Wool scouring device used for cloth material

A technology of cleaning device and cloth feeding device, which is applied in the direction of processing textile material equipment configuration, spraying/jetting textile material processing, etc., can solve the problems of large water consumption, small washing force, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

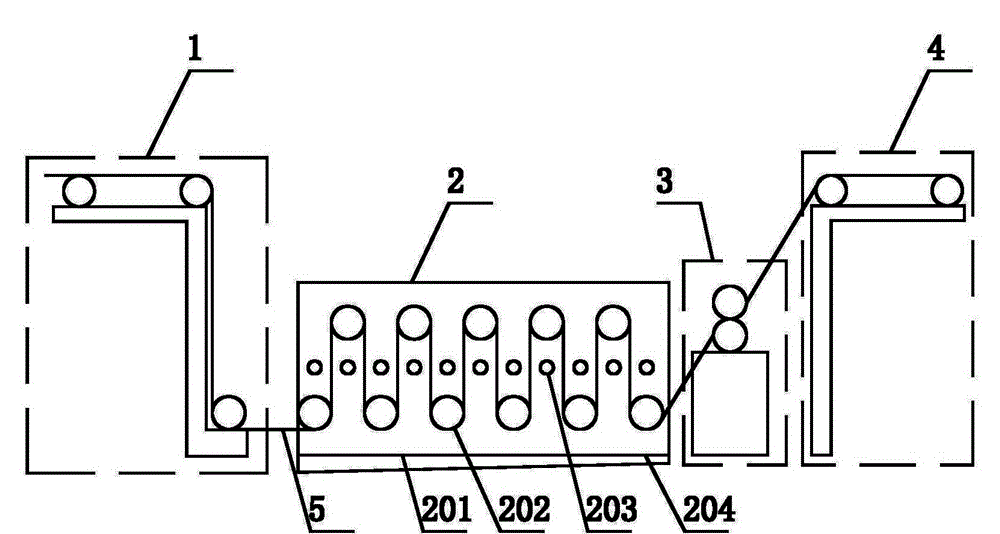

[0015] Such as figure 1 As shown, a wool scouring device for cloth includes: a cloth feeding device 1 discharged sequentially from left to right, a cleaning device 2, a traction paddle 3, a cloth falling device 4, and the cloth 5 is pulled by the cloth feeding device 1 Enter the cleaning device 2 for cleaning, and the cleaned cloth 2 is drawn out of the cleaning device 2 by the traction rolling car 2, and the cloth 5 is sent to the cloth falling device 4 for winding processing to complete the scouring; wherein, the cleaning device 2. It includes a cleaning water tank 201 in the shape of a rectangular parallelepiped. The left and right side walls of the cleaning water tank 201 are provided with cloth feeding slits, and the upper and lower sides of the cloth feeding slit are provided with intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com