Pipe bending machine and gear transmission device thereof

A technology of gear transmission and input gear, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of unsatisfactory product quality, low stability of manufacturing accuracy, insufficient bending accuracy, etc. The effect of ensuring parallelism, improving stability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

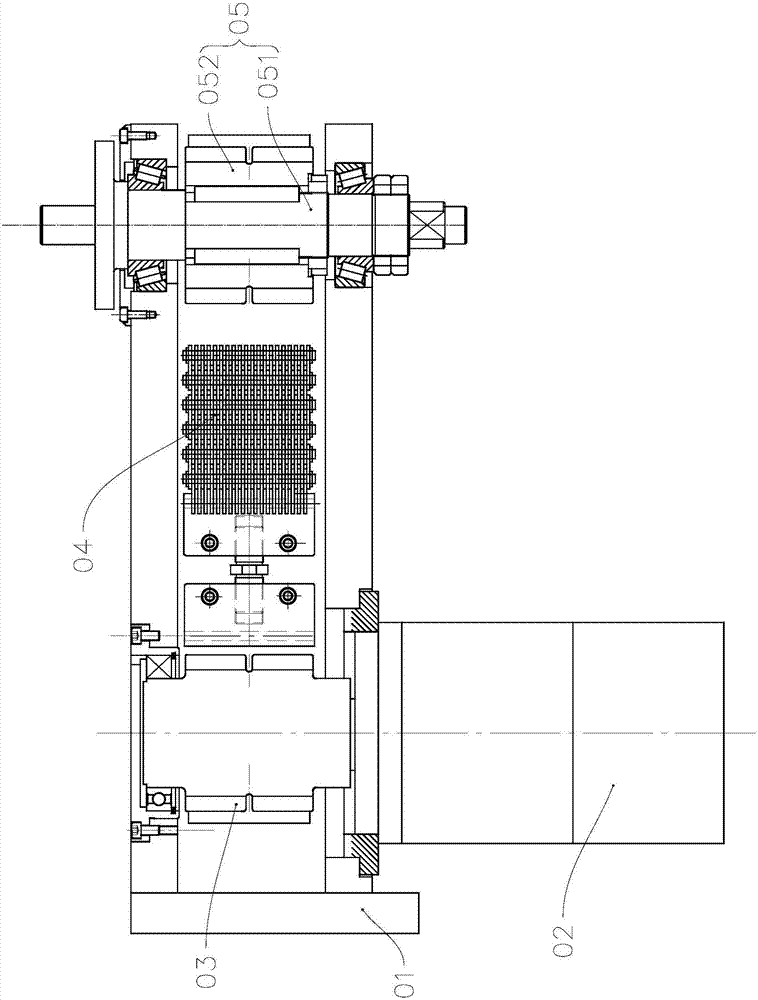

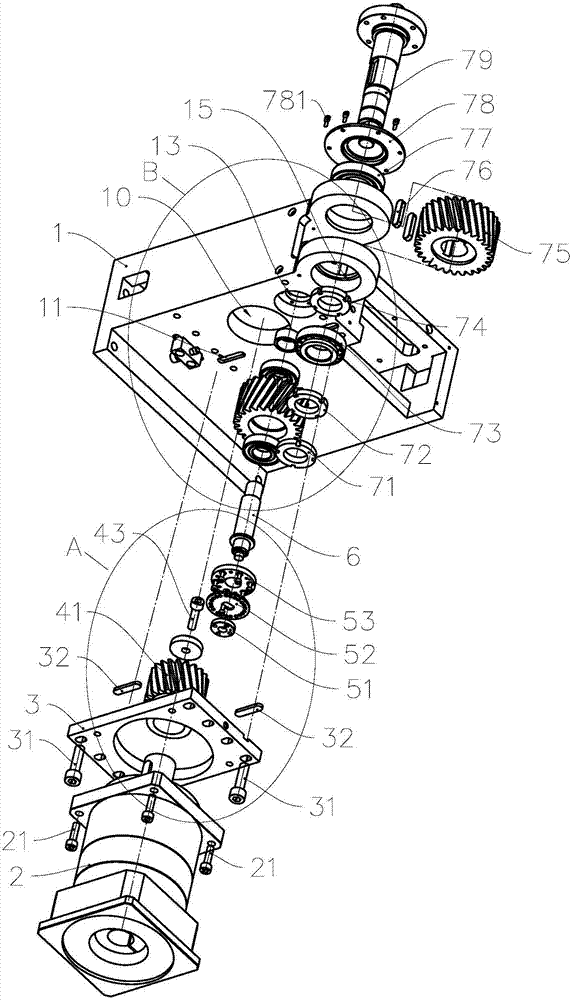

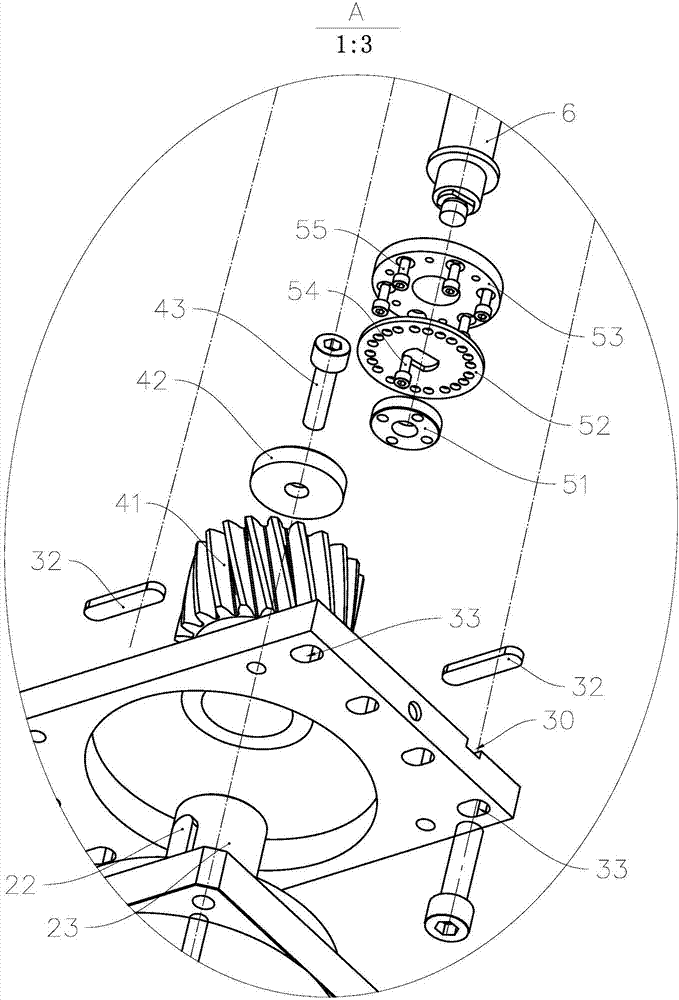

[0036] see Figure 2 to Figure 7 , the pipe bender of the present invention includes a frame 1 and a power unit installed on the frame 1, a gear transmission device and a pipe bending device (not shown in the figure), and the frame 1 is a cavity structure with an installation chamber 100, The power device includes a reducer 2; the gear transmission is a three-stage gear transmission, including an input unit, a transition unit and an output unit; the input unit includes a reducer mounting plate 31, an input gear 41 and an adjustment assembly; the transition unit includes an eccentric shaft 6, The transition gear 57 and the adjustment locking mechanism; the output unit includes an output shaft 79 and an output gear 75 .

[0037] The reducer 2 is fixed on the reducer mounting plate 3 through four fixing bolts 21, and the input gear 41 is set on the output shaft 23 of the reducer 2 through the flat key 22 to form a limit for the movement of the input gear 41 in the circumferential...

Embodiment 2

[0059] As an illustration of Embodiment 2 of the present invention, only the differences from Embodiment 1 above will be described below.

[0060] see Figure 11 to Figure 13 , by setting the pin hole 170 on the side wall plate 17 of the frame 1, in this embodiment, the adjustment locking mechanism also includes a locking pin 61 and a locking screw 62, and the outer port of the pin hole 170 is provided with a locking Screw 62 matches the screw thread, and the inner end surface of anti-loosening pin 81 is formed with the arc-shaped extruding surface 810 that matches with the side wall surface of the mounting shaft portion 61 of eccentric shaft 6, and the arc of anti-loosening pin 81 is made by locking screw 82. The shaped extrusion surface 810 extrudes the side wall surface of the mounting shaft portion 61 to form a friction fit surface to assist in locking the rotation angle position of the eccentric shaft 6 .

Embodiment 3

[0062] As an illustration of Embodiment 3 of the present invention, only the differences from Embodiment 1 above will be described below.

[0063] The above-mentioned adjustment and locking mechanism can be replaced by a subdivision mechanism to form the first gap adjustment mechanism, that is, the requirements for adjusting, indexing and positioning locking of the rotation angle of the eccentric shaft can be realized by using the subdivision mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com