A self-cleaning food processor

A food processing machine and self-cleaning technology, applied in kitchen utensils, household utensils, applications, etc., can solve the problems of easy breeding of bacteria, complex cleaning structure, and easy cleaning dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

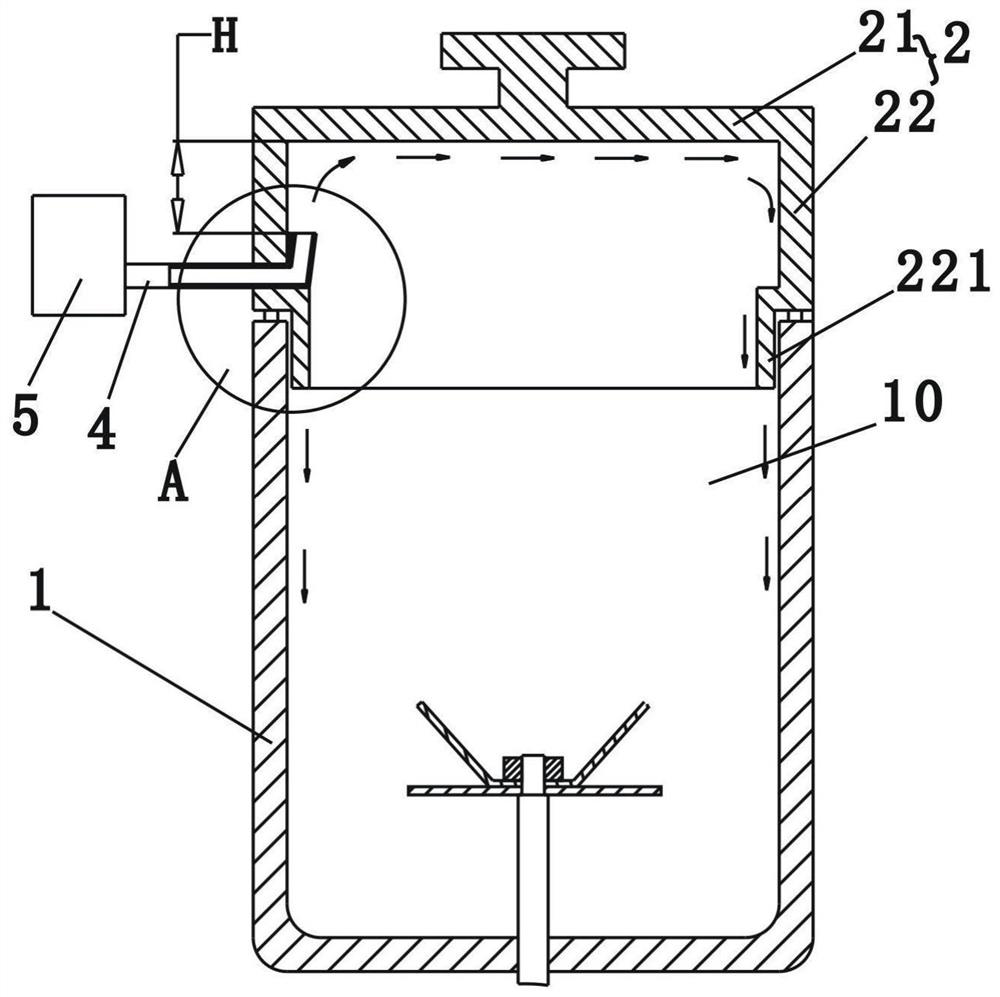

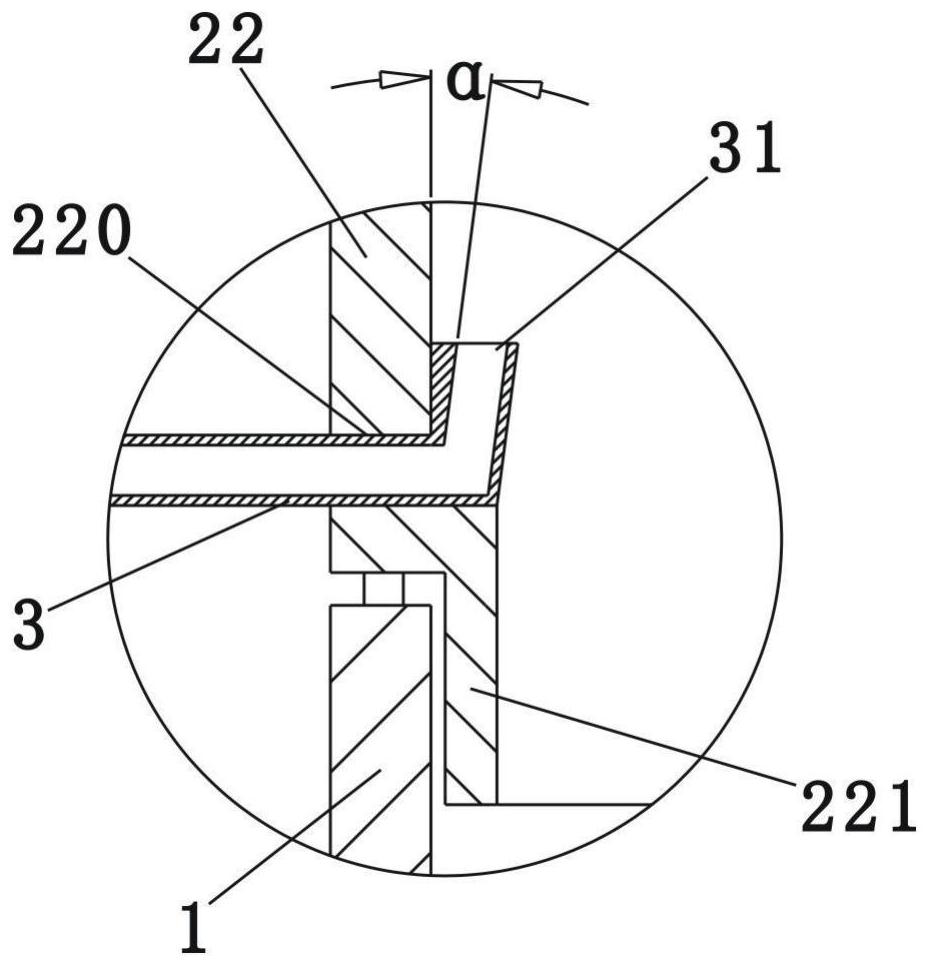

[0036] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the first embodiment of the present invention. A food processor, comprising a cup body 1, a cup cover 2 mounted on the top of the cup body 1, the cup cover 2 has a top wall 21 and a peripheral wall 22 extending downward from the top wall 21, inside the cup body 1 A crushing device (not marked in the figure) for crushing materials is provided, and a nozzle 3 is provided on the peripheral wall 22 of the cup cover, and the nozzle 3 is formed by extending from the outside of the cup cover 2 into the cup cover 2 and the cup body 1 The nozzle 3 has an upper nozzle 31 for spraying cleaning liquid toward the inner surface of the top wall 21 of the cup cover.

[0037] In this embodiment, the peripheral wall 22 of the cup cover is provided with a through hole 220, and the nozzle 3 extends into the cavity 10 enclosed by the cup cover 2 and the cup body 1 through the through hole 220, wherein the nozzle 3 and...

