Paper straw bending and skew notch cutting process method

A process method and straw technology, applied in metal processing and other directions, can solve the problems of difficulty in bending paper straws, easily broken or damaged bending parts, and poor quality of oblique mouth origami straws, so as to achieve good oil and water repellency. , good acid resistance

Active Publication Date: 2019-11-15

庄孔庆

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The quality of the obliquely bent paper straws produced is poor, and the indentation of the bent part makes it more difficult for users to bend the paper straw, and the bent part is easy to break or break

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0059] Carry out experiment according to table 1 corresponding embodiment 1 data.

Embodiment 2

[0061] Carry out experiment according to table 1 corresponding embodiment 2 data.

Embodiment 3

[0063] Carry out experiment according to the corresponding embodiment 3 data of table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

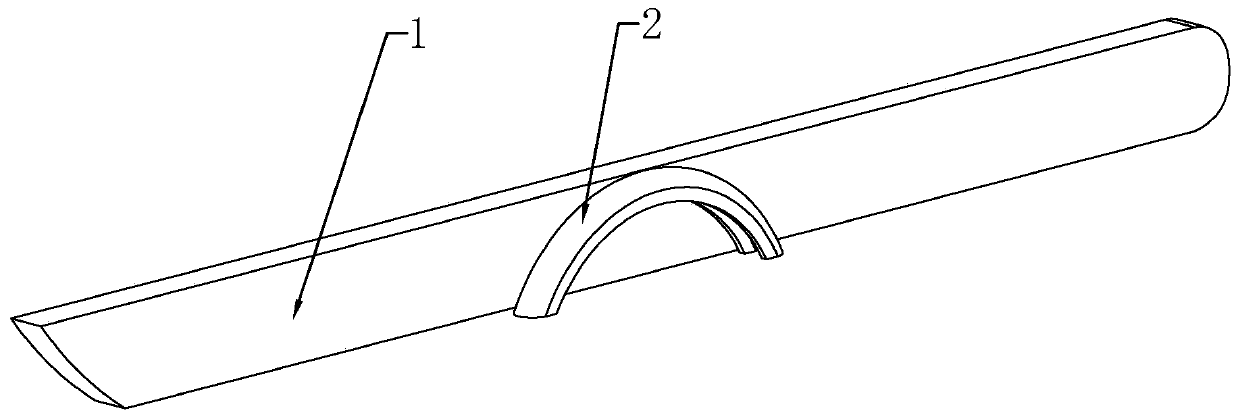

