Single-oscillating-arm leftward and rightward co-bending type numerical control pipe bending machine

A pipe bending machine and pipe bending technology, which is applied in the field of single swing arm left and right co-bending CNC pipe benders, can solve the problems of affecting the quality of the bending pipe, unstable pipe bending devices, and inability to configure the swing arm clamping mechanism, etc. Improve the stability of product manufacturing accuracy, ensure parallelism, and ensure the effect of transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

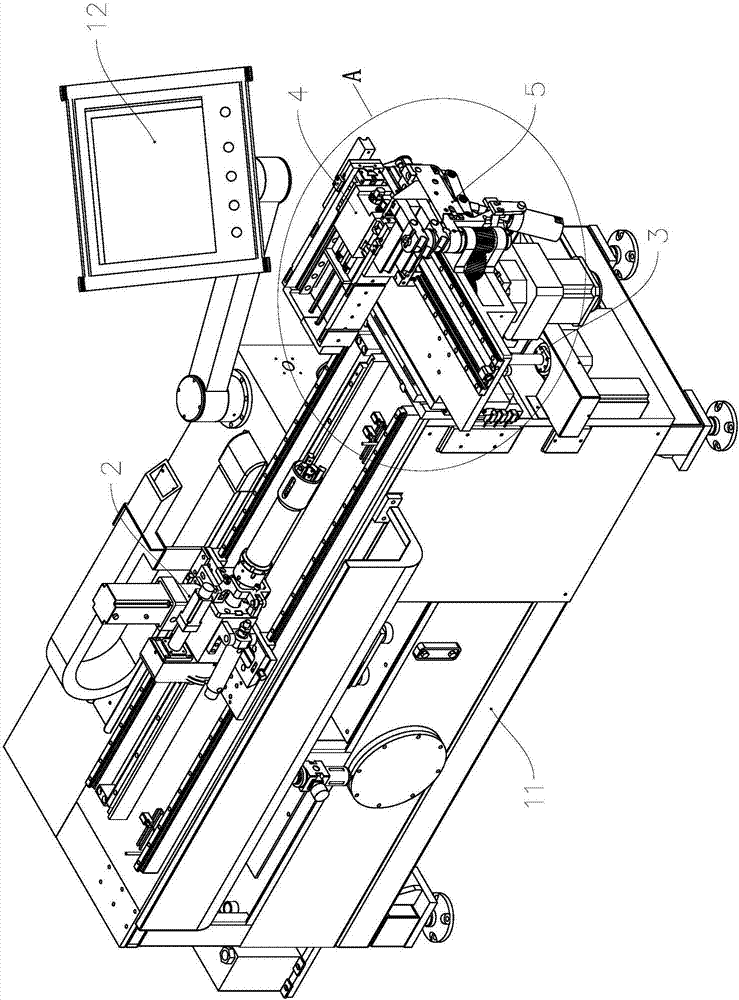

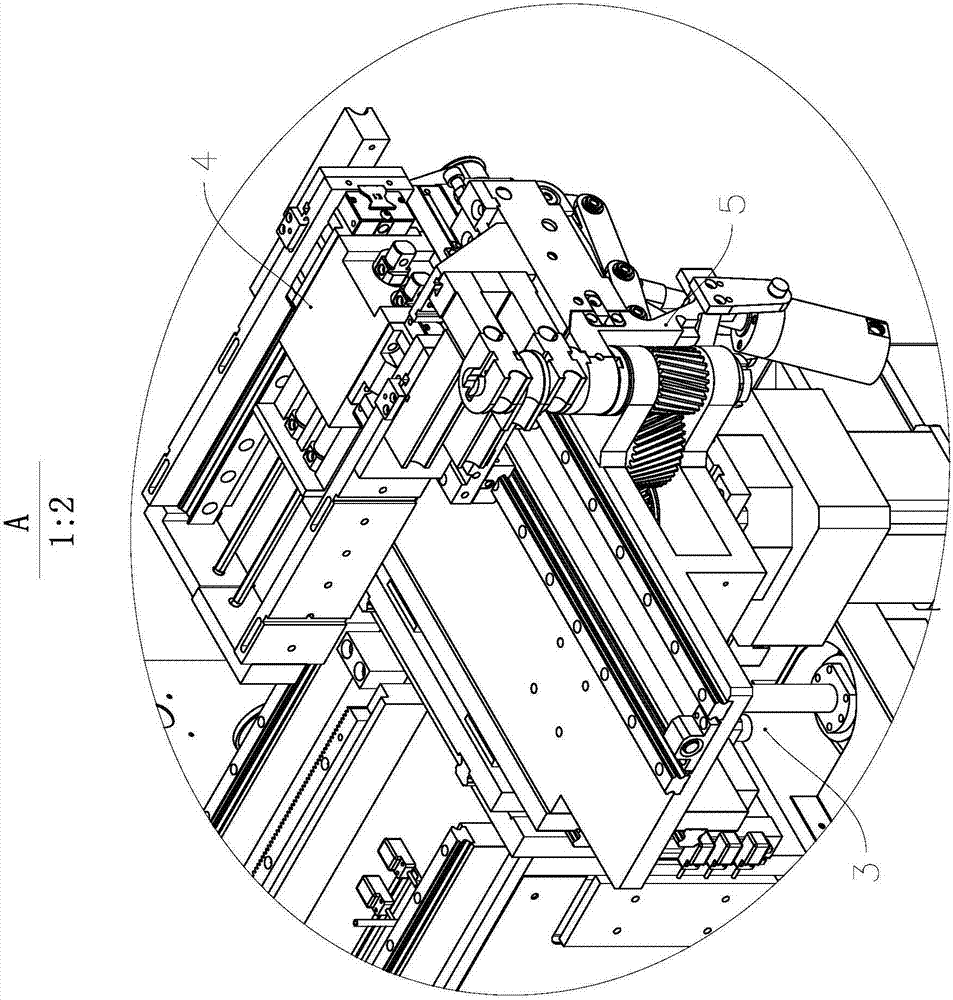

[0045] see figure 1 and figure 2 , the CNC pipe bending machine 1 includes a frame 11, a control unit, and a pipe bending device and a feeding trolley 2 installed on the frame 11 and controlled by the control unit; wherein, the pipe bending device includes a switching unit 3 and a mold guiding unit 4 And nose 5.

[0046] In this embodiment, the control unit includes a processor, a memory, and a touch screen 12. The processor receives input instructions from the operator through the touch screen 12, and at the same time controls the action of the pipe bending device and the feeding trolley 2 by executing the corresponding computer program stored in the memory. Perform pipe bends, switchovers, and more.

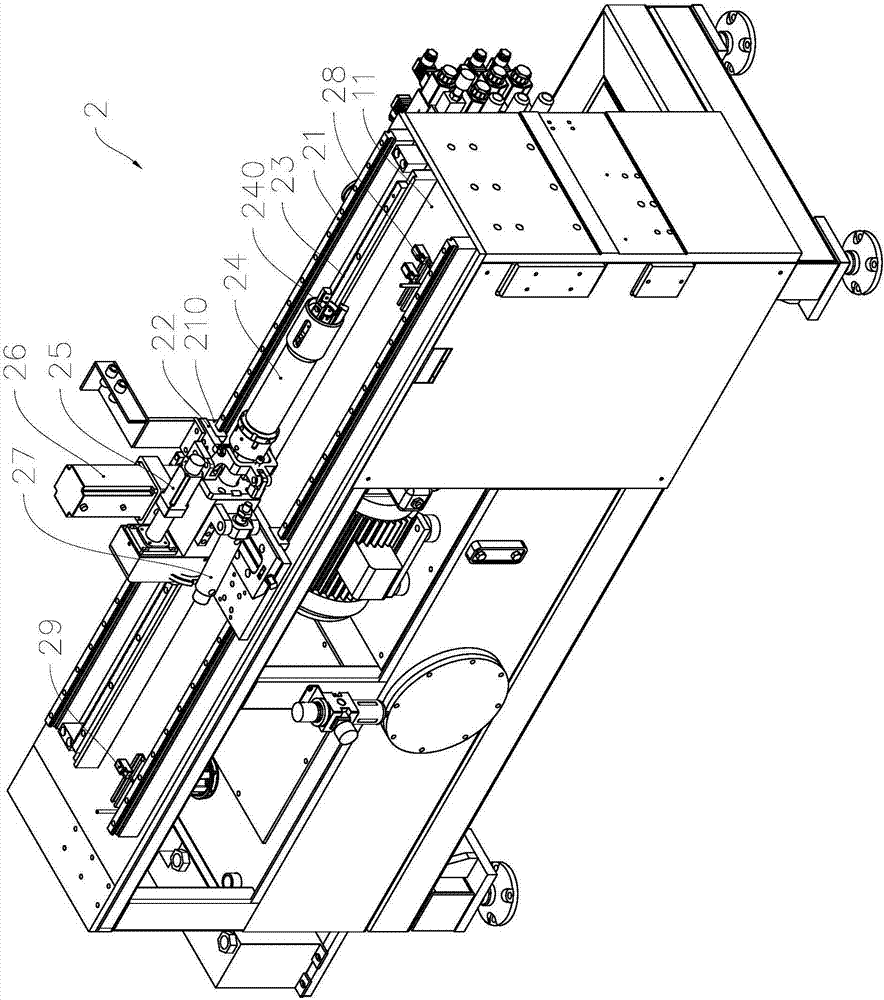

[0047] see image 3 , the feeding trolley 2 includes a feeding rail 21 fixed on the frame 11, a feeding slide 22 slidably installed on the feeding rail 21 through a slider 210, arranged and fixed on the frame 11 along a direction parallel to the feeding rail 21 The feeding...

Embodiment 2

[0094] As a description of Embodiment 2 of the present invention, only the differences from Embodiment 1 above will be described below, that is, only the structure of the clamping mold assembly will be described.

[0095] see Figure 17 and Figure 18 , by setting a pin hole 5170 on the side wall plate of the installation 50, in this embodiment, the adjustment locking mechanism also includes a locking pin 961 and a locking screw 962, and the outer port of the pin hole 5170 is provided with a locking screw 962 Matching threads, the inner end surface of the anti-loosening pin 961 is formed with an arc-shaped extrusion surface 9610 that matches the side wall surface of the mounting shaft portion 761 of the eccentric shaft 76, and the arc-shaped extrusion of the anti-loosening pin 961 is made by the locking screw 962. The pressing surface 9610 presses the side wall surface of the mounting shaft portion 761 to form a friction fit surface to assist in locking the rotation angle pos...

Embodiment 3

[0097] As an explanation of Embodiment 3 of the present invention, only the differences from Embodiment 1 above will be described below.

[0098] see Figure 19 and Figure 20 , multiple rings of locking holes uniformly arranged in the radial direction (only two rings are shown in the figure) can be provided on the fixed hole plate 953 , and each ring of locking holes is evenly arranged along the circumference of the hole plate. And in the gear gap adjustment hole plate 952, a multi-turn locking hole with the same number of turns and equal hole spacing in the radial direction is set (only two turns are shown in the figure), but there is a difference in the center angle of the interval between two adjacent turns, so that it can be The purpose of adjusting the rotation angle is achieved by aligning the locking holes at different radial positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com