An anti-loosening rope system

An anti-loosening rope and anti-loosening technology, which is applied in the field of anti-loosening rope system, can solve the problem of no external cable winch anti-loosening rope system, and achieve the effect of preventing wire rope from being messy, low cost and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

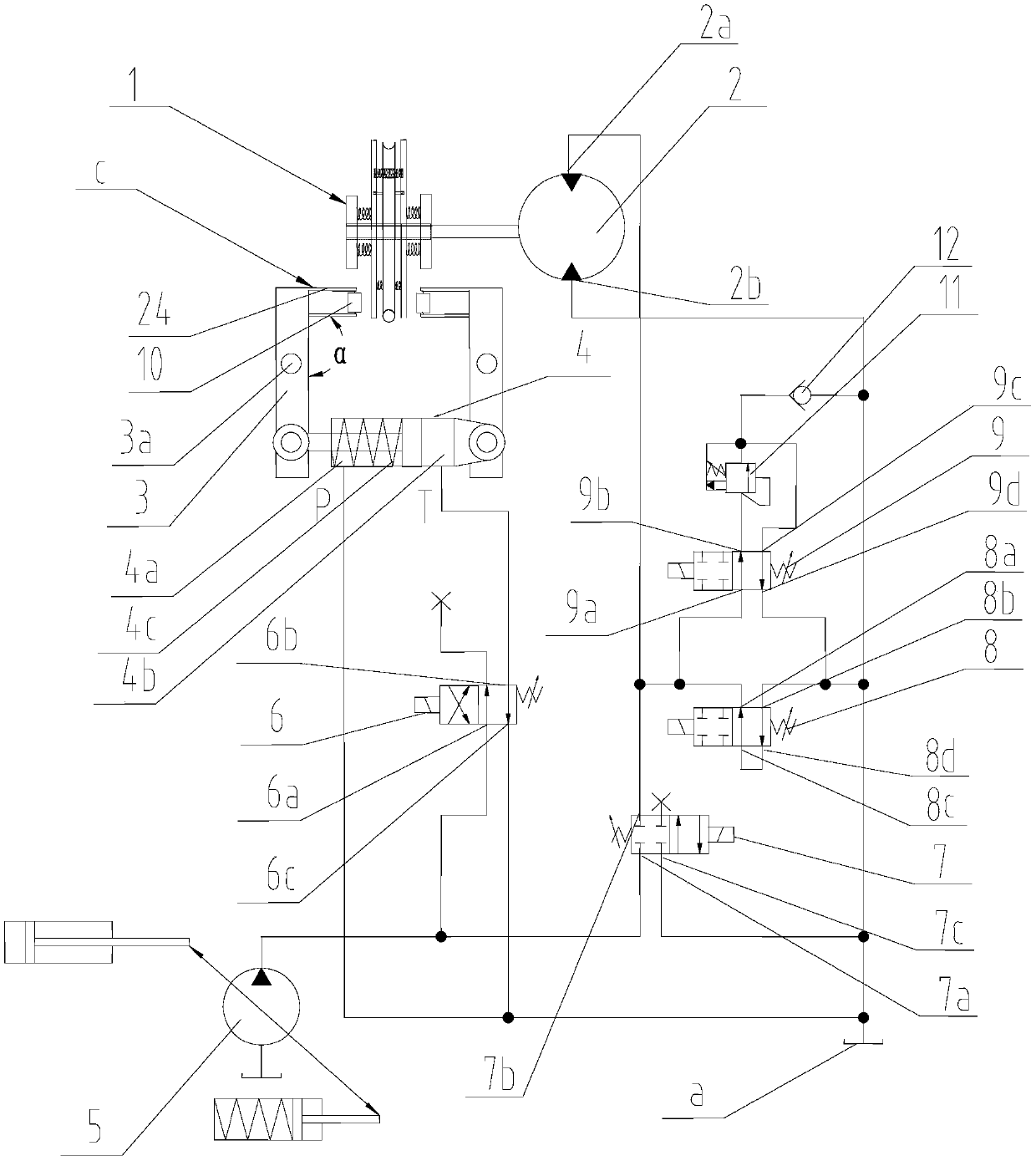

Method used

Image

Examples

Embodiment

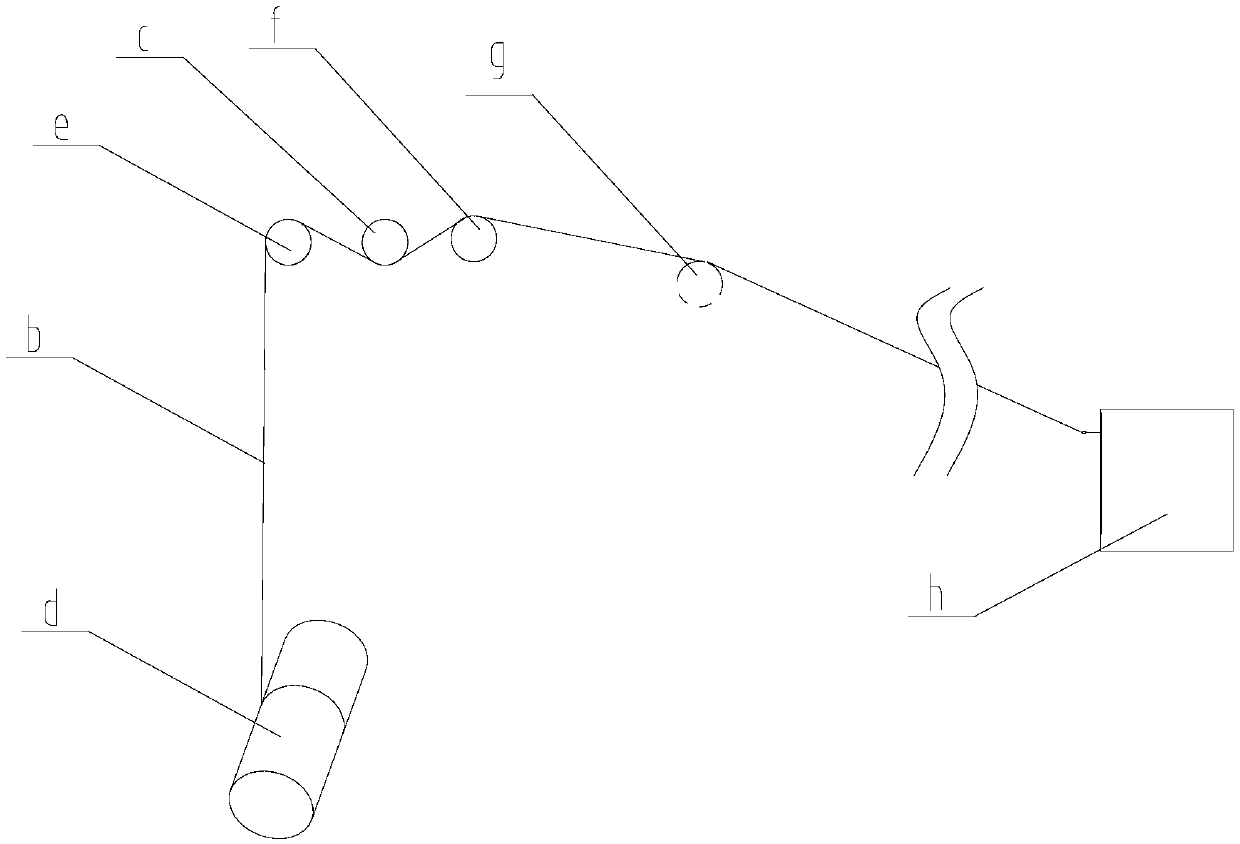

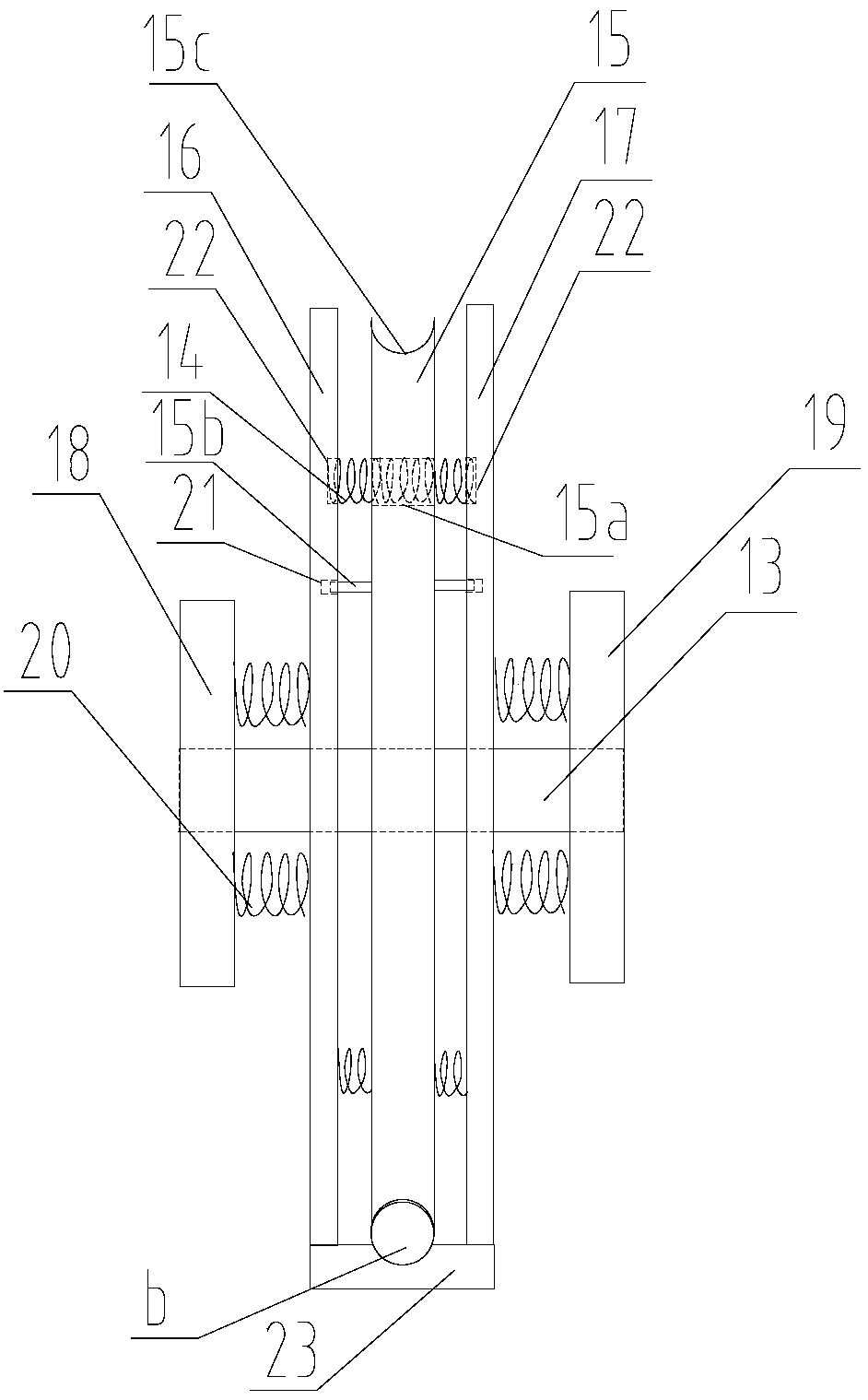

[0027] The embodiment of the present invention provides an anti-loosening rope system, such as figure 2 As shown, the anti-loosening rope system c can be used together with the winch, such as the outer traction winch d, and the outer drag winch d can pass through the first guide pulley e, the second guide pulley f and the The third guide pulley g changes the direction of the wire rope b respectively, and transfers the substance to the receiving ship h through the wire rope b. The anti-loosening rope system c can be installed between the first guide pulley e and the second guide pulley f. After the rope system c is loosened, the wire rope b between the first guide pulley e and the second guide pulley f bypasses the anti-loosening rope system c and bends downward. The upper end of the guide pulley e passes through the upper end of the first guide pulley e to the lower end of the runner 1 of the anti-loosening rope system c, then passes through the upper end of the second guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com