Patents

Literature

136results about How to "Ensure transmission stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

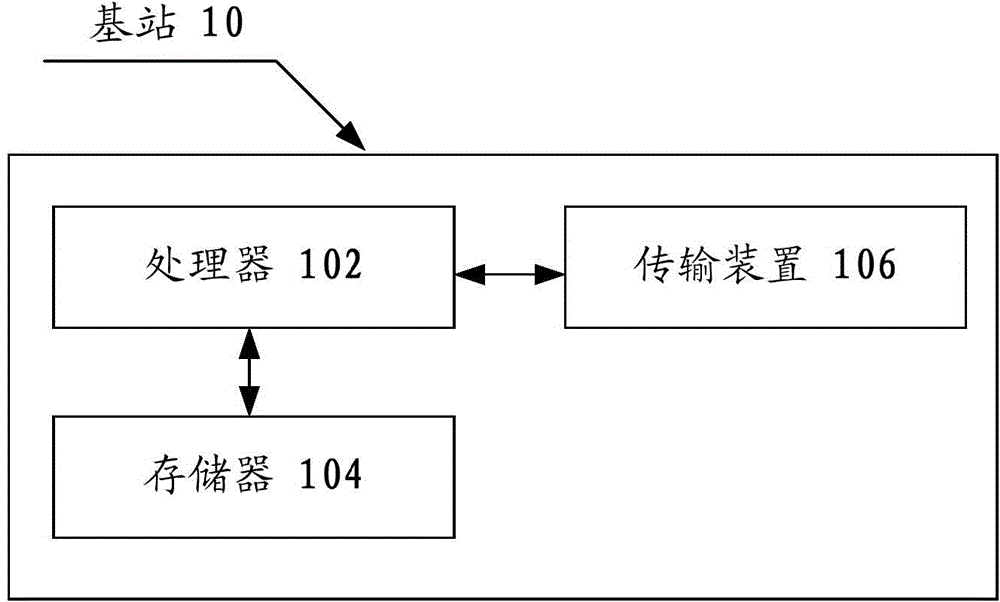

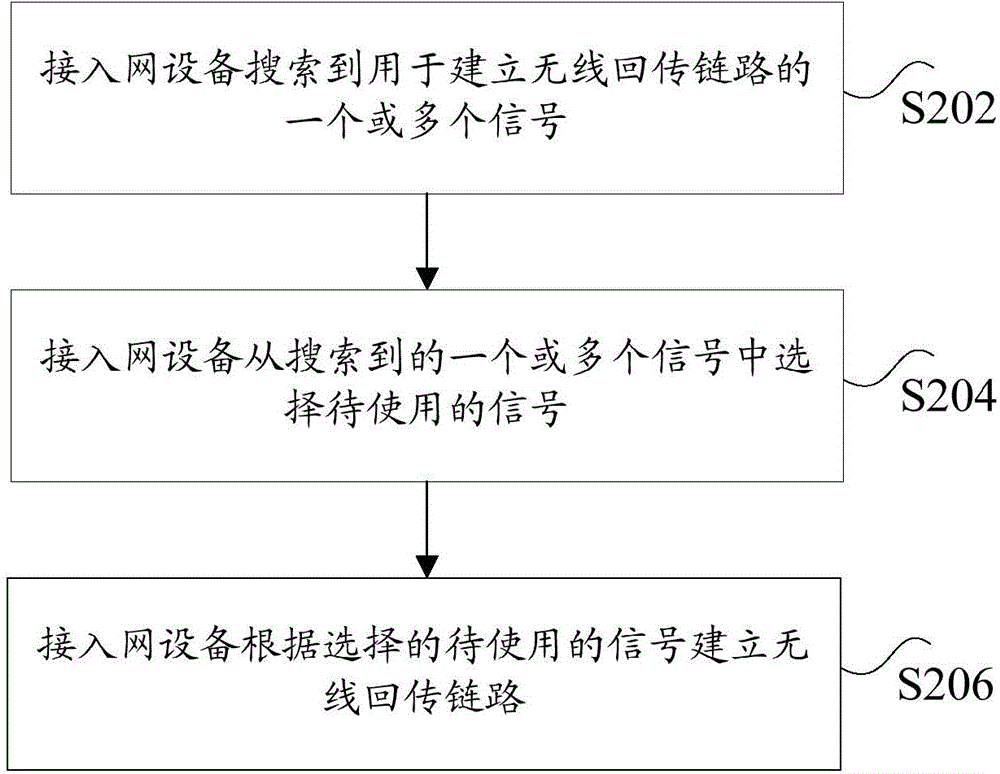

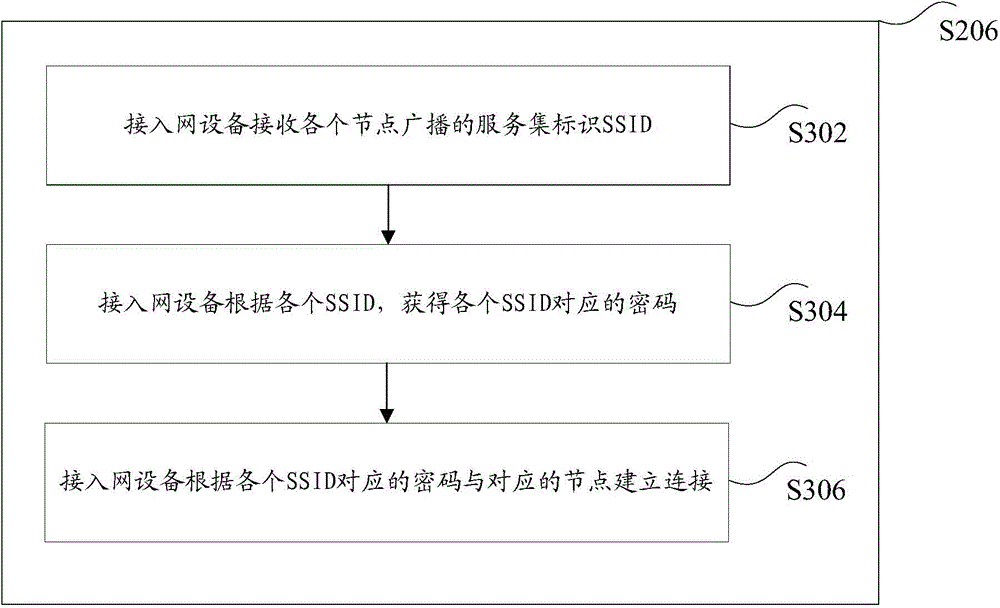

Method and apparatus for establishing wireless backhaul link and communication system

InactiveCN106162817AIncrease flexibilityLow costAssess restrictionConnection managementAccess networkWireless backhaul

The invention discloses a method and an apparatus for establishing a wireless backhaul link and a communication system. The method comprises the steps that an access network device searches one or more signals for establishing the wireless backhaul link; the access network device selects a to-be-used signal from the searched one or more signals; and the access network device establishes the wireless backhaul link according to the selected to-be-used signal. According to the method and the apparatus disclosed by the invention, the technical problem of relatively complex deployment resulting from the use of wired connection in the backhaul link in the prior art is solved.

Owner:BAICELLS TECH CO LTD

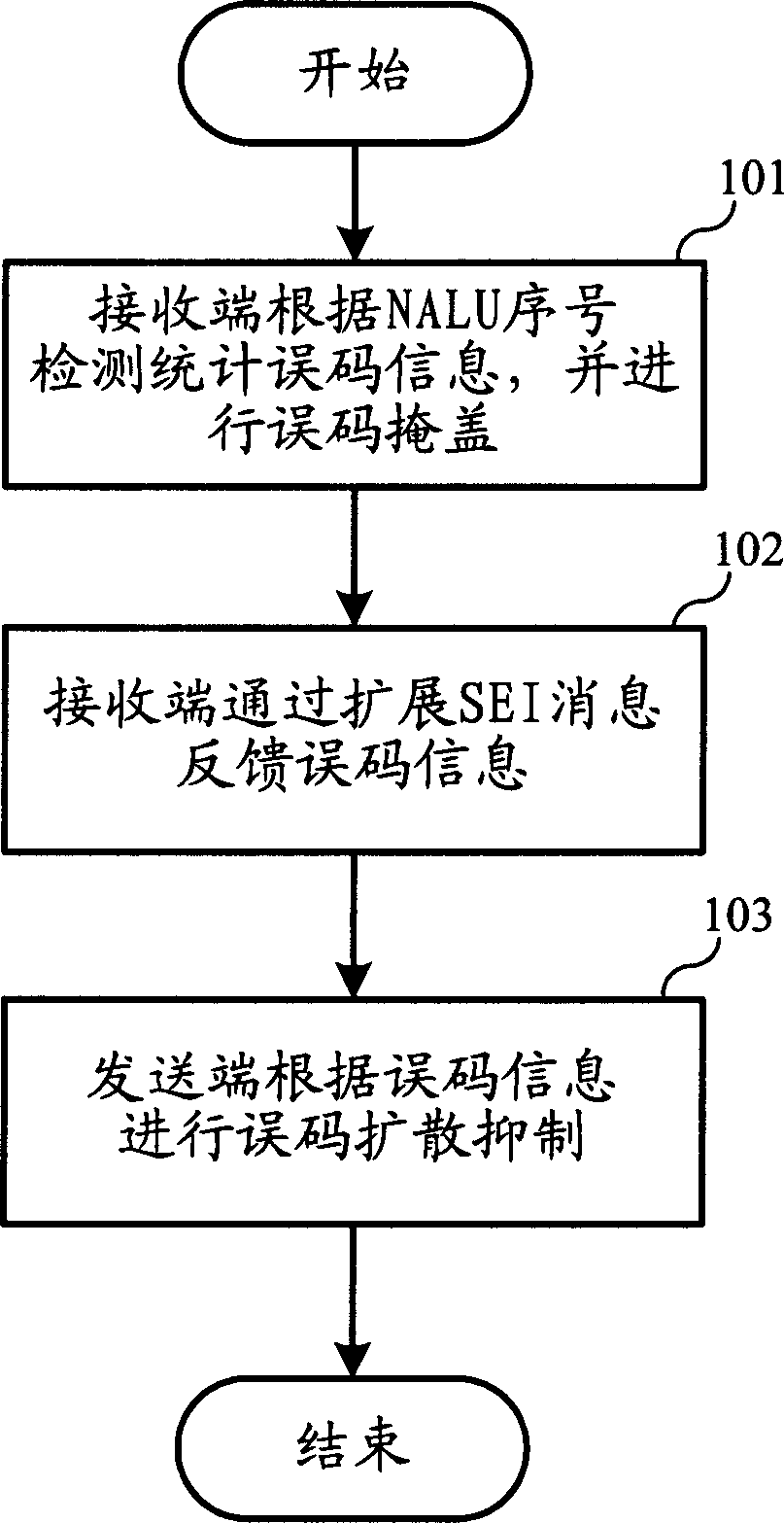

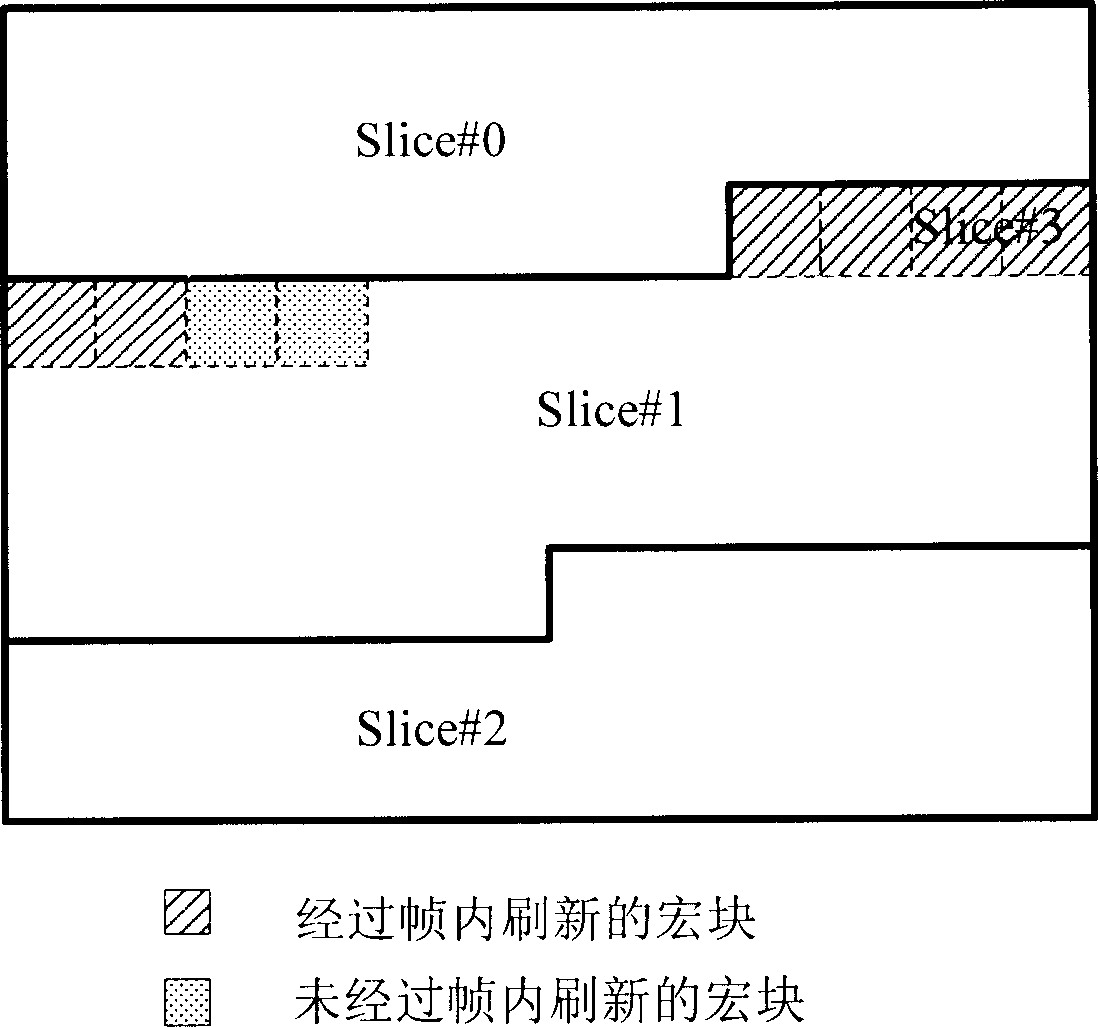

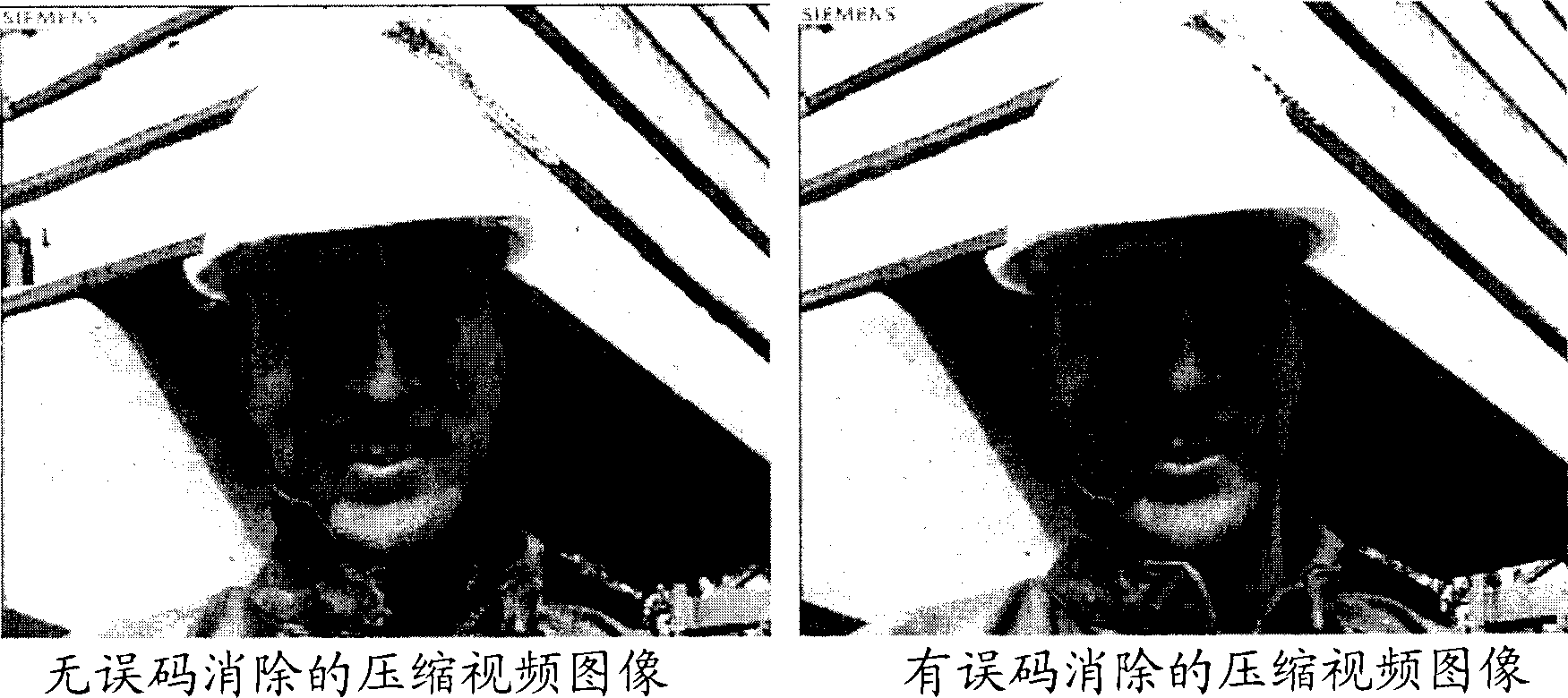

Error elimination of compressed video transmission based on H.264

InactiveCN1856112AError Diffusion SuppressionImprove transmission qualityDigital video signal modificationVideo transmissionData location

The invention is concerned with compressing video transmitting error-code eliminative method based on H.264, in order to eliminate the error-code simply and effectively, it is: combines the error-code cover and the error-code pervasion-control to achieve the error-code elimination by the feedback mechanism of the error-code information; loads the information check error-code occur of the Slice and the statistic of the error-code information such as the losing data location by the serial number of the NALU; establishes the inner error-code information feedback channel of the H.264 system by defining the extending SEI information; achieves the error-code pervasion-control by the sectional time-by-time in-frame coding.

