Pneumatic winch capable of automatically tensioning and arranging ropes

A pneumatic winch and rope arrangement technology, applied in the direction of the mainspring mechanism, hoisting device, etc., can solve the problems of easy rope bite, uneven winding of wire rope, disordered rope, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

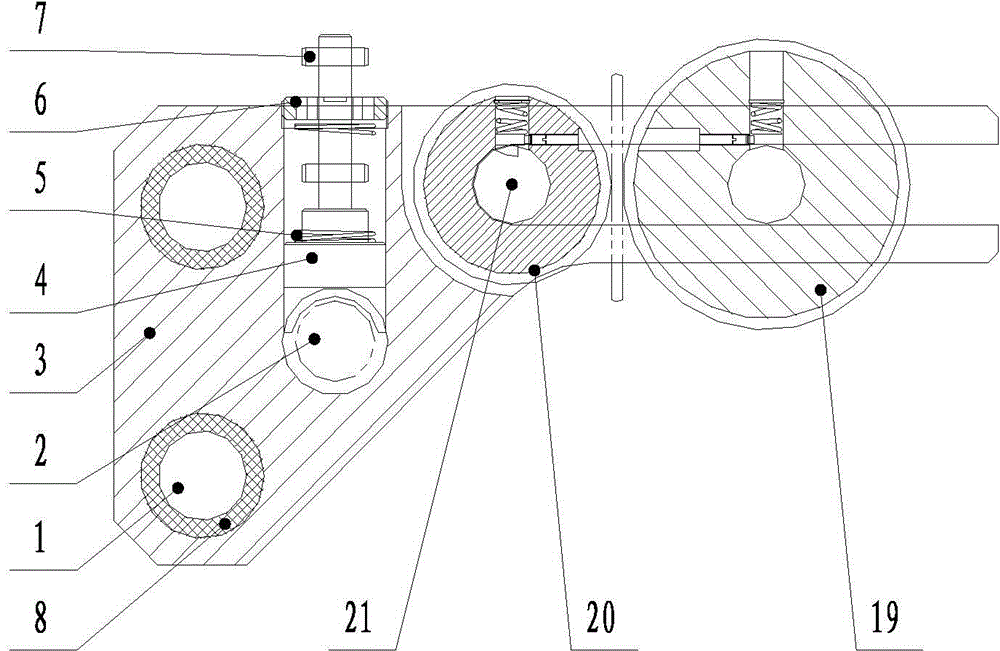

[0018] refer to Figure 1-3 As shown, the present invention provides a pneumatic winch capable of automatically tensioning and arranging ropes, including a rope arranging mechanism, a transmission mechanism and a wire rope tensioning mechanism, and the described rope arranging mechanism includes a guide rod 1, a lead screw 2, and a rope arranging seat 3 , slider 4, compression spring 5, spring cover 6, pull pin 7, sliding sleeve 8, described guide bar 1 and leading screw 2 are slidably installed on the row rope seat 3, guide bar 1 and row rope A sliding sleeve 8 is installed between the seats 3, and a slide block 4 is also arranged on the described rope row seat 3, and the slide block 4 is installed in the thread groove of the lead screw 2, and the thread groove of the lead screw 2 is also provided with Compression spring 5 is arranged, and spring gland 6 is installed on the compression spring 5, and pull pin 7 is also installed on the described slide block 4.

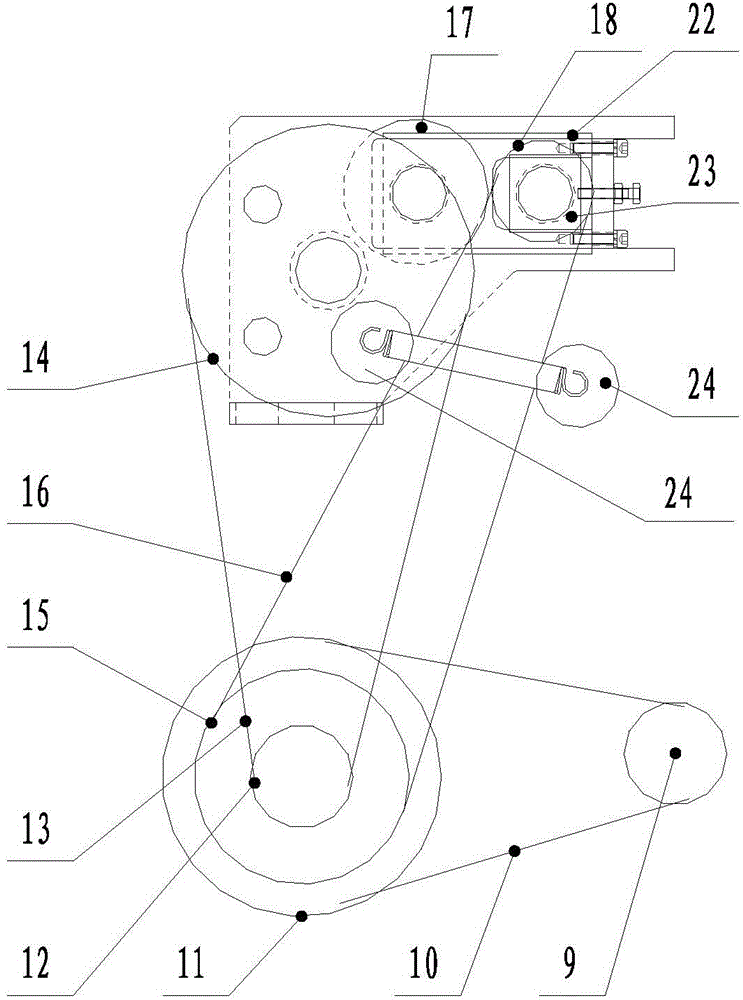

[0019] refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com