Pressure control reverser, in-situ stress measurement equipment and in-situ stress measurement method using same

A pressure control and commutator technology, which is used in earth-moving drilling, wellbore/well components, etc., can solve the problems of difficulty in determining the working state of the reversing valve, difficulty in determining the middle position, affecting measurement efficiency, etc., to improve work efficiency. , the effect of eliminating water leakage and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

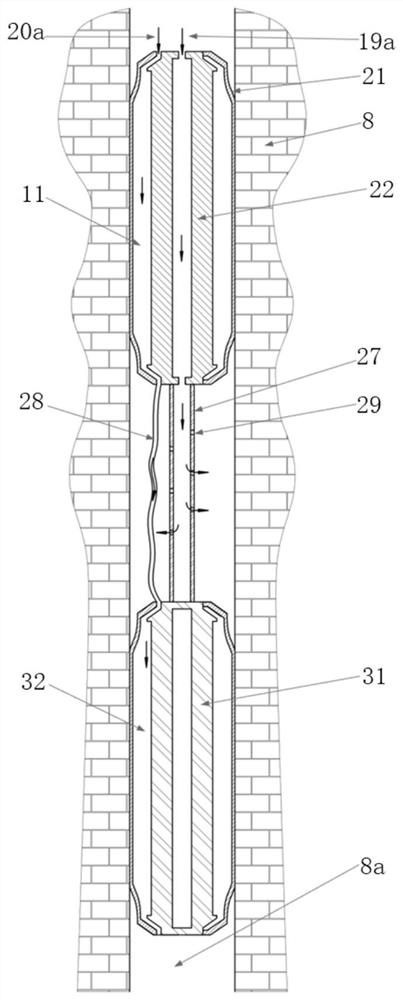

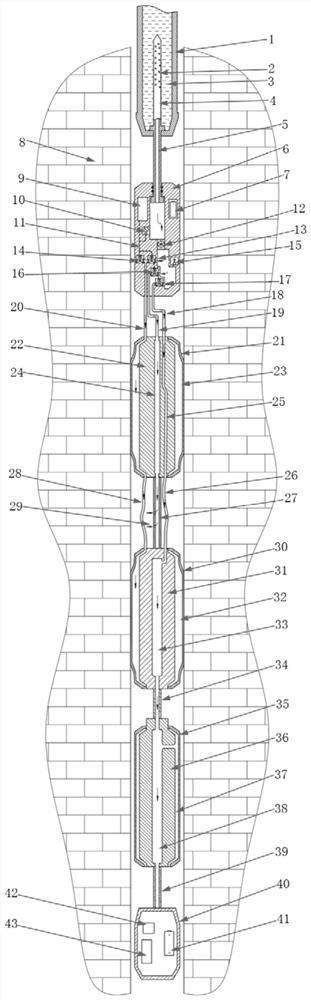

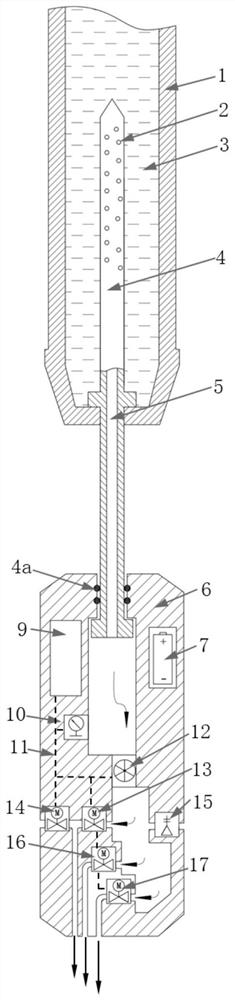

[0057] Hereinafter, the present application will be described in detail with reference to the accompanying drawings.

[0058] The embodiments in the drawings in the description include two packers, but the present application is not limited to the case of two packers, and there may be three or even more packers.

[0059] The pressure control reversing valve is composed of connecting rod 4 and main control bin 6 .

[0060] The connecting rod 4 is fixedly connected to the bottom of the drill rod 1 , the upper part of the connecting rod 4 is provided with a filter hole 2 , and the center is provided with a water passage 5 . The function of the filter hole 2 is to filter out impurities such as sediment in the water and protect the back-end devices. The connecting rod 4 and the main control bin 6 can rotate relatively freely, and a sealing ring 4a is provided at the rotating contact part.

[0061] The main control bin 6 is provided with a main control board 9 (usually implemented...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com