Owner:SNAPTRACK

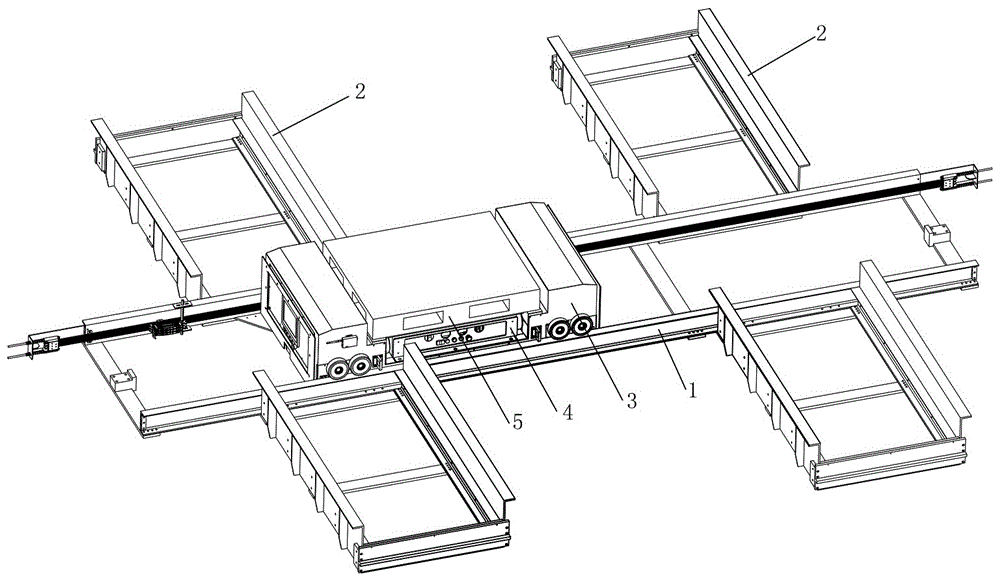

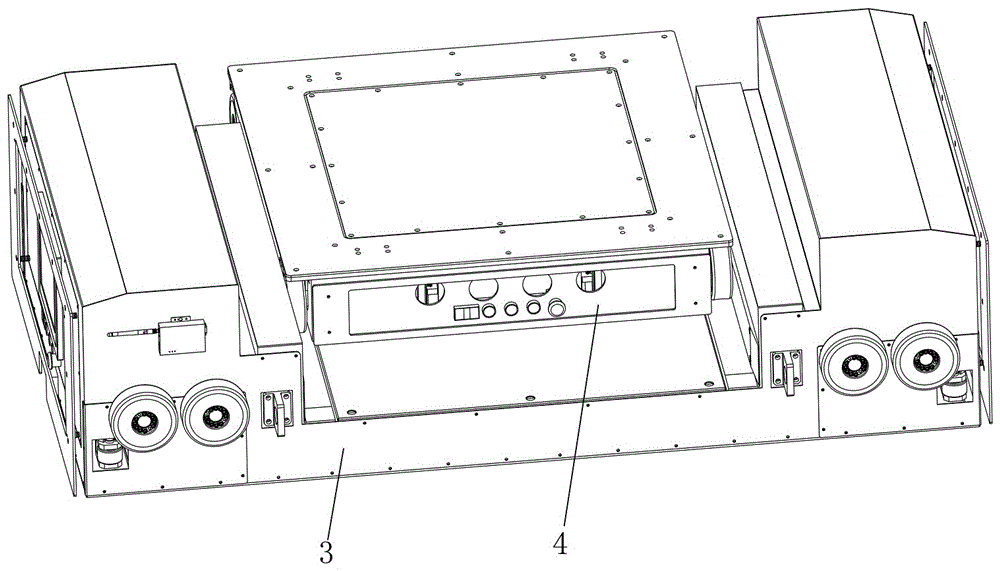

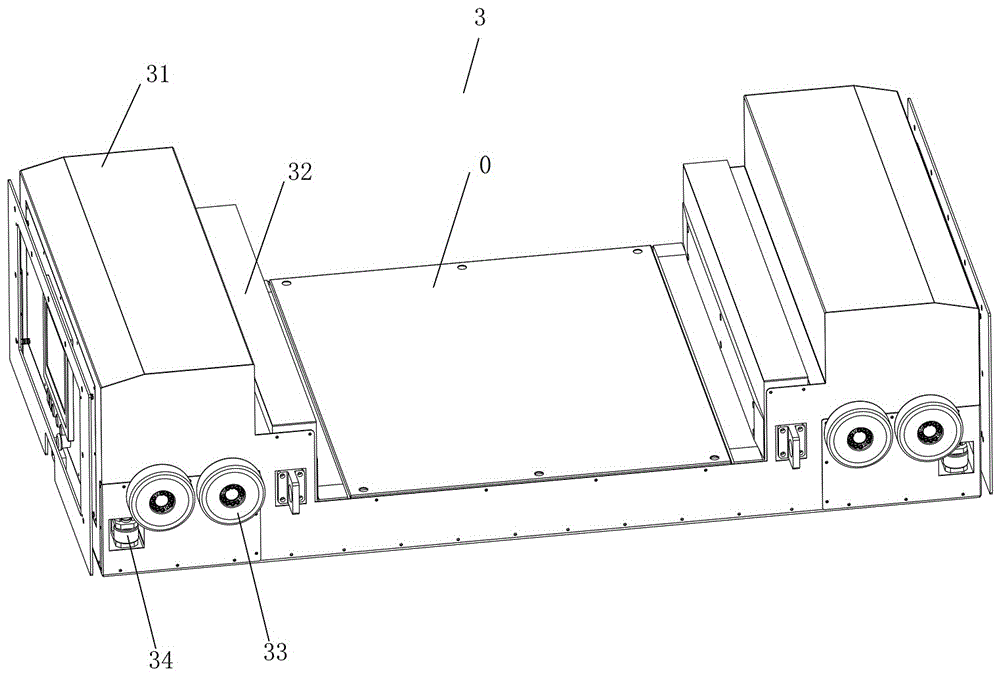

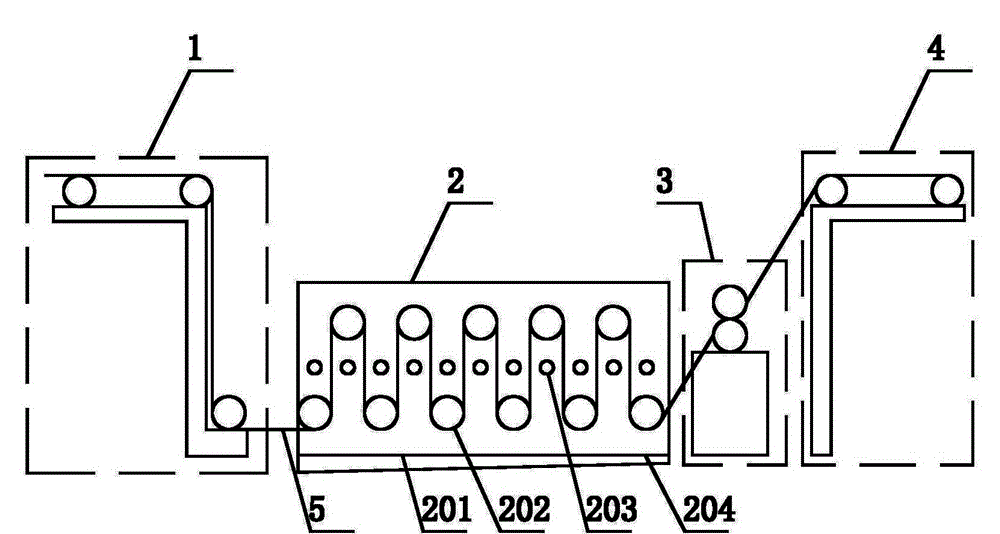

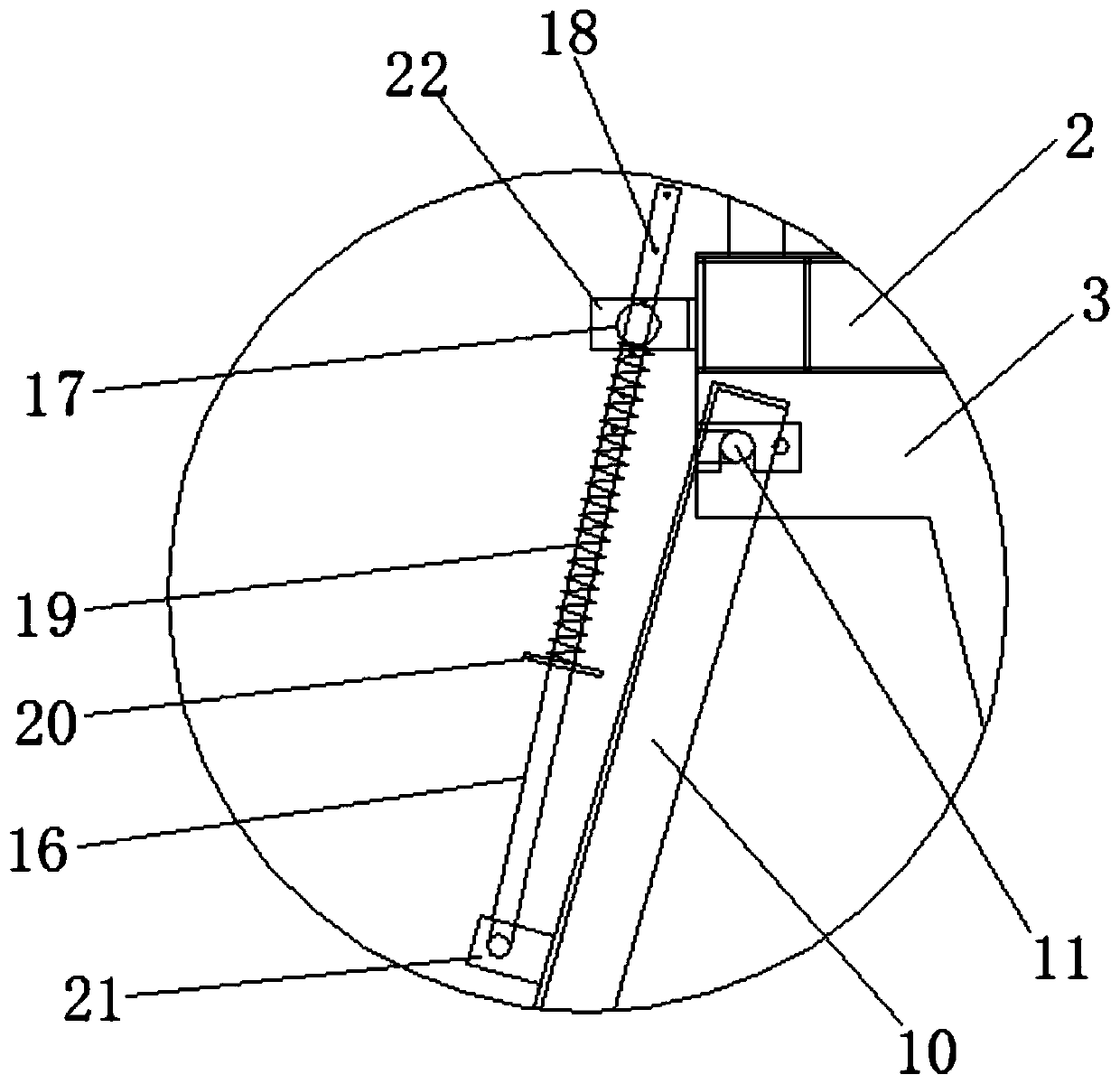

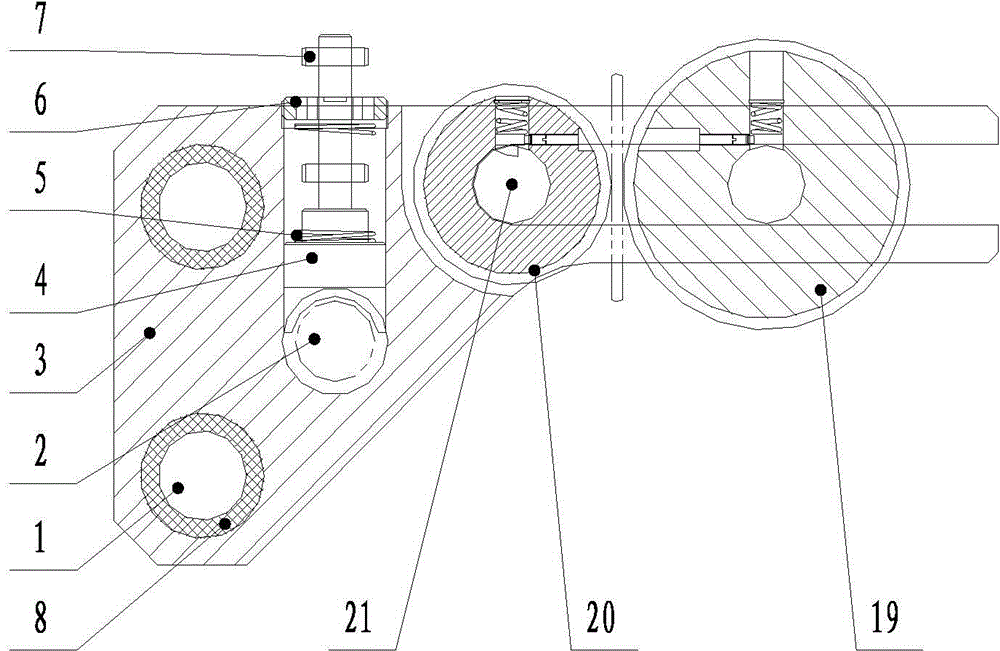

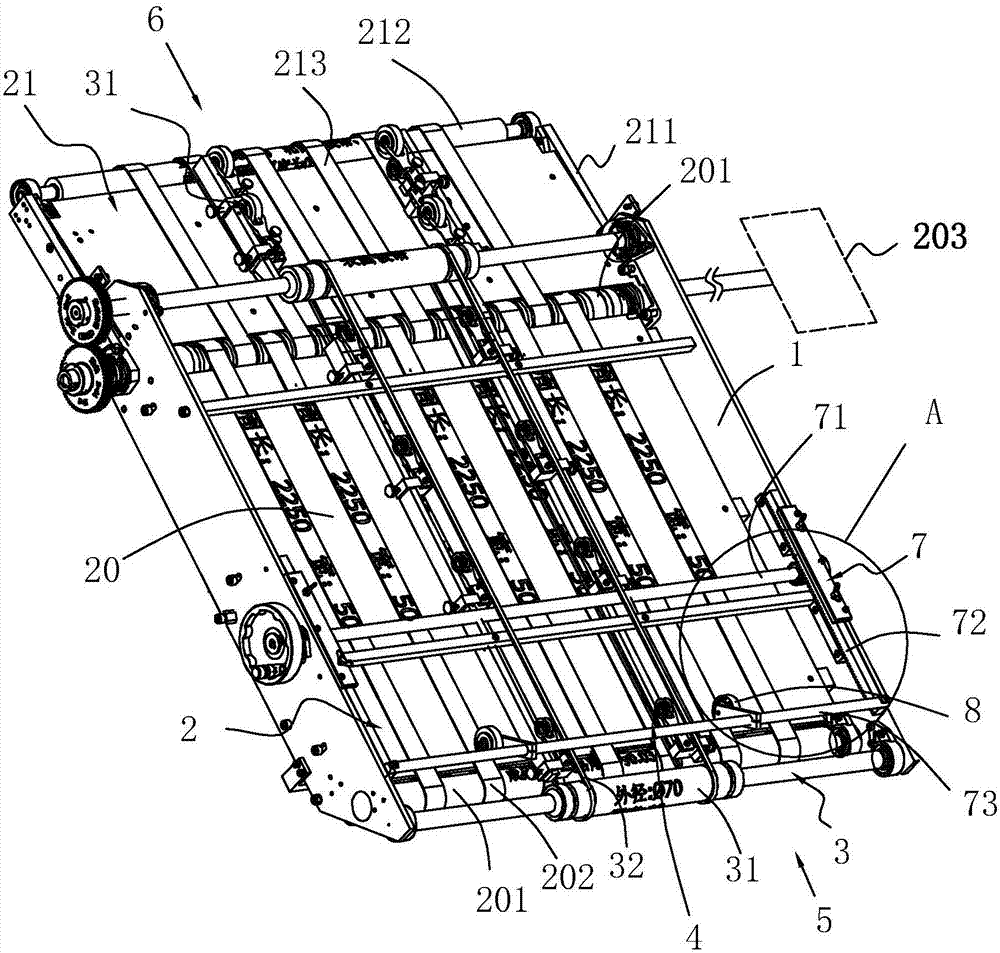

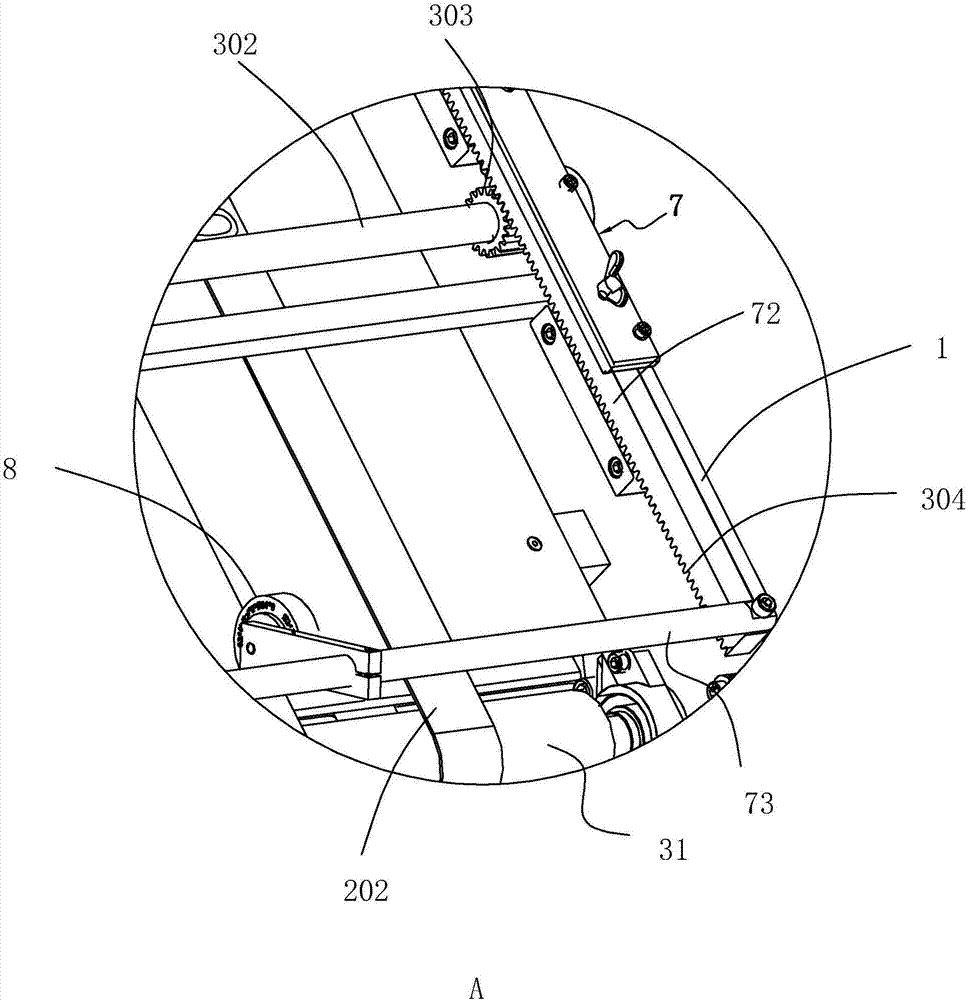

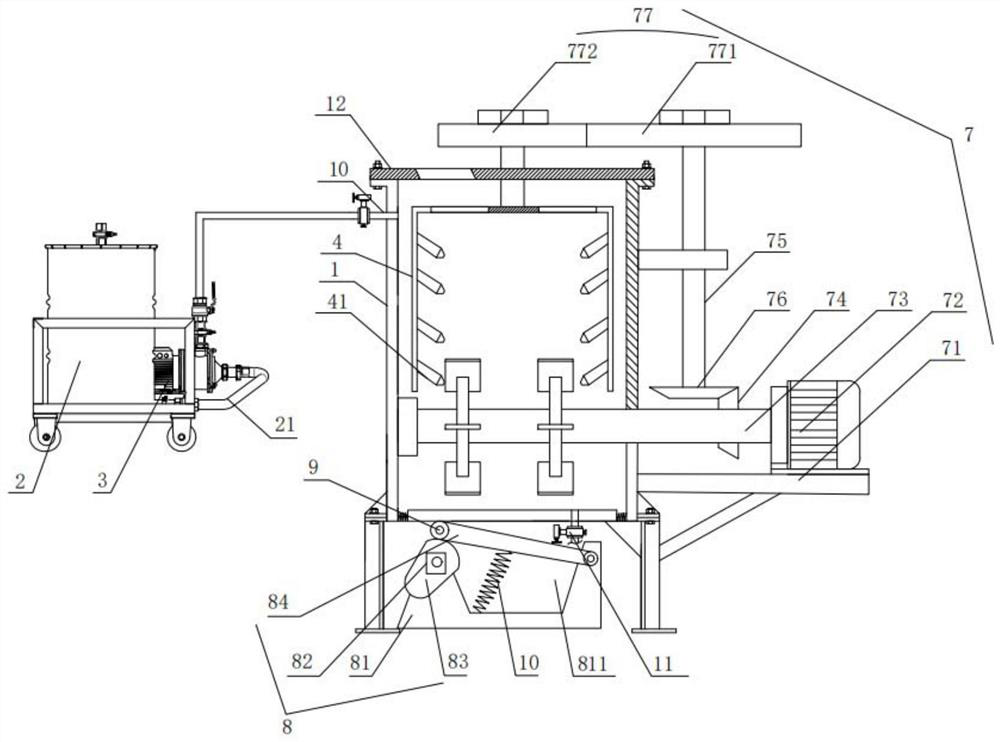

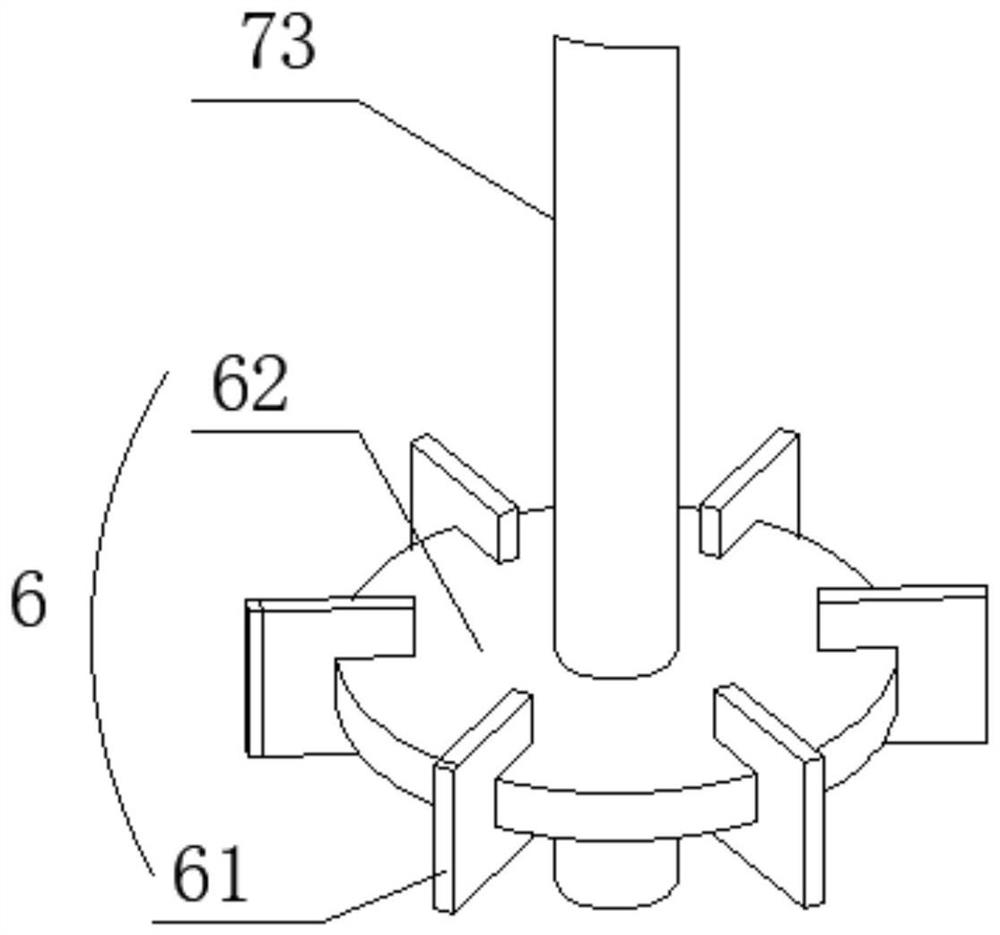

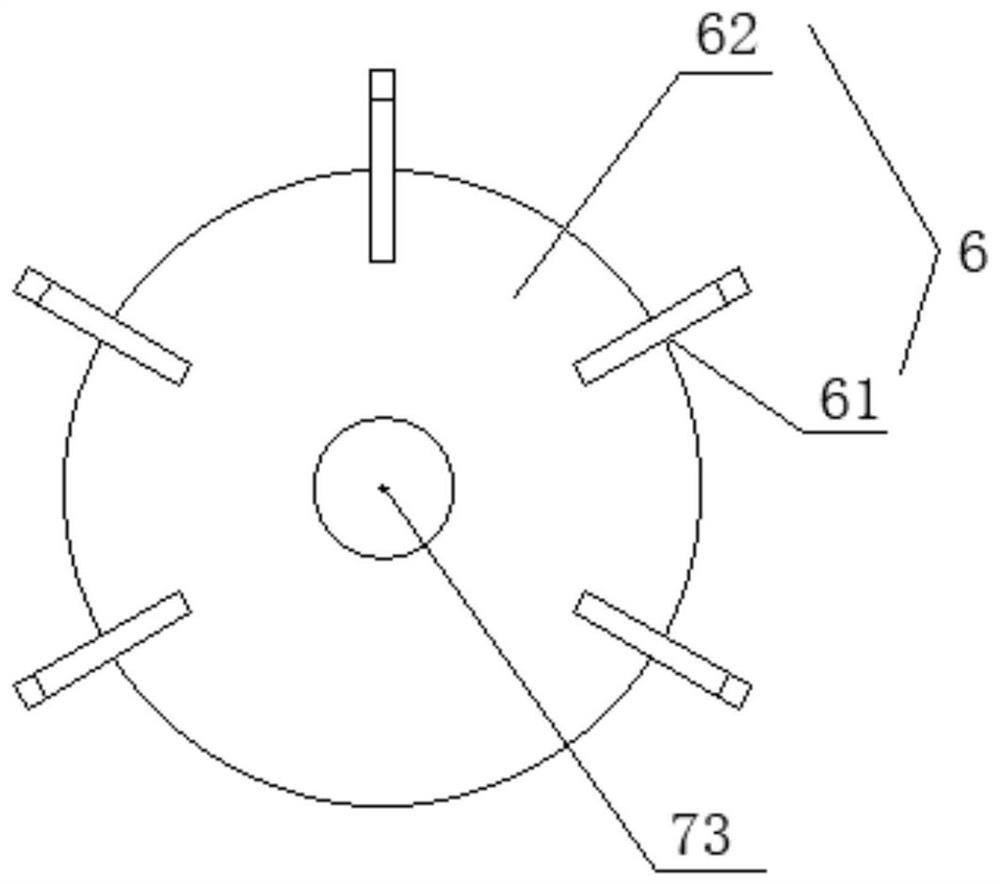

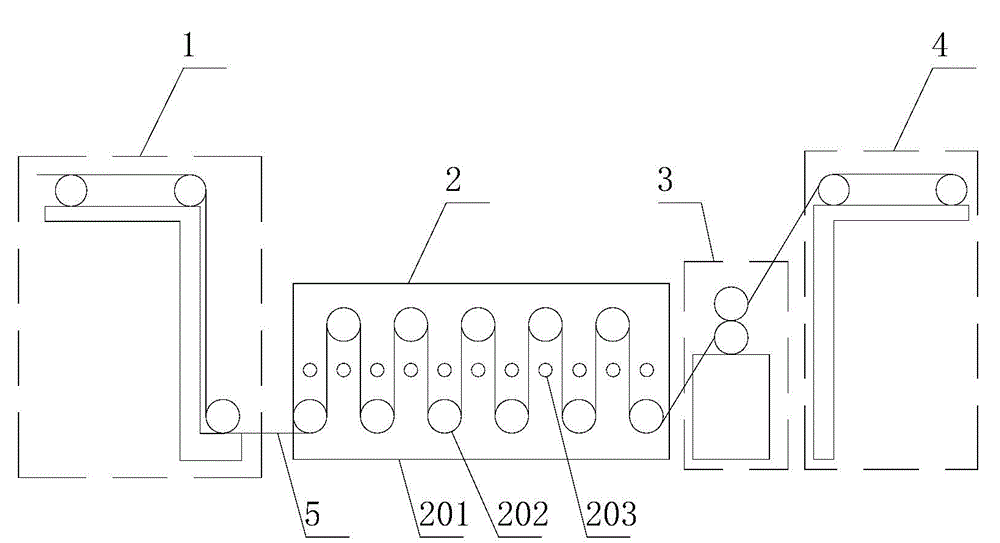

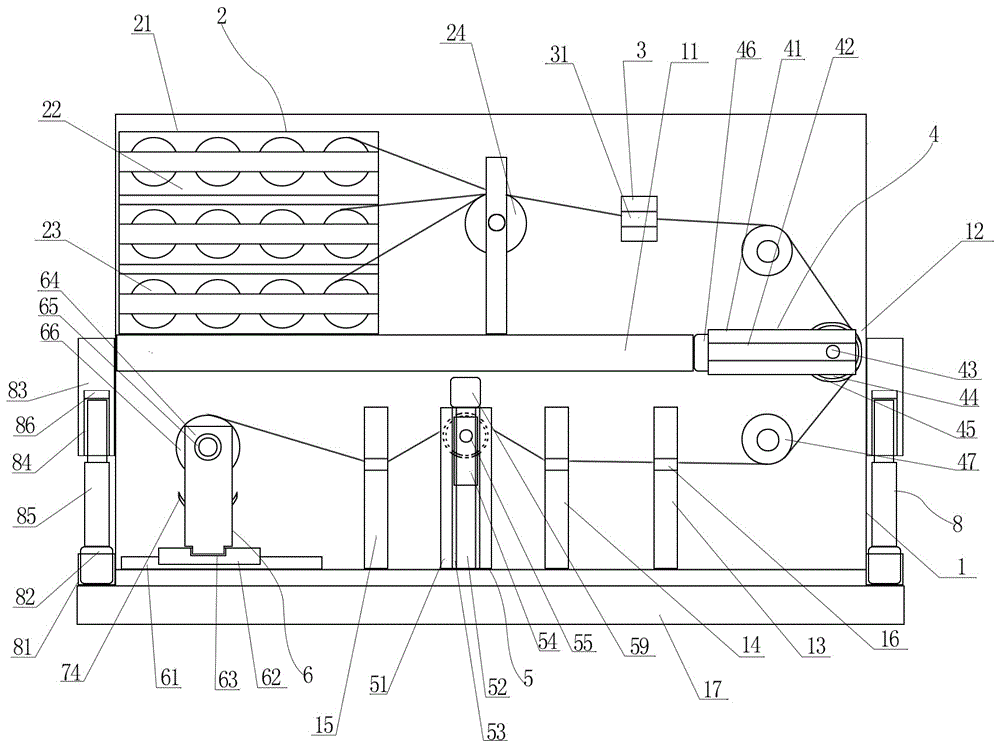

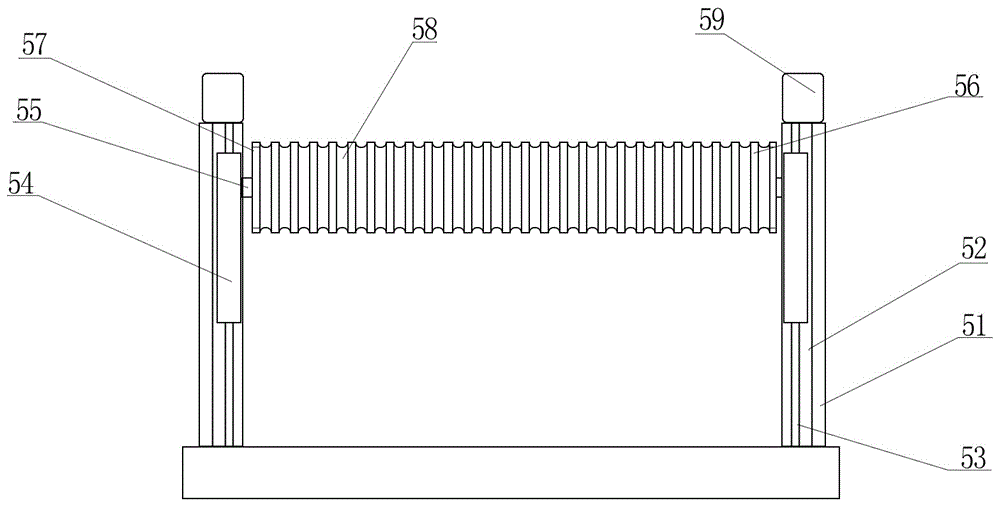

Shuttle child-mother vehicle for automatically carrying materials in and out from warehouse

InactiveCN106429156AImprove carrying capacityGuaranteed stabilityStorage devicesAutomotive engineering

The invention discloses a shuttle child-mother vehicle for automatically carrying materials in and out from a warehouse. The shuttle child-mother vehicle comprises at least two lanes spaced in parallel, and rails vertically connected to two sides of the lanes; and the lanes and the rails form material transportation rails. The shuttle child-mother vehicle further comprises a mother vehicle, and a child vehicle slidingly arranged on the mother vehicle; the mother vehicle is arranged on the lanes, and linearly slides along the lanes in a reciprocating manner; a child vehicle groove inwards recessed is formed in the middle part of the mother vehicle; slide ways are respectively formed in two sides of the child vehicle groove; the child vehicle is arranged in the child vehicle groove; child wheels on two sides of the child vehicle are put on the slide ways for supporting the child vehicle; a walking module and an ejecting module are arranged in the child vehicle, and adopt independent driving mechanisms; the walking module drives the child vehicle to linearly slide on the slide ways or the rails; and the ejecting module drives an object carrying plate to lift in the vertical direction. The shuttle child-mother vehicle matches the mother vehicle with the child vehicle to realize full-automatic material carrying, effectively promotes the carrying efficiency, and reduces the carrying cost.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

