Shipborne expendable optical-fiber bathythermograph

A profile measurement, throwaway technology, applied in measurement devices, heat measurement, liquid/fluid solid measurement, etc., can solve the problem of increasing the optical fiber transmission loss of the fiber shaft, unable to meet the needs of ocean observation, and not considering the impact of data transmission, etc. To achieve the effect of realizing temperature and depth synchronous detection, reducing the volume of the fiber shaft, and reducing the difficulty of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

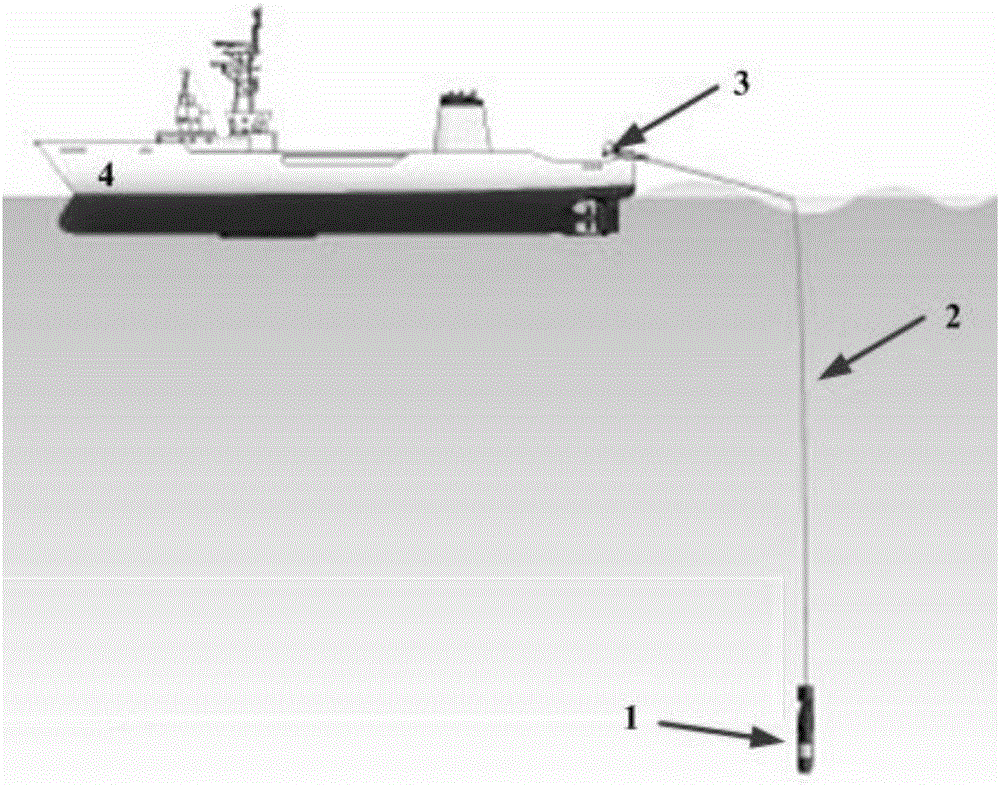

[0035] A ship-mounted discarded fiber optic seawater temperature and depth profile measurement system includes an all-fiber probe 1, a transmission fiber 2, and a deck unit 3. The above-mentioned devices are carried on an engineering ship 4, such as figure 2 shown. in:

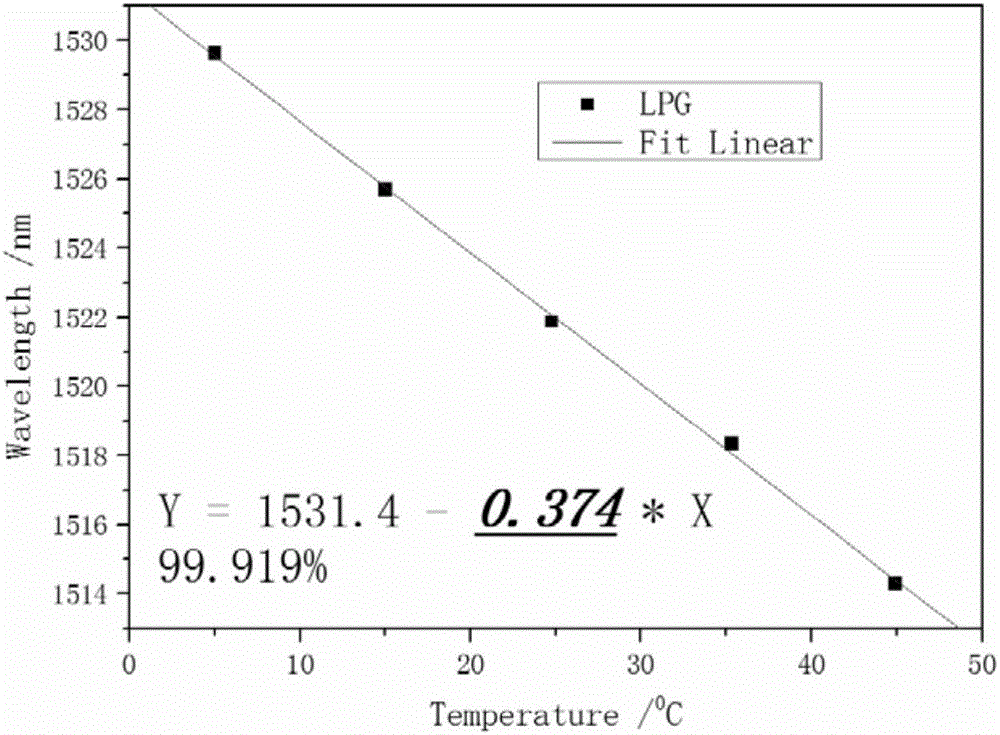

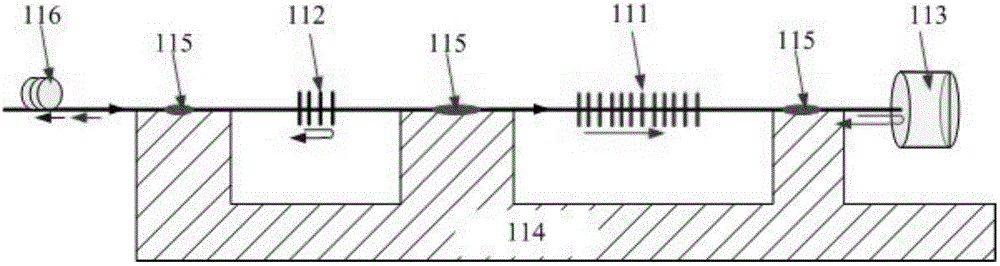

[0036] The all-fiber probe 1 includes an optical fiber sea temperature depth sensor 11 and a lower fiber shaft 21 installed in a protective cover, and its internal sensing structure includes an LPG temperature sensor 111 coated with a sensitizing film, a FBG depth sensor, and an optical fiber end face reflector 113 And the fixed base 114, the internal sensing structure of the optical fiber temperature and depth probe is as follows image 3 shown. During specific implementation, the optical fiber end face reflector 113, the LPG111 coated with a sensitizing film as a seawater temperature sensor, the FBG112 as a seawater depth sensor, and the pigtail 116 can be sequentially connected by an optical fiber fusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com