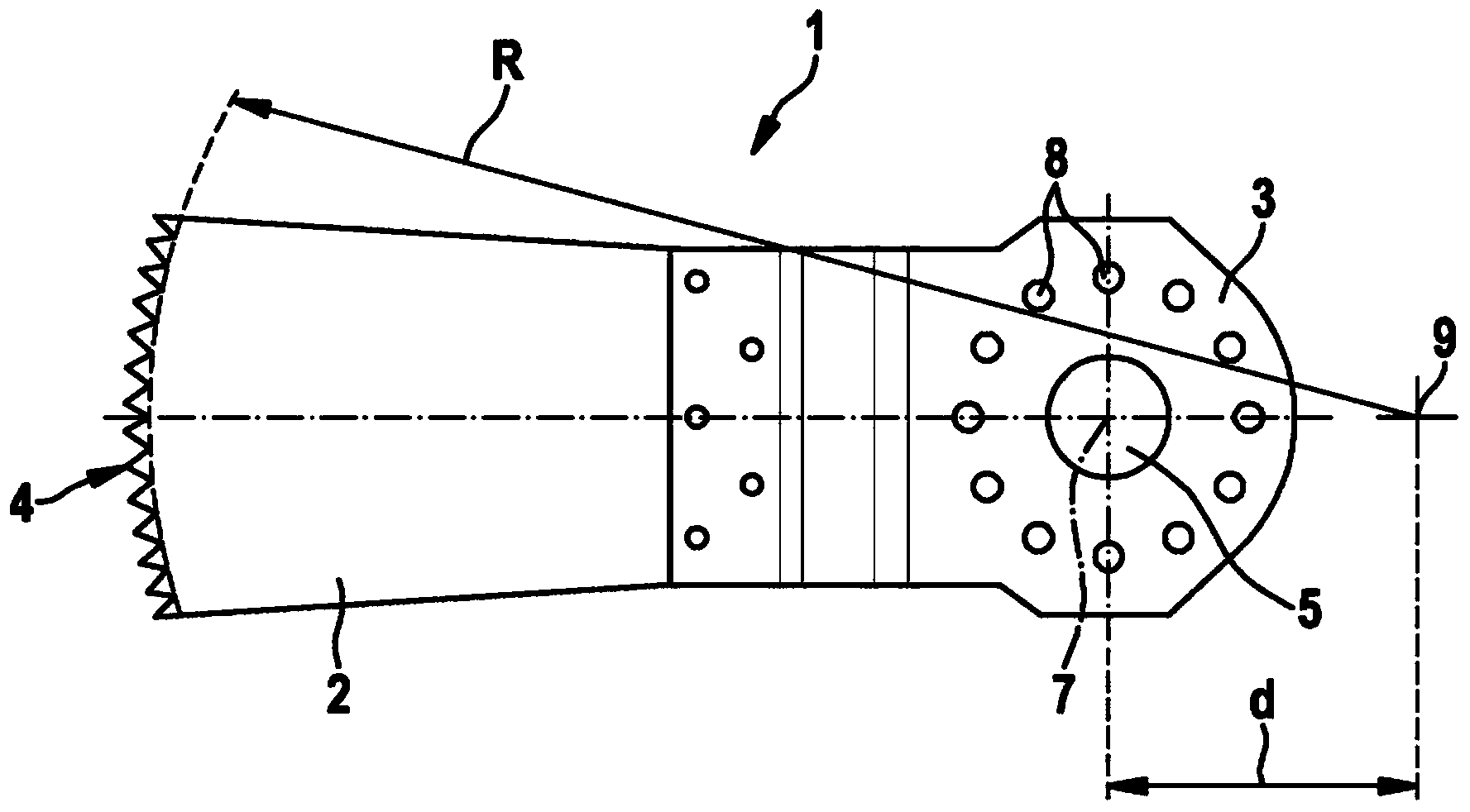

[0019] exist figure 1 shows a saw blade 1 embodied as a sinker saw blade for a hand tool with a rotary oscillating drive. The saw blade 1 comprises: a main blade 2, which is embodied in the shape of a plate with an approximately rectangular, if necessary slightly trapezoidal, geometry; The tool axis 6 is connected. The front edge of the main plate 2 facing away from the fastening section 3 is designed as a cutting edge 4 with cutting teeth.

[0020] A central fastening recess 5 for receiving the tool shaft 6 is introduced into the substantially disk-shaped fastening section 3 . The fastening is carried out by means of a suitable fastening device, wherein in the fastening section 3 for torque transmission, a snap-in opening 8 arranged around the fastening recess 5 is introduced annularly, the catch of the fastening device in the mounted state The locking projection protrudes into the locking opening in order to transmit the torque from the tool shaft to the saw blade 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com