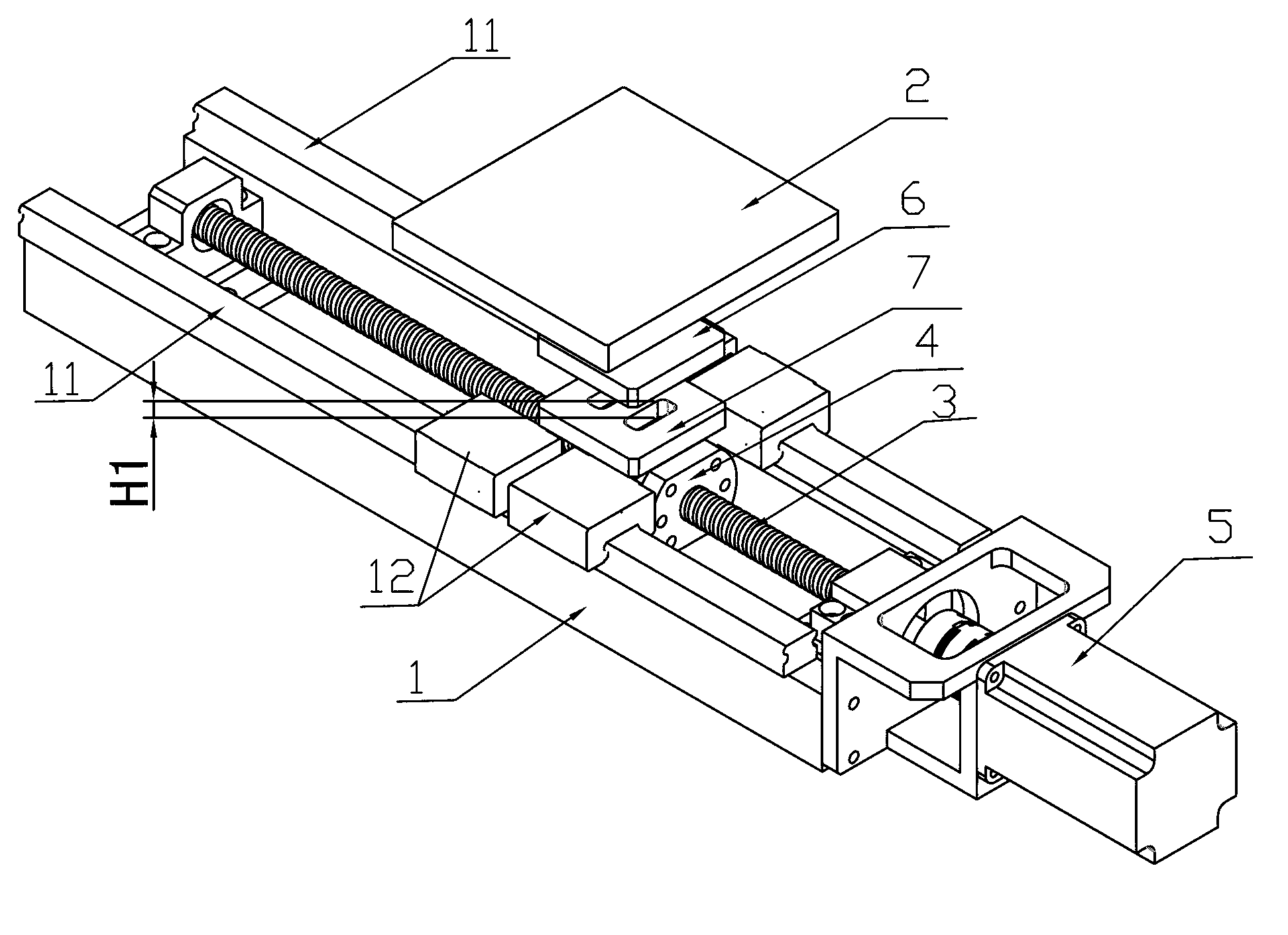

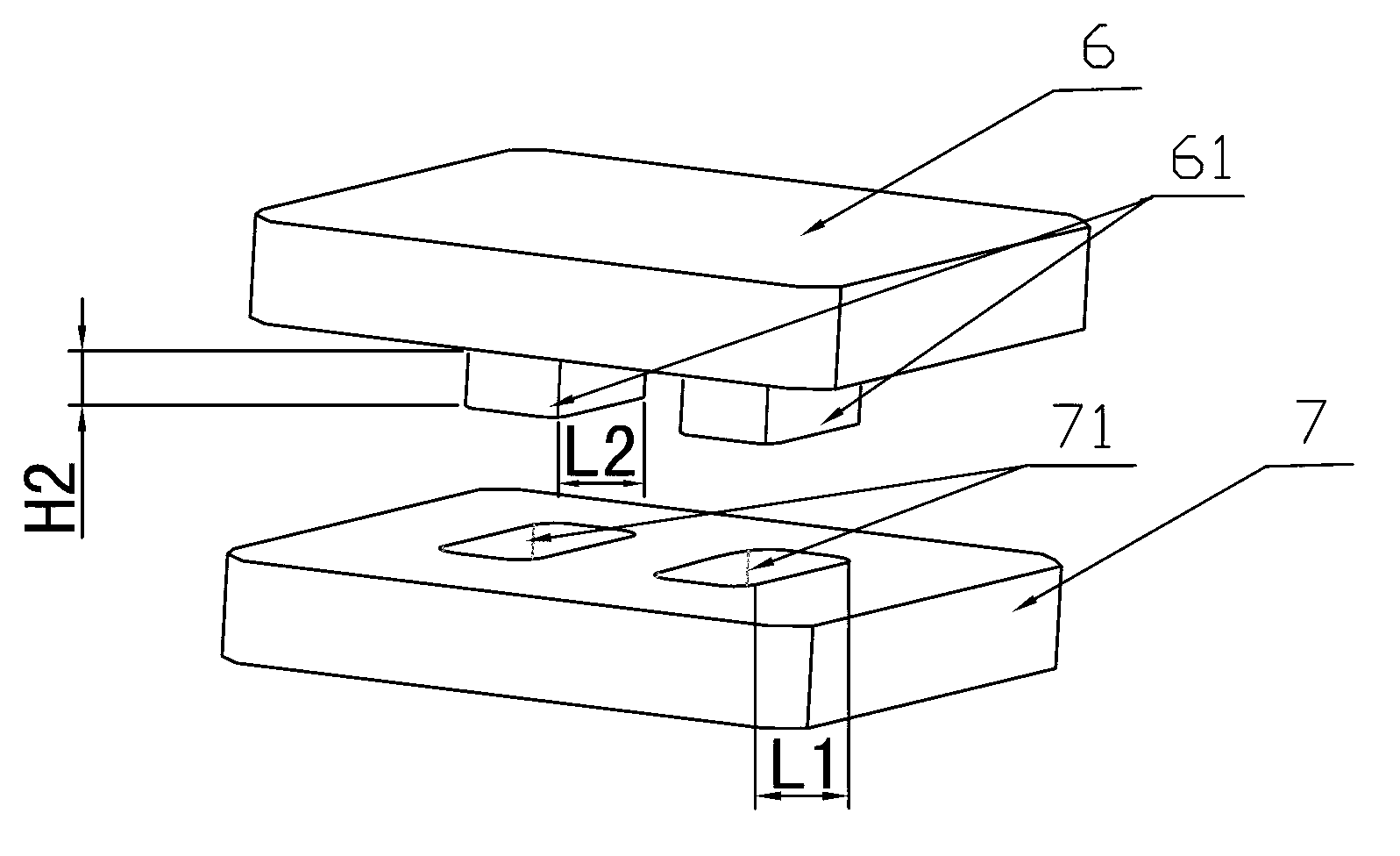

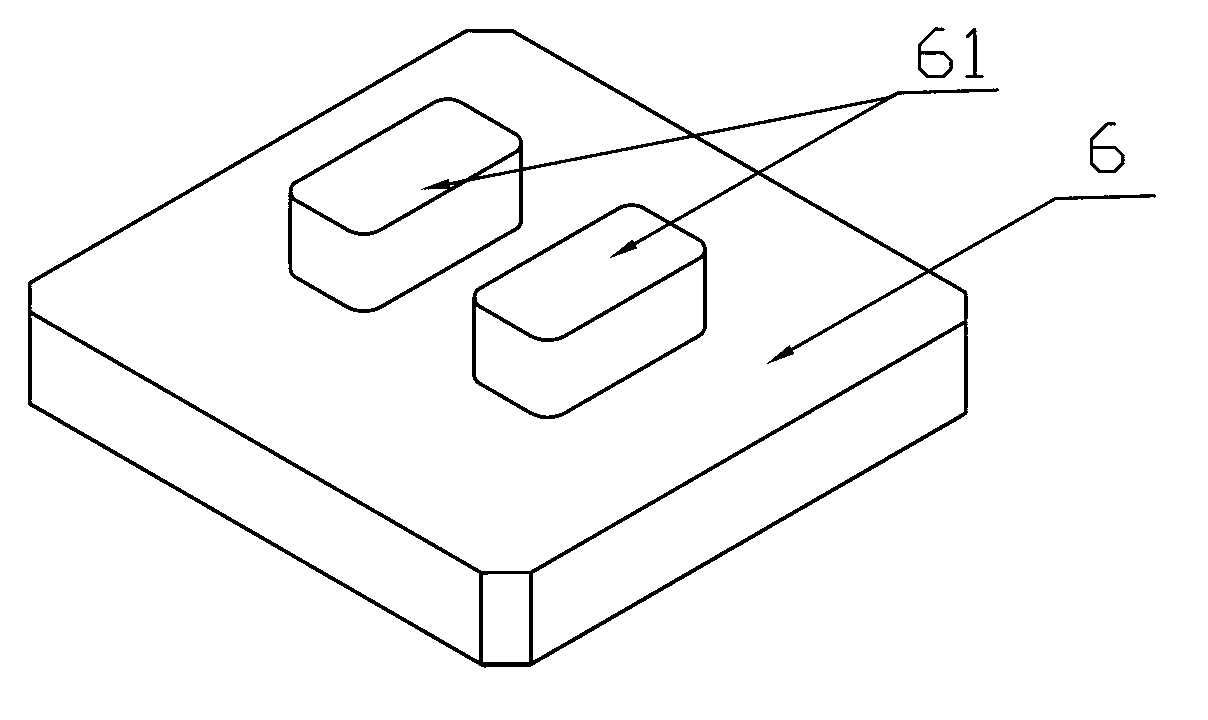

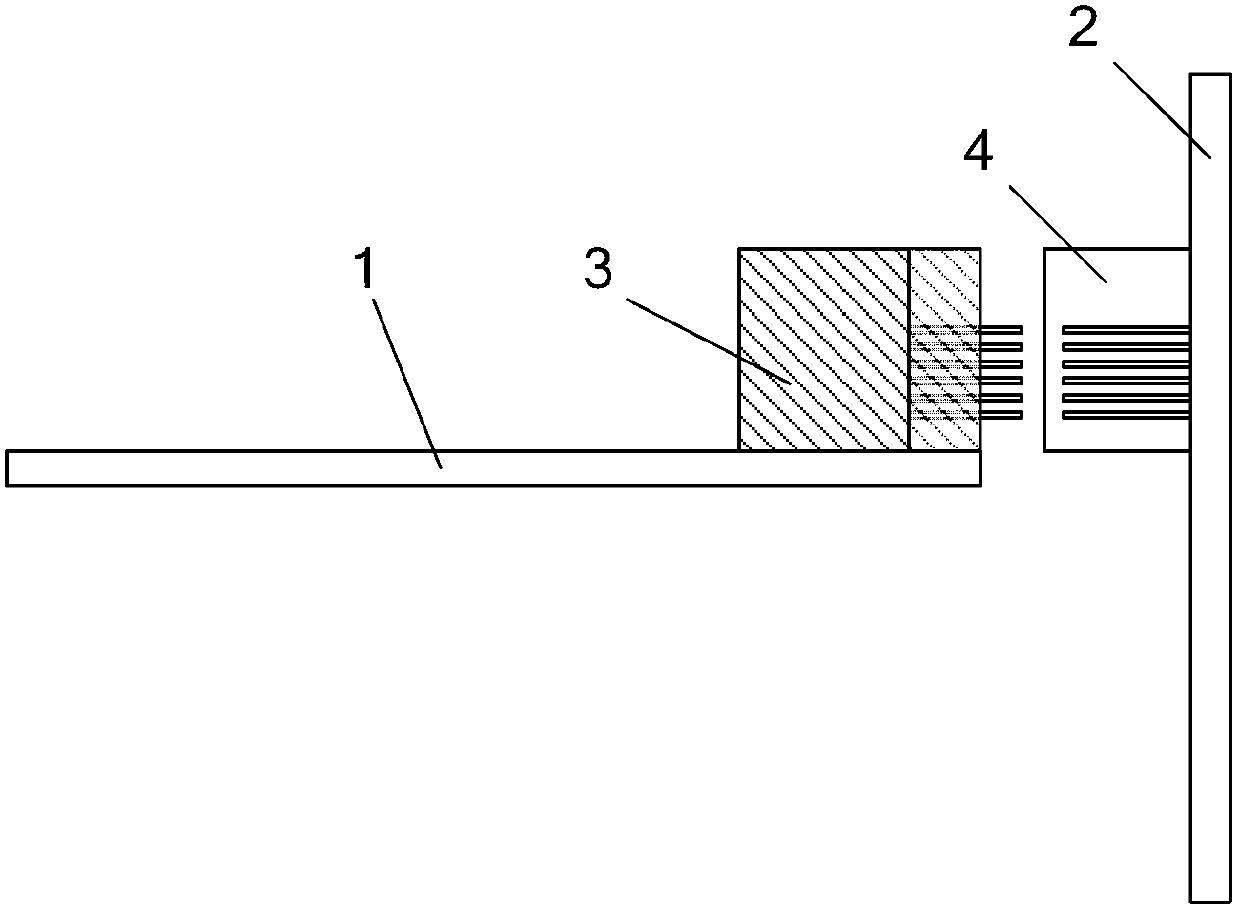

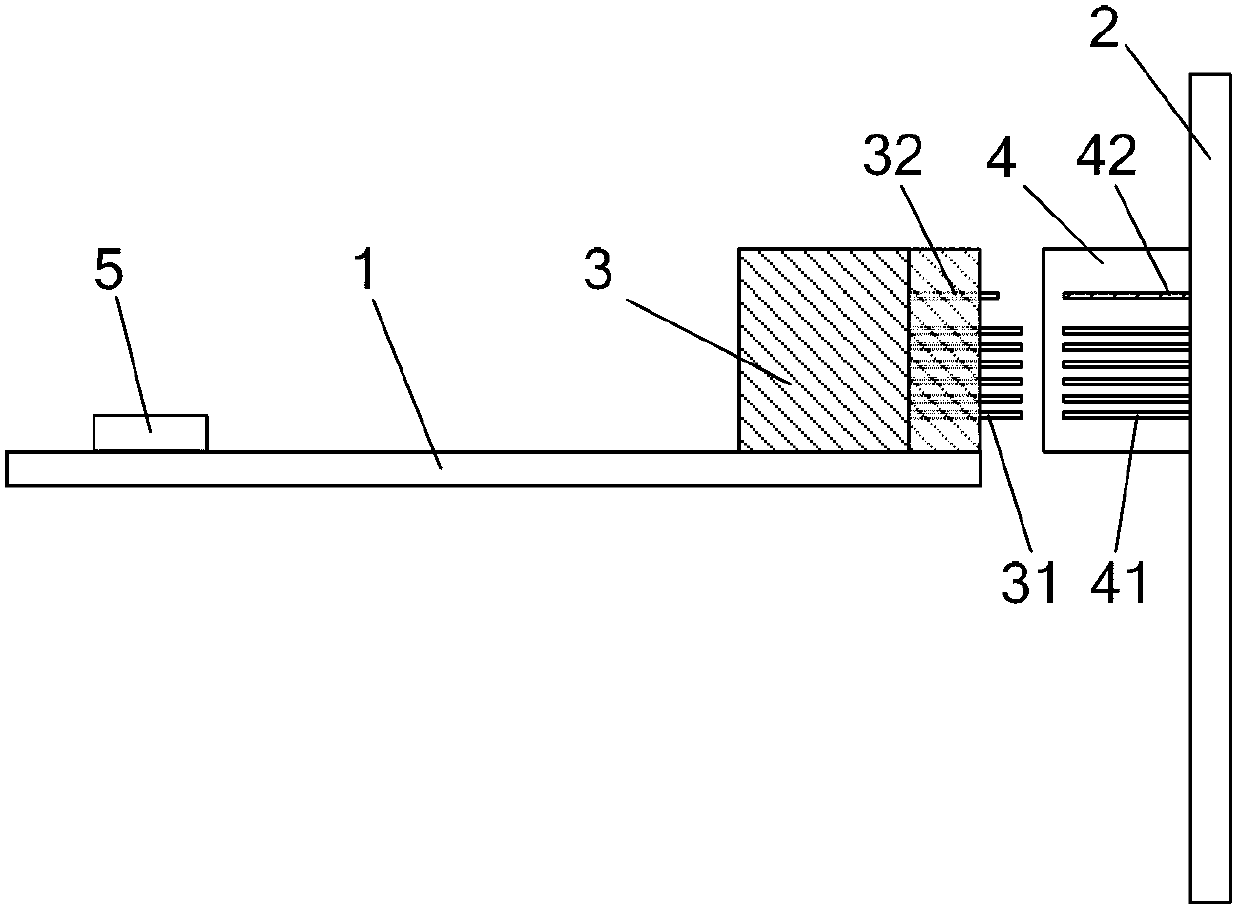

Linear moving device

ActiveCN103010689ANo deformationDoes not generate distortionMechanical conveyorsMechanical engineering

Owner:NINGBO YUNSHENG INTELLIGENT TECHNOLOGY CO LTD +1

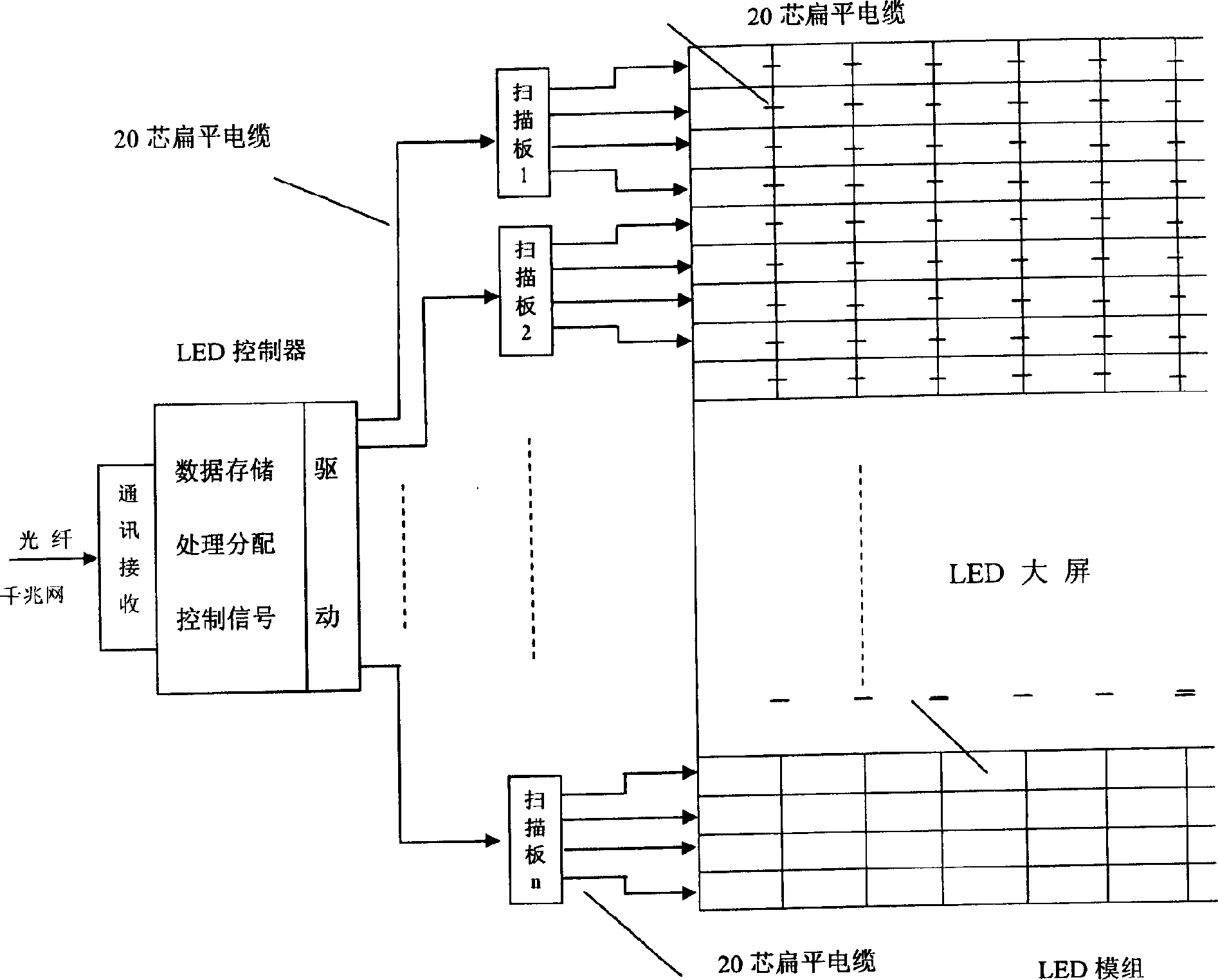

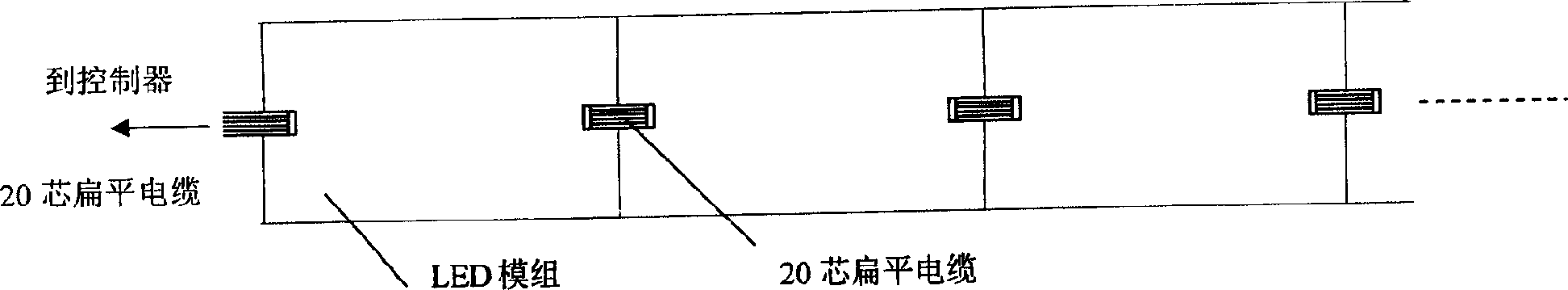

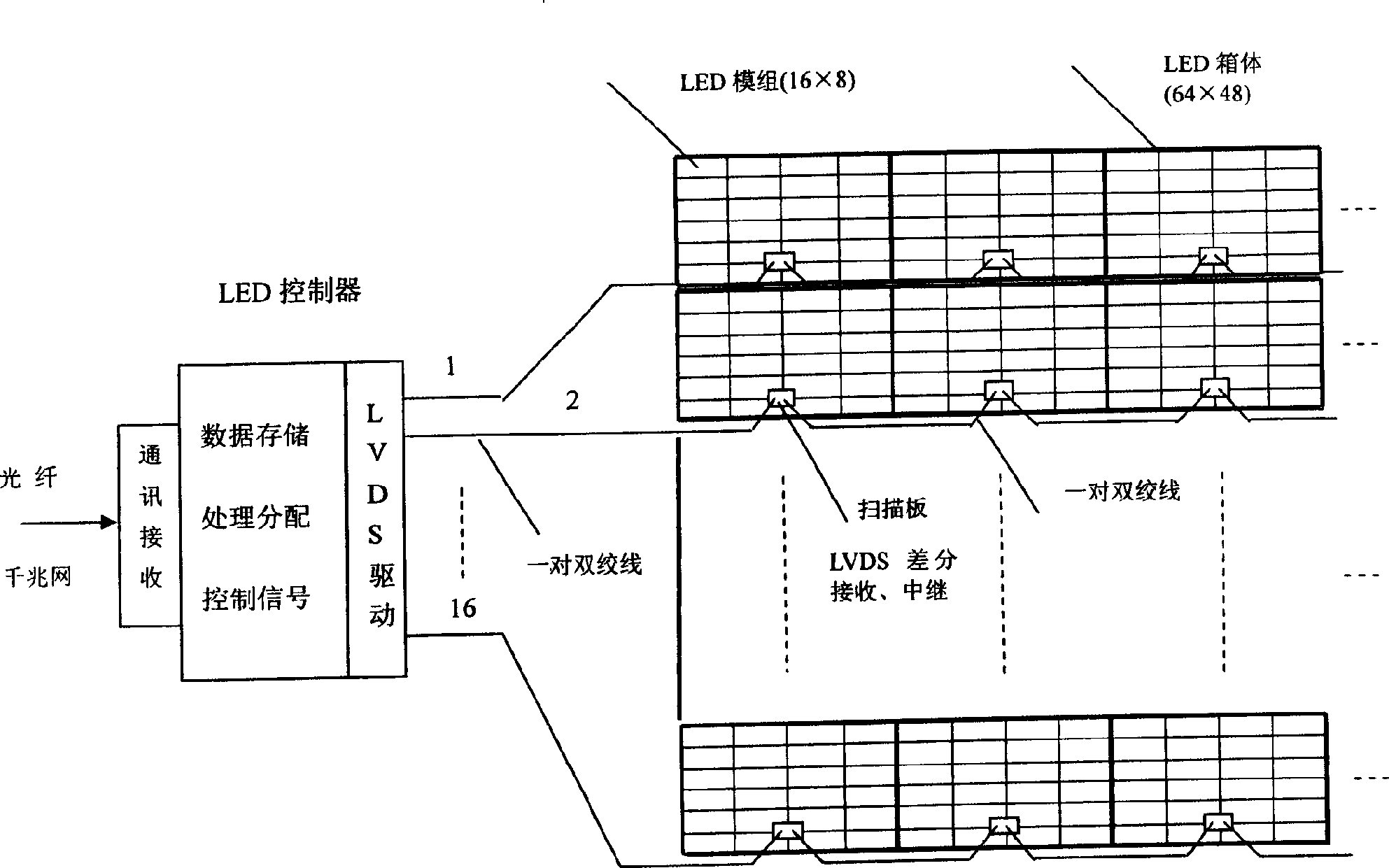

LED display screen signal interconnection method

ActiveCN1734545ASimple connection structureEnsure transmission stabilityStatic indicating devicesLED displayEngineering

The invention discloses an interconnecting method of LED display screen signal, which consists of LED display screen controller and several boxes of bus groups and comprises the following steps: a) the LED display screen controller cascades each leading-end bus of bus groups by twisted-pair line; b) several boxes of each box group cascade by twisted-pair line.

Owner:KONKA GROUP

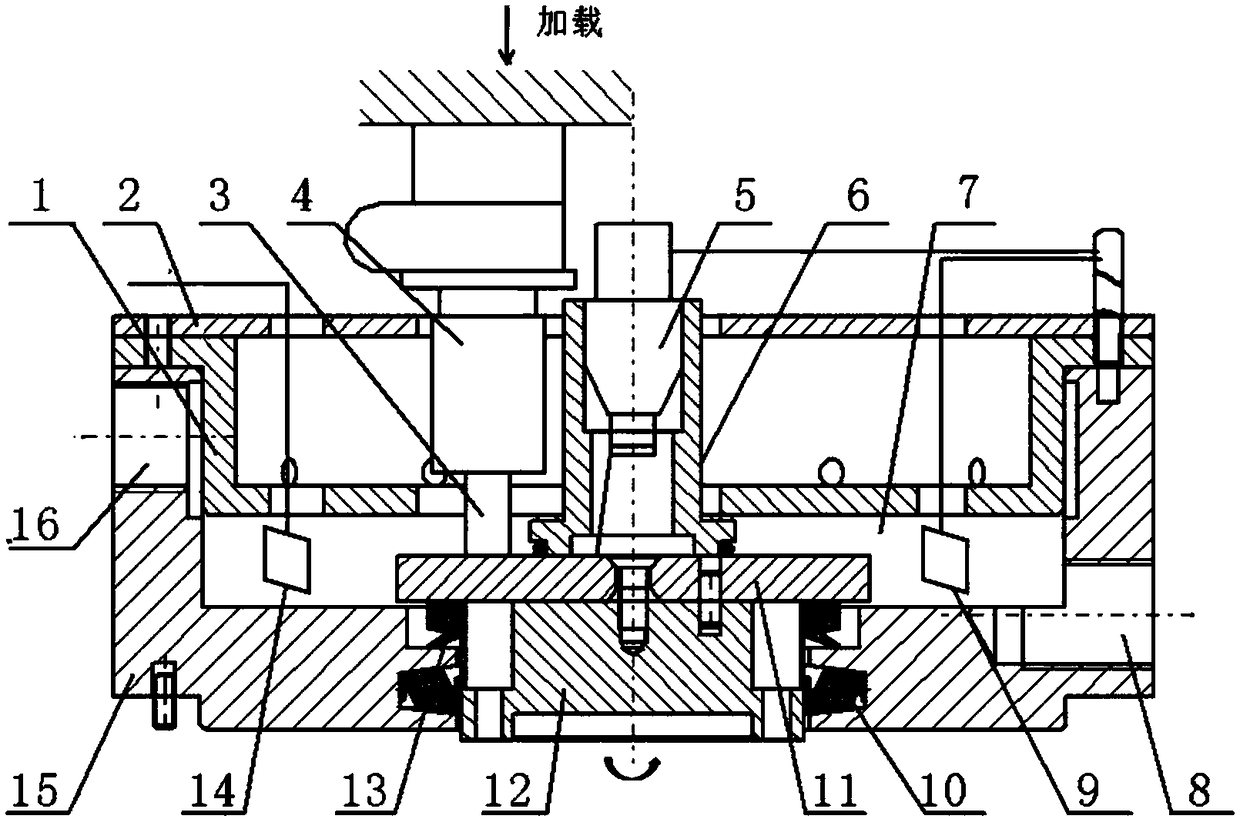

Dynamic electrochemical corrosion and wearing test device

InactiveCN108593536ASolve signal transmission problemsEnsure transmission stabilityWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceContact modeWorkstation

The invention discloses a dynamic electrochemical corrosion and wearing test device. An electrochemical workstation and friction and wearing functions are integrated, and in-situ and dynamic test of the interaction of corrosion and wearing is carried out. The corrosion and wearing test device is rotary, and adopts a pin-disc friction contact mode and a three-electrode electrochemical test system,a lower test piece is a working electrode, and is connected with the electrochemical workstation through a mercury slip ring to dynamically test the electrochemical parameters in a rotating friction state. The device can detect the simple grinding weight loss, the corrosion weight loss and the corrosion and wearing interaction amount, can respectively detect the corrosion rates under simple corrosion and the co-action of corrosion and wearing, realizes real-time monitoring of the electrochemical performances and the friction performance under different conditions (load, rotating speed and medium), can accurately realize simultaneous test and in-situ research of the corrosion and wearing of the material, further realizes the dynamic research of the corrosion and wearing interaction mechanism, and has wide application values.

Owner:BEIJING UNIV OF TECH

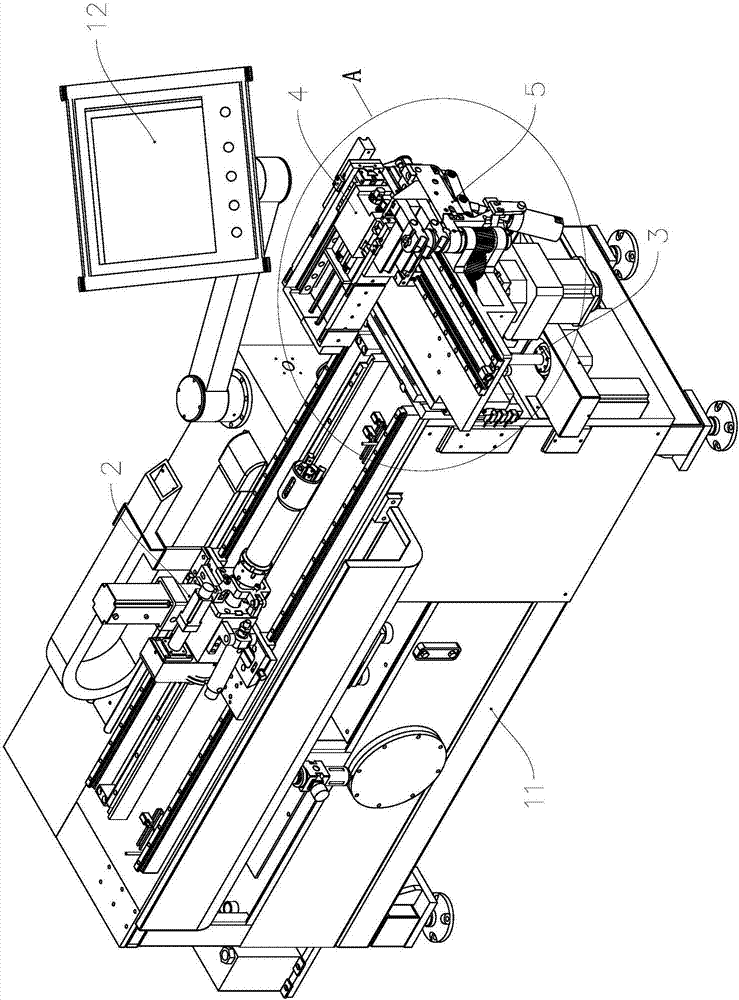

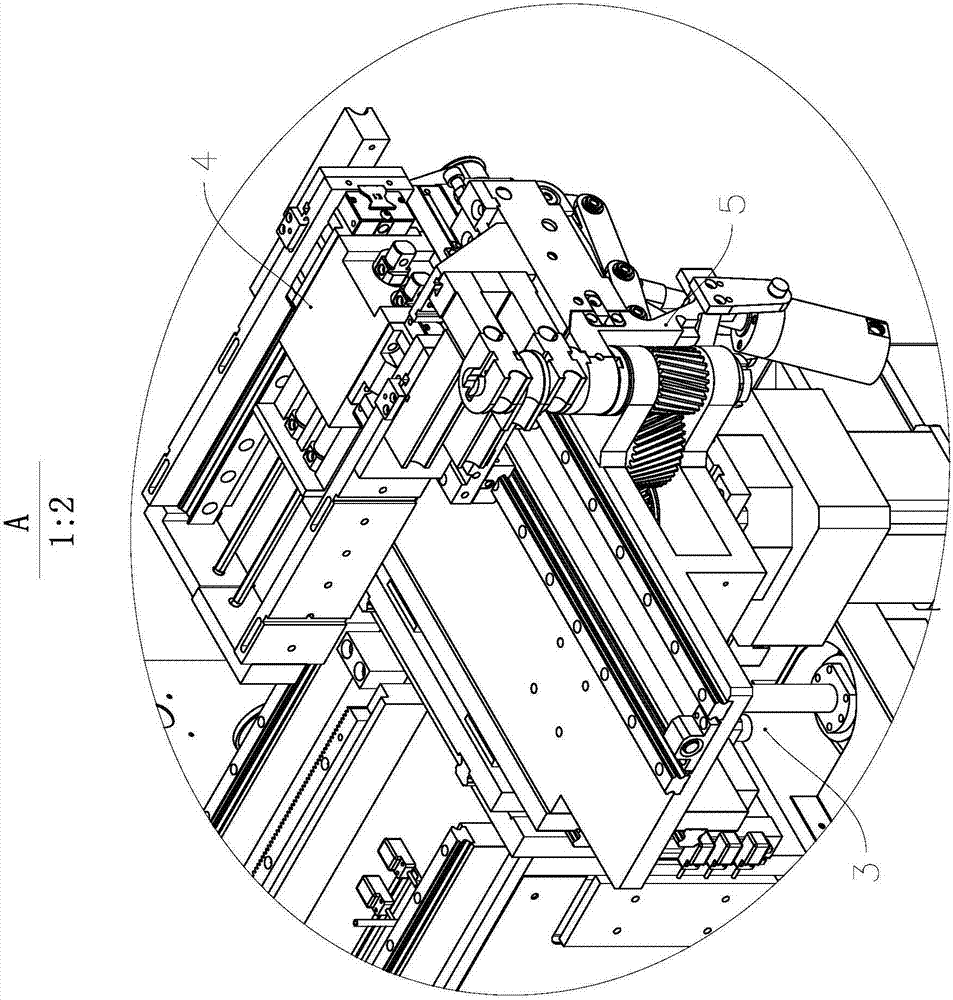

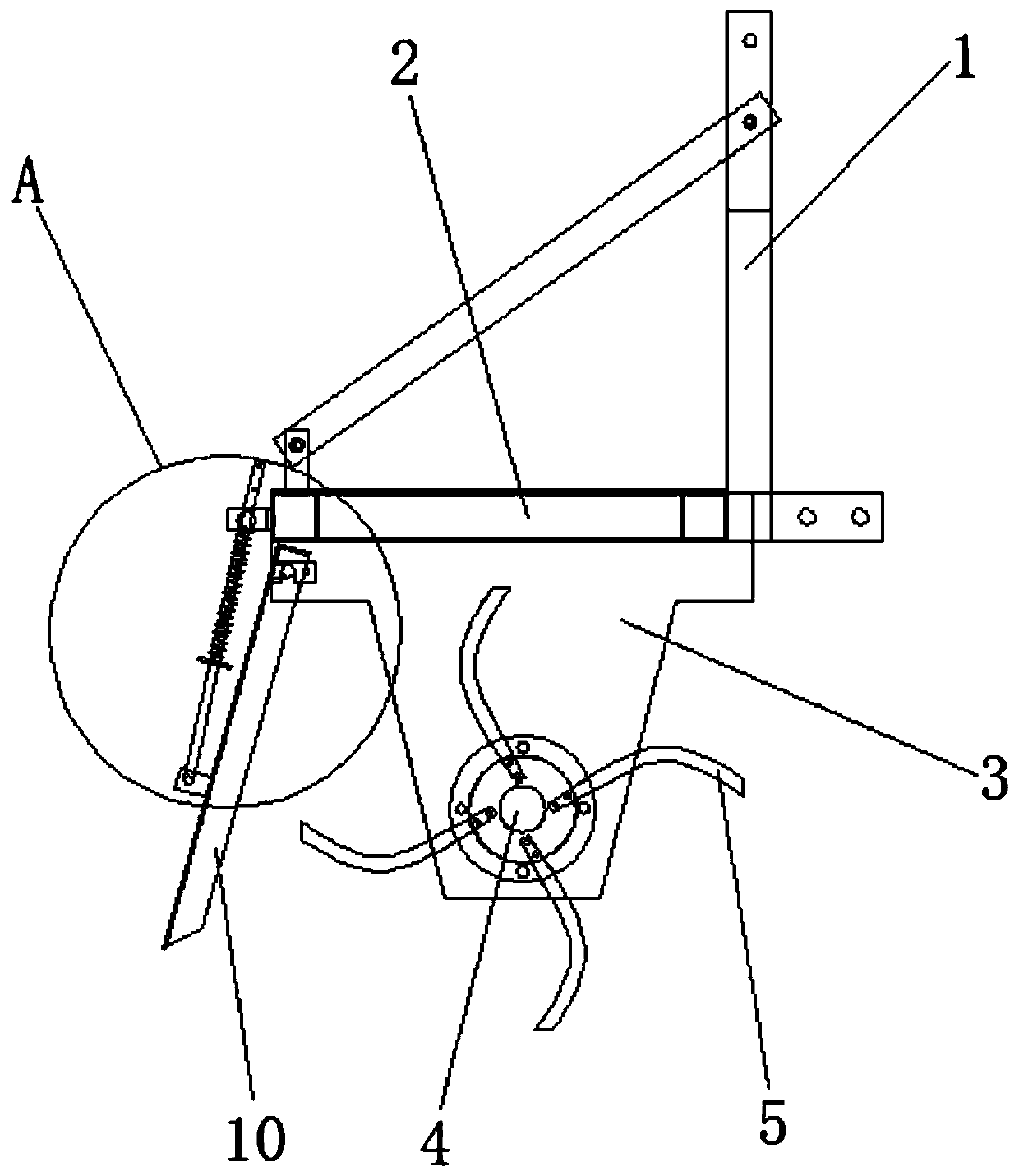

Single-oscillating-arm leftward and rightward co-bending type numerical control pipe bending machine

The invention relates to a single-oscillating-arm leftward and rightward co-bending type numerical control pipe bending machine and belongs to the technical field of pipe processing. The numerical control pipe bending machine comprises a machine frame, a control unit, a feeding trolley, a machine head, a mold guide unit and a switching unit, wherein the feeding trolley, the machine head, the mold guide unit and the switching unit are installed on the machine frame and controlled by the control unit; the machine head comprises a clamping mold, a round mold, an oscillating arm and a pipe bending motor, the oscillating arm shares the same drive spindle with the round mold, and the pipe bending motor is used for driving the round mold and the oscillating arm to rotate to bend a pipe and to rotate at the leftward pipe bending position or the rightward pipe bending position in a switching mode; and the switching unit is controlled by the control unit to drive the machine head to move transversely or vertically perpendicular to the axial direction of the pipe to be bent relative to the machine frame so that the machine head can be driven to switch between the leftward pipe bending position and the rightward pipe bending position. By means of the single-oscillating-arm leftward and rightward co-bending type numerical control pipe bending machine, leftward and rightward co-bending can be achieved based on the single oscillating arm, the pipe bending quality can be effectively improved, and the numerical control pipe bending machine can be widely applied to the fields of air conditioners, aviation and the like.