Embodiment 2

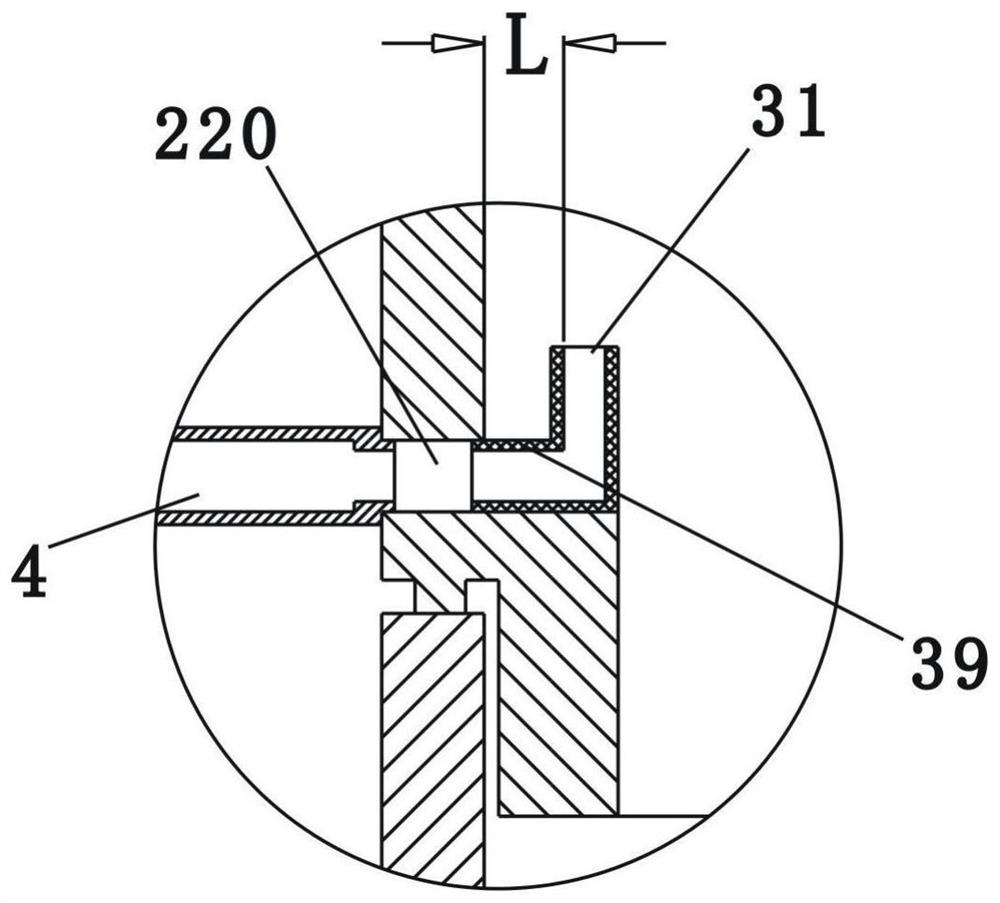

[0046] Such as image 3 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that in this embodiment, the nozzle includes a through hole 220 penetrating through the peripheral wall of the cup cover, and one end of the through hole 220 communicates with the upper spout 31 through the connection part 39 and is connected to the water supply system. The connected connecting pipe 4 communicates with the other end of the through hole 220 to realize water supply from the water supply system to the nozzle. Wherein, the upper spout 31 is arranged towards the top wall of the cup cover.

[0047] In this embodiment, the horizontal minimum distance from the edge of the upper spout to the inner surface of the adjacent cup cover peripheral wall is L, where L is required to be no more than 10mm, because the cleaning water sprayed from the upper spout hits the top wall of the cup cover and will bo...

Embodiment 3

[0050] Such as Figure 4 Shown is a schematic structural view of the third embodiment of the present invention. The difference between this embodiment and Embodiment 2 is that in this embodiment, the nozzle is a through hole 220 penetrating through the peripheral wall of the cup cover. It is the upper spout 31, and in this embodiment, the peripheral wall of the cup cover is provided with a plurality of nozzles around the peripheral wall, and the plurality of nozzles intersect and spray the top wall of the cup cover to realize the full coverage of the cup cover. Clean dead corners.

[0051] It should be pointed out that, in this embodiment, the peripheral wall of the cup cover is a single-layer structure. Of course, the cup cover can also have a double-layer structure of an outer wall and an inner wall, and there can be a gap between the outer wall and the inner wall. A water storage cavity is formed, and the nozzle with a through hole is arranged on the inner wall. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com