Dynamic electrochemical corrosion and wearing test device

A corrosion and wear test, friction and wear test technology, applied in the field of new friction and wear-electrochemical testing and data acquisition devices, can solve the inability to realize the synchronous output of material wear performance signals, the limitation of synchronous research on corrosion and wear performance, and the inability to investigate the impact of load, etc. problem, to ensure transmission stability, ensure accuracy, and prevent galvanic corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

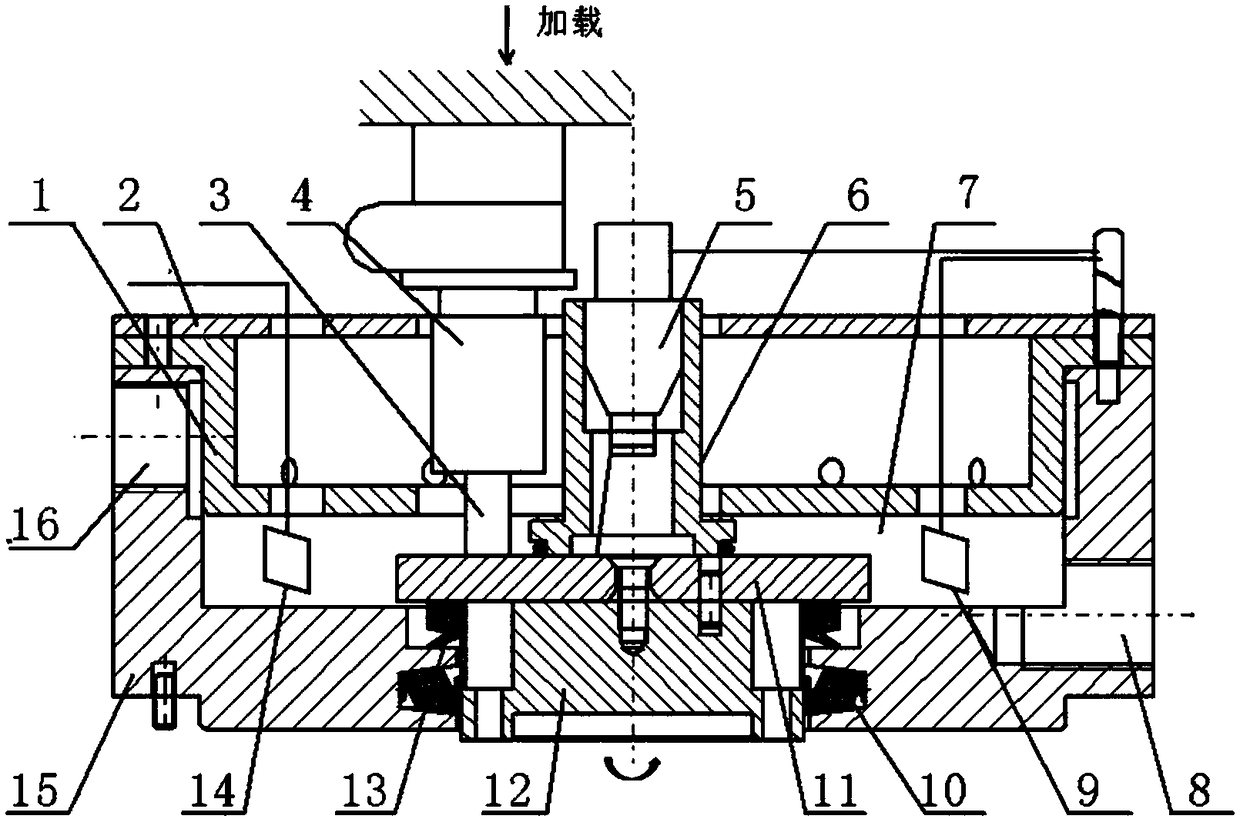

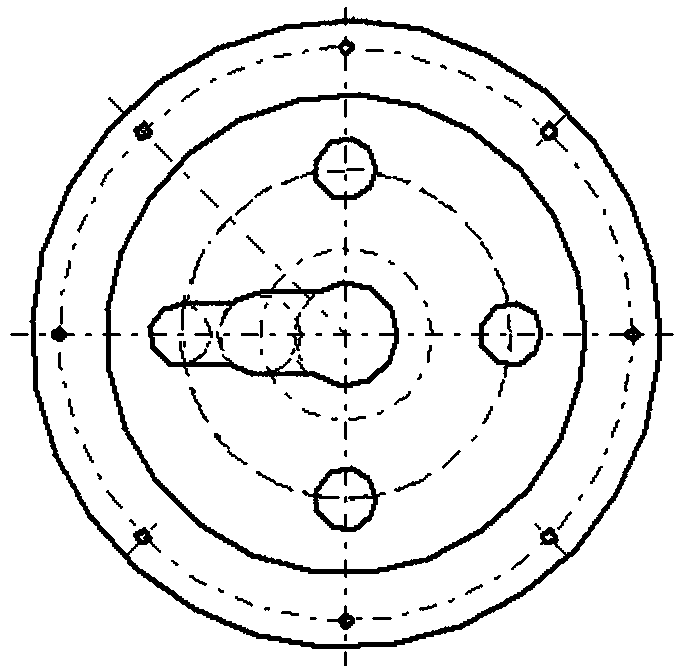

[0017] Build a test bench, prepare test samples, weigh them with a balance with an accuracy of 0.1 mg, and conduct friction and wear tests. A dynamic electrochemical corrosion and wear test device according to the present invention adopts the "pin-disc" friction contact mode, which is used for the corrosion and wear test research of materials under rotating conditions, and can realize the real-time test of electrochemical corrosion and wear under dynamic conditions. The testing device includes a pool 15, a rotary friction and wear testing machine, a three-electrode electrochemical test system, etc.; the pool 15 and the mounting base 12 are formed by a Z-shaped rotary seal 10 and a D Type water seal 13 carries out combined rotary sealing, and water inlet 16 and water outlet 8 are arranged on both sides of pool 15, and are used for pool inlet and outlet in the test. The lower test piece (working electrode) 11 is fixed on the installation base 12 through the central screw and pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com