Hydraulic system for automatically controlling mast retraction of crawler crane

A technology of crawler crane and hydraulic system, applied in cranes and other directions, can solve the problems of poor high pressure stability of oil cylinder, low efficiency, and many human control factors, and achieve the effect of avoiding rope disorder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

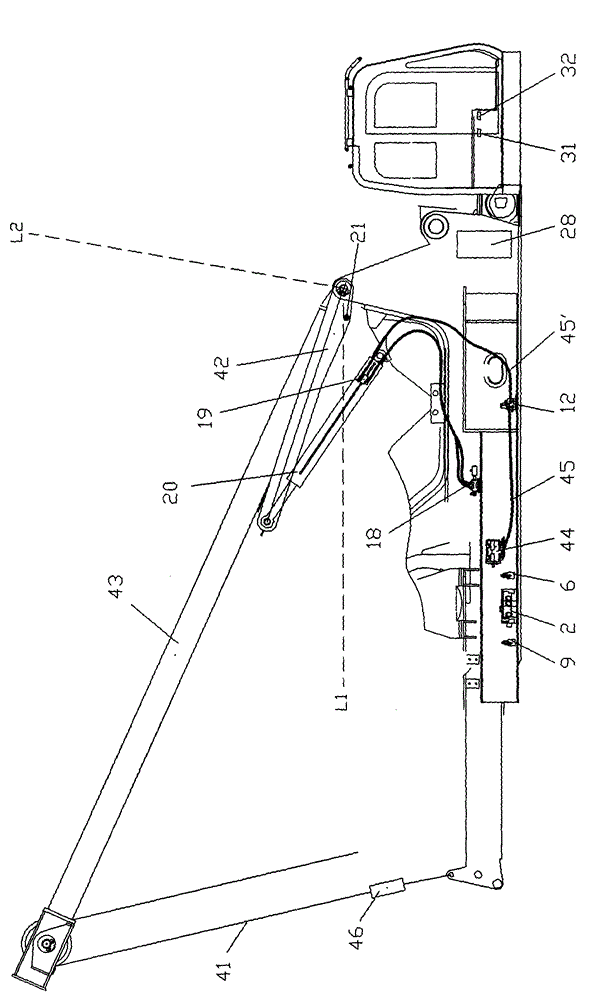

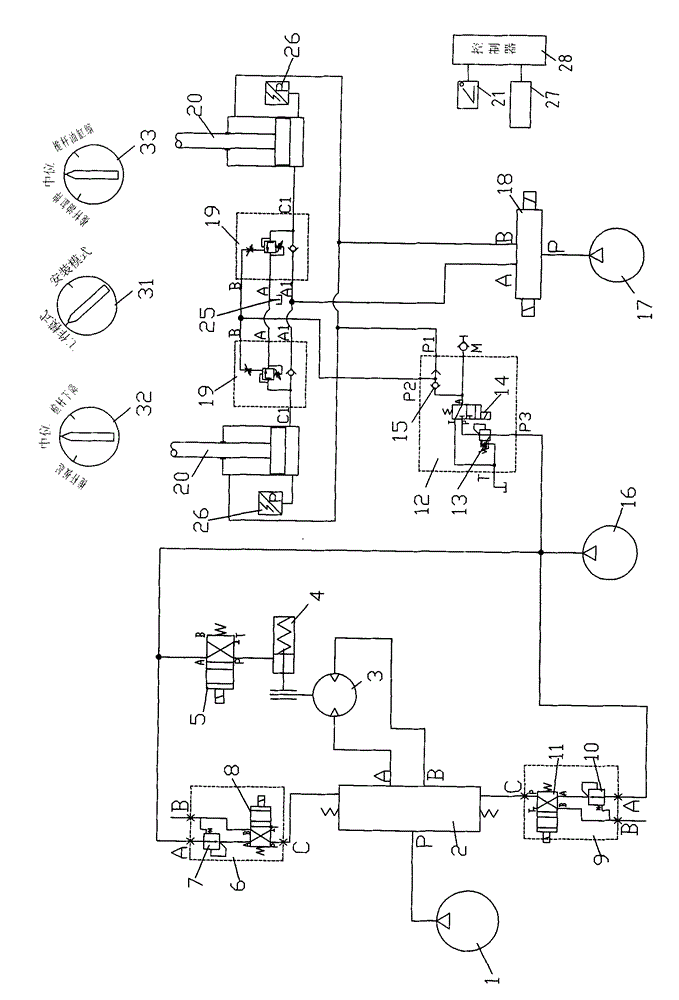

[0028] The structural features of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as figure 1 , figure 2 As shown, the crawler crane mast retracting automatic control hydraulic system of the present invention includes a first hydraulic pump 1, a second hydraulic pump 16, a main valve 2, a third hydraulic pump 17, a first switching valve group 9, a second switching valve group 6. Solenoid valve 5, brake 4, motor 3, auxiliary valve 18, balance valve 19, pressure control valve group 12, angle sensor 21, pressure sensor 26 and controller 28.

[0030] The main valve 2 has P ports, A ports and B ports, the P port of the main valve 2 is connected to the first hydraulic pump 1, and the main valve 2 is also connected to the first switching valve group 9 and the second switching valve group 6 , the first switching valve group 9 and the second switching valve group 6 are respectively connected to the hydraulic control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com