Owner:浙江和良智能装备有限公司

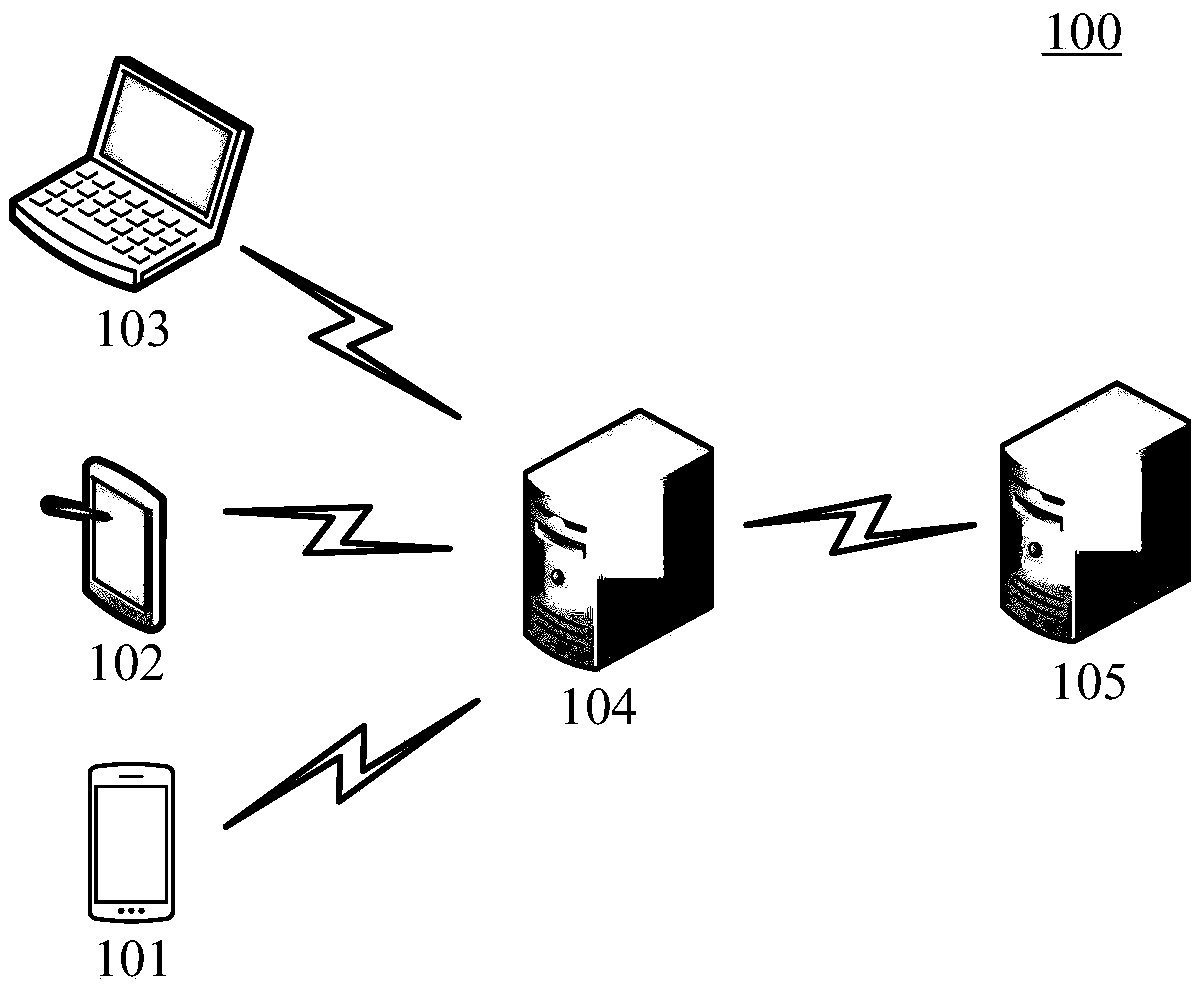

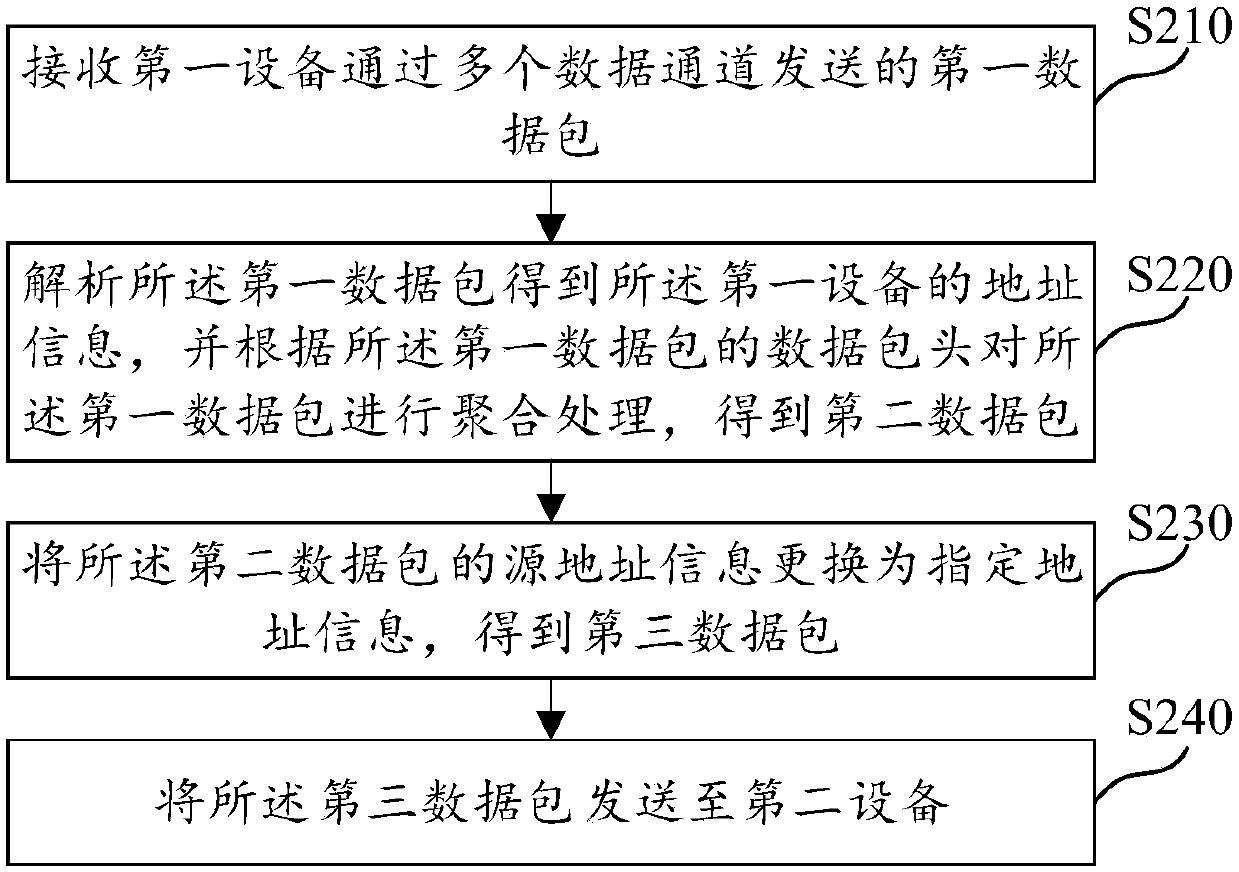

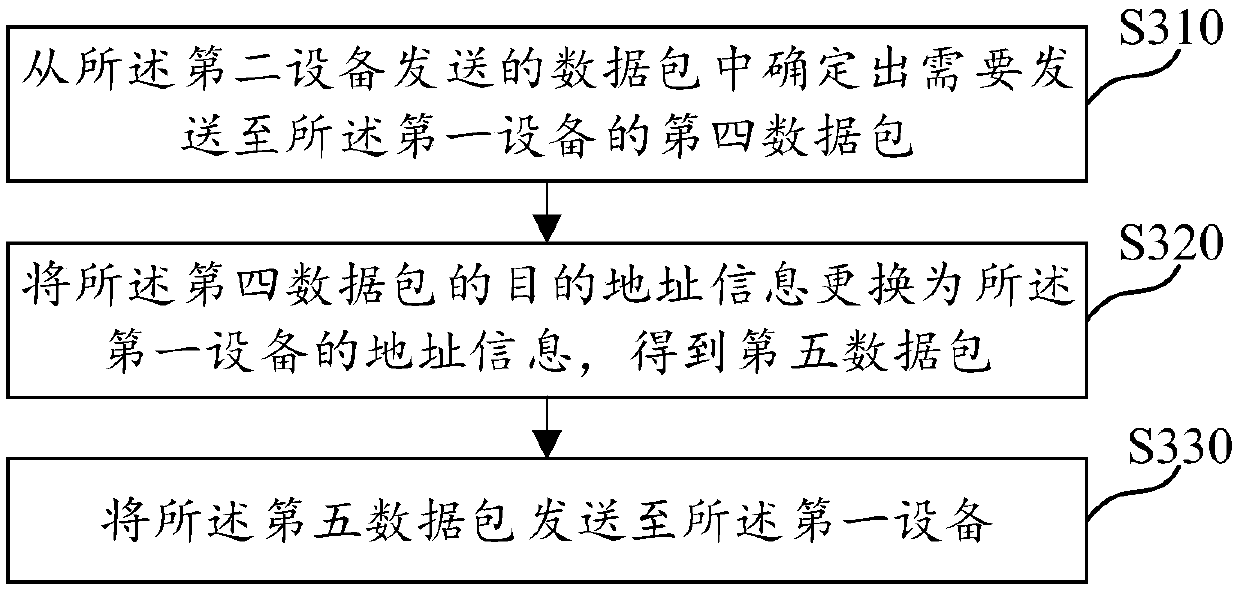

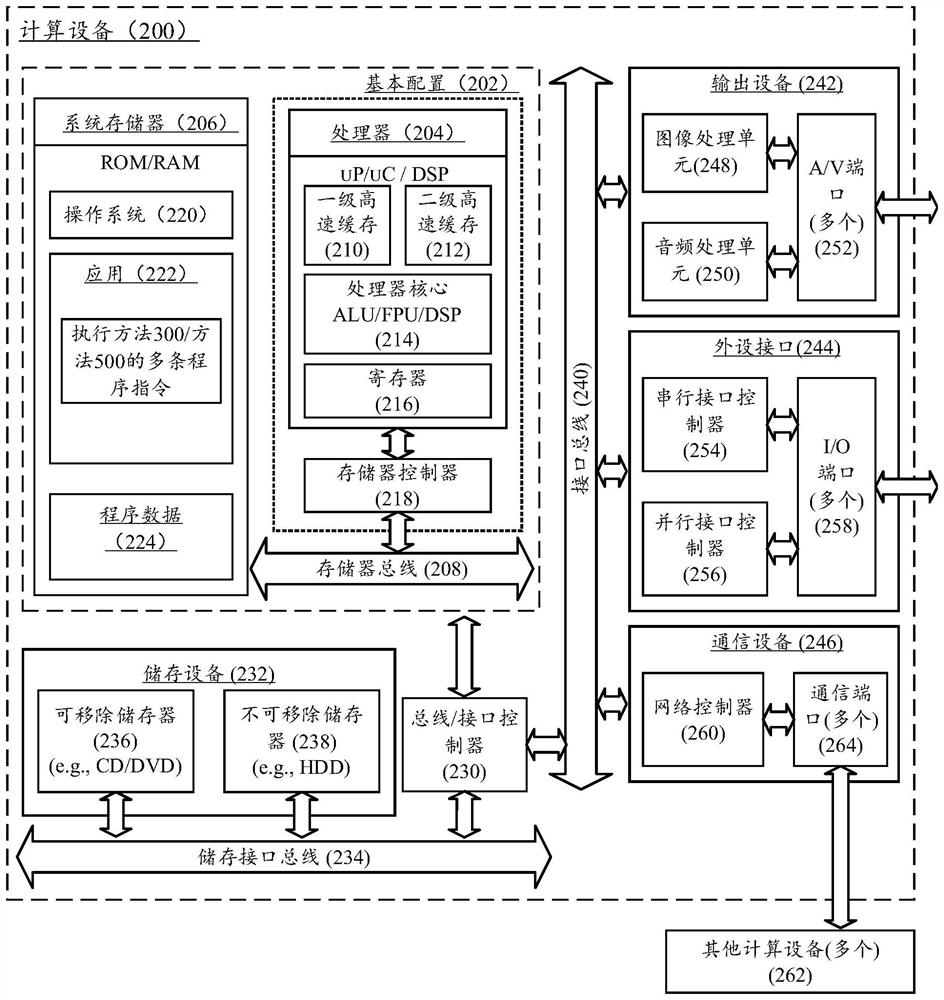

Data transmission method and device, computer readable medium and electronic equipment

ActiveCN109600388AFix high latencyEnsure transmission stabilityNetwork traffic/resource managementConnection managementPacket loss rateData transmission

The embodiment of the invention provides a data transmission method and device, a computer readable medium and electronic equipment. The data transmission method comprises the following steps: receiving a first data packet sent by first equipment through a plurality of data channels; analyzing the first data packet to obtain address information of the first equipment, and performing aggregation processing on the first data packet according to a data packet header of the first data packet to obtain a second data packet; replacing the source address information of the second data packet with specified address information to obtain a third data packet; and sending the third data packet to a second device. According to the technical scheme provided by the embodiment of the invention, the transmission stability of the data packet can be ensured by jointly transmitting the data packet through a plurality of data channels, the problems of high packet loss rate and high delay in the data transmission process are effectively solved, and meanwhile, the full-stack multi-channel data transmission process can be realized.

Owner:TENCENT TECH (SHENZHEN) CO LTD

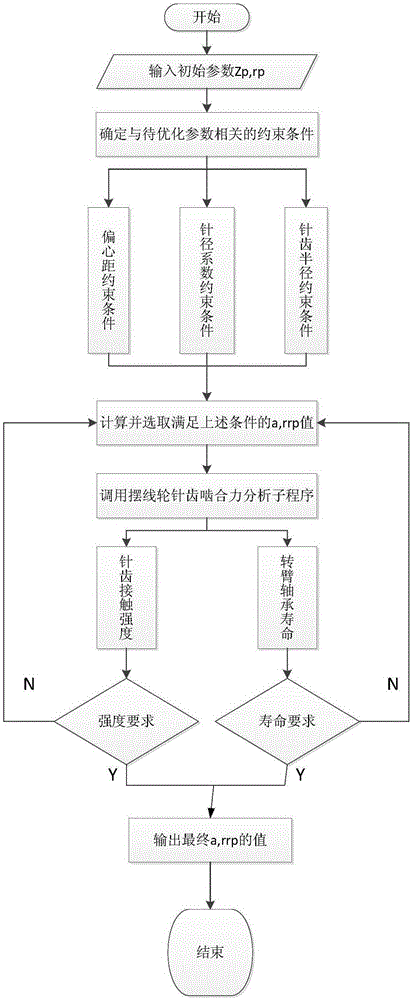

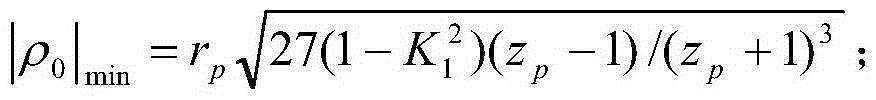

MATLAB based cycloid gear parameter optimization method

InactiveCN105404737AShorten calculation cycleGuarantee the rationality of the designGeometric CADSpecial data processing applicationsCarrying capacityTooth number

The invention discloses an MATLAB based cycloid gear parameter optimization method. The method comprises the following steps: step1. obtaining number ZP of needle teeth and needle teeth central circle radius rp; step2. according to restricting conditions, obtaining an eccentric distance and a needle gear sleeve outer circle radius rrp; step3. determining tooth number range and maximum engagement force involving in engagement simultaneously at the moment when the cycloid gear transmits; and step4. when needle teeth contact stress reaches strength requirement and rotary arm bearing life meets the requirement, outputting the eccentric distance a and the needle gear sleeve outer circle radius rrp, otherwise, executing step 2 until the requirement is met. According to the cycloid gear parameter optimization method, cycloidal gear parameter optimization is completed by analyzing basic principles of cycloid pin gear transmission and a design method of the cycloid gear. In the optimization, main parameters affecting cycloid gear transmission carrying capacity, the eccentic distance and the needle tooth radius rrp, are used as design variables, cycloid pin gear engagement strength and rotary arm bearing life are to-be-solved targets, and certain constraints are met.

Owner:天津市鑫达物业管理有限公司

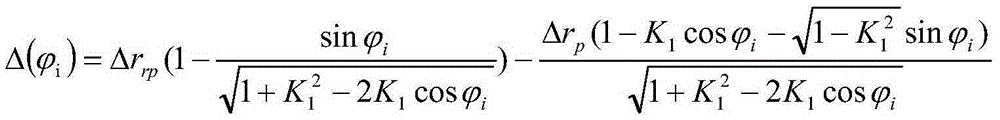

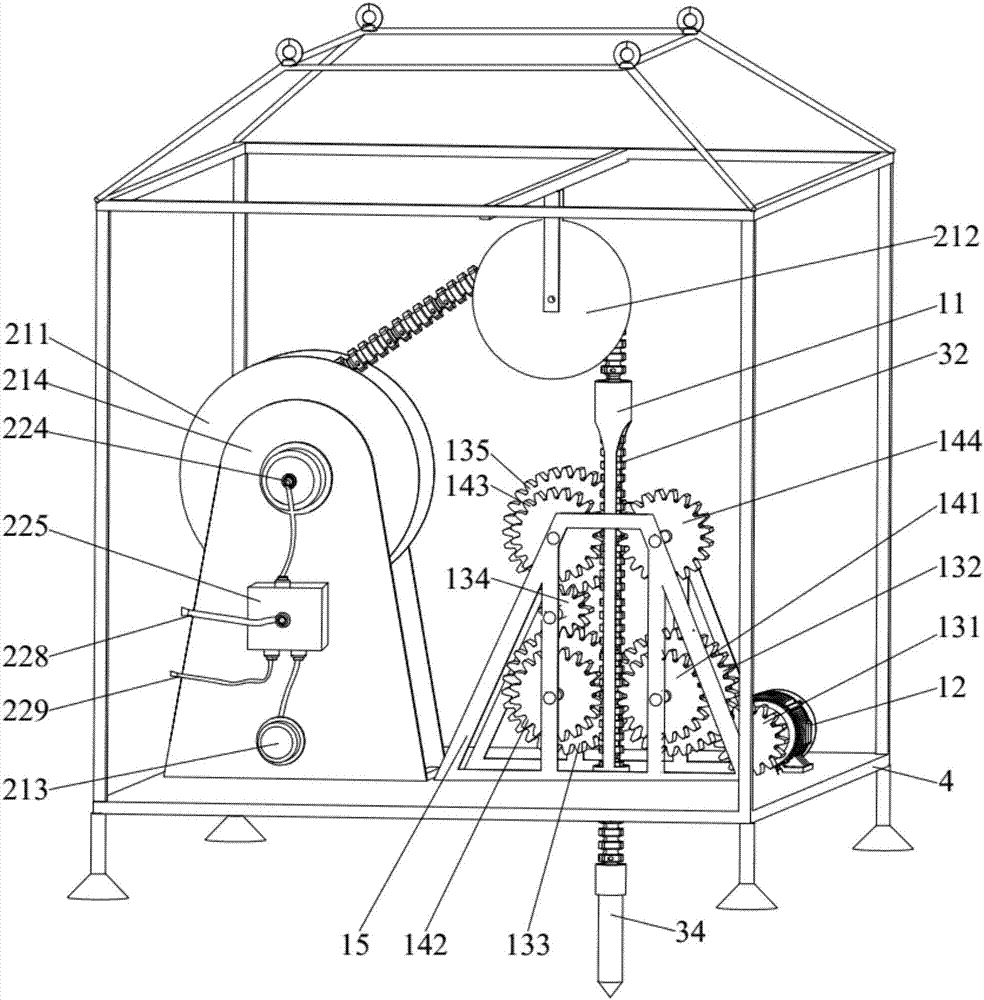

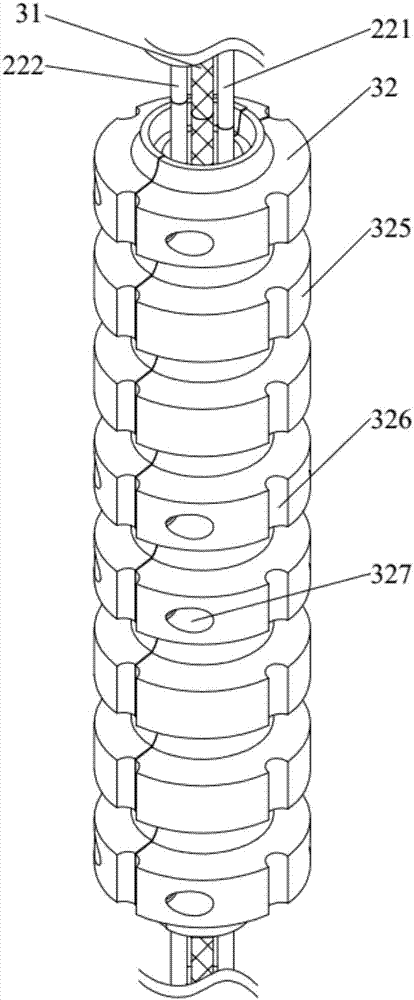

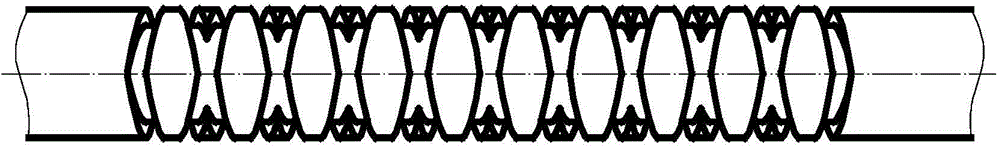

Seabed type static cone penetrating device and control method thereof

ActiveCN107476276AEasy to operateImprove stabilityIn situ soil foundationGear transmissionEngineering

The invention discloses a seabed type static cone penetrating device and a control method thereof. The seabed type static cone penetrating device comprises a penetrating mechanism, a winding mechanism and a flexible tooth-shaped post, wherein the penetrating mechanism comprises an aligning tube and a gear transmission mechanism; the winding mechanism comprises a winch and a guide plate; the flexible tooth-shaped post comprises a steel cable and a plurality of tooth-shaped post sections which are in sliding sleeve on the steel cable and are connected in series; one end of the flexible tooth-shaped post is in winding connection with a winch; the other end of the flexible tooth-shaped post gets across a guide disc and then passes through the aligning tube; adjacent tooth-shaped post sections positioned in the aligning tube are in splicing connection; the two sides of each tooth-shaped post section are engaged with the gear transmission mechanism; the flexible tooth-shaped post has a straight state and a bent state, is convenient to operate, and is high in stability; the tooth-shaped post sections are connected in series automatically, and are not additionally connected, so that seabed static penetration under a deep-layer condition is conveniently realized; and through a dual-engagement structure that the gear transmission mechanism is engaged with the two sides of each tooth-shaped post section, collimation degree and pressure needed for penetrating are guaranteed.

