Method of implementing real-time bending follow of bending robot

A robot and bending machine technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as inability to follow bending in real time, achieve the effects of improving following accuracy and bending quality, reducing time, and improving debugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

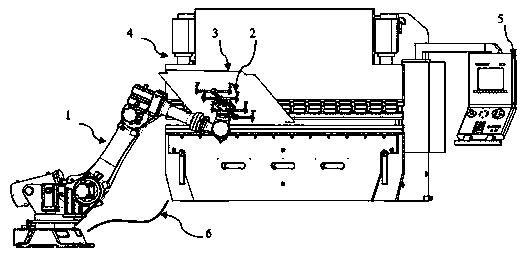

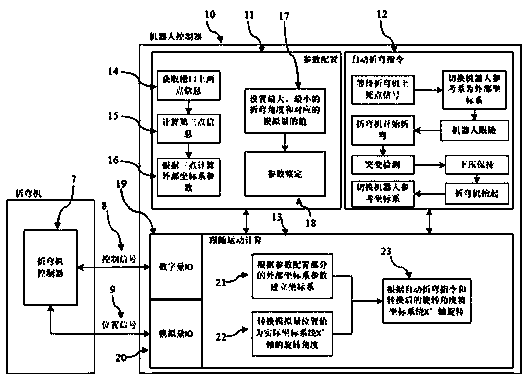

[0024] figure 1 The device for realizing the real-time following method of bending by a bending robot includes a robot 1, a robot gripper 2, a plate 3, a bending machine and a communication cable 6, and the bending machine includes a body 4 and a bending controller 5. Among them, robot 1 is a general-purpose six-joint series industrial robot, which has general-purpose industrial robot functions: the coordinate system includes joint coordinate system, Cartesian coordinate system, tool coordinate system and external coordinate system, and can establish and set the external coordinate system. It can use the four-point method to establish the tool coordinate system, and has the characteristic of keeping the position and posture unchanged under the current coordinate system during normal operation, and can manually and automatically contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com