Cleaning device for electronic semiconductor machining

A cleaning device and a technology for semiconductors, which are applied in the manufacture of semiconductor/solid-state devices, cleaning methods using tools, cleaning methods using liquids, etc., can solve the damage of fine pattern structure on the surface of semiconductors, the cleaning quality is not high, and the chemical cleaning solution is limited. use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

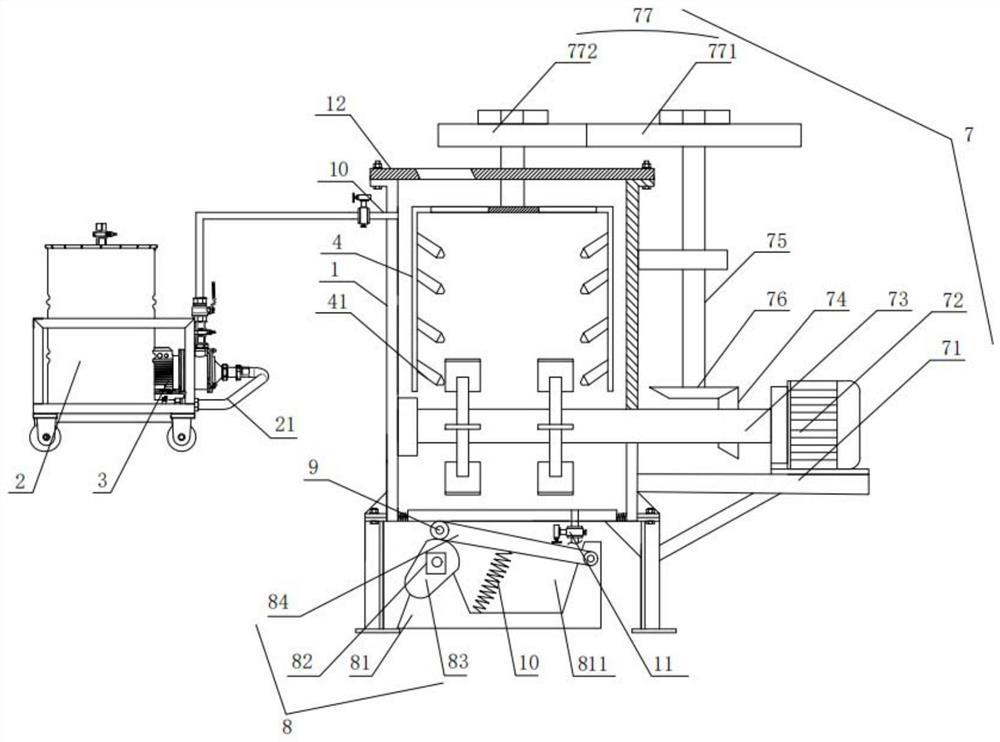

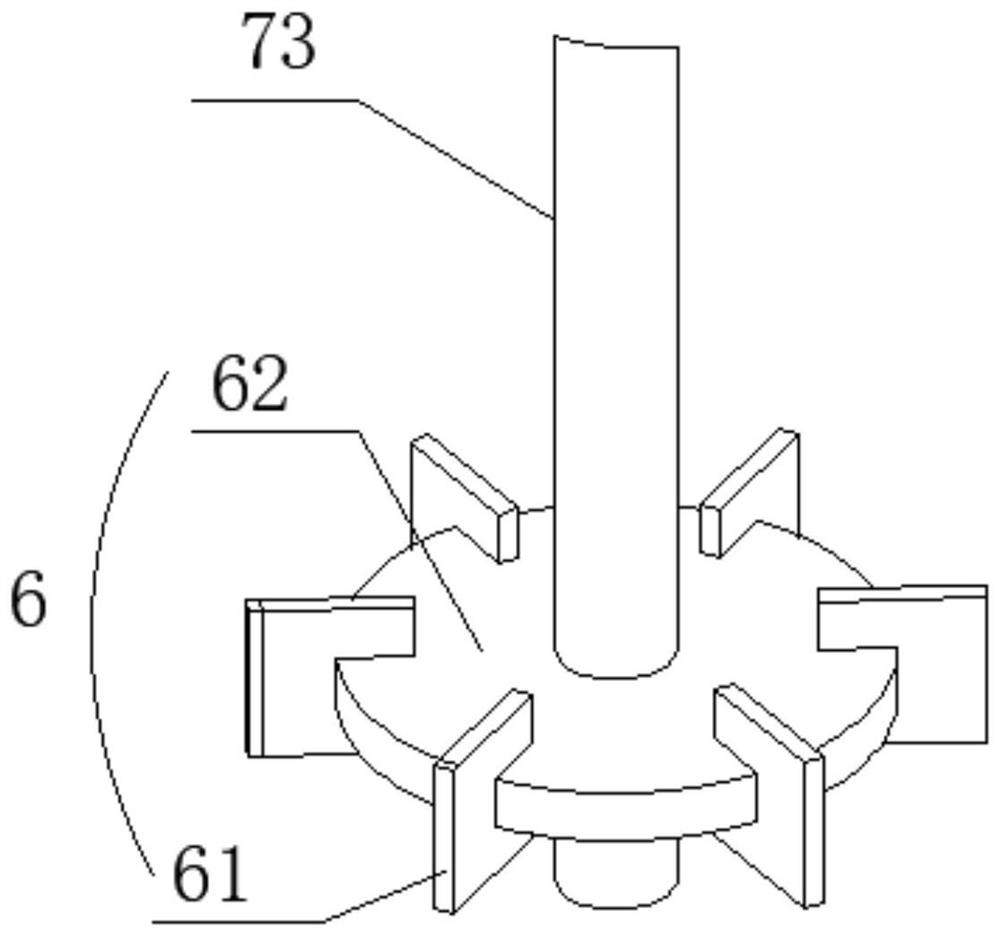

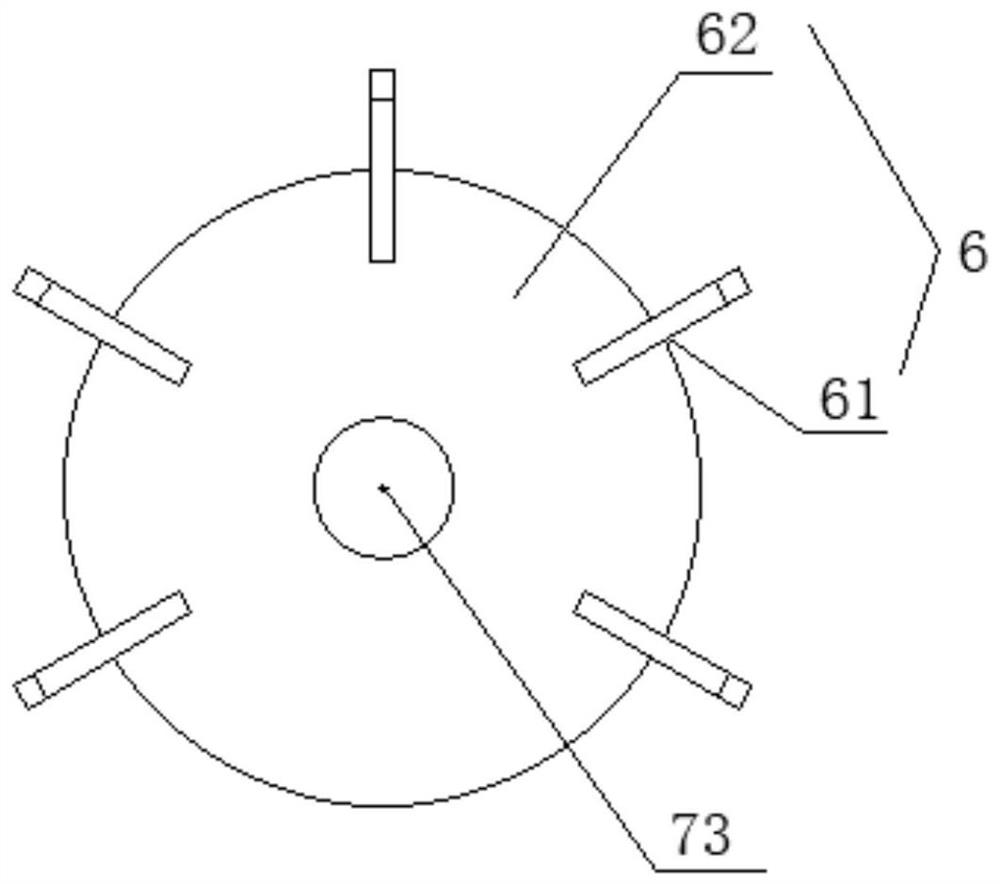

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0044] Figure 1-4 As shown, a cleaning device for electronic semiconductor processing, comprising:

[0045] The megasonic cleaning shell 1, the bottom of the megasonic cleaning shell 1 is provided with an elastic vibrating plate 11 which vibrates periodically; There is a megasonic resonant cavity transducer on the outside;

[0046] The cleaning liquid storage device 2 is used to store the cleaning liquid, and pump the cleaning liquid into the megasonic cleaning shell 1 through the pump body 3;

[0047] The electromagnetic pulse vibrator 4, the electromagnetic pulse vibrator 4 generates pulse vibration in the cleaning liquid, and can be continuously emitted by the electromagnetic pulse source;

[0048] The cleaning pipeline assembly 5 is distributed in an annular array on the inner wall of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com