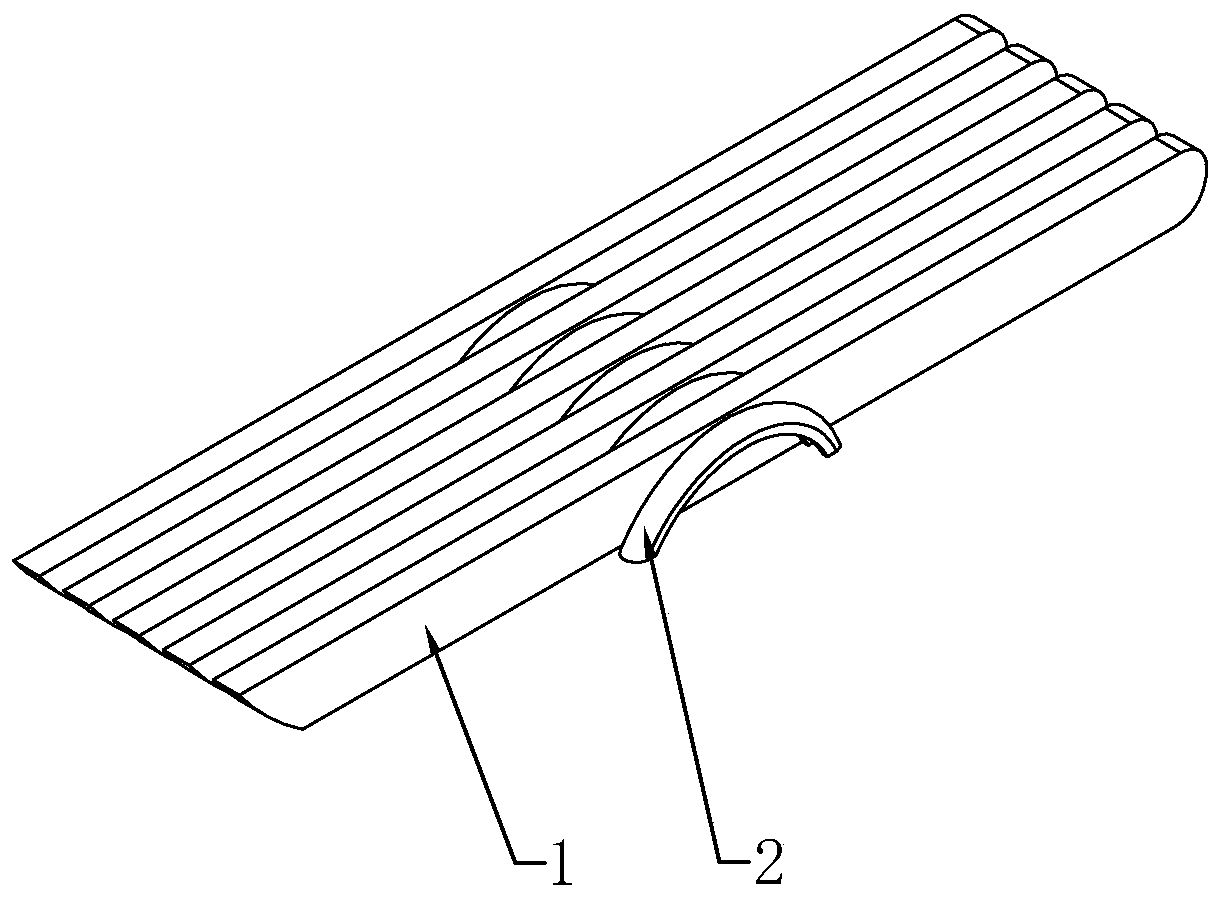

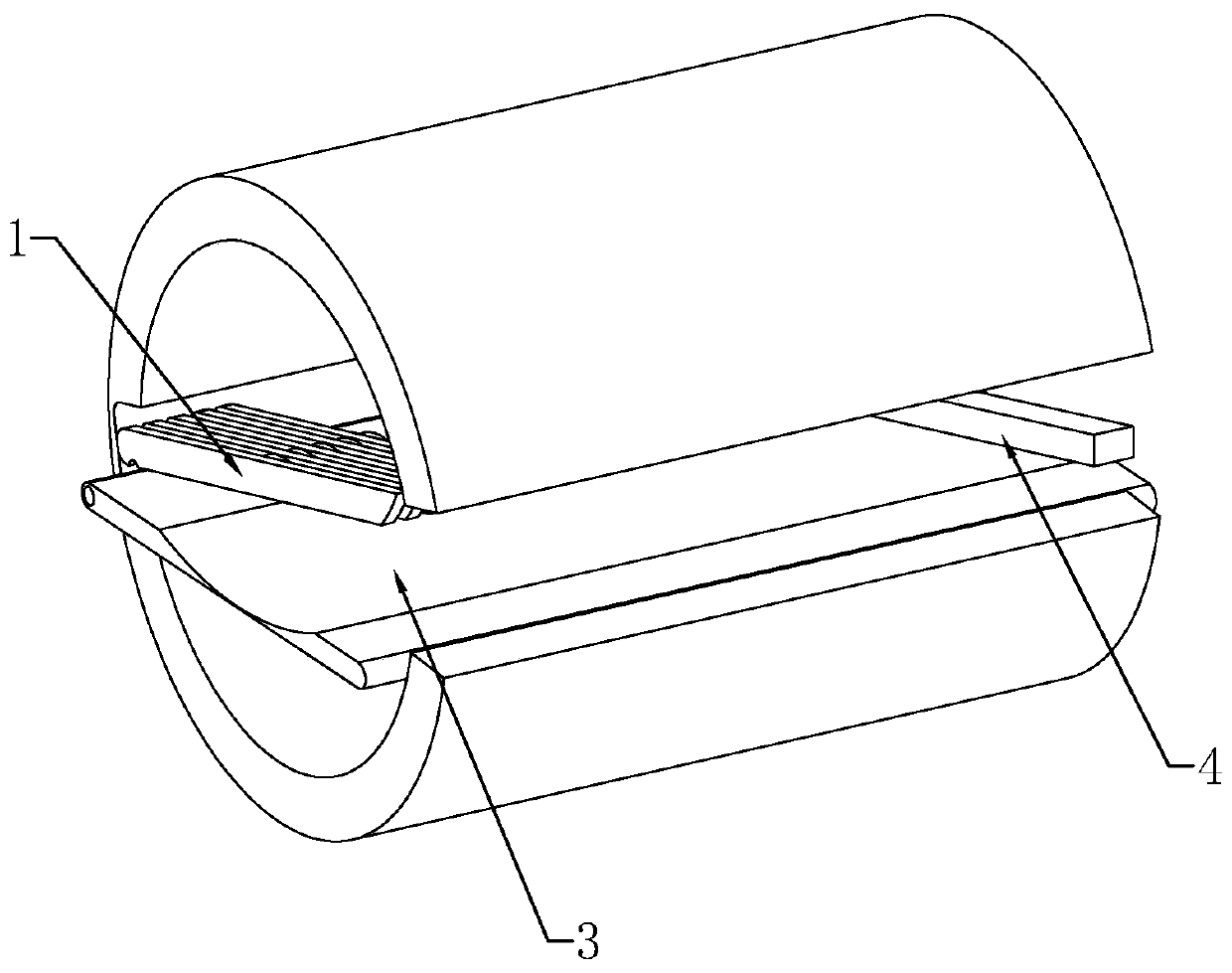

The invention discloses a paper straw bending and skew notch cutting process method. The paper straw bending and skew notch cutting process method includes the following steps that 1, paper straws areconveyed; 2, the paper straws are impressed, according to an impressing method, an impressing knife and round groove blocks fixedly connected with the impressing knife cooperate with multiple impressing assemblies for impressing, and every two impressing assemblies are seamlessly connected and fixed; 3, skew notches of the paper straws are cut, the tail ends of the paper straws are obliquely cutthrough the obliquely-arranged impressing knife, and the skew notches are formed; and 4, collecting is completed. The paper straw bending and skew notch cutting process method has the following beneficial effects that the bending difficulty of the paper straws is reduced, and bent portions are not likely to be broken.

Description

technical field [0001] The invention relates to a process flow of a paper straw, in particular to a process method for bending and beveling a paper straw. Background technique [0002] Straw, as a common object used to drink beverages in cups in daily life, is generally made of plastic in industrial production. The liquid after the plastic is melted is injected into the mold, and it is formed after cooling. Nowadays, people pay more and more attention to the concept of health and environmental protection. In order to solve people's needs, paper straws came into being. [0003] The Chinese patent with the publication number CN109463964A discloses a paper straw, which includes a first paper layer and an adhesive attached to the first paper layer, and then the first paper layer is bonded to the second paper layer , the first paper layer is spirally wound to form a tube. This paper straw has better water repellency, oil repellency and better acid resistance. [0004] The Chin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B26D3/00B26D3/08B26D1/00

CPCB26D3/00B26D3/08B26D1/0006

Inventor 庄孔庆

Owner 庄孔庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com