Gel-state polymer lithium ion battery suitable for high-temperature and low-temperature environment and preparation method thereof

A lithium-ion battery, high and low temperature technology, used in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., to achieve good low temperature performance, reduced polarization, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

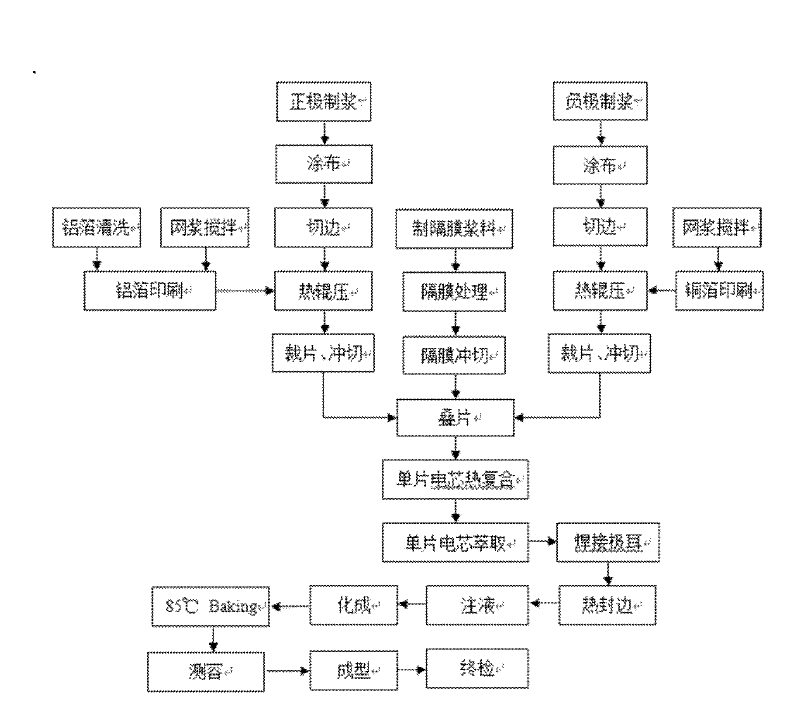

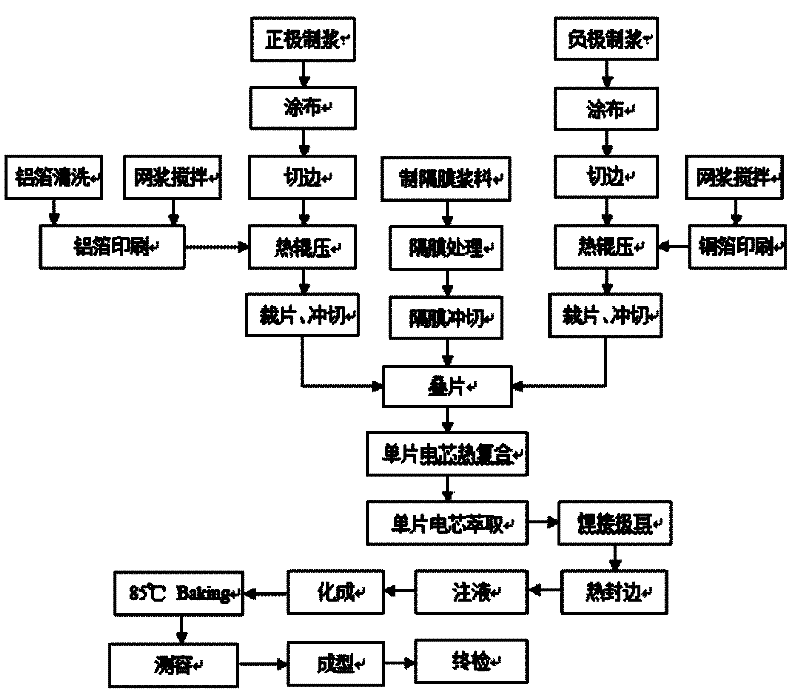

[0051] The present invention will be described in further detail below in conjunction with the appendix description: as figure 1 Shown, concrete technique of the present invention:

[0052] (1) According to the traditional process, the positive and negative pole pieces and the diaphragm are stacked to form a battery cell, which is extracted, welded and packaged and placed in a flexible packaging film to seal the three sides of the flexible packaging film;

[0053] (2) Inject the high and low temperature electrolyte into the cell obtained in step 1, and then seal the fourth side of the film by means of vacuum packaging;

[0054] (3) The battery obtained in step 2 is formed through a special formation process to make a gel-state polymer lithium-ion battery that can be discharged at high and low temperatures.

[0055] (4) The positive electrode active material is lithium cobaltate, lithium manganate, ternary material or lithium iron phosphate with a D50 of 2-15um;

[0056] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com