Owner:OCEAN UNIV OF CHINA

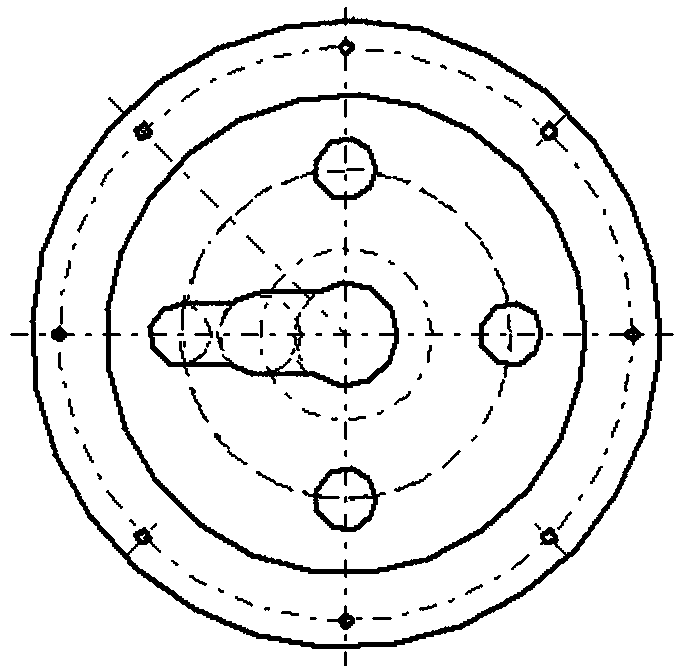

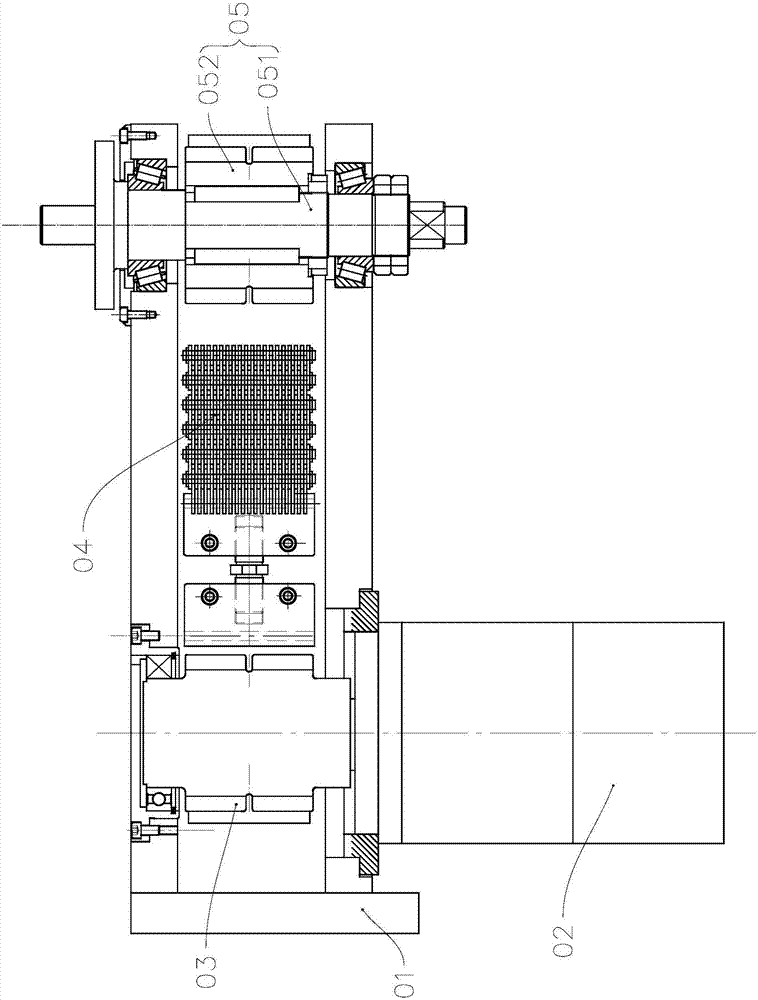

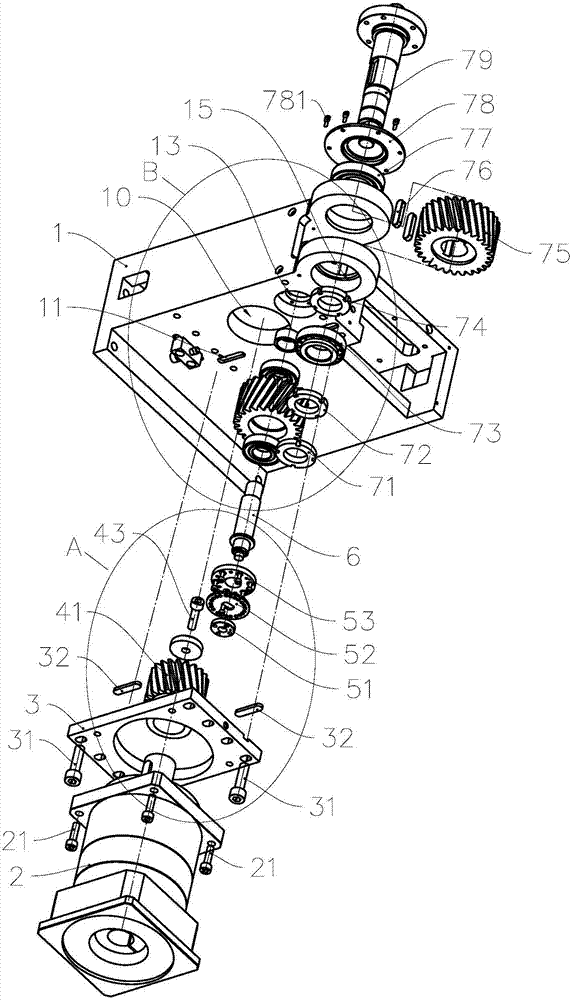

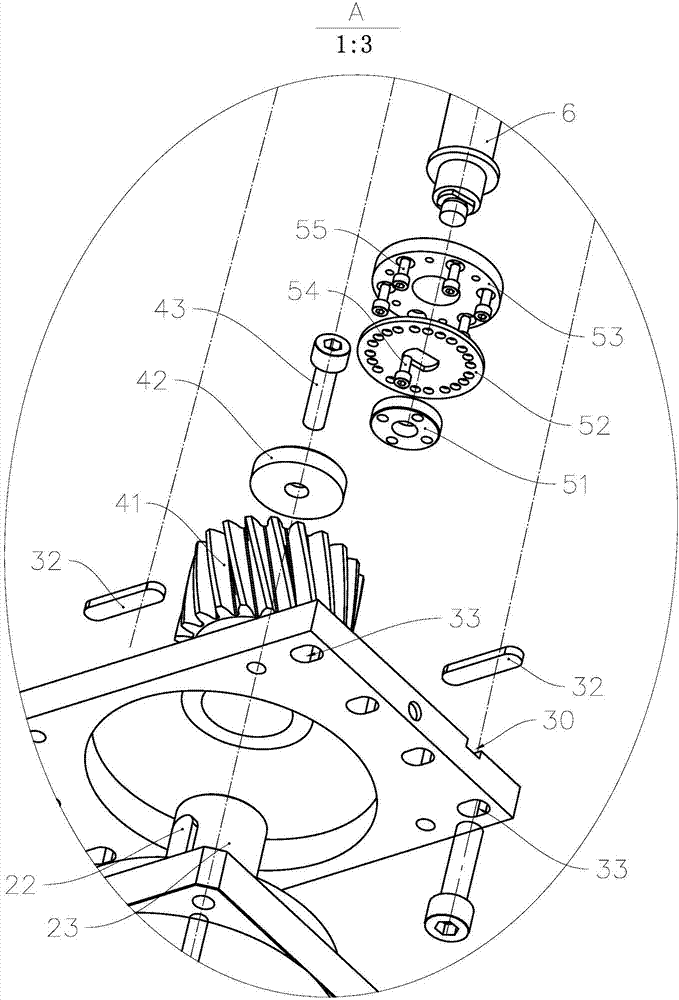

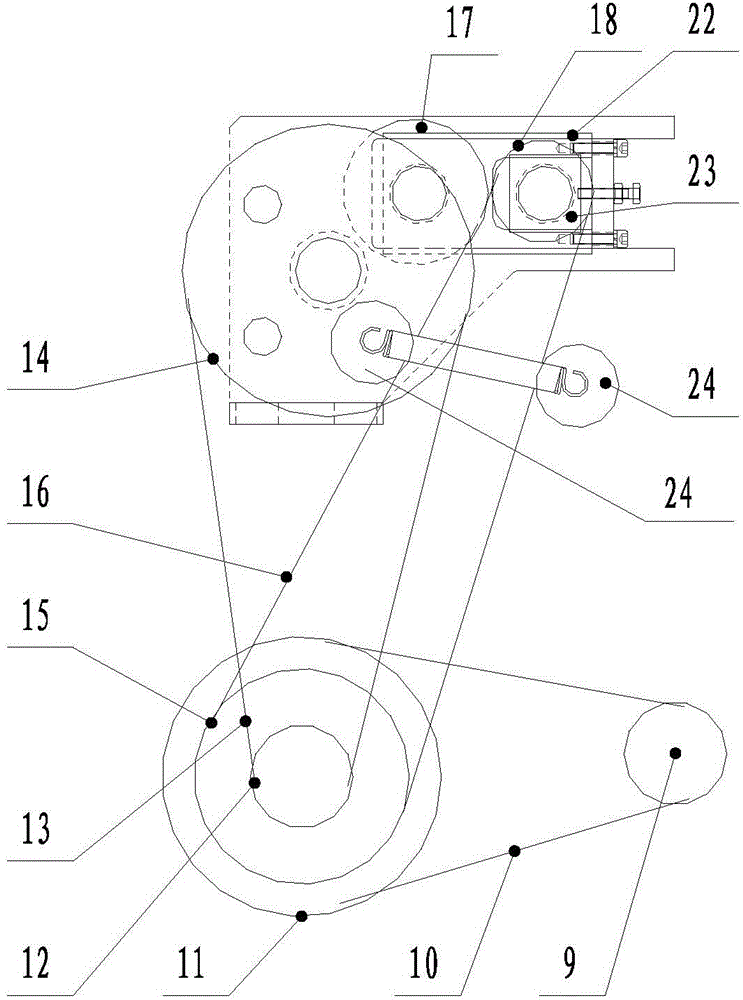

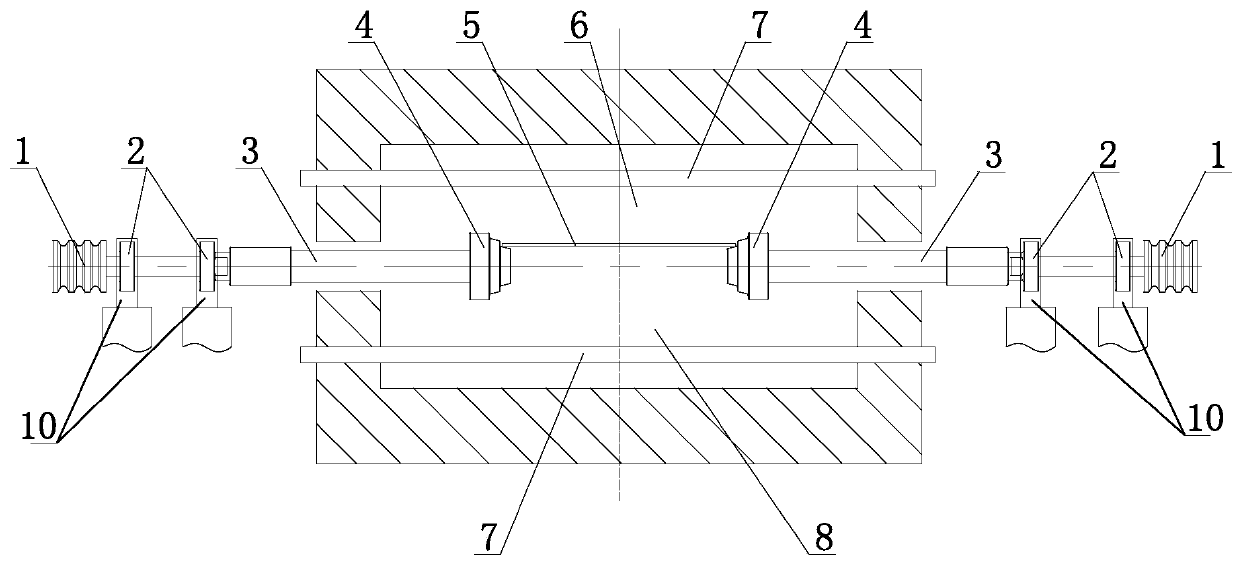

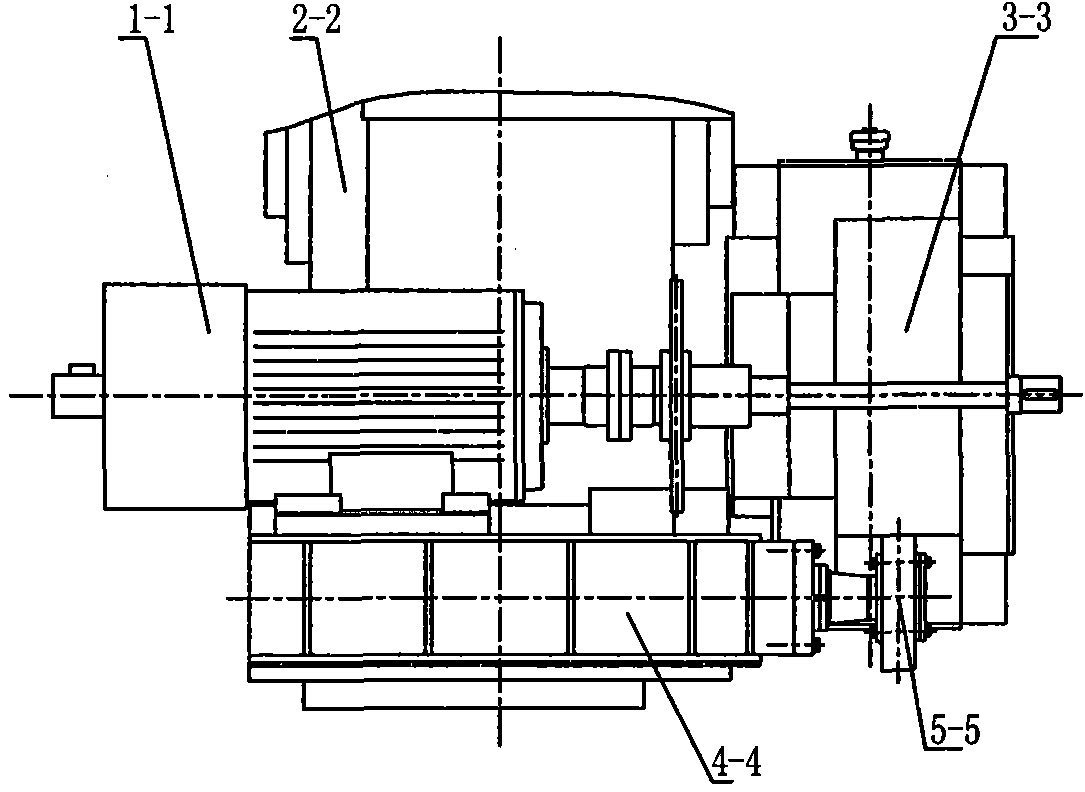

Pipe bending machine and gear transmission device thereof

The invention relates to a pipe bending machine and a gear transmission device thereof, and belongs to the technical field of pipe machining treatment. The gear transmission device comprises a rack and an output unit, a transitional unit, an input unit and a clearance adjustment mechanism which are mounted on the rack, wherein the output unit comprises an output gear; the input unit comprises an input gear; the transitional unit comprises a transitional gear simultaneously meshing with the output gear and the input gear; the clearance adjustment mechanism comprises a first clearance adjustment mechanism for adjusting a side clearance between the transitional gear and the output gear and a second clearance adjustment mechanism for adjusting a side clearance between the input gear and the transitional gear; the first clearance adjustment mechanism comprises an eccentric shaft and an adjustment and locking mechanism for adjusting a rotating angle of the eccentric shaft and locking the position of the rotating angle of the eccentric shaft; and the transitional gear is arranged on the eccentric shaft in a rotatable sleeving manner. The pipe bending machine consisting of the gear transmission device is high in product manufacturing precision and stability, and the gear transmission device can be widely applied to equipment such as the pipe bending machine.

Owner:浙江和良智能装备有限公司

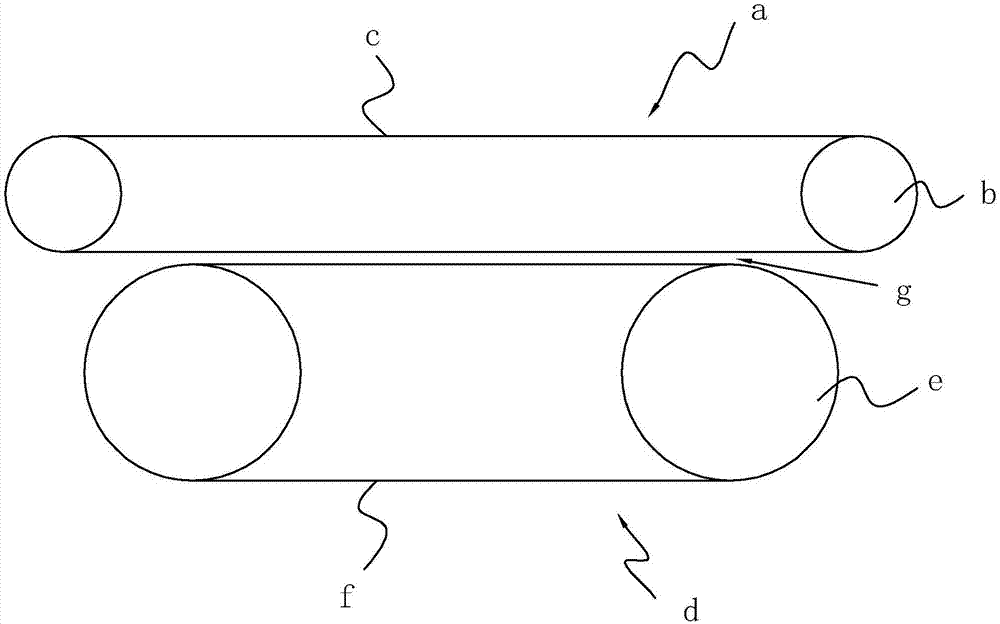

Wool scouring device used for cloth material

InactiveCN105586735APrevent slippingEnsure transmission stabilityTextile treatment machine arrangementsTextile treatment by spraying/projectingWater circulationWool

The invention discloses a wool scouring device used for cloth material. The wool scouring device comprises a cloth-feeding device, a cleaning device, a traction padder and a cloth-falling device. The cleaning device comprises a cuboid cleaning water tank, left and right side walls of which are provided with cloth-feeding gaps. Upper and lower sides of each cloth-feeding gap are provided with middle rollers. Upper and lower layers of cloth guide rollers are arranged in the cleaning water tank. Cloth guide rollers at the upper layer and cloth guide rollers at the lower layer are arranged at intervals. Front and back side walls of the cleaning water tank are provided with multiple water sprayers capable of swinging up and down. The water sprayers are located in the middle between the upper and lower layers of cloth guide rollers. Water sprayers on the front wall of the cleaning water tank and water sprayers on the back wall of the cleaning water tank are arranged at intervals. A detachable filtering net is arranged in the cleaning water tank and disposed below the cloth-guide rollers. The bottom surface of the cleaning water tank is an oblique plane, the lowest position of which is provided with a water outlet. The water outlet is communicated with a water supply pipe of the water sprayers via a water pipe. The wool scouring device used for cloth material is high in cleaning efficiency and used for water circulation.

Owner:WUXI HONGFEN MACHINERY FACTORY

Double-layer clean-type warping machine

ActiveCN106283323AReasonable transmissionAvoid wastingWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention discloses a double-layer clean-type warping machine. The double-layer clean-type warping machine comprises a frame, a partition plate is arranged in the middle of the frame horizontally and partitions the frame into an upper layer and a lower layer, and a passage is formed on one side of the partition plate. A bottom plate is arranged at the bottom of the lower layer, a yarn unwinding component is arranged on the upper layer, a first rotating roller is arranged on one side of the yarn unwinding component, a yarn collecting beam is arranged on one side of the first rotating roller, and a tensioning component is arranged on one side of the yarn collecting beam and in the passage. A first dividing frame is arranged on the lower layer and disposed below the tensioning component, a second dividing frame, a yarn guide component and a third dividing frame are arranged on one side of the first dividing frame, a warping component is arranged on one side of the third dividing frame, the bottom plate is provided with a plurality of rectangular grooves in which negative pressure blowers are disposed, and a plurality of square pipes correspondingly connected with the rectangular grooves are arranged at the bottom of the bottom plate in the frame and are disposed in a collecting box arranged at the bottom of the frame.

Owner:吴江市晓月昱喷织厂

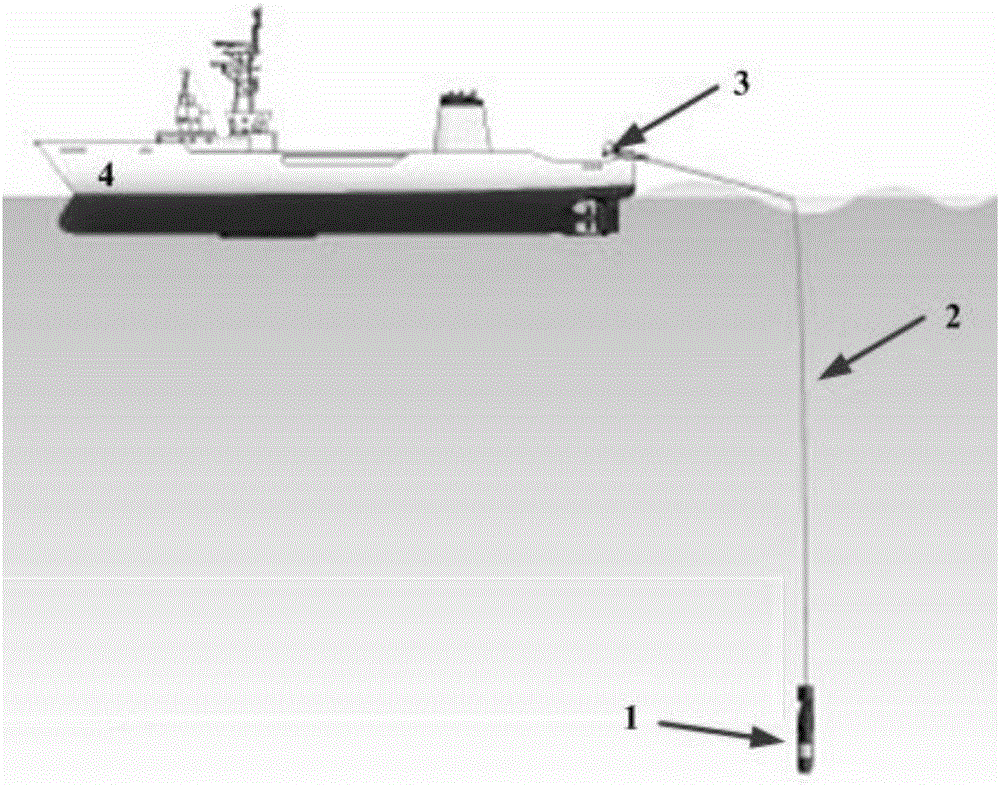

Shipborne expendable optical-fiber bathythermograph

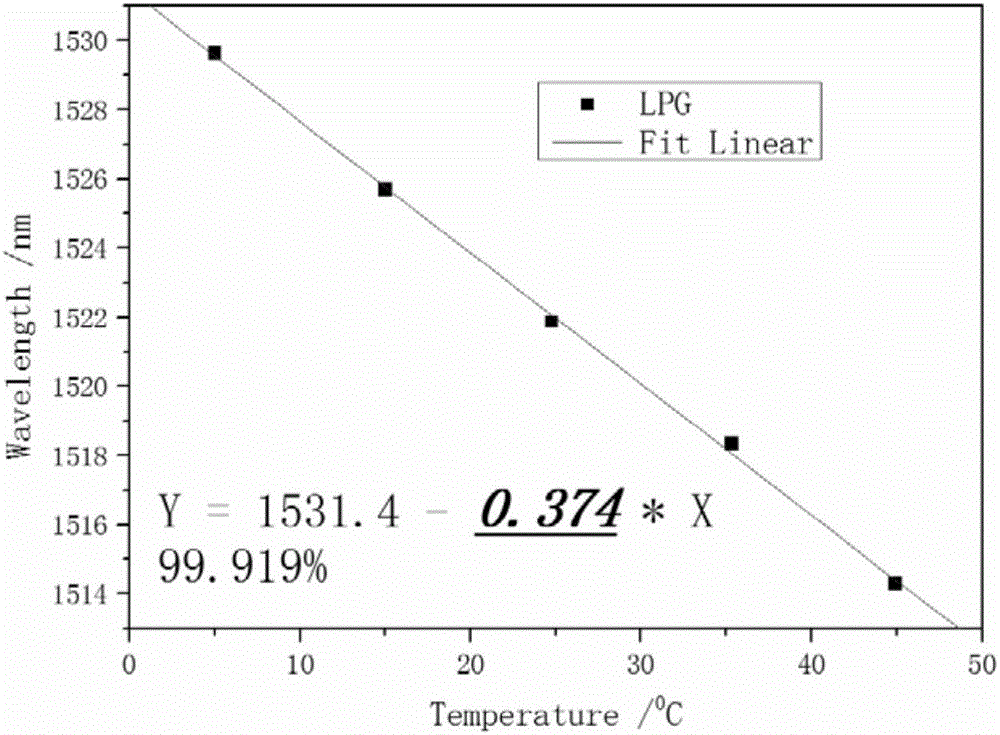

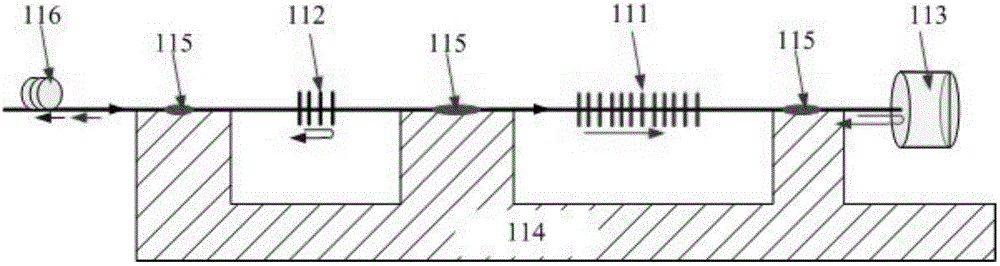

PendingCN106768478AImprove temperature measurement accuracyAccurate measurementThermometers using physical/chemical changesMachines/enginesOptical pathSeawater

A shipborne expendable optical-fiber bathythermograph comprises an all optical fiber probe, transmission optical fibers and a deck unit, wherein the probe measures the seawater temperature through LPG (long period fiber gratings) and measures the seawater depth through FBG (fiber bragg gratings), and seawater temperature and depth profiles are measured independently at high sensitivity; the deck unit comprises a broadband light source, a dynamic fiber grating fast and high-precision demodulation module, an optical fiber isolator, a first optical fiber coupler, a second optical fiber coupler, an upper fiber shaft and a telescopic support mounted on the board of the stem of a working ship. The thermograph solves the problems of cross sensitivity and sensitization of a sensor, the sensitivity of temperature and depth measurement is improved, errors caused by enameled wire channels are overcome, the signal transmission rate and the stability are guaranteed, single light path cascade of FBG and LPG is realized, a light path structure is optimized, the spectral region is allocated reasonably, temperature and depth synchronous detection is realized, the thermograph is simple to manufacture, the probe is low in cost, and a new technical means is provided for detection of the seawater temperature and depth profiles.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

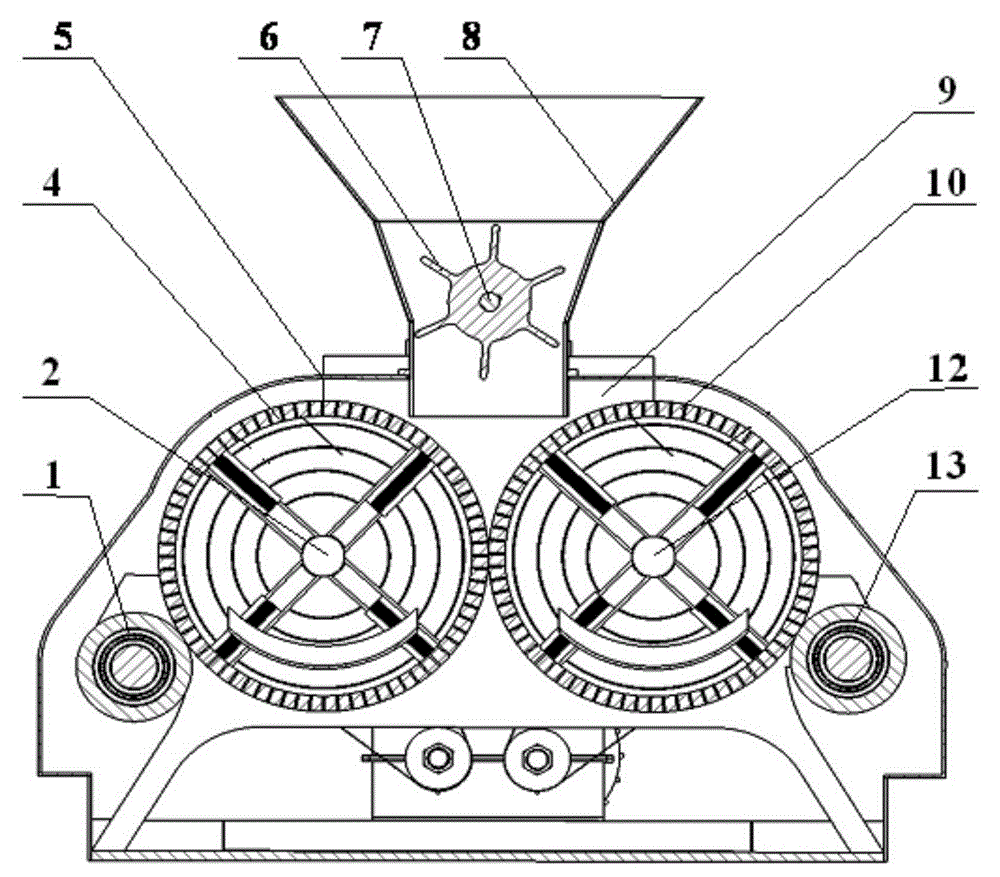

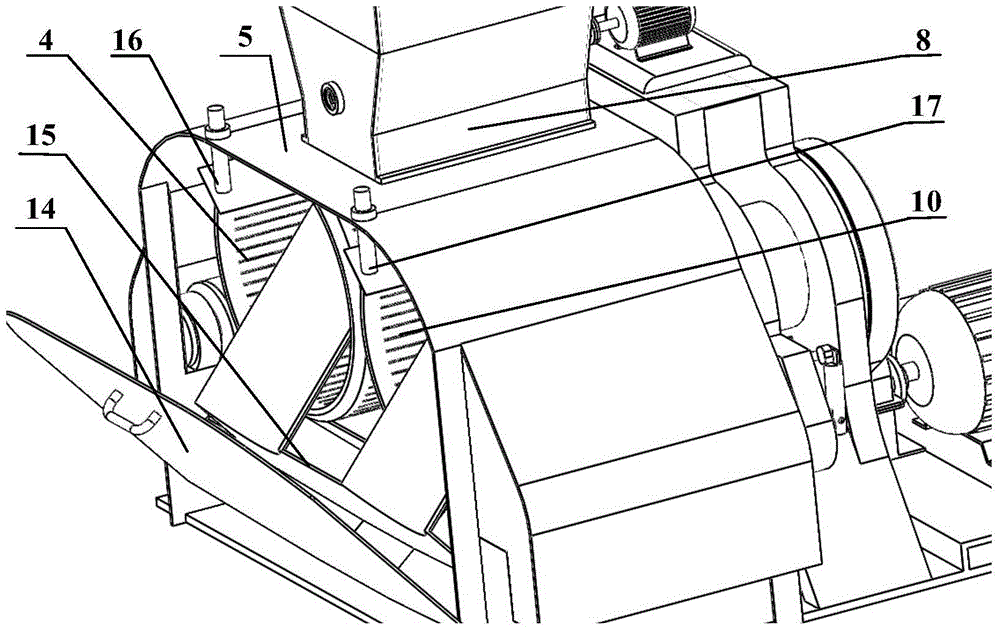

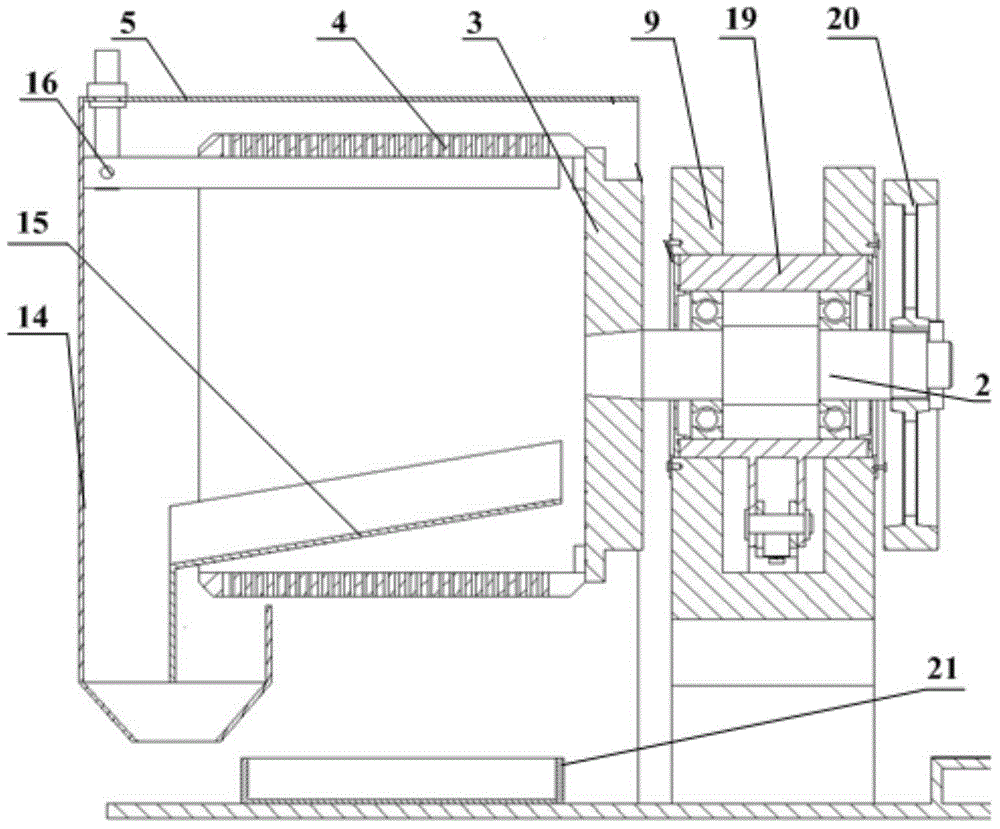

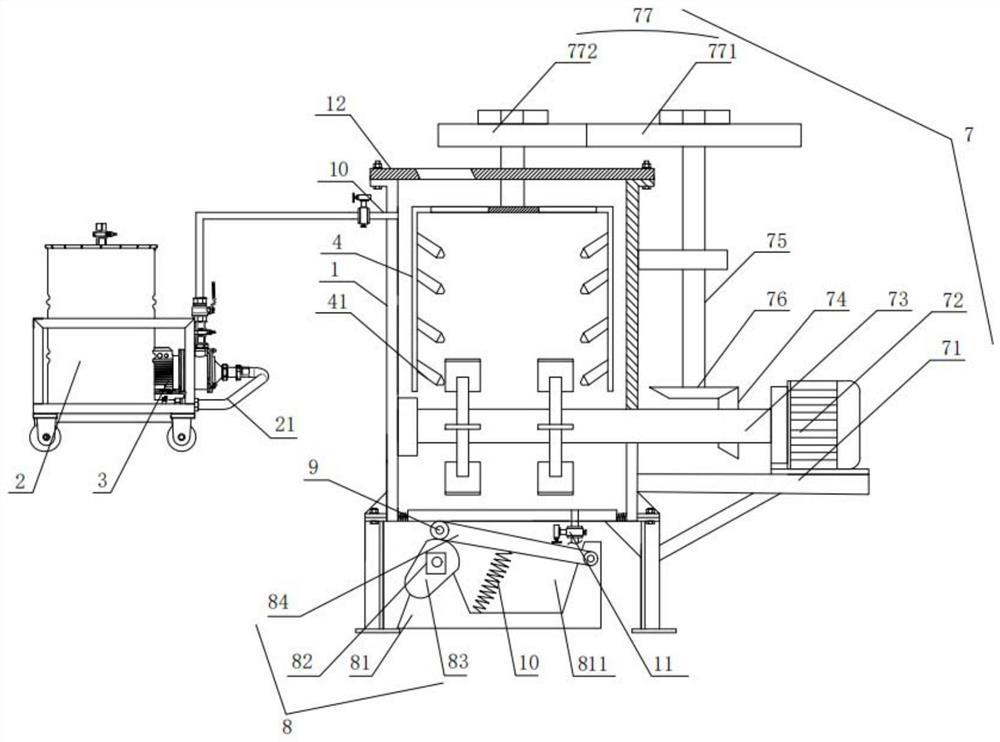

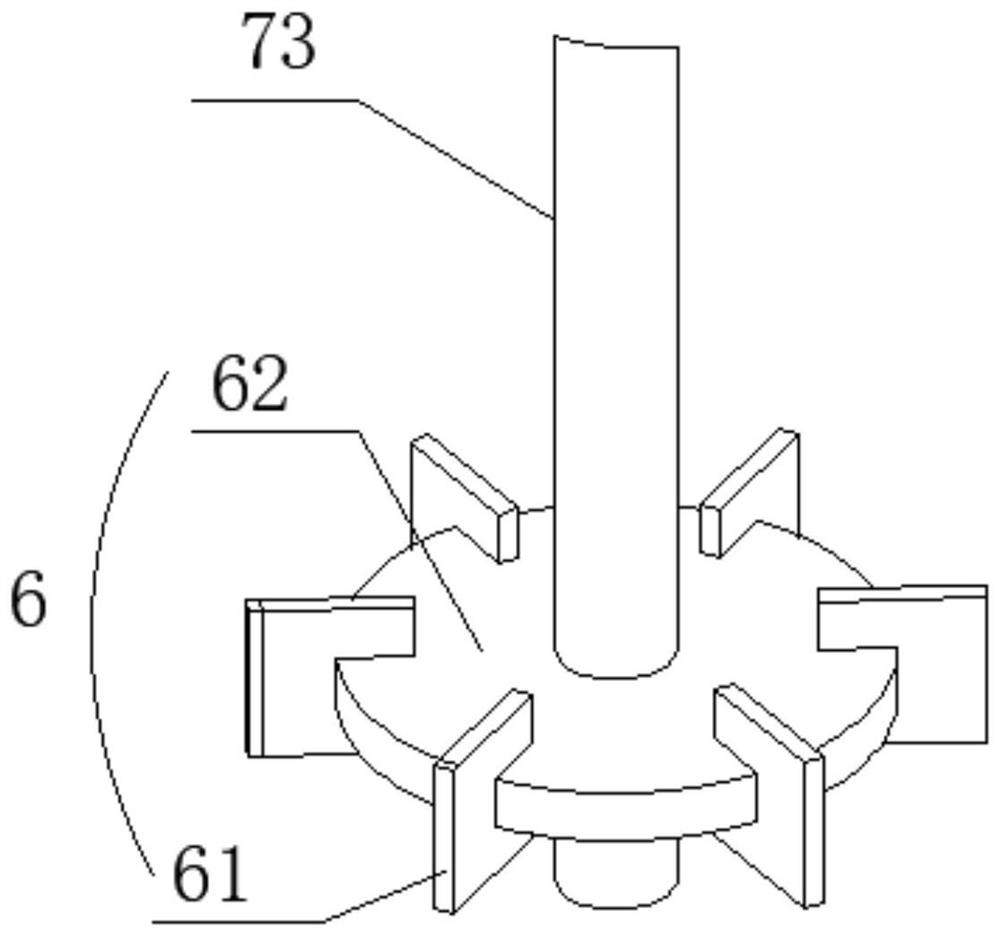

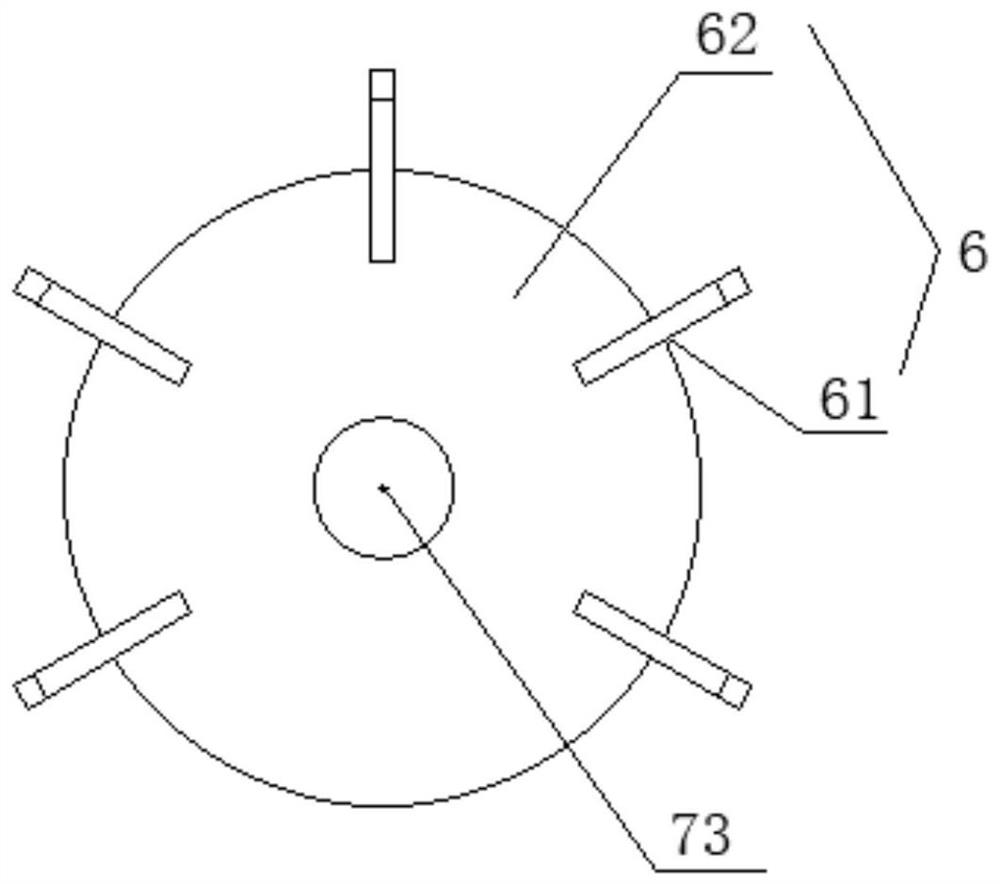

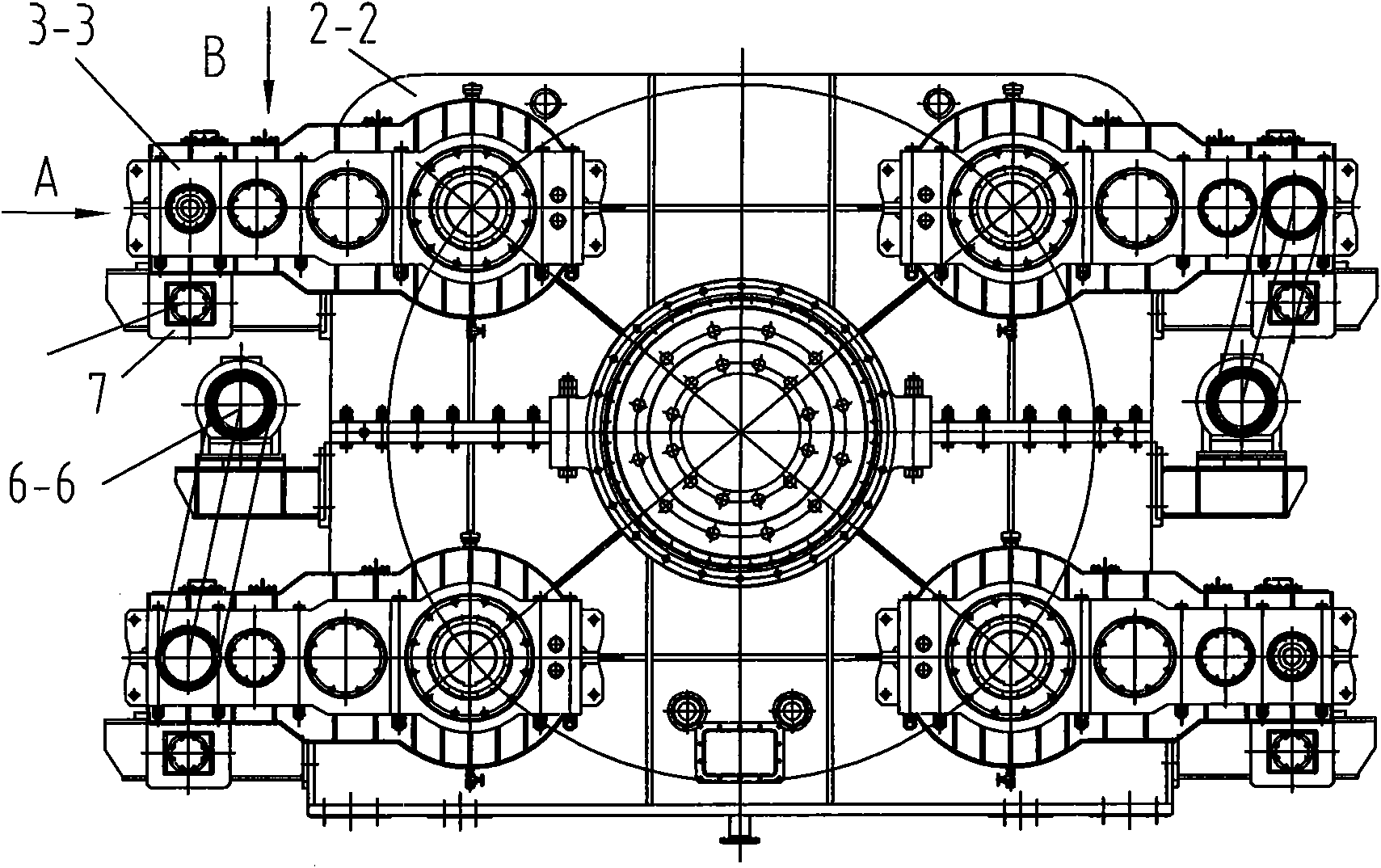

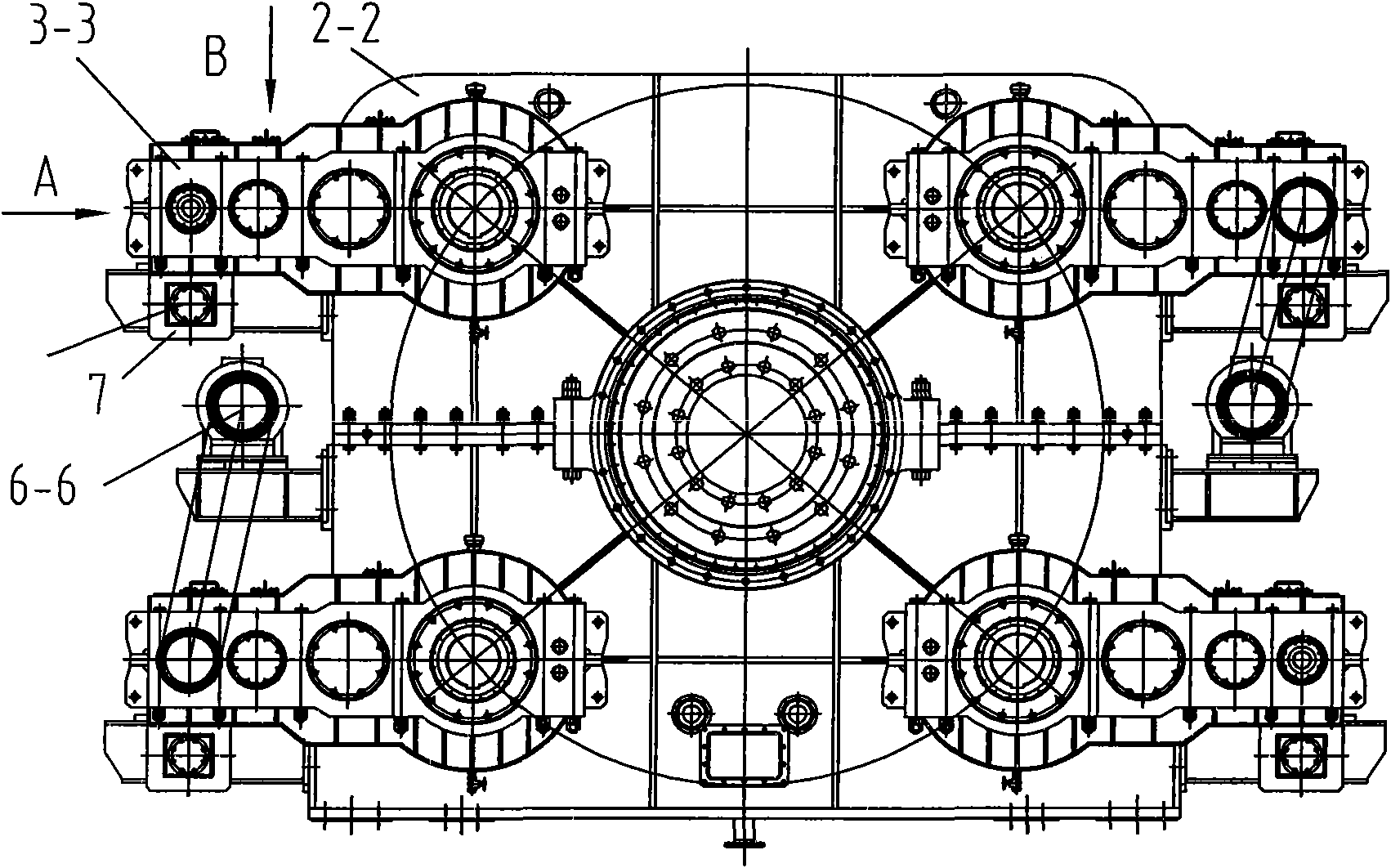

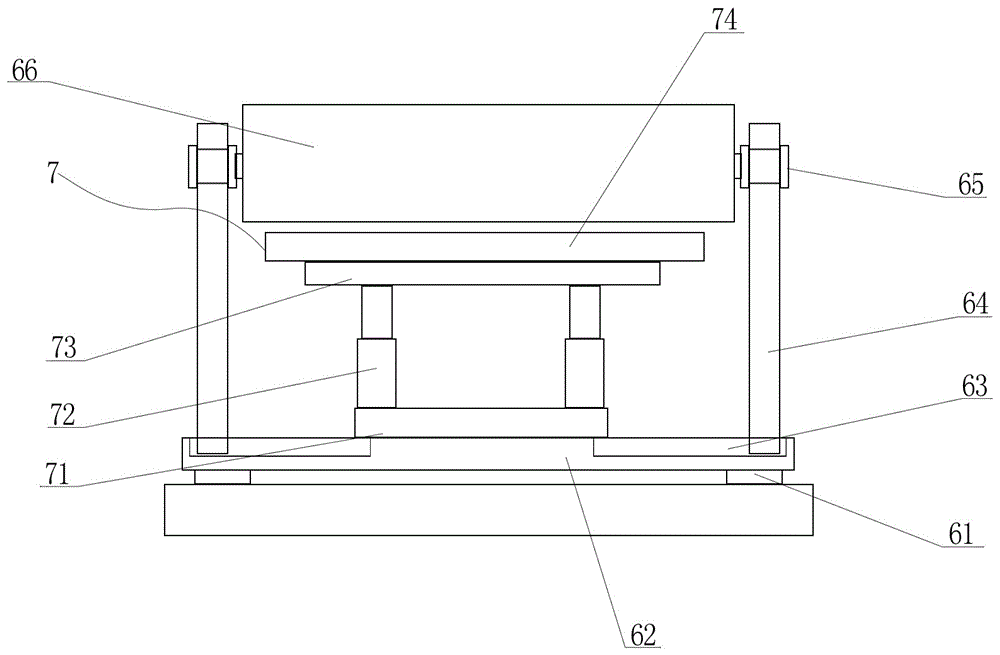

Double supporting rollers-type double circular molds granulator

InactiveCN105013397AEasy to disassemble and replaceImprove support stiffnessGranulation by pressingImpellerReducer

The invention discloses a double supporting rollers-type double circular molds granulator, which comprises a first supporting roller, a first rotating shaft, a first circular mold, a casing, an impeller, an impeller shaft, a hopper, a support, a second circular mold, a second rotating shaft, a second supporting roller, a door cover, a material collecting trough, a first scraper, a second scraper, a first bearing sleeve, a first belt wheel, a residual material groove, a gear reducer, a main motor, a second belt wheel, a second bearing sleeve, a first synchronous belt, a third belt wheel, a first compaction wheel, a second compaction wheel, a fourth belt wheel, a second synchronous belt, and an impeller motor. The double circular molds granulator has the advantages that dismounting and replacing of the circular molds are convenient and fast, the supporting rollers support the circular molds, support rigidity of the circular molds can be greatly increased, the granulator can be used for extruding the difficultly-extruded materials, width of the circular molds can be increased greatly, granulation efficiency is greatly increased; the scraper is employed for cooperating the material collecting trough for collecting the material, the material collecting trough is arranged on the door cover, when the door cover is opened, a cutter on the scraper is dismounted so that the circular molds can be rapidly replaced.

Owner:NANJING UNIV OF SCI & TECH

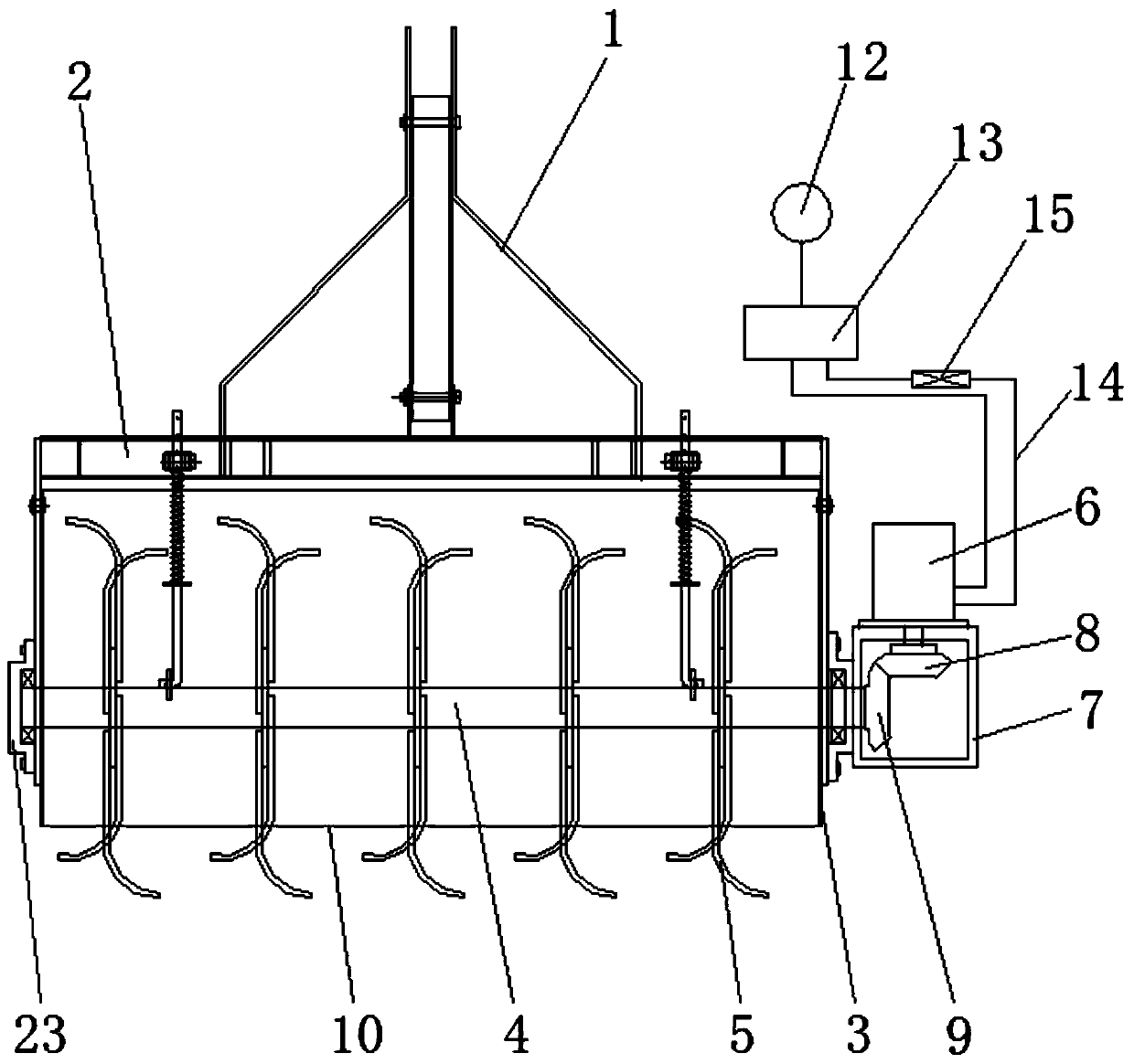

Hydraulic-driven rotary cultivator

InactiveCN110178459ACompact structureEasy to useTilling equipmentsHydraulic motorAgricultural engineering

The invention discloses a hydraulic-driven rotary cultivator. The rotary cultivator comprises a connecting frame, a cover plate, two side plates, a plurality of rotary tillage cutter shafts and a rotary tillage blade, and further comprises a hydraulic motor, a gearbox body, a first bevel gear, a second bevel gear and a hydraulic driving system. The first bevel gear is connected with the output endof the hydraulic motor, the second bevel gear is connected with one end of each rotary tillage cutter shaft, and the first bevel gear is meshed with the second bevel gear; the two bevel gears are installed in the gearbox body, and the gearbox body is arranged on the side plate at one ends of the rotary tillage cutter shafts; the hydraulic motor is fixedly arranged on the outer wall of the gearboxbody, and the hydraulic driving system is connected with a hydraulic oil way of the hydraulic motor. According to the hydraulic-driven rotary cultivator, the hydraulic driving system is adopted to drive a rotary cultivator rotating shaft to rotate to do work, the transmission efficiency is effectively improved, the transmission stability of the rotary cultivator is ensured, and the rotary cultivator has the advantages of being convenient to assemble and disassemble and convenient to operate and adjust.

Owner:HUBEI FUYI AGRI MACHINERY MFG

Pneumatic winch capable of automatically tensioning and arranging ropes

InactiveCN104310257APrevent tangled ropePrevent loose ring phenomenonWinding mechanismsEngineeringWinch

The invention relates to a pneumatic winch capable of automatically tensioning and arranging ropes. The pneumatic winch comprises a rope arranging mechanism, a transmission mechanism and a steel wire rope tensioning mechanism, wherein the rope arranging mechanism comprises a guide rod, a screw rod, a rope arranging seat, a slider, a pressure spring, a spring pressing cover, a pull pin and a sliding sleeve; the transmission mechanism is connected with the screw rod; the steel wire rope tensioning mechanism is connected with the rope arranging mechanism. According to the pneumatic winch capable of automatically tensioning and arranging ropes disclosed by the invention, the steel wire rope is winched without disordering and loosening, and the steel wire rope is maintained at a tensioning state no matter when the rope is wound or unwound. The steel wire rope is guided by a rope arranging and clutch device to be uniformly wound along a roller without rope pressing and jumping, and the rope can also separated from the device; the power of the rope arranging mechanism is from the pneumatic winch, and the speed of the rope arranging mechanism is matched with the speed of the pneumatic winch, so that the transmission stability is ensured.

Owner:YANTAI GASOLINEEUM MACHINERY

Cleaning device for electronic semiconductor machining

InactiveCN112893302AAchieve full coverage cleaningImplementation locationSemiconductor/solid-state device manufacturingCleaning using toolsResonant cavitySemiconductor materials

The invention discloses a cleaning device for electronic semiconductor machining. The cleaning device comprises a megasonic cleaning shell, wherein an elastic vibration plate which vibrates periodically is arranged at the bottom of the megasonic cleaning shell; the elastic vibration plate movably covers the bottom of the megasonic cleaning shell; a megasonic resonant cavity transducer is arranged on the outer side of the megasonic cleaning shell; the cleaning device further comprises a cleaning liquid storage device, an electromagnetic pulse vibrator, a cleaning pipeline assembly, a driving part and a vibration assembly, and periodic vibration is generated on the elastic vibration plate; the electromagnetic pulse vibrator and the megasonic resonant cavity transducer are matched to realize high-efficiency cleaning of an electronic semiconductor; and the semiconductor material is flushed more cleanly and cleaned more thoroughly, and the cleaning efficiency and effect are improved.

Owner:江西龙芯微科技有限公司

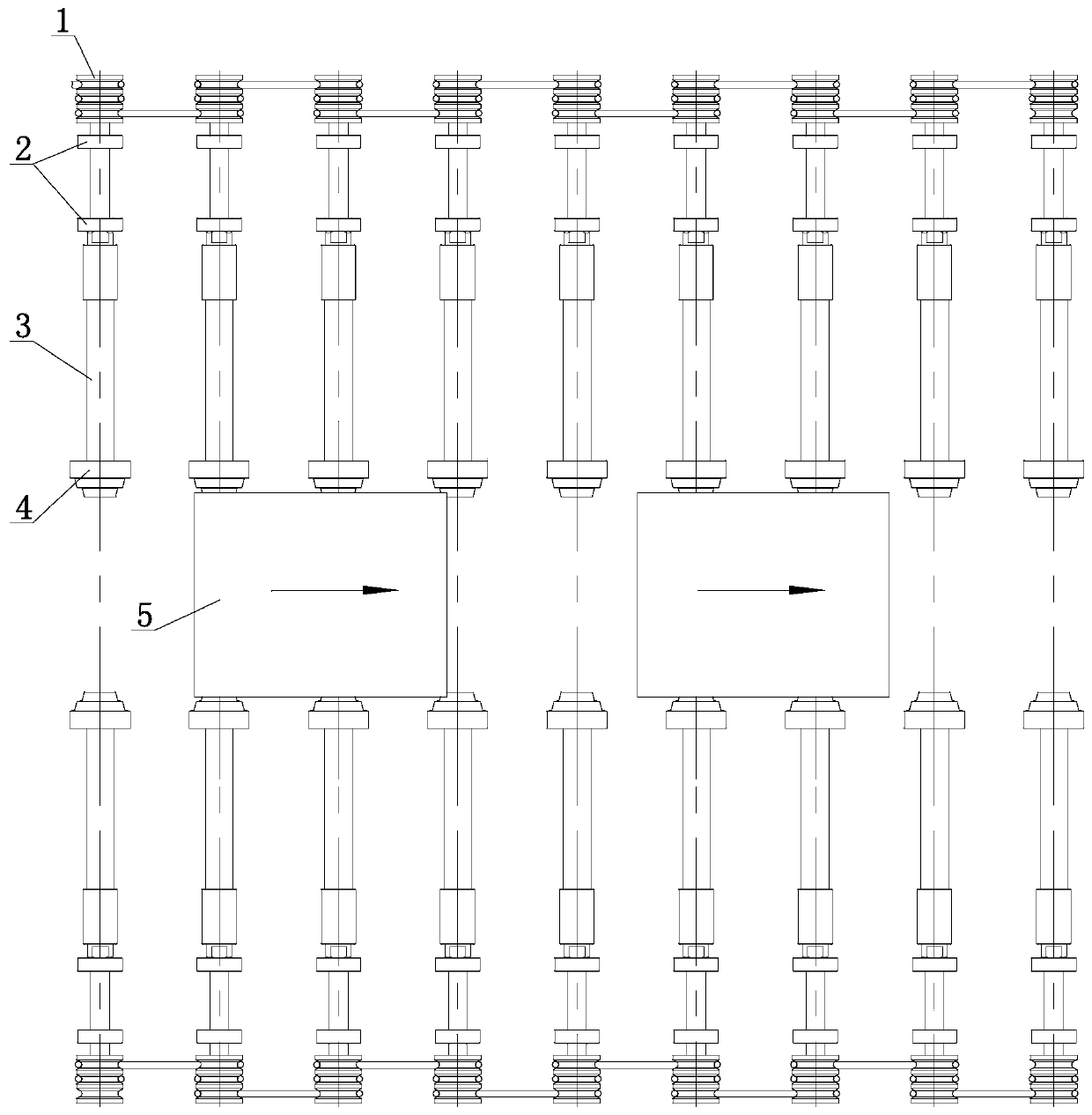

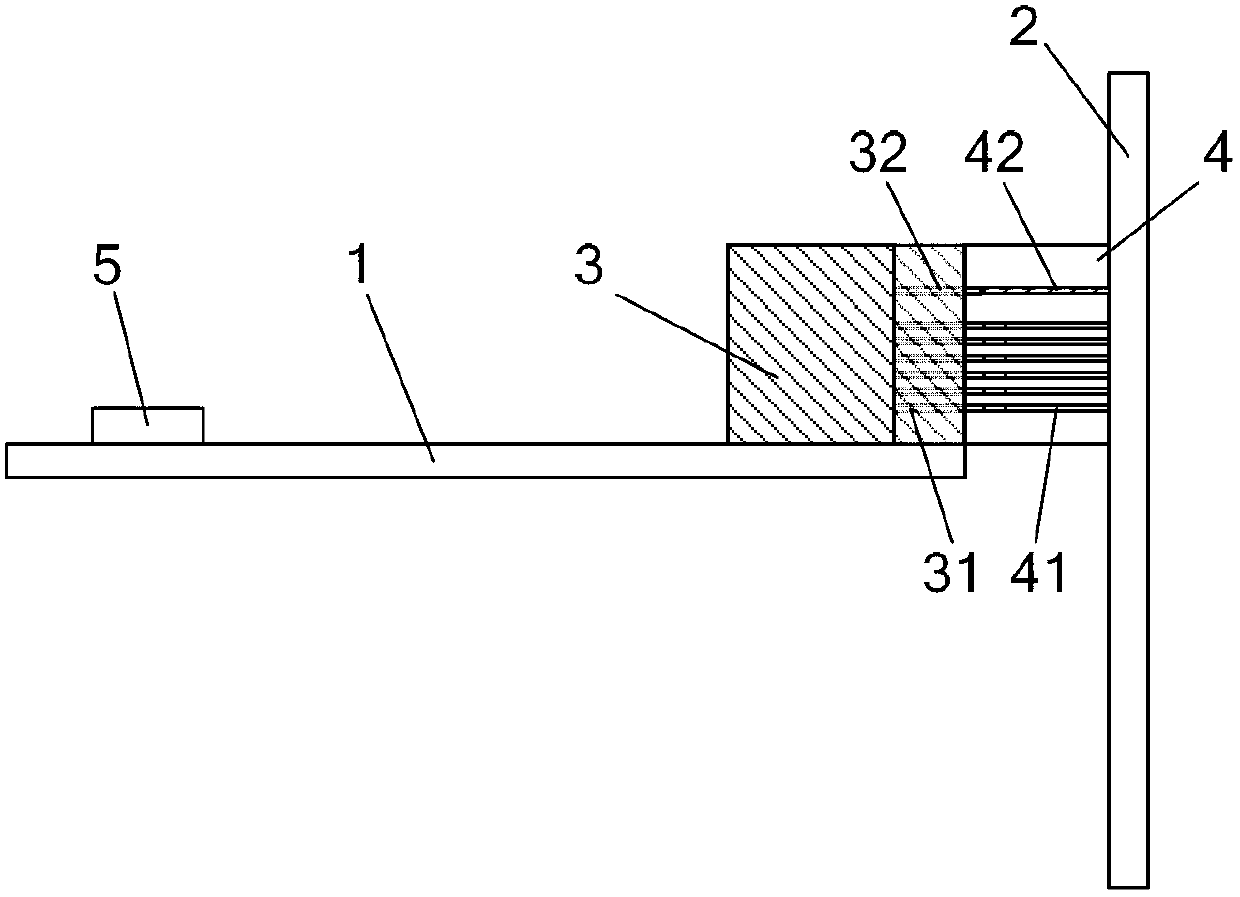

Novel roller way transmission structure of solar cell roller way furnace

PendingCN111383978AReasonable designEliminate occlusionFinal product manufactureSemiconductor/solid-state device manufacturingElectrical batteryMechanical engineering

The invention belongs to the technical field of photovoltaic solar cells, and particularly relates to a novel roller way transmission structure of a solar cell roller way furnace. A plurality of roller ways are arranged in a furnace body, the roller ways are arranged on two sides of the furnace body, a gap is arranged between the roller ways on two sides, and the size of the gap is matched with the size of a battery piece. The novel roller way transmission structure of the solar cell roller way furnace is reasonable in design, eliminates the shielding effect of an original roller way on radiation of a heating lamp tube or an LED light source from the lower portion, improves the sintering or irradiation effect of the back face of a cell piece, eliminates the sintering or irradiation difference of the front face and the back face, and therefore, the product quality is integrally improved. Furthermore, when the battery pieces incline or are broken in the conveying process, the battery pieces can fall into the lower hearth from the intervals in time, and rear-end collision or lamination accidents of the battery pieces are prevented.

Owner:BEIJING SOLARRAY TECHNOIOGY CO LTD +2

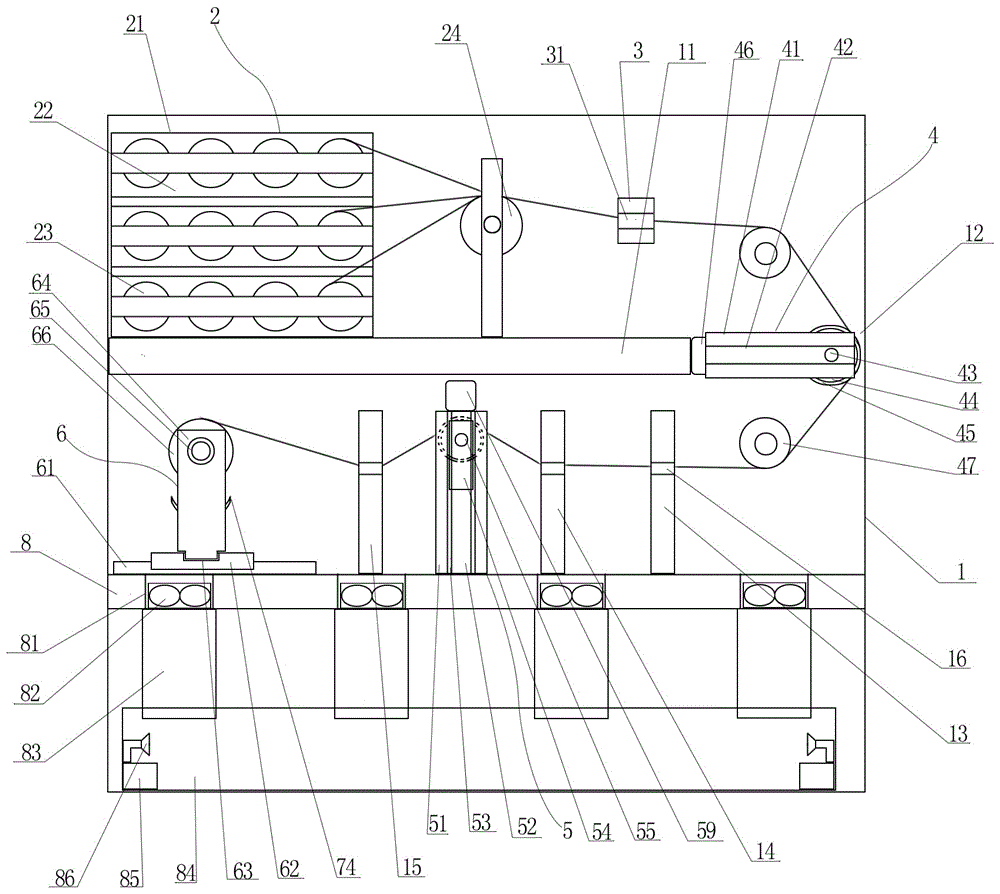

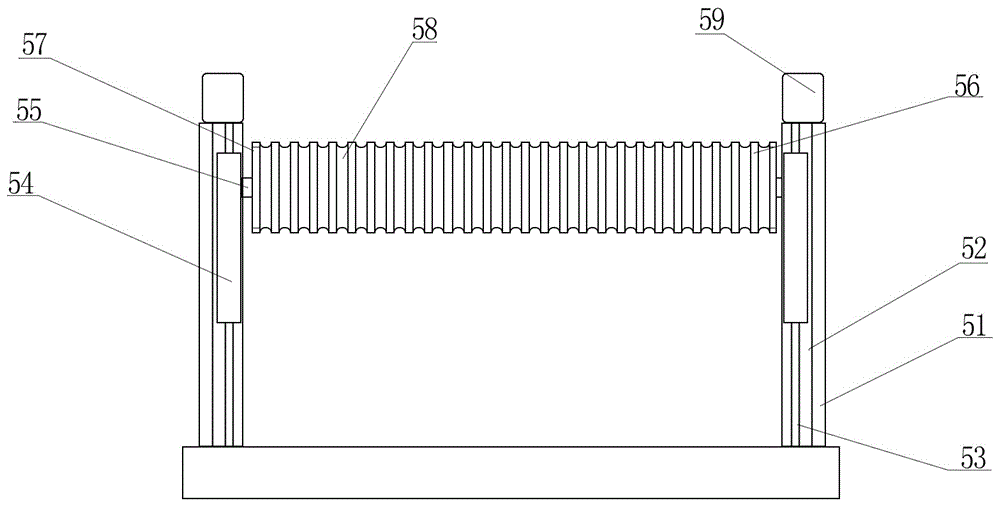

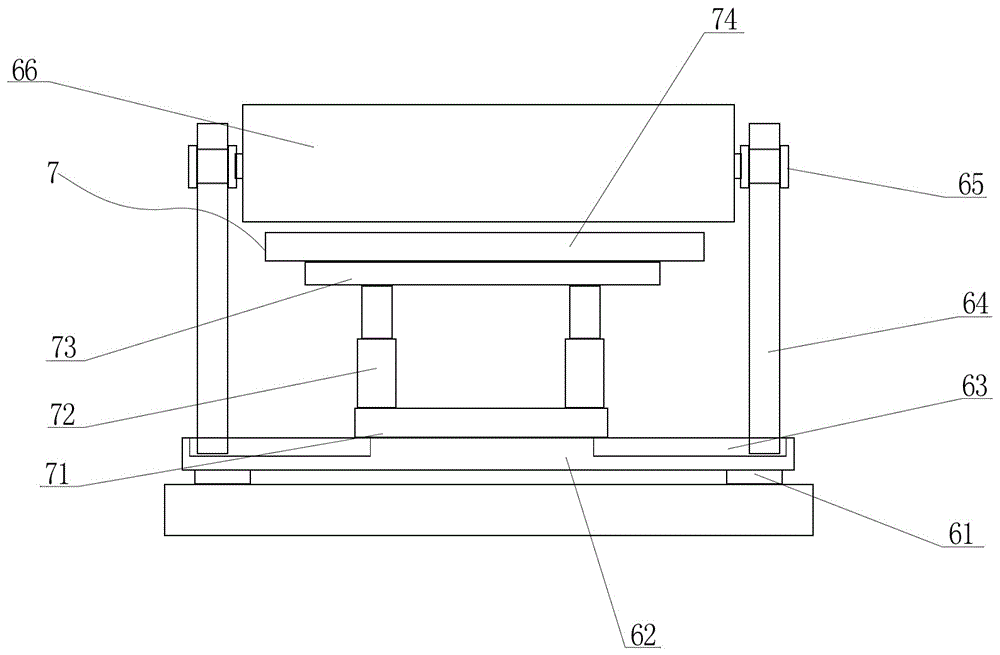

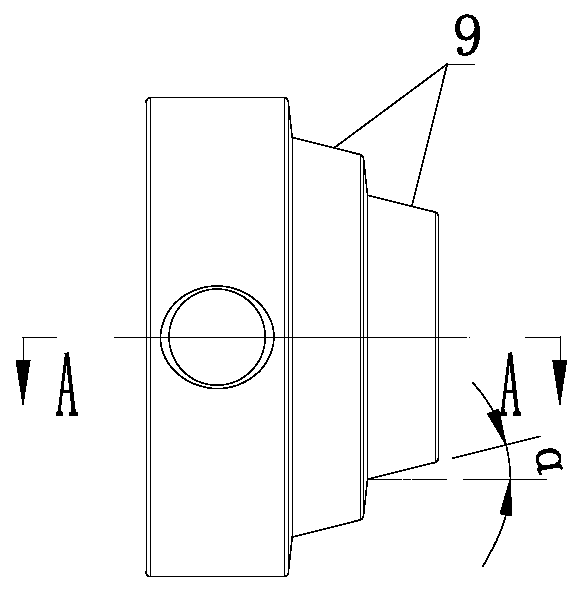

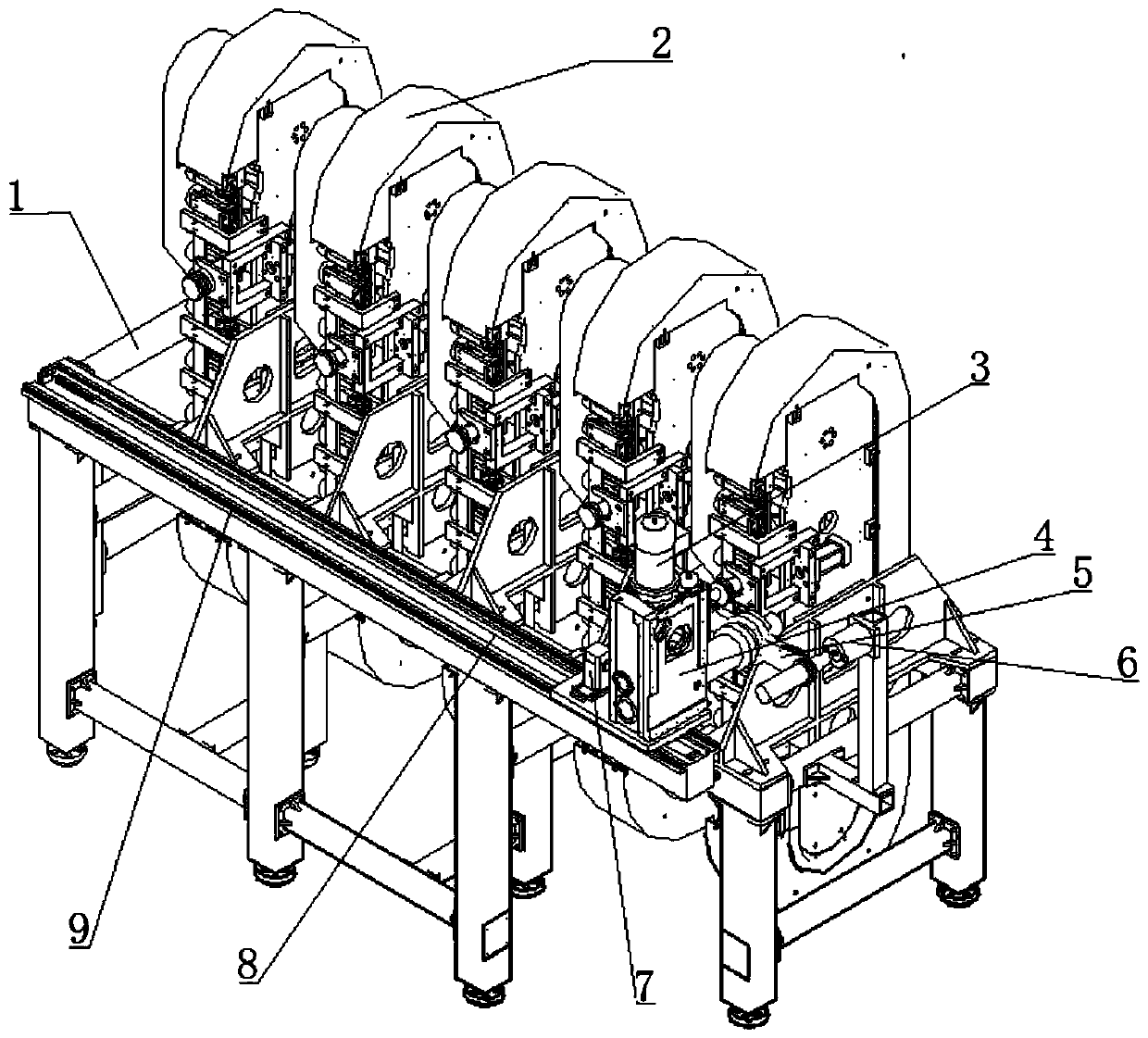

Paper overturning machine and paper feeding mechanism thereof

ActiveCN107879151AGuaranteed transmission efficiencyEnsure transmission stabilityOverturning articlesArticle feedersControl engineeringElectric machinery

The invention discloses a paper overturning machine and a paper feeding mechanism thereof. According to the main technical scheme, the paper feeding mechanism comprises a feeding rack, a feeding mainconveying component and a feeding subsidiary conveying component; the feeding main conveying component comprises two or more feeding rollers, feeding conveying belts and a feeding driving motor, wherein the feeding rollers are rotatably connected to the feeding rack, the feeding conveying belts are mounted among the feeding rollers, and the feeding driving motor is used for driving the feeding rollers to rotate; the feeding subsidiary conveying component comprises two or more compression rollers and compression conveying belts, wherein the compression rollers are rotatably connected to the feeding rack, and the compression conveying belts are mounted among the compression rollers; a feeding gap is formed between each compression conveying belt and the corresponding feeding conveying belt,wherein each feeding gap allows paper to enter therein. The two ends of each feeding gap are a paper inlet end and a paper outlet end correspondingly. The paper feeding mechanism further comprises a paper compression portion, wherein the paper compression portion is located at the side of the paper inlet ends and comprises paper compression wheels, wherein the paper compression wheels are mountedon the feeding rack and used for tightly pressing the paper to the feeding conveying belts. By means of the paper feeding mechanism, the to-be-overturned paper can be stably conveyed into the paper overturning mechanism; and conveying efficiency and conveying stability are fully guaranteed.

Owner:浙江星锋智能设备有限公司

Semiconductor material cleaning device

InactiveCN112435918AImprove stabilityImprove securitySemiconductor/solid-state device manufacturingCleaning using toolsSemiconductor materialsLiquid storage tank

The invention discloses a semiconductor material cleaning device, which comprises: a cleaning box capable of hierarchically cleaning a semiconductor material in the height direction, a vibrating plateis arranged at the bottom of the cleaning box, and the vibrating plate is elastically arranged at the bottom of the cleaning box; a liquid storage tank which is used for storing cleaning liquid, wherein the cleaning liquid is pumped into the cleaning tank through a pump body, so that the semiconductor material is flushed by layers in a circumferential array manner; a circulating material stirringbarrel which is in a thin-plate cylindrical shape, the top and the bottom of the circulating material stirring barrel are open, wherein a plurality of material stirring rods are arranged on the circumferential inner side wall of the circulating material stirring barrel; cleaning pipeline assemblies which are distributed on the inner side wall of the cleaning box in an annular array mode; a cleaning roller assembly which is located at the bottom of the cleaning box and conducts rolling cleaning on the semiconductor material; a driving part which can simultaneously control the circulating material stirring barrel body and the cleaning roller assembly to synchronously rotate; and a vibration assembly which generates periodic vibration on the vibration plate, wherein overturning and positionreplacement of the semiconductor material are realized by matching with a material stirring rod, and therefore, the semiconductor material can be flushed more cleanly and cleaned more thoroughly, andthe cleaning efficiency and effect are improved.

Owner:江西舜源电子科技有限公司

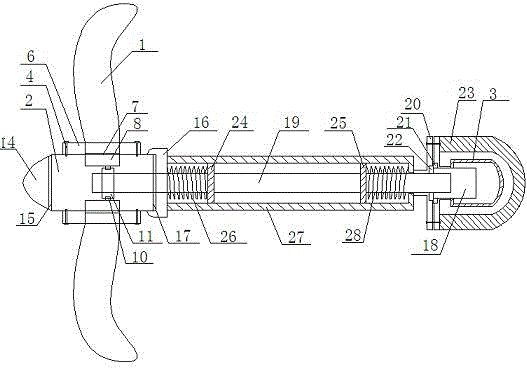

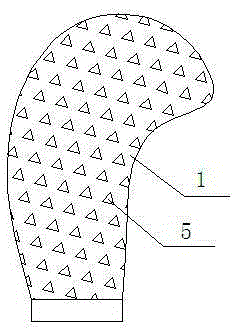

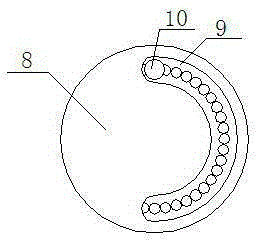

Propeller propelling plant with controllable pitch

InactiveCN105416546AAchieve propulsionPlay a shock absorbing roleRotary propellersBall bearingCoupling

The invention relates to a propeller propelling plant with the controllable pitch. The propeller propelling plant comprises main propelling blades, a propeller hub, an oil cylinder and bolts. Paddle flanges are arranged outside the main propelling blades; the propeller hub is provided with a self-aligning ball bearing disc which is provided with a rotating groove; an eccentric pin is arranged in the rotating groove, and a deflection plate is arranged in the propeller hub. A piston rod is arranged in the oil cylinder; a push-pull rod is arranged in the piston rod; a coupling is arranged outside the piston rod and the push-pull rod. A first damping disc and a second damping disc are arranged on the outer wall of the push-pull rod; a first spring is arranged between the first damping disc and a protecting cover, and a second spring is arranged between the second damping disc and one end of a push-pull rod sleeve. The propeller propelling plant with the controllable pitch is good in damping effect, high in transmission efficiency, and conductive to prolonging the service life and improving the stability.

Owner:ZHENJIANG TONGZHOU PROPELLER

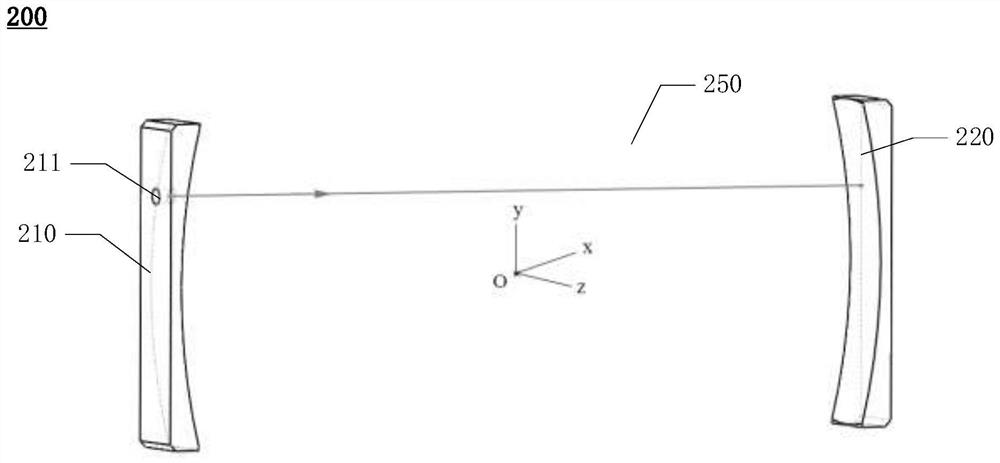

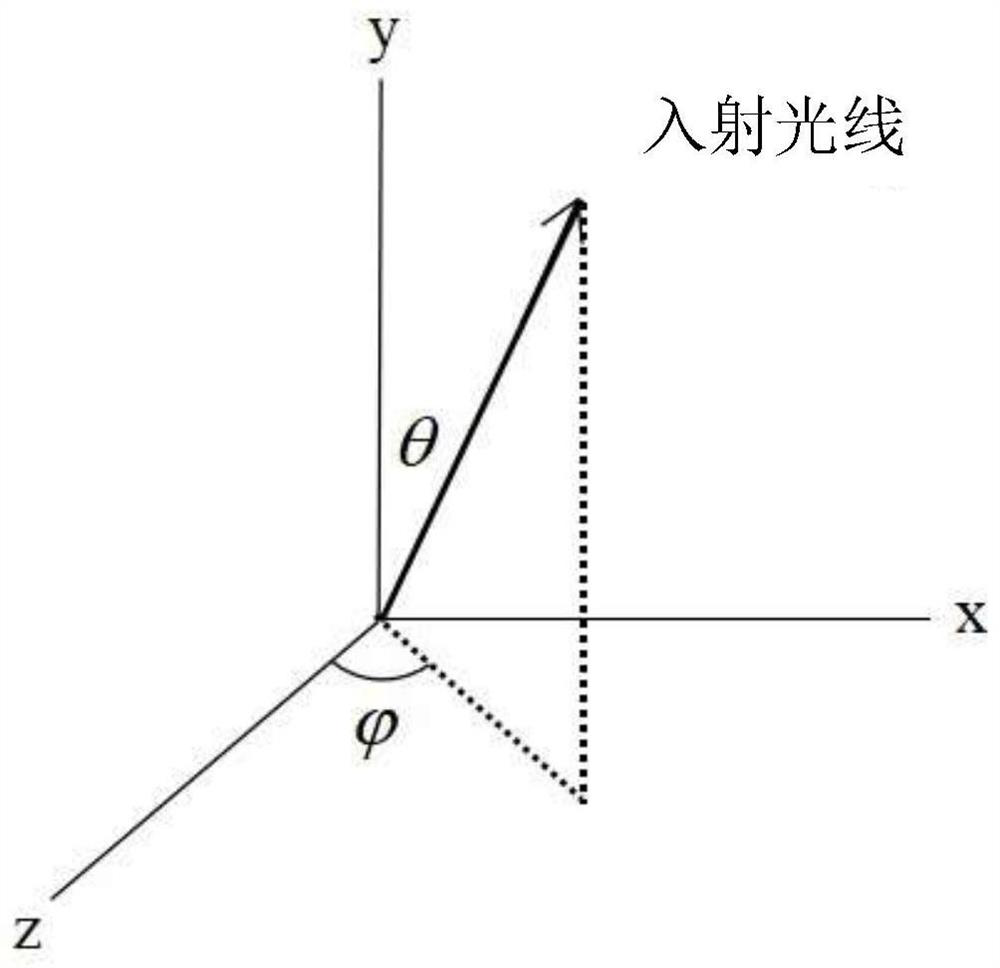

Method for determining formation of linear light spots in multi-reflection gas chamber, method for determining test of multiple gases in multi-reflection gas chamber and multi-reflection gas chamber

ActiveCN111735784AEasy to carrySmall and compactColor/spectral properties measurementsAngle of incidenceLight spot

The invention discloses a method for determining formation of a linear light spot in a multi-reflection air chamber. The method comprises the steps: setting a relative distance range of a first reflector and a second reflector, and constructing a relative distance array based on a preset distance interval; for each relative distance value in the relative distance array, setting light to be incident at a preset initial incident point coordinate and a preset initial incident angle, and setting the incident light to pass through the central symmetry axis of the two reflecting mirrors, so that a plurality of light spots formed on the reflecting mirrors form a linear light spot pattern, and determining the path of the light in the multi-reflection air chamber according to an optical model; selecting a path of which the reflection frequency is within a preset reflection frequency range and the light spot spacing is within a preset light spot spacing range in the linear light spot pattern asa first candidate path, and obtaining a corresponding first linear light spot pattern; and generating a candidate path set and a candidate linear spot pattern set. In addition, the invention also discloses a method for determining the test of various gases in the multi-reaction gas chamber and the multi-reaction gas chamber.

Owner:BEIJING NORMAL UNIVERSITY

Communication plugboard and communication device

InactiveCN103346893AGuaranteed transmission qualityEnsure transmission stabilityData switching detailsEngineeringTransmission quality

The invention, which belongs to the communication technology field, discloses a communication plugboard and a communication device, so that whether a connector is plugged firmly can be detected accurately and thus a transmission quality and stability of a high-speed signal are ensured. The communication plugboard comprises a plugboard connector and a firm plugging detection apparatus. Specifically, the plugboard connector being plugged with an opposite connector includes a plugboard signal pin and a plugboard detection pin; a sum of the length of the plugboard detection pin and a length of an opposite detection pin of the opposite connector is less than a sum of the length of the plugboard signal pin and a length of an opposite signal pin of the opposite connector. And the firm plugging detection apparatus that is connected with the plugboard detection pin is used for detecting whether the plugboard detection pin is contacted with the opposite detection pin.

Owner:HUAWEI TECH CO LTD

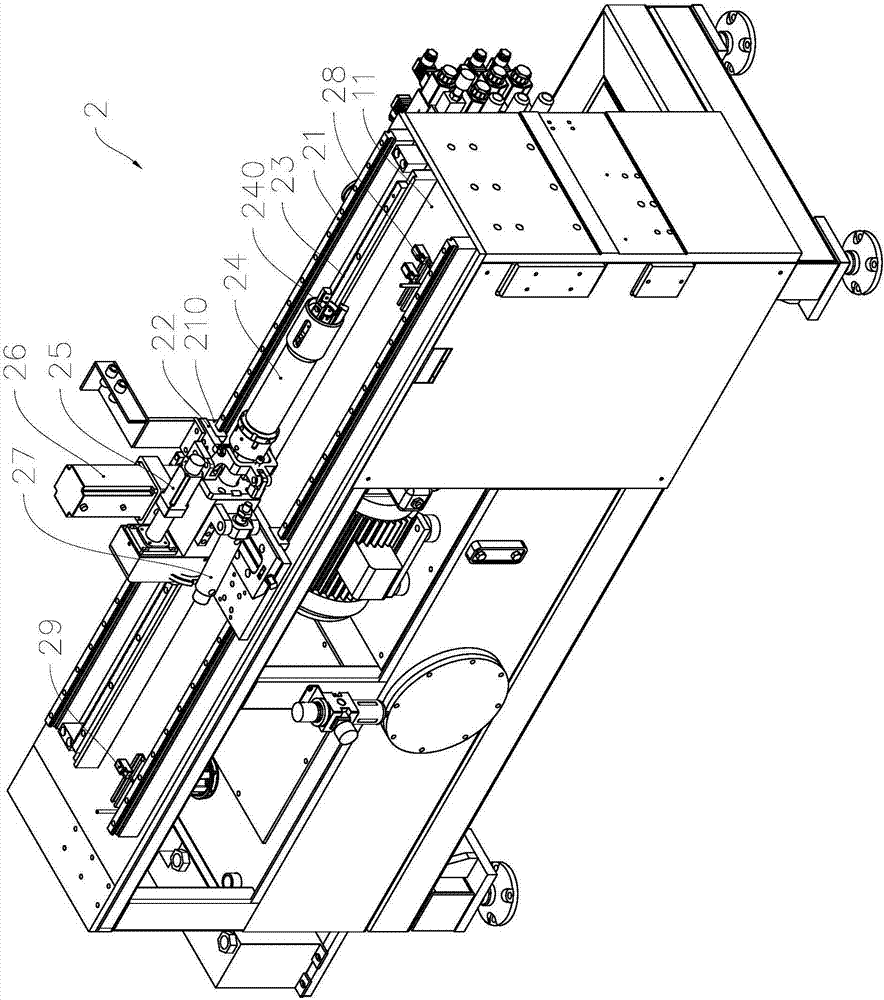

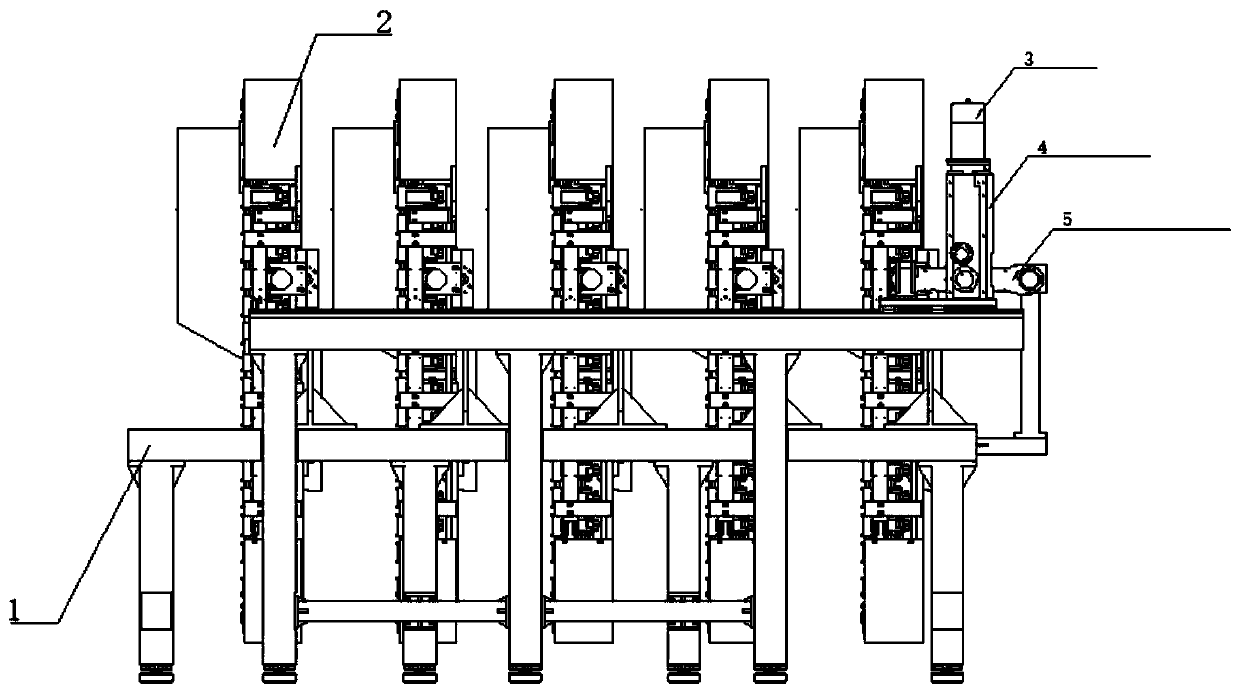

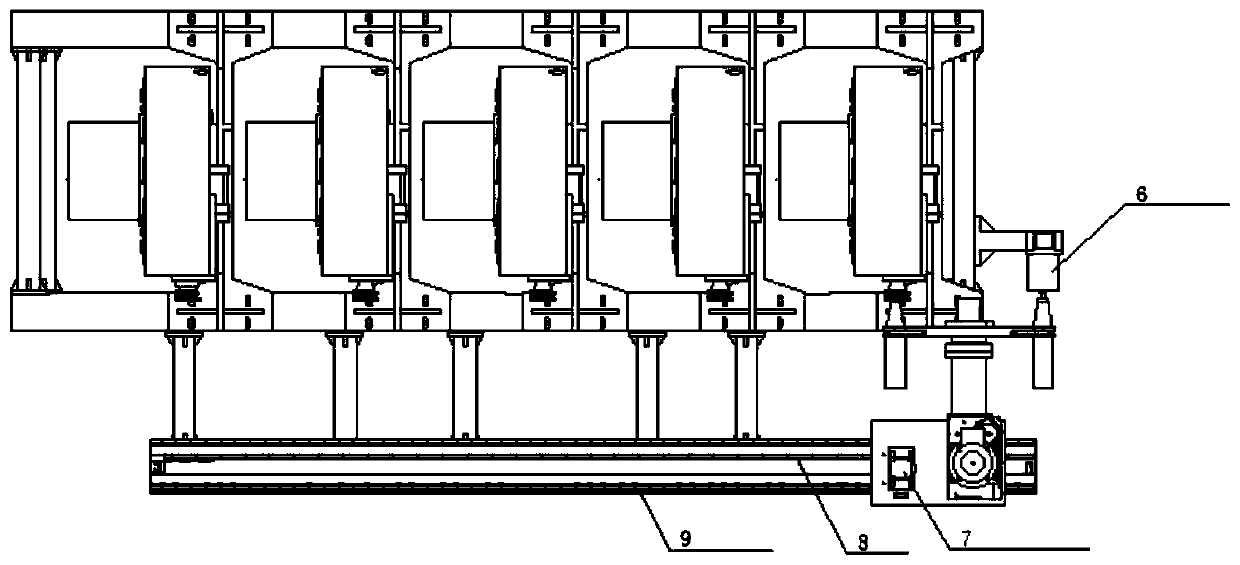

Modular structure chain type tool magazine and automatic tool change control method

InactiveCN110064955ASolve large capacityReasonable structural designPositioning apparatusMetal-working holdersElectric machineryChain type

The invention provides a modular structure chain type tool magazine and an automatic tool change control method; the modular structure chain type tool magazine compriess a machine frame, a main controller, a linear mechanism, an ATC automatic tool change mechanism, an ATC translation motor and a virtual main shaft, wherein the ATC automatic tool change mechanism comprises an ATC motor and a cutterarm driven by the ATC motor to change the tool; a plurality of sub-module tool magazines are arranged on the machine frame in the movement direction of the ATC automatic tool change mechanism on thelinear mechanism; an independent servo motor, a sensing mechanism and a unit controller are arranged in each sub-module tool magazine; the unit controllers in the sub-module tool magazines are connected with a main controller circuit through a bus interface and a field bus respectively; and each submodule tool magazine is independently controlled by the main controller. With reasonable structure design, the tool magazine provided by the invention can solve the problem of large capacity of the tool magazine effectively under the condition of ensuring transmission stability, precision and structural rigidity; and the tool change efficiency is effectively improved.

Owner:CHANGZHOU DESU MACHINERY

Suspension support speed reducing transmission device

InactiveCN101813176AEasy to assemble and disassembleEasy maintenanceGearingKey type connectionsReduction driveReducer

The invention relates to a suspension support speed reducing transmission device, which belongs to the technical field of a mechanical transmission device. The device comprises a motor, a primary speed reducer and a secondary speed reducer, wherein the motor is arranged on a motor support seat, the input end of the primary speed reducer is coupled with an output shaft of the motor, the input end of the secondary speed reducer is coupled with the output end of the primary speed reducer, the motor support seat is fixedly connected with a case of the secondary speed reducer, the motor support seat is sheathed with a support shaft through an eccentric shaft, the support shaft is parallel to the output shaft of the motor, a support seat block extends from one side of the case of the primary speed reducer, a slide block is arranged in the support seat block, a support hole is formed in the slide block, the slide block and the support seat block form a moving pair vertical to the direction of the output shaft of the motor, and the outer end of the support shaft is arranged in the support hole. The invention can conveniently regulate the assembly position of the motor and the primary speed reducer according to the requirement so that the motor and the primary speed reducer can be in an ideal transmission state. In addition, the structure brings great convenience for the dismounting and the installation of the primary speed reducer, and the repair and the maintenance are convenient.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Cloth material wool washing device used for dyeing, finishing and weaving processes

InactiveCN105586733APrevent sprayingEnsure transmission stabilityTextile treatment by spraying/projectingWater savingSprayer

The invention discloses a cloth material wool washing device used for dyeing, finishing and weaving processes. The cloth material wool washing device comprises a cloth-feeding device, a cleaning device, a traction padder and a cloth-doffing device. The cleaning device comprises a rectangular cleaning water tank, left and right side walls of which are provided with cloth-feeding gaps. Upper and lower sides of each cloth-feeding gap are provided with middle rollers. Upper and lower layers of cloth-guiding rollers used for connecting the front and back wall of the cleaning water tank are arranged at interval and arranged in the cleaning water tank. Front and back sidewalls of the cleaning water tank are provided with multiple water sprayers capable of swinging up and down. The water sprayers are of fan-shaped sector structures. The central angle of each water sprayer is of 35 to 50 degrees and located in the middle of the upper and lower layers of cloth-guiding rollers. Water sprayers on front and back walls of the cleaning water tank are arranged at interval. One water sprayer corresponds to one cloth-guiding roller. The cloth material wool washing device used for dyeing, finishing and weaving processes is high in washing efficiency and can save water.

Owner:WUXI HONGFEN MACHINERY FACTORY

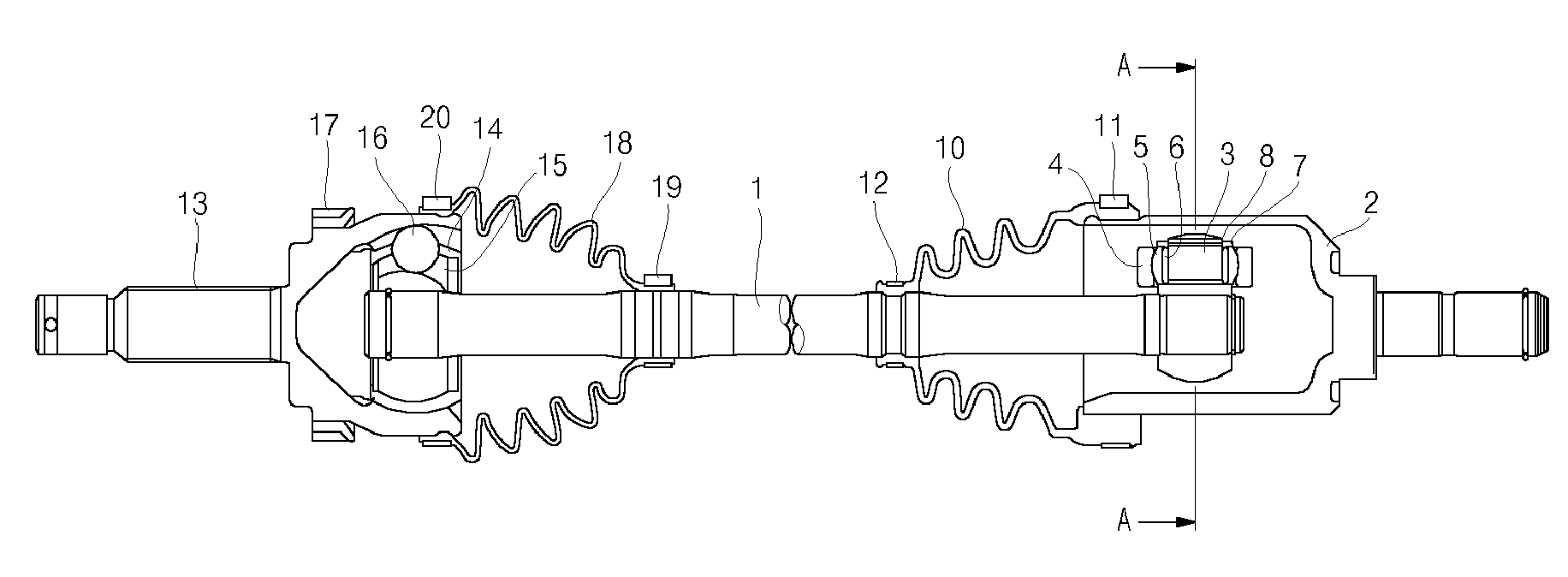

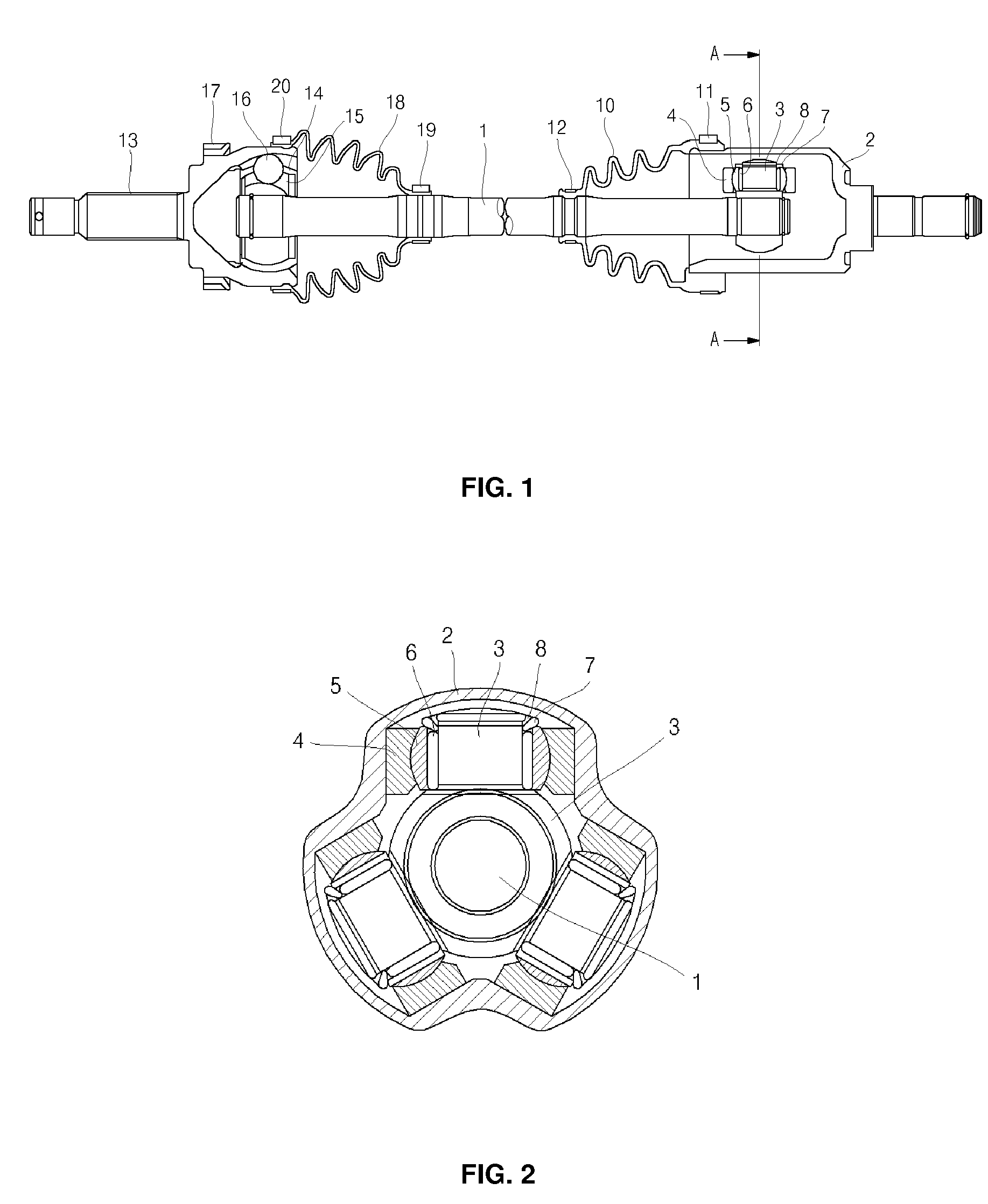

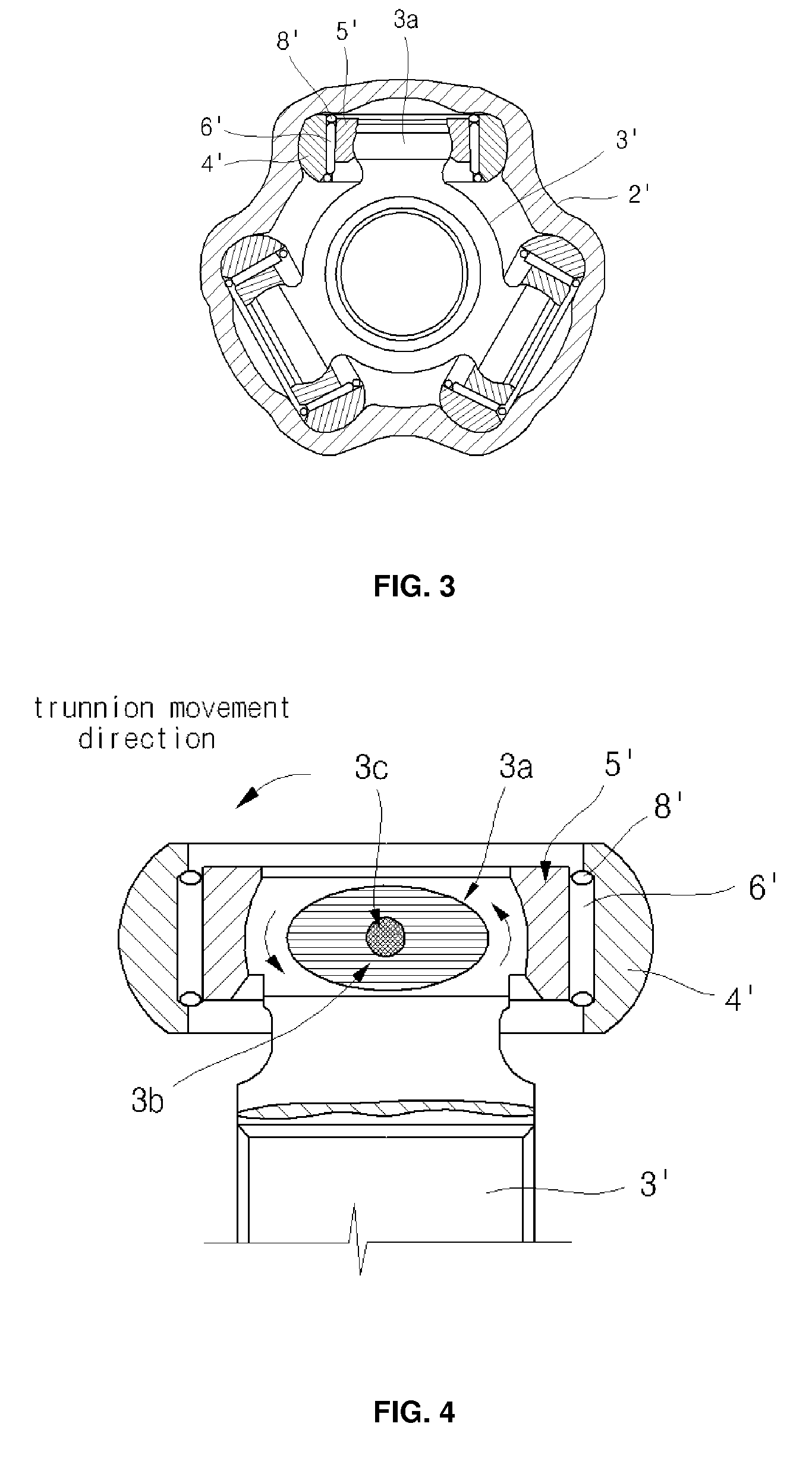

Tripod Type Constant Velocity Joint

ActiveUS20080058107A1Large frictional forceAvoid drivingYielding couplingRotary machine partsTrunnionConstant-velocity joint

A tripod type constant velocity joint comprises a housing having three track grooves which are defined at trisected positions of the housing along a circumferential direction and extend in a radial direction; a spider having three polyhedral trunnions which are projectedly formed at trisected positions of the spider along the circumferential direction to be respectively inserted into the track grooves and each of which has at least two polygonal surfaces; inner rollers a circumferential inner surface of each of which has a curved contour for surrounding the polyhedral trunnion; a plurality of needle rollers assembled to a circumferential outer surface of each inner roller; and outer rollers each formed to be rotated through the needle rollers, to be moved in an axial direction of the inner roller, and to be moved in an axial direction of the track groove along a guide surface of the housing.

Owner:WIA CORP

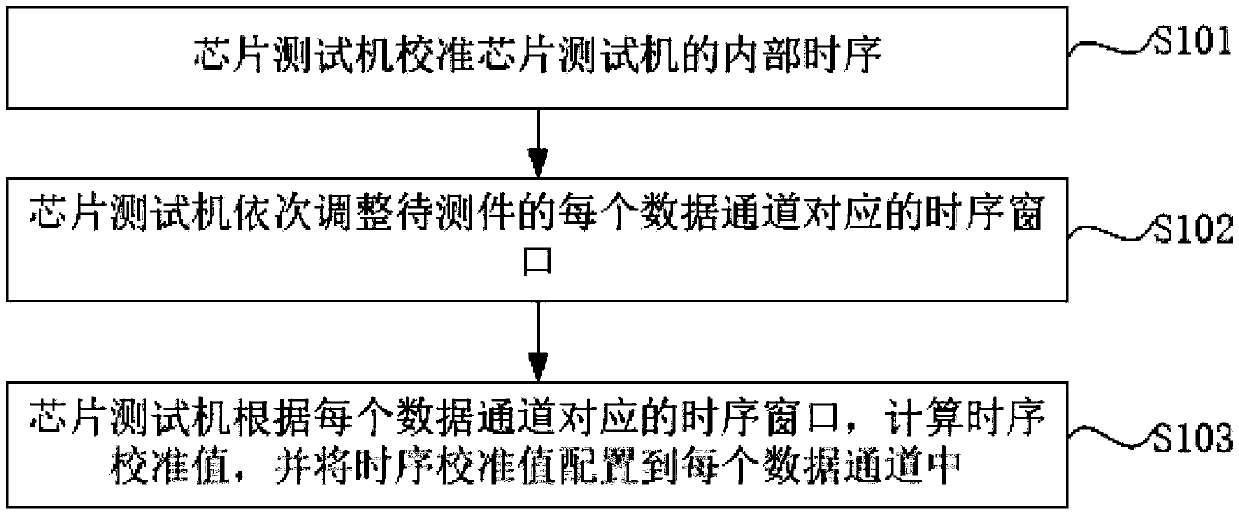

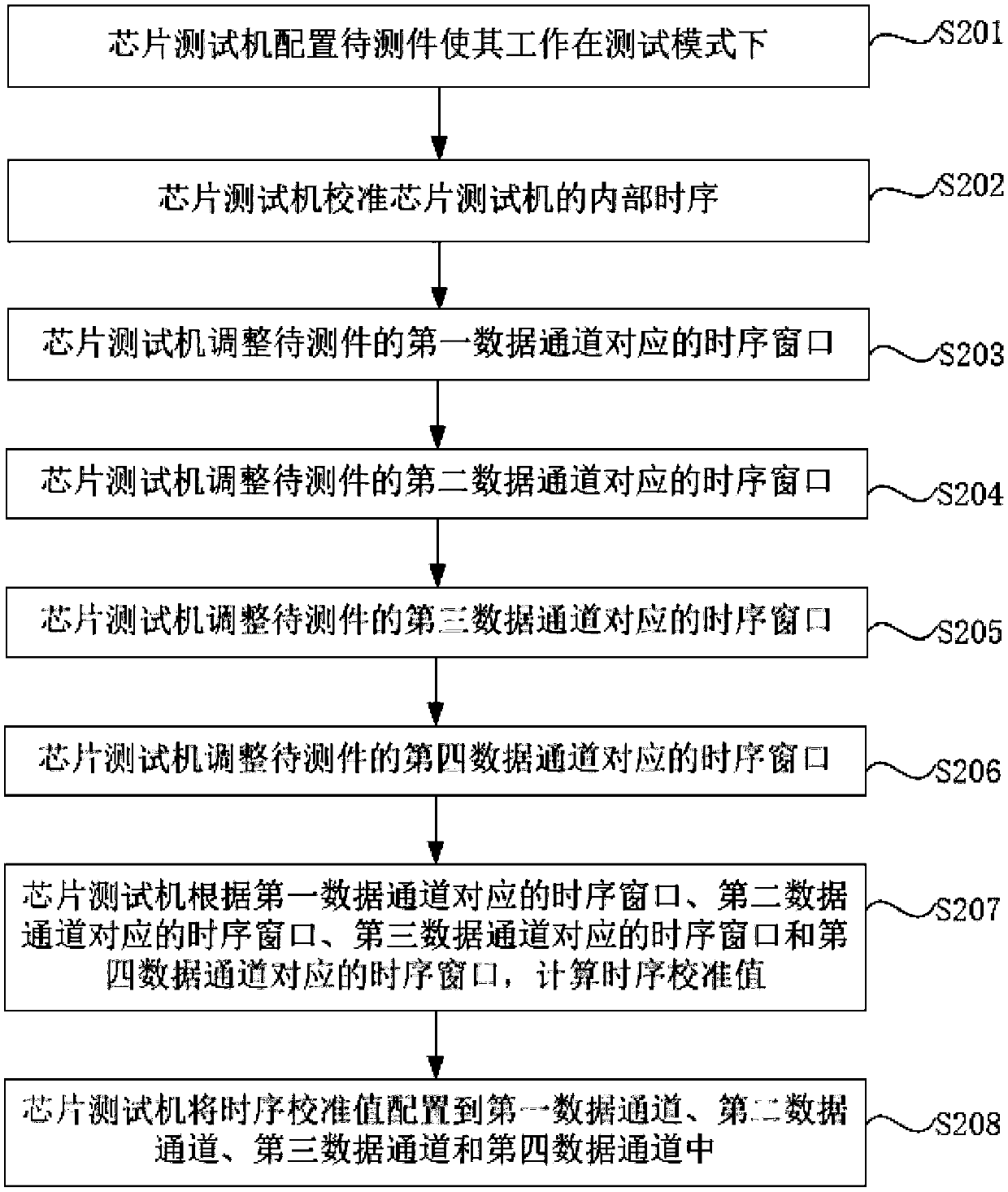

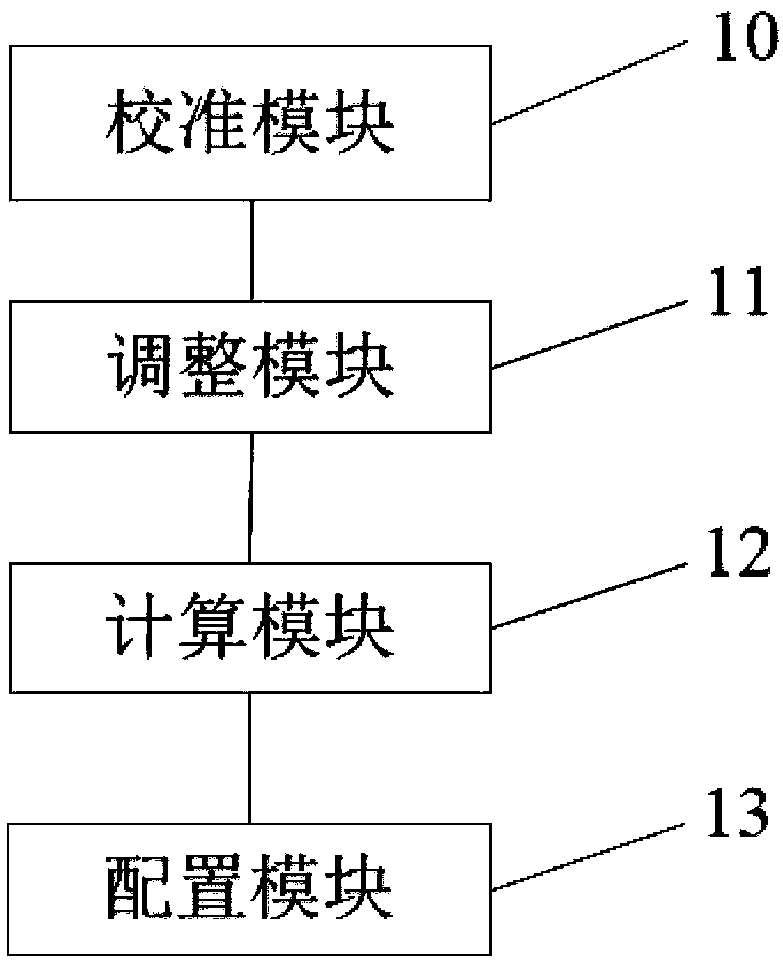

Timing sequence calibration method, and chip test machine

ActiveCN109640013AGuaranteed transfer rateEnsure transmission stabilityTelevision system detailsElectronic circuit testingComputer scienceTransmission delay

The invention discloses a timing sequence calibration method, and a chip test machine. The method comprises the following steps: calibrating an internal timing sequence of the chip test machine; sequentially adjusting a timing sequence window corresponding to each data channel of a workpiece to be tested; and calculating a timing sequence calibration value according to the timing sequence window corresponding to each data channel, and configuring the timing sequence calibration value in each data channel. By adoption of the timing sequence calibration method disclosed by the embodiment of theinvention, the timing sequence calibration of an MIPI signal is achieved without adding any device, thereby ensuring the transmission rate and stability of the MIPI signal, and reducing the maintenance and use costs of the device.

Owner:SUZHOU HUAXING YUANCHUANG TECH CO LTD

Double-layer lifting warping machine

ActiveCN106283320AReasonable transmissionAvoid wastingWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention discloses a double-layer lifting warping machine. The double-layer lifting warping machine comprises a base, a frame is arranged at the top of the base, a partition plate is arranged in the middle of the frame horizontally and partitions the frame into an upper layer and a lower layer, and a passage is arranged on one side of the partition plate. A yarn unwinding component is arranged on the upper layer, a first rotating roller is arranged on one side of the yarn unwinding component, a yarn collecting beam is arranged on one side of the first rotating roller, and a tensioning component is arranged on one side of the yarn collecting beam and in the passage. A first dividing frame is arranged on the lower layer and disposed below the tensioning component, a second dividing frame, a yarn guide component and a third dividing frame are arranged on one side of the first dividing frame, a warping component is arranged on one side of the third dividing frame, and lifting components are arranged on two side faces of the base and the frame. The double-layer lifting warping machine has the advantages of space saving, reasonable conveyance, less proneness to knotting, clear layering, high yarn guide precision, good warping quality and the like.

Owner:WUJIANG XIAOYU